Professional Documents

Culture Documents

Deutz Fahr Agrolux 55e Test Report

Deutz Fahr Agrolux 55e Test Report

Uploaded by

Mamta RaybageOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deutz Fahr Agrolux 55e Test Report

Deutz Fahr Agrolux 55e Test Report

Uploaded by

Mamta RaybageCopyright:

Available Formats

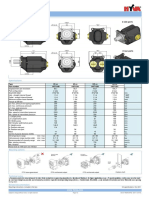

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

Manufacturer : M/s. SAME DEUTZ-FAHR INDIA (P) LTD.

72, SIPCOT, Industrial Complex,

Ranipet – 632 403 (Tamil Nadu)

Month: February Test Report No. T-757/1265/2011 Year : 2011

GOVERNMENT OF INDIA

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE

TRACTOR NAGAR, BUDNI (MADHYA PRADESH) 466445, INDIA

Email: fmti-mp@nic.in

Web site: dacnet.nic.in/cfmtti

Telephone: 07564-234729 FAX: 07564-234743

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 1 of 12

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

Type of Test : COMMERCIAL (INITIAL)

Test code/Procedure : IS: 5994-1998, (Reaffirmed in 2003)

IS: 9253-2001 and IS: 12207:2008

Period of Test : June, 2010 to November, 2010

Test Report No. : T-757/1265/2011

Month/Year : February, 2011

i) The results reported in this report are observed values and no corrections

have been applied for atmospheric and site conditions.

ii) The data given in this report pertain to the particular machine submitted by

the applicant for test.

iii) The results presented in this report do not in any way attribute to the

durability of the machine.

iv) This report should not be reproduced in part or full without prior permission of

the Director, Central Farm Machinery Training and Testing Institute, Budni

(M.P.).

SELECTED CONVERSIONS

SELECTED CONVERSIONS ABBREVIATIONS

Sl.

Units Conversion Factor

No

1 Force: As per applicant apa

1 kgf 9.80665 N Top Dead Centre TDC

2.20462 lbf Indian Standard IS

2 Power: Left Hand Side/ LHS/RHS

Right Hand Side

1 hp 1.01387metric hp (Ps) Mercury Hg.

745.7 W Temperature Temp.

1 Ps 735.5 W Not recorded N.R.

1 kW 1.35962 Ps Revolutions per minute rpm

3 Pressure: Outer diameter/ O.D/I.D

Inner diameter

1 psi 6.895 kPa Not available/ N.A.

Not applicable

2

1 kgf/cm 98.067 kPa = 735.56 Power take-off PTO

mm of Hg

2

1 bar 100 kPa = 10 N/cm Relative Humidity R.H.

1 mm of Hg 1.3332 m-bar

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 2 of 12

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

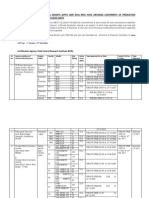

16. SUMMARY OF OBSERVATIONS, COMMENTS & RECOMMENDATIONS

16.1 Evaluative (mandatory) / Non-evaluation (Non-mandatory) parameter applicable for

qualifying Minimum Performance criteria as per Clause-4 (Table-1) of IS: 12207-2008 for

acceptance of the tractor for the purpose of subsidies/NABARD financing are

summarized as under:

Values Whether

Category Requirements declared by As meets

S. No. Characteristic (Evaluative as per IS: 12207-2008 the observed the

/ Non applicant(D)/ requirem

Evaluative) Requirement ents

(R) (Yes/No.)

1 2 3 4 5 6 7

16.1.1 PTO Performance :

a) - Maximum power Declared value to be

under 2 h test, Evaluative achieved with a 33.6 34.8 Yes

(kW ) (Natural tolerance of: -5 / +10%

for PTO power >35hp. (D)

ambient condition)

–7.5/+10% for PTO

power 35 hp

b) Power at rated Non -do- 33.6 34.8 Yes

engine speed, (kW) Evaluative (D)

c) Specific fuel Non

consumption Evaluative 5% 265 262 Yes

corresponding to (D)

maximum power,

(g/kWh)

d) Maximum Non

equivalent Evaluative 8% 175 179 Yes

crankshaft torque, (D)

(Nm)

e) Back-up torque, Non 7 percent, min. 7 percent 26.8 Yes

percent Evaluative (R)

O

f) Maximum operating temperature ( C):

1) Engine oil Non The declared value

Evaluative should not exceed the 155 121 Yes

max. value specified by

the oil company and the (D)

observed value under

high ambient condition

should not exceed the

declaration.

1 2 3 4 5 6 7

2) Coolant Evaluative The declared value

(water) should not exceed the 110 94 Yes

boiling temperature of

coolant under the (D)

pressurized or otherwise

and the observed value

under high ambient

condition should not

exceed the declaration.

g) Engine oil Evaluative Not exceeding 1% of

consumption, SFC at max. power 2.69 0.05 Yes

(g/kWh) under High ambient (R)

conditions

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 3 of 12

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

h) Smoke level Evaluative Maximum light

absorption coefficient 3.25 0.62 Yes

of 3.25 per metre or (R) per

equivalent BOSCH

meter

No. 5.2 or 75 Hatridge

value (As per CMVR)

16.1.2 Drawbar performance :

a) Max. drawbar pull Non Minimum 65% of

with ballast Evaluative static mass with 23.04(D) 29.20 Yes

corresponding to ballast

15 percent wheel 22.44 (R)

slip, (kN)

b) Max. drawbar pull Evaluative Minimum 65% of

without ballast static mass of tractor 15.21(D) 20.73 Yes

corresponding to without ballast

15 percent wheel 14.79 (R)

slip, (kN)

c) Maximum drawbar Evaluative Min. 80% of PTO

power without power as referred in 26.90(D) 28.3 Yes

ballast (kW). 16.1.1 (a) of PTO 27.8 (R)

performance

d) Max. transmission Non The declared value

oil temperature Evaluative should not exceed the 120 89 Yes

o maximum value

( C)

specified by oil company

16.1.3 Power lift and hydraulic pump performance :

a) Maximum lifting capacity throughout the range of lift, (kN):

1) At hitch Non [Tolerance of minus 14.0 (D) Yes

points Evaluative 10%] 21.41

2) With the Evaluative The lift capacity should

standard at least be 18 kg/PTO 8.88 (D) Yes

frame hp. and it should be 16

kg/engine hp where the 8.24 (R) 19.97

tractor is not provided

with a PTO shaft

b) Maximum drop in the Non 25 (D)

height of the point of Evaluative [Tolerance of plus 00 Yes

application of the 5 mm] 50 (R)

force after each 5

minutes interval for a

total duration of 30

minute, (mm)

1 2 3 4 5 6 7

16.1.4 Brake performance at 25 kmph:

a) Maximum stopping distance at a force, equal to or less than 600 N on brake pedal

with road ballast, (m):

1) Cold brake Evaluative 10 10 (R) 6.60 Yes

2) Hot brake Evaluative 10 10 (R) 7.10 Yes

b) Maximum force Evaluative

exerted on the 600 600 (R) 402

brake pedal to to Yes

achieve a

418

deceleration of 2.5

2

m/s (N)

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 4 of 12

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

c) Whether parking

brake is effective at Evaluative Yes Yes Yes Yes

a force of 600 N at

foot pedal(s) or

400 N at hand

lever

16.1.5 Noise measurement :

a) Maximum ambient Evaluative As per CMVR 88 (R) 87 Yes

noise emitted by

the tractor dB(A)

b) Maximum noise at Evaluative As per CMVR 98 (R) 98 Yes

operator’s ear level

dB(A)

16.1.6 Amplitude of mechanical vibrations at :

1) Left foot rest 100 (R) 190 No

Right food rest 100 microns (max) 100 (R) 790 No

2) Seat (with Non 100 (R) 90 Yes

driver seated) Evaluative

3) Steering 100 (R) 140 No

wheel

16.1.7 Haulage requirements :

a) Gross mass of the trailers, (tones):

1) Two wheel Non -- 5.0 (D) 5.0 Yes

2) Four wheel Evaluative -- 6.0 (D) 6.0 Yes

b) Distance travelled / litre of fuel consumption, (km):

1) Two wheel -- 4.25 to 4.35 to Yes

Non 6.75 (D) 4.44

2) Four wheel Evaluative -- 4.25 to 4.22 to Yes

6.75 (D) 4.24

c) Fuel consumption (ml/km/tonne):

1) Two wheel -- 25 to 50 45.0 to Yes

Non (D) 45.9

2) Four wheel Evaluative -- 25 to 50 39.3 to Yes

(D) 39.5

1 2 3 4 5 6 7

16.1.8 Wetland cultivation :

Sealing for the Evaluative The identified

following assemblies: assemblies should

1) Clutch -do- essentially meet the

assembly requirement of IS: There No

11082. No water ingress should ingress

2) Brake -do- in the identified Yes

housings

be no of mud

assembly given in

column-2. ingress and / or

3) Front axle -do-

hubs If tractor does not meet of water water

the requirements of and/or was

wetland cultivation, it mud (R) observed

may be recommended

for dry land operation

only.

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 5 of 12

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

16.1.9 Safety features :

a) Guards against Evaluative As per CMVR At present --- --

moving and hot no

parts require-

ments

b) Lighting Evaluative As per CMVR -- Provided Yes

arrangement

16.1.10 Labelling of tractors (Provision of labelling plate):

1) Make Evaluative Should conform to DEUTZ-FAHR Yes

2) Model Evaluative the requirements of AGROLUX Yes

CMVR along-with 55e

declared value of

3) Year of Evaluative 2010 Yes

PTO HP

manufacture

4) Engine Evaluative 3A26403C10 Yes

number

5) Chassis Evaluative D10S503WT1 Yes

number E1002C10

6) Declaration Evaluative 33.60 Yes

of PTO

power, (kW)

16.1.11 Discard limit for:

(a) Cylinder bore Evaluative To be specified by 105.10 105.00 to Yes

diameter, (mm) the manufacturer 105.02

(b) Clearance Non -do- 0.42 0.133 to Yes

between piston & Evaluative 0.140

cylinder liner at

skirt, (mm)

(c) Ring end gap (mm):

- Top comp. ring. -do- 1.50 0.50 to 0.55 Yes

nd

- 2 comp. ring. Evaluative -do- 1.50 0.60 to 0.65 Yes

- Oil ring. -do- 1.50 0.50 Yes

(d) Ring groove clearance (mm):

- Top comp. -do- 0.25 0.146 to Yes

ring. 0.149

nd

- 2 comp. ring. -do- 0.25 0.059 to Yes

Evaluative

0.067

- Oil ring. -do- 0.15 0.033 to Yes

0.062

(e) Clearance of main bearings (mm):

- Diametrical 0.40 0.061 to Yes

clearance Evaluative -do-

0.131

- Crankshaft end 0.50 0.15 Yes

Evaluative -do-

float

1 2 3 4 5 6 7

(g) Clearance of big end bearings, (mm):

(h) - Diametrical 0.40 0.066 to Yes

Evaluative -do-

0.147

- Axial Evaluative -do- 0.50 0.40 Yes

(i) Clearance Not --

Non

between king pin -do- 0.85 applicable

Evaluative

and bush, (mm)

(j) Clearance 0.85 0.12 to 0.37 Yes

Non

between center pin -- do--

Evaluative

and bush, (mm)

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 6 of 12

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

16.1.12 CATEGORY OF BREAKDOWNS / DEFECTS :

Category Whether

S. No. Characteristic (Evaluative / Requirements As meets the

Non as per IS: 12207-2008 observed requirement

Evaluative) s (Yes/No.)

1. Critical Evaluative No critical breakdown None Yes

2. Major Not more than two and neither of None Yes

Evaluative them should be repetitive in

nature

3. Minor Not more than five and frequency Mn24 Yes

Evaluative of each should not be more than (two

two. times)

4. Total In no case, the total number of Two Yes

breakdowns breakdowns should exceed five, minor

Evaluative

that is, (2 major + 3 minor) or 5

minor breakdowns

16.2 Optional requirements as per Clause-4 (Table-2) of IS:12207-2008:

Whether

S. No. Characteristic Requirements AS observed meets the

require-

as per IS: 12207-2008

ments

(Yes/No.)

1 2 3 4 5

1 Air cleaner oil pull over, 0.25% (max.) Not applicable --

max. oil pull over (%)

2. Seating requirements Should meet the requirements of Meets the Yes

IS: 12343-1998 requirements

3. Fitment of ROPS With a provision for fitment of Provided Yes

ROPS.

If ROPS fitted it should meet the ROPS not fitted --

requirement of IS: 11821-1992

4. Technical requirements Should meet the requirements of Meets the Yes

for PTO shaft IS: 4931 -1995 requirements

5. Dimensions of three Should meet the requirements of Meets the Yes

point linkage IS: 4468 (Part-I)-1997 requirements

6. Specifications of linkage Should meet the requirements of Meets the Yes

drawbar IS: 12953-1990 requirements

Specifications of Should meet the requirements of Not provided --

swinging drawbar IS: 12362 Part 3-1994.

7. Accessories Trailer hitch, front tow hook, Provided Yes

linkage drawbar may be provided.

16.3 Conformity with following IS:

i) Guide lines for declaration of power and specific fuel : Conforms

consumption and labeling of agricultural tractors (First

revision) [IS 10273:1987 (Reaffirmed in March,

2009)]

ii) Agricultural tractors – Rear mounted power take-off - : Conforms

Types 1, 2 and 3 (third revision) [IS: 4931-1995

(Reaffirmed in March, 2009)]

iii) Agricultural wheeled tractors - Rear mounted three- : Conforms

point linkage: Part 1 Categories 1, 2, 3 & 4 (fourth

revision) [IS:4468(Part-I):1997(Reaffirmed in March,

2009)/ISO730-1:1994]

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 7 of 12

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

iv) Drawbar for agricultural tractors – Link type : Conforms

[IS 12953:1990 (Reaffirmed in March, 2009)]

v) Agricultural tractors - Operator’s seat technical : Conforms

requirement [IS 12343 –1998 (First revision) (Re-

affirmed in March, 2009)]

vi) Guide for safety & comfort of operator of agricultural : Conforms

tractors: Part 1 General requirements (first revision):

[IS 12239 (PT-1) 1996 (Reaffirmed in March,

2007)/ISO 4254-1:1989]

vii) Tractors and machinery for agriculture and forestry, : Conforms

powered lawn and garden equipment – Symbols for

operator controls and other displays [IS: 6283 (Part-

1) – 2006 (Reaffirmed in March, 2009) and IS: 6283

(Part-2)-2007 (Reaffirmed in March, 2009)]

viii) Tractors and machinery for agriculture and forestry – : Does not conform

Technical means for ensuring safety Part 2: Tractors

(first revision) [(IS 12239 (PT-2) 1999) (Re-affirmed

in March, 2009)]

ix) Guide lines for location and operation of operator : Conforms

controls on agricultural tractors and machinery (first

revision) (IS: 8133 – 1983) (Re-affirmed in March,

2009)

x) Agricultural Tractor & Machinery Lighting device for : Conforms

travel on public roads (IS: 14683-1999) (Re-affirmed

in March, 2009)

16.4 Salient Observations:

16.4.1 Laboratory tests:

16.4.1.1 PTO Performance:

i) The backup torque is 26.8%.

ii) The specific fuel consumption corresponding to maximum power was

recorded as 262 g/kWh, against the declaration of 265 g/kWh, which meet the

requirement of IS: 12207-2008 with regard to tolerance.

iii) The drop in maximum power in high ambient condition in comparison to

natural ambient condition was recorded as 4.9 % which is considered on

higher side. This should be looked into.

16.4.1.2 Drawbar performance:

During drawbar performance ten hour test, excessive creeping of RHS rear tyre

over rim was observed and nozzle was separated from tube. The tube was

replaced with new ones. This should be looked into.

16.4.1.3 Hydraulic performance :

i) During the hydraulic performance lifting capacity test at standard frame, the

hydraulic system was not functioning properly and the lower links fallen down

suddenly. On inspection it was found that, the non-return valve (Pt. No.

0.016.3190.4) got chocked. The hydraulic system was opened and its cleaning

was done twice.

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 8 of 12

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

ii) The lifting capacity at standard frame was recorded as 19.97 kN and the

moment about the rear axle was computed as 21.41 kN-m, which is

considered on higher side as compared to the moment from front axle i.e.

20.48 kN-m. It is therefore, recommended that the lifting capacity of the

hydraulic system may be reduced suitably or standard ballast mass at front

axle may be provided to avoid front lifting of the tractor.

iii) The maximum tilt angle of mast from vertical was measured as 8.1 degree

only against the minimum requirements of 10 degree. This should be looked

into for necessary corrective action.

16.4.1.4 Mechanical Vibration:

The amplitude of mechanical vibration on various assemblies marked as (*) in

Chapter-8 of this test report is on very higher side, especially at the steering control

wheel and foot rests. This calls for dampening down of vibrations to improve the

operational comfort and service life of components.

16.4.1.5 Three point linkage:

Distance from the end of power take-off to centre of lower hitch point (lower links in

horizontal position) conforms to ‘Cat-I’ whereas other parameters conforms to ‘Cat-

II’. Keeping in the view the sprit of standardization, necessary improvements may

be incorporated.

16.4.2 Field Performance:

16.4.2.1 Dryland Operation:

The average area covered in rotavation operation with recommended size of

rotavator was recorded in the range of 0.335 to 0.375 ha/h. Keeping in view the

PTO power of the tractor, the area coverage is considered less, hence the

recommended size of the rotavator may be reviewed.

16.4.2.2 Wet land cultivation (Puddling Operation):

No ingress of mud/or water was observed during wetland cultivation. Hence the

tractor meets the requirements for wet land cultivation as per IS: 11082-1984 and

found suitable for wetland cultivation

16.4.2.3 Haulage Performance:

The load carrying capacity of the tractor has been declared as 5.0 & 6.0 tons only

with two & four wheel trailer respectively. Keeping in view the PTO power of the

tractor, the declared hauling capacity is considered less, hence the declaration of

hauling capacity may be reviewed.

16.5 Recommendation with regard to safety on tractor:

The following requirements, inter alia, may be considered for incorporation on the

tractor:

i) Provision for spark arresting device in exhaust system.

ii) The working clearance around the position control lever & draft control lever

may be provided as per IS: 12239 (Part-2) – 1999.

16.6 Maintenance / Service Problems:

No noticeable maintenance or service problem was observed during the test.

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 9 of 12

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

However, suitable provision for draining the sediments/water may be provided in the

fuel supply system.

16.7 Adequacy of Literature supplied with machine:

The following literature was supplied with the tractor for reference during the test:

i) Use and maintenance book of Agrolux 40e D10S403 WX1E 5001A10,

Agrolux 55e D10S503WT1E5001A10, Agrolux 60e D10S553 WT1E 5001A10

and Agrolux 70e D10S653 WT1E 5001A10.

ii) Workshop manual of Agrolux 40e, Agrolux 50e, Agrolux 60e and Agrolux 70e.

iii) Spare parts Catalogue of Agrolux 40, Agrolux 55, Agrolux 60 and Agrolux 70

16.7.1 The above literature may also be brought out in national as well as other regional

languages for the guidance of users and service personnel.

TESTING AUTHORITY:

J.J.R. NARWARE

SENIOR AGRICULTURAL ENGINEER

V.N. KALE

DIRECTOR

Test Report compiled by: Shri Sanjay Kumar, Senior Technical Assistant.

17. APPICANT’S COMMENTS

Para. No. Our Reference Applicant’s Comment’s

17.1 16.4.1.2, 16.4.1.3,

16.4.1.4, 16.4.1.5,

Would be reviewed

16.4.2.1, 16.4.2.3,

16.5

ANNEXURE – I

BRIEF SPECIFICATION OF IMPLEMENTS USED DURING FIELD TEST

S.

Item Disc Plough Rotavator

No.

1. Make M&M TAFE ACCESS

2. Type Mounted Mounted

3. No. of bottoms/blades Three 36 in 7 flanges

4. Type of bottoms/blades Plain concave Hatchet

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 10 of 12

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

5. Size of bottoms/blades, (mm) 625 160 x 80 x 8

6. Spacing of bottoms/flanges, (mm) 455 250

7. Lower hitch point span, (mm) 690 740

8. Mast height, (mm) 455 570

9. Overall dimensions:

- Length 1610 1770

- Width 850 1020

- Height 1080 980

10. Gross mass, (kg) 370 315

ANNEXURE -II

BRIEF SPECIFICATION OF FULL CAGE WHEELS

S. No. Items Specification

1. Type Full

2. Dia, (mm) 1210

3. Width, (mm) 900

24, straight lugs made of MS angle

4. No. and types of lugs

section welded to angle iron frame.

5. Size of angle section, (mm) 40 x 40 x 5

6. Length of lugs, (mm) 444

7. Spacing of lugs, (mm) 315

8. Weight of each cage wheels (kg) 120

ANNEXURE-III

TRACTOR RUN HOURS DURING TEST

A. LABORATORY AND TRACK TESTS: HOURS

1. Running-in Nil

2. PTO performance test 12.8

3. Power lift and hydraulic pump performance test 3.0

4. Drawbar performance test 18.8

5. Turning ability 0.2

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 11 of 12

DEUTZ-FAHR, AGROLUX-55 e, TRACTOR-

T-757/1265/2011

Commercial (Initial)

6. Location of centre of gravity 0.2

7. Operator’s field of vision --

8. Brake test 2.3

9. Noise measurement 2.0

10. Mechanical vibration test 1.0

11. Theoretical speed test 2.2

B. FIELD TEST:

1. Disc ploughing 10.0

2. Rotavation 10.0

3. Puddling (Including water proof test) 15.5

C. HAULAGE TEST: 9.2

D. Miscellaneous test and other run hours including idle run, 5.0

transportation, trials and preparation for test

TOTAL: 92.2

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI 12 of 12

You might also like

- Hoist ForkliftDocument12 pagesHoist ForkliftMamta RaybageNo ratings yet

- Process Validation ReportDocument4 pagesProcess Validation ReportSUBODHH100% (1)

- Hyva Gear PumpsDocument2 pagesHyva Gear PumpsMamta RaybageNo ratings yet

- Diesel Progress Sourcing Guide 2021Document367 pagesDiesel Progress Sourcing Guide 2021Mamta RaybageNo ratings yet

- MCM Catalog Rev 16Document31 pagesMCM Catalog Rev 16Enrique HortaNo ratings yet

- Auto Parts Plaza Korean Suppliers List (ENG) UpdatedDocument5 pagesAuto Parts Plaza Korean Suppliers List (ENG) UpdatedKotra la KbcNo ratings yet

- Winch System-Mechanical-Electrical-Clutch-HydraulicDocument2 pagesWinch System-Mechanical-Electrical-Clutch-HydraulicMamta Raybage100% (1)

- TRIMA Front End Loadres & ImplementsDocument32 pagesTRIMA Front End Loadres & ImplementsMamta RaybageNo ratings yet

- Mahindra XD3P BOLERO PDFDocument107 pagesMahindra XD3P BOLERO PDFMamta Raybage100% (6)

- Come Once Again and Love PDFDocument338 pagesCome Once Again and Love PDFdemsNo ratings yet

- Mahindra 475 DI Tractor BUDNI TEST REPORTDocument15 pagesMahindra 475 DI Tractor BUDNI TEST REPORTShyam Katare0% (1)

- Top 10 Tractors in IndiaDocument7 pagesTop 10 Tractors in IndiaRamanan MrrNo ratings yet

- PM Kit PTDH - Interval 250 Hrs - PR754-LiebherrDocument8 pagesPM Kit PTDH - Interval 250 Hrs - PR754-LiebherrFrans MetinNo ratings yet

- PV Series Solar Pumping VFD ManualDocument89 pagesPV Series Solar Pumping VFD Manualamad100% (1)

- BANGALORE Email DataDocument864 pagesBANGALORE Email DatapostofficeNo ratings yet

- BTR 2018 BTR 2017 Rank Diff. Brand Name Super Category CategoryDocument5 pagesBTR 2018 BTR 2017 Rank Diff. Brand Name Super Category CategoryHMNo ratings yet

- Runner Parts LifeDocument28 pagesRunner Parts LifeRajat yelneNo ratings yet

- Introduction Letter - 3.4.21Document2 pagesIntroduction Letter - 3.4.21Gunjan PatelNo ratings yet

- List of Toll PlazaDocument16 pagesList of Toll Plazaanitha86_muru100% (1)

- V47 Components From Crank To Link Head (Conical) : Crank and Crank PlateDocument4 pagesV47 Components From Crank To Link Head (Conical) : Crank and Crank PlatebalaNo ratings yet

- Detail of Machine TestedDocument8 pagesDetail of Machine Testedtejasp56No ratings yet

- Annexure - I List of Bse - 500 Companies: S.No Scrip Code Scrip ID Company Name/ IndustryDocument16 pagesAnnexure - I List of Bse - 500 Companies: S.No Scrip Code Scrip ID Company Name/ IndustrySushant KumarNo ratings yet

- Wind Turbine Spares Supply ListDocument8 pagesWind Turbine Spares Supply ListbalaNo ratings yet

- QR Codes - Print & ShipDocument1,081 pagesQR Codes - Print & Shipramansharma1769No ratings yet

- Details of 2 Wheeler Companies in IndiaDocument32 pagesDetails of 2 Wheeler Companies in Indiaapurva_chunarkarNo ratings yet

- Dealer Kit Book 31-5-19 Final PDFDocument51 pagesDealer Kit Book 31-5-19 Final PDFSamsher AliNo ratings yet

- VD2019 01.07.2019 Rev.6Document223 pagesVD2019 01.07.2019 Rev.6qc deNo ratings yet

- EV Product Catalogue PDFDocument174 pagesEV Product Catalogue PDFAkNo ratings yet

- XGC130 Packing ListDocument9 pagesXGC130 Packing ListCarlos GuajardoNo ratings yet

- Thyssenkrupp Industries India Pvt. LTD.: "All Disputes Subject To Pune Jurisdiction"Document23 pagesThyssenkrupp Industries India Pvt. LTD.: "All Disputes Subject To Pune Jurisdiction"Caspian DattaNo ratings yet

- Construction Equipment Rental CompanyDocument3 pagesConstruction Equipment Rental CompanyAnkitNo ratings yet

- List of 100 Proposals Approved by DFPD UnderDocument7 pagesList of 100 Proposals Approved by DFPD UnderNarayan KambleNo ratings yet

- Bawal ListDocument5 pagesBawal Listromeoyadav100% (1)

- Brief Industrial Profile of Koppal District, Karnataka StateDocument14 pagesBrief Industrial Profile of Koppal District, Karnataka StateShyam J VyasNo ratings yet

- List of Organisations Covered by Regional Office-Doddaballapura (As On 30.09.2014) (F-Register)Document123 pagesList of Organisations Covered by Regional Office-Doddaballapura (As On 30.09.2014) (F-Register)Prashant SinghNo ratings yet

- Project For FixtureDocument49 pagesProject For FixtureEr KarthikNo ratings yet

- Companywise Plant ListDocument9 pagesCompanywise Plant ListSabyasachi BangalNo ratings yet

- RJML mb51Document9 pagesRJML mb51Protap KumarNo ratings yet

- Monoblock & Suction Pump SNB-SNK-CatalogDocument28 pagesMonoblock & Suction Pump SNB-SNK-Catalogbagus saputraNo ratings yet

- Contact Details (Spares Department)Document1 pageContact Details (Spares Department)Prince KumarNo ratings yet

- India AutocomponentsectorcompaniesDocument19 pagesIndia AutocomponentsectorcompaniesAbdur RahmanNo ratings yet

- Combine Harvester List (Revised July 2015)Document15 pagesCombine Harvester List (Revised July 2015)Nikola ElekNo ratings yet

- Factory List Having Ambica PreseDocument19 pagesFactory List Having Ambica PreseJayant Kumar JhaNo ratings yet

- Guidelines & Application Form: DigitalDocument26 pagesGuidelines & Application Form: DigitalAvinash KamuniNo ratings yet

- Deeper Neet DCT - PhysicsDocument8 pagesDeeper Neet DCT - Physicshbhaiya643No ratings yet

- Machinery Old December 21 ComparisonDocument2 pagesMachinery Old December 21 ComparisonEr Akshay ParmarNo ratings yet

- AutomotiveDocument15 pagesAutomotiveKrishna ChaitanyaNo ratings yet

- IMME - 2014 - Show - Preview - 23 - 10-2014Document55 pagesIMME - 2014 - Show - Preview - 23 - 10-2014kavenindia0% (1)

- VX2T 50NPDocument36 pagesVX2T 50NPNishant AnandNo ratings yet

- Sale List - July 2013Document24 pagesSale List - July 2013Raji Billa0% (1)

- Solvent ListDocument11 pagesSolvent ListKotnis Kollu100% (1)

- List of Functioning Cold Storage of West Bengal District Wise As On 18Document10 pagesList of Functioning Cold Storage of West Bengal District Wise As On 18Nabin Biswas50% (2)

- Ralson Tyre Connection FeseabilityDocument2 pagesRalson Tyre Connection FeseabilityKaustubh SaksenaNo ratings yet

- Machinery PartsDocument2 pagesMachinery PartsSHANTHALASPHEROCAST PVT LTDNo ratings yet

- Electric VehiclesDocument7 pagesElectric Vehiclesna_1nanaNo ratings yet

- Exhibitor ListDocument2 pagesExhibitor Listfredaster21No ratings yet

- CodeDocument13 pagesCodeKamlesh Steel industriesNo ratings yet

- Diesel Gensets Manufacturers PDFDocument45 pagesDiesel Gensets Manufacturers PDFmartand86No ratings yet

- PKG 5 Customer List in IndiaDocument5 pagesPKG 5 Customer List in IndiaGiri DharNo ratings yet

- DLW Vendor Directory July - 16Document275 pagesDLW Vendor Directory July - 16majjisatNo ratings yet

- List Machines Tested13Document36 pagesList Machines Tested13Rajat GuptaNo ratings yet

- Showpreview BC India Participants Australia 2013Document58 pagesShowpreview BC India Participants Australia 2013indusexposiumNo ratings yet

- AIP Mangalore Airprot, IndiaDocument20 pagesAIP Mangalore Airprot, Indiass khadriNo ratings yet

- Swaraj 855 Fe Xtra Tractor - T - 852-1362-2012Document12 pagesSwaraj 855 Fe Xtra Tractor - T - 852-1362-2012Surajit SarkarNo ratings yet

- MahindraDocument13 pagesMahindraCvsiva Krishna ReddyNo ratings yet

- Swaraj 735 Fe Tractor - T - 768-1276-2011Document13 pagesSwaraj 735 Fe Tractor - T - 768-1276-2011Amit Chopra Amit0% (1)

- Agrolux 50E Tractor - T-676-1182-2009 PDFDocument10 pagesAgrolux 50E Tractor - T-676-1182-2009 PDFPreet SinghNo ratings yet

- Mahindra 605 Di PS Tractor-T-954-1472-2015Document12 pagesMahindra 605 Di PS Tractor-T-954-1472-2015Prashant PatilNo ratings yet

- JCB Tracked Excavator Js 330 L/NL HRD JCB Tracked Excavator Js 330 L/NL HRD JCB Tracked Excavator Js 330 L/NL HRDDocument6 pagesJCB Tracked Excavator Js 330 L/NL HRD JCB Tracked Excavator Js 330 L/NL HRD JCB Tracked Excavator Js 330 L/NL HRDMamta RaybageNo ratings yet

- Kubota MU 5501 Test ReportDocument50 pagesKubota MU 5501 Test ReportMamta RaybageNo ratings yet

- Rail Design CriteriasDocument19 pagesRail Design CriteriasMamta Raybage100% (1)

- Ex 210LCHDocument2 pagesEx 210LCHMamta RaybageNo ratings yet

- Ipdqr 1684540Document2 pagesIpdqr 1684540Mamta RaybageNo ratings yet

- Bowex Bowex Fle-Pa Bowex-Elastic Monolastic Pump Mounting FlangesDocument34 pagesBowex Bowex Fle-Pa Bowex-Elastic Monolastic Pump Mounting FlangesMamta RaybageNo ratings yet

- Roots Blower Guide For CementDocument8 pagesRoots Blower Guide For CementMamta RaybageNo ratings yet

- BOSS Construction Equip PumpsDocument1 pageBOSS Construction Equip PumpsMamta RaybageNo ratings yet

- Hylomar Universal Blue: Light GradeDocument2 pagesHylomar Universal Blue: Light GradeMamta RaybageNo ratings yet

- High Performance and Rugged Motor GradersDocument4 pagesHigh Performance and Rugged Motor GradersMamta RaybageNo ratings yet

- L&T Case 450DXDocument154 pagesL&T Case 450DXMamta RaybageNo ratings yet

- Dynapac PaverDocument158 pagesDynapac PaverMamta Raybage100% (1)

- Container Tank SpecificationDocument6 pagesContainer Tank SpecificationMamta RaybageNo ratings yet

- JS120 Spec SheetDocument2 pagesJS120 Spec SheetMamta RaybageNo ratings yet

- Atlas Copco ZS Series BlowersDocument46 pagesAtlas Copco ZS Series BlowersMamta Raybage100% (1)

- Unic Ur 1504Document8 pagesUnic Ur 1504Mamta RaybageNo ratings yet

- Emco Brake ManualDocument37 pagesEmco Brake ManualMamta RaybageNo ratings yet

- Gates Belts PDFDocument65 pagesGates Belts PDFMamta RaybageNo ratings yet

- Angular With NodeJS - The MEAN Stack Training Guide - UdemyDocument15 pagesAngular With NodeJS - The MEAN Stack Training Guide - UdemyHarsh TiwariNo ratings yet

- Accomplishment Report On 2019 SchoolDocument10 pagesAccomplishment Report On 2019 SchoolJuliet AlanNo ratings yet

- Frank Lloyd WrightDocument16 pagesFrank Lloyd WrightKhiZra ShahZadNo ratings yet

- The Dilemma of Dr. Faustus: The Medieval-Renaissance Conflict in Christopher Marlowe's "The Tragic History of Dr. Faustus" by April Rose FaleDocument5 pagesThe Dilemma of Dr. Faustus: The Medieval-Renaissance Conflict in Christopher Marlowe's "The Tragic History of Dr. Faustus" by April Rose FaleApril Rose100% (5)

- Final InaSAU GAF Meeting Brochure CompressedDocument20 pagesFinal InaSAU GAF Meeting Brochure CompressedsamuelionardiNo ratings yet

- Calculate Size of SolarDocument2 pagesCalculate Size of SolarMuhammad SalmanNo ratings yet

- Exercise 1 WorkDocument9 pagesExercise 1 Workعبد الكريم المصطفىNo ratings yet

- Hakan Ozkan. Speaking Difficulties Among Turkish Students in Learning The English LanguageDocument2 pagesHakan Ozkan. Speaking Difficulties Among Turkish Students in Learning The English LanguagedetektifconnyNo ratings yet

- Revised - First Mid Examination-B.tech, BBA, BCA, MBA, MCA, BSC, BArch, Diploma ID (Except First Year) Odd Sem 2022-23Document12 pagesRevised - First Mid Examination-B.tech, BBA, BCA, MBA, MCA, BSC, BArch, Diploma ID (Except First Year) Odd Sem 2022-23Roʜʌŋ AŋʌŋɗNo ratings yet

- Hoshizaki Technical Support - Warranty Labor Claim InstructionsDocument12 pagesHoshizaki Technical Support - Warranty Labor Claim InstructionsJohn DuttingerNo ratings yet

- Soal Kalimat Prohibition SMP Kelas 7Document3 pagesSoal Kalimat Prohibition SMP Kelas 7yura chanNo ratings yet

- (With Script) June 2021 Saturday WSF Teaching GuideDocument3 pages(With Script) June 2021 Saturday WSF Teaching GuideMichael T. BelloNo ratings yet

- A Project Study On "BANKING AT HDFC BANK LTD.": MBA in Banking (Finance)Document99 pagesA Project Study On "BANKING AT HDFC BANK LTD.": MBA in Banking (Finance)Hitesh kumar jenaNo ratings yet

- COBIT 2019 vs. COBIT 5Document6 pagesCOBIT 2019 vs. COBIT 5Baatar SukhbaatarNo ratings yet

- Corporate Tax - UAEDocument48 pagesCorporate Tax - UAEUmair BaigNo ratings yet

- Keyword: 50s Music Title: Great 50s Songs For Different Moods: ContentDocument1 pageKeyword: 50s Music Title: Great 50s Songs For Different Moods: Contentaditya_bb_sharmaNo ratings yet

- Mark Scheme (Results) : Summer 2018 Pearson Edexcel International GCSE in Further Pure Mathematics (4PM0) Paper 01Document26 pagesMark Scheme (Results) : Summer 2018 Pearson Edexcel International GCSE in Further Pure Mathematics (4PM0) Paper 01Newton JohnNo ratings yet

- 2 LandDocument50 pages2 LandJose Jess AmaoNo ratings yet

- Units Or: 1 Which IsDocument5 pagesUnits Or: 1 Which IsTanvi PriyaNo ratings yet

- Cell Discovery & Cell TheoryDocument24 pagesCell Discovery & Cell TheoryFIGHTING TAYKINo ratings yet

- Shark ClassificationDocument44 pagesShark ClassificationSheeka TareyamaNo ratings yet

- Laurie Baker: (The Brick Master of Kerala)Document8 pagesLaurie Baker: (The Brick Master of Kerala)Malik MussaNo ratings yet

- POSTMODERN, 253s '12Document270 pagesPOSTMODERN, 253s '12Raluca Gîlcă100% (1)

- ResearchGate PDFDocument3 pagesResearchGate PDFAmrinder SharmaNo ratings yet

- Duhamel's PrincipleDocument14 pagesDuhamel's Principlejoel24348584No ratings yet

- PDF The Military Balance 2020 First Edition The International Institute For Strategic Studies Iiss Ebook Full ChapterDocument53 pagesPDF The Military Balance 2020 First Edition The International Institute For Strategic Studies Iiss Ebook Full Chapteranita.reese465100% (1)

- PHD Thesis Library Science DownloadDocument8 pagesPHD Thesis Library Science Downloadyvrpugvcf100% (2)

- Alter Ego 181 PreviewDocument20 pagesAlter Ego 181 PreviewJohn LloydNo ratings yet