Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

9 viewsJob Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or Procedure

Job Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or Procedure

Uploaded by

Bernard Christian DimaguilaThis document provides a job hazard analysis for the construction of a catwalk. It identifies potential hazards for three basic job steps: 1) Installation of scaffolding, which could result in collapse during erection or falls from scaffolding. Certified erectors with proper safety equipment are recommended. 2) Panel installation, which could involve cuts, abrasions, pinch points, overhead hazards or falls. Proper PPE and fall protection over 6 feet is recommended. 3) Pouring of concrete, which could involve workers being run over by equipment or high-speed bursts of concrete from air in hoses. The use of spotters, equipment shut-off after 3 minutes of idling, and trained whip-hose operators are

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Excavation and Back Filling Works JsaDocument3 pagesExcavation and Back Filling Works Jsarashid zaman78% (18)

- JHA DrillingDocument4 pagesJHA Drillingjay RNo ratings yet

- Method Statement of Gantry Crane Dismantling - DIFD 20-09-18Document8 pagesMethod Statement of Gantry Crane Dismantling - DIFD 20-09-18mechajay2002100% (1)

- 39 Jha On Blok Masonary WorkDocument4 pages39 Jha On Blok Masonary WorkDheeraj KumarNo ratings yet

- Excavation and Back Filling Works JsaDocument3 pagesExcavation and Back Filling Works JsaNazir Hussain67% (12)

- Job Hazard Analysis For Crane DismantlingDocument2 pagesJob Hazard Analysis For Crane DismantlingKamlesh Bule Lonari100% (2)

- GMW 8-2008Document9 pagesGMW 8-2008Clauco Tiago Seno RoqueNo ratings yet

- JSA GroutingDocument2 pagesJSA GroutingSyazWyn100% (5)

- Job Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or ProcedureDocument3 pagesJob Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or ProcedureBernard Christian DimaguilaNo ratings yet

- JHA ConcretePlacingOperationDocument3 pagesJHA ConcretePlacingOperationAnonymous XJ9663C6N4No ratings yet

- IPM - MOS - 005 - Mobile ScaffoldDocument6 pagesIPM - MOS - 005 - Mobile ScaffoldmohdnurasyraafNo ratings yet

- JSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadDocument1 pageJSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadRyanNo ratings yet

- Job Safety AnalysisDocument2 pagesJob Safety AnalysiscitraNo ratings yet

- Job Hazard Analysis and Standards Operating ProcedureDocument3 pagesJob Hazard Analysis and Standards Operating ProcedureRachelle Ann NotoNo ratings yet

- Demolition JhaDocument2 pagesDemolition JhaElvyn Fabellore HerreraNo ratings yet

- Scffolding Erection and Dismanatel JsaDocument5 pagesScffolding Erection and Dismanatel Jsakhaja asifuddinNo ratings yet

- Backfilling in FoundationDocument1 pageBackfilling in Foundationm.rehanhseNo ratings yet

- Jsa-013 Well DevelopmentDocument2 pagesJsa-013 Well DevelopmentRehman Muzaffar100% (2)

- CraneOperations PDFDocument2 pagesCraneOperations PDFIrshad AkhterNo ratings yet

- JSA - Backfilling at The Side of Retaining WallDocument2 pagesJSA - Backfilling at The Side of Retaining WallNFRNNo ratings yet

- Backfilling in Foundation - Plinth JSA HSE ProfessionalsDocument1 pageBackfilling in Foundation - Plinth JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Shuttering in Foundation HSE ProfessionalsDocument1 pageShuttering in Foundation HSE Professionalsalaa_2305No ratings yet

- Jsa For Installation of Additional Storm Down Ties and Stow Pin Slots On Crane Rail at West Pier of City Comercial PortDocument7 pagesJsa For Installation of Additional Storm Down Ties and Stow Pin Slots On Crane Rail at West Pier of City Comercial PortSebin VargheseNo ratings yet

- Pit Cleaning HSE ProfessionalsDocument1 pagePit Cleaning HSE ProfessionalsSamadov 13No ratings yet

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- Jsa Ground Grid MocksvilleDocument2 pagesJsa Ground Grid MocksvilleChristopher NewbyNo ratings yet

- Jsa Roof Sheeting & Wall CladdingDocument23 pagesJsa Roof Sheeting & Wall Claddingsamir ranjan dhalNo ratings yet

- Critical Steps Hazard(s) Controls/Recommended Action: Concrete Cutting & Breaking Core Cutting On Existing Man HoleDocument5 pagesCritical Steps Hazard(s) Controls/Recommended Action: Concrete Cutting & Breaking Core Cutting On Existing Man HoleSrikanth GandepalliNo ratings yet

- 02 Job Hazard Analysis For Deep Excavation & TrenchingDocument3 pages02 Job Hazard Analysis For Deep Excavation & TrenchingAmanNo ratings yet

- Hira For Esp Outlet PannalDocument5 pagesHira For Esp Outlet Pannalshahhussain1031100% (1)

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- PTW Jha Air PipeDocument3 pagesPTW Jha Air PipePHH9834No ratings yet

- JSA 004 Sand Blasting of Exposed RebarDocument1 pageJSA 004 Sand Blasting of Exposed RebarRyanNo ratings yet

- JSA-009a Drilling and Mon Well Construction-Sonic - 2Document4 pagesJSA-009a Drilling and Mon Well Construction-Sonic - 2sudarmanNo ratings yet

- AHAa RoofingDocument7 pagesAHAa RoofingjunomarsNo ratings yet

- AGF-01-115 62 Job Safety Analysis - INTAKE PIT ASPIRATION SYSTEM - GFMDocument1 pageAGF-01-115 62 Job Safety Analysis - INTAKE PIT ASPIRATION SYSTEM - GFMArslanNo ratings yet

- Risk Assessment For Demolishing of Burnt Ware of Procurement DepartmentDocument10 pagesRisk Assessment For Demolishing of Burnt Ware of Procurement DepartmentEdmund KonoteyNo ratings yet

- Pole Unit Install JhaDocument2 pagesPole Unit Install JhafatimahNo ratings yet

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- JSA For HP and LP Piping ErectionDocument1 pageJSA For HP and LP Piping ErectionAmit SinghNo ratings yet

- Jsa For Scafolding ErectionDocument1 pageJsa For Scafolding ErectionKoneti Janardhanarao100% (1)

- Tower CarneDocument2 pagesTower CarnenabeelNo ratings yet

- HIRA For Machanical WorkDocument8 pagesHIRA For Machanical Workshahhussain1031No ratings yet

- PCW Pipe Installation JhaDocument2 pagesPCW Pipe Installation Jhafatimah100% (1)

- Job Safety Analysis (JSA) - Earthworks DateDocument1 pageJob Safety Analysis (JSA) - Earthworks DatenabeelNo ratings yet

- SSSP Site Inspection Checklist Generic InteractiveDocument2 pagesSSSP Site Inspection Checklist Generic InteractivehaziqNo ratings yet

- A. Identify Task/Job Description B. Identify Lifesavers InvolvedDocument3 pagesA. Identify Task/Job Description B. Identify Lifesavers InvolvedPaul TamayoNo ratings yet

- 5B High Rise Building Summary of FindingsDocument3 pages5B High Rise Building Summary of FindingsJholo LopezNo ratings yet

- Hira For Kiln - 8Document6 pagesHira For Kiln - 8shahhussain1031No ratings yet

- Risk Mitigation Plan 1Document25 pagesRisk Mitigation Plan 1Omar BahakimNo ratings yet

- WMS Summary EnglishDocument1 pageWMS Summary EnglishKarthik babuNo ratings yet

- Safe Work Method - PilingDocument6 pagesSafe Work Method - PilingJustin RanjitNo ratings yet

- Risk AssessmentDocument5 pagesRisk AssessmentDurga PrasadNo ratings yet

- Method StatementsDocument5 pagesMethod Statementsjogesh sharmaNo ratings yet

- JSA For Replacement of Metal Roofsheet (East) .AB.1Document4 pagesJSA For Replacement of Metal Roofsheet (East) .AB.1hse2No ratings yet

- Jsa For - SRPDocument3 pagesJsa For - SRPVijay chauhanNo ratings yet

- Tool Box Talk For Block Works MasdarDocument2 pagesTool Box Talk For Block Works MasdarRyan PertezNo ratings yet

- Method Statement For Transmission Line Lanco PDFDocument37 pagesMethod Statement For Transmission Line Lanco PDFAmar Wadood100% (1)

- JSA-010 Excavation Sampling PDFDocument5 pagesJSA-010 Excavation Sampling PDFArgaYurIstiawanNo ratings yet

- Risk Assessment Form WSHDocument29 pagesRisk Assessment Form WSHDynamic ramNo ratings yet

- Bombers' Training, and Application of Same in Trench WarfareFrom EverandBombers' Training, and Application of Same in Trench WarfareNo ratings yet

- Guide For Officer and AdvisersDocument58 pagesGuide For Officer and AdvisersLane RandallNo ratings yet

- Online Polynomial Regression: Regressiontools: The ProgramDocument2 pagesOnline Polynomial Regression: Regressiontools: The Programsepideh rajaeiradNo ratings yet

- Unit 2 Evolution of Industrial Relations and Current DevelopmentsDocument10 pagesUnit 2 Evolution of Industrial Relations and Current DevelopmentsSatyam mishra100% (2)

- Group 5 PRACTICAL RESEARCHDocument28 pagesGroup 5 PRACTICAL RESEARCHJefford Vinson ValdehuezaNo ratings yet

- Fire SafetyDocument14 pagesFire SafetySubadharshiniNo ratings yet

- Cisco Systems, Inc.: Implementing ERP: - Submitted by Group 2Document5 pagesCisco Systems, Inc.: Implementing ERP: - Submitted by Group 2Aditya Vidolkar100% (1)

- Manual de Instalacion Marmita F-GL (20-100) - Man PDFDocument12 pagesManual de Instalacion Marmita F-GL (20-100) - Man PDFPitter M Montilla NNo ratings yet

- Hydraulic System 1Document28 pagesHydraulic System 1Udhaya Kumar100% (1)

- PaySlip-34 (LANKALAPALLI DURGA PRASAD) - JUN - 2022Document2 pagesPaySlip-34 (LANKALAPALLI DURGA PRASAD) - JUN - 2022Durga PrasadNo ratings yet

- Ra 11549Document6 pagesRa 11549Joemar Manaois TabanaoNo ratings yet

- Music Analysis, Retrieval and Synthesis of Audio Signals MARSYAS (George Tzanetakis)Document2 pagesMusic Analysis, Retrieval and Synthesis of Audio Signals MARSYAS (George Tzanetakis)emad afifyNo ratings yet

- Internal Audit Report FormatDocument3 pagesInternal Audit Report FormatSaket TibrewalNo ratings yet

- Status of Value Addition and Export of Moringa Produce in Tamil Nadu A Case StudyDocument14 pagesStatus of Value Addition and Export of Moringa Produce in Tamil Nadu A Case StudyvarunbeNo ratings yet

- ICI Pakistan LimitedDocument74 pagesICI Pakistan LimitedZeeshan GillNo ratings yet

- PIIS2589750020301606Document3 pagesPIIS2589750020301606Sadaf QasimNo ratings yet

- Overtourism Causes Implications and Solutions 1St Ed Edition Hugues Seraphin Full ChapterDocument67 pagesOvertourism Causes Implications and Solutions 1St Ed Edition Hugues Seraphin Full Chapterevelyn.kennedy635100% (6)

- Energy Auditing Proposal Scope of WorkDocument19 pagesEnergy Auditing Proposal Scope of WorkOmar Bilal AkashNo ratings yet

- 6in TBRS613Document1 page6in TBRS613pendexxNo ratings yet

- IBPS PO Main Exam PDF by AffairsCloud 1Document268 pagesIBPS PO Main Exam PDF by AffairsCloud 1Pranalee DhamaneNo ratings yet

- Maniego v. People: (The Law On Public Officers, Civil Service Laws, Election Laws)Document1 pageManiego v. People: (The Law On Public Officers, Civil Service Laws, Election Laws)Cari Mangalindan Macaalay100% (1)

- Electrical Submersible Pump (Esp)Document88 pagesElectrical Submersible Pump (Esp)kuldeepNo ratings yet

- Bonds Payable 2023Document59 pagesBonds Payable 2023Kirstine SanchezNo ratings yet

- Osh Accident Investigation Study CaseDocument23 pagesOsh Accident Investigation Study CaseMinho OnionsNo ratings yet

- TEIP 11-PS ABB I-P Conveter ManualDocument16 pagesTEIP 11-PS ABB I-P Conveter ManualsatindiaNo ratings yet

- The WCUDocument8 pagesThe WCUPatrick GroenNo ratings yet

- A Guide To Using The 100 Home Based Businesses For Malaysians ManualDocument63 pagesA Guide To Using The 100 Home Based Businesses For Malaysians ManualMohd Afif Sukri100% (1)

- Assignment 4 Unit 4Document4 pagesAssignment 4 Unit 4Maharshi Sanand Yadav TNo ratings yet

- Man BL 982411Document2 pagesMan BL 982411lordsethdarknessNo ratings yet

- Grade 8 - Criteria B and C Factors Affecting Rocket Performance AssessmentDocument8 pagesGrade 8 - Criteria B and C Factors Affecting Rocket Performance Assessmentapi-291745547No ratings yet

Job Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or Procedure

Job Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or Procedure

Uploaded by

Bernard Christian Dimaguila0 ratings0% found this document useful (0 votes)

9 views2 pagesThis document provides a job hazard analysis for the construction of a catwalk. It identifies potential hazards for three basic job steps: 1) Installation of scaffolding, which could result in collapse during erection or falls from scaffolding. Certified erectors with proper safety equipment are recommended. 2) Panel installation, which could involve cuts, abrasions, pinch points, overhead hazards or falls. Proper PPE and fall protection over 6 feet is recommended. 3) Pouring of concrete, which could involve workers being run over by equipment or high-speed bursts of concrete from air in hoses. The use of spotters, equipment shut-off after 3 minutes of idling, and trained whip-hose operators are

Original Description:

Job Hazard Analyis

Original Title

Jha

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a job hazard analysis for the construction of a catwalk. It identifies potential hazards for three basic job steps: 1) Installation of scaffolding, which could result in collapse during erection or falls from scaffolding. Certified erectors with proper safety equipment are recommended. 2) Panel installation, which could involve cuts, abrasions, pinch points, overhead hazards or falls. Proper PPE and fall protection over 6 feet is recommended. 3) Pouring of concrete, which could involve workers being run over by equipment or high-speed bursts of concrete from air in hoses. The use of spotters, equipment shut-off after 3 minutes of idling, and trained whip-hose operators are

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

9 views2 pagesJob Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or Procedure

Job Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or Procedure

Uploaded by

Bernard Christian DimaguilaThis document provides a job hazard analysis for the construction of a catwalk. It identifies potential hazards for three basic job steps: 1) Installation of scaffolding, which could result in collapse during erection or falls from scaffolding. Certified erectors with proper safety equipment are recommended. 2) Panel installation, which could involve cuts, abrasions, pinch points, overhead hazards or falls. Proper PPE and fall protection over 6 feet is recommended. 3) Pouring of concrete, which could involve workers being run over by equipment or high-speed bursts of concrete from air in hoses. The use of spotters, equipment shut-off after 3 minutes of idling, and trained whip-hose operators are

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

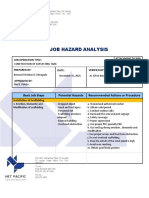

JOB HAZARD ANALYSIS

ATTACHMENT TO WP#

JOB OPERATION TITLE:

CONTRUCTION OF CATWALK

PREPARED BY: DATE: VERIFIED BY: (MANAGER IN CHARGE)

Bernard Christian D. Dimaguila September 14, 2021 Ar. Efren Bergado

APPROVED BY:

Niel S. Petate

Basic Job Steps Potential Hazards Recommended Actions or Procedure

Installation of scaffolding

- Collapse erection of Clear the area erection, supervision of

scaffolding supervisors and safety in charge

-fall from scaffolding Must be certified scaffolding erector with NC11

Panel installation

1. Cutting of Plywood and - Cuts and Abrasions Wear safety glasses, gloves,

accessories -eye hazards Longsleeve and secure the

Powertool with machine guard.

2. Installing Formworks - Pinch Points a. Make sure there is enough

- Overhead Hazards lighting in the work area.

- Cuts/Abrasions b. Do not place hands in between

-Falls forms.

c. Wear also proper PPE.

d. Pull or bend all nails that are

potruding to prevent cuts and

abrasions.

e. Secure scaffold or ladder at the

top and bottom.

f. Fall protection must be used

when climbing forms or when

exposed to falls from 6 feet or

higher.

Pouring of Concrete

1. Positioning concrete pumper -Workers run over/backed into by While heavy equipment is

and redi-mix trucks equipment. operating, all workers on the

ground will wear hivisibility vests

and hardhats.

2. Placing concrete as it comes - Air in line causing high-speed a. Concrete pumpers and redi-mix

from the hose burst of concrete. trucks will always have spotters

while backing up.

b. Equipment idling longer than 3

minutes shall be turned off.

c. Only trained workers will

handle the whip-hose.

d. Whip-hose operator and

others will coordinate on signals

with pump operator.

You might also like

- Excavation and Back Filling Works JsaDocument3 pagesExcavation and Back Filling Works Jsarashid zaman78% (18)

- JHA DrillingDocument4 pagesJHA Drillingjay RNo ratings yet

- Method Statement of Gantry Crane Dismantling - DIFD 20-09-18Document8 pagesMethod Statement of Gantry Crane Dismantling - DIFD 20-09-18mechajay2002100% (1)

- 39 Jha On Blok Masonary WorkDocument4 pages39 Jha On Blok Masonary WorkDheeraj KumarNo ratings yet

- Excavation and Back Filling Works JsaDocument3 pagesExcavation and Back Filling Works JsaNazir Hussain67% (12)

- Job Hazard Analysis For Crane DismantlingDocument2 pagesJob Hazard Analysis For Crane DismantlingKamlesh Bule Lonari100% (2)

- GMW 8-2008Document9 pagesGMW 8-2008Clauco Tiago Seno RoqueNo ratings yet

- JSA GroutingDocument2 pagesJSA GroutingSyazWyn100% (5)

- Job Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or ProcedureDocument3 pagesJob Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or ProcedureBernard Christian DimaguilaNo ratings yet

- JHA ConcretePlacingOperationDocument3 pagesJHA ConcretePlacingOperationAnonymous XJ9663C6N4No ratings yet

- IPM - MOS - 005 - Mobile ScaffoldDocument6 pagesIPM - MOS - 005 - Mobile ScaffoldmohdnurasyraafNo ratings yet

- JSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadDocument1 pageJSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadRyanNo ratings yet

- Job Safety AnalysisDocument2 pagesJob Safety AnalysiscitraNo ratings yet

- Job Hazard Analysis and Standards Operating ProcedureDocument3 pagesJob Hazard Analysis and Standards Operating ProcedureRachelle Ann NotoNo ratings yet

- Demolition JhaDocument2 pagesDemolition JhaElvyn Fabellore HerreraNo ratings yet

- Scffolding Erection and Dismanatel JsaDocument5 pagesScffolding Erection and Dismanatel Jsakhaja asifuddinNo ratings yet

- Backfilling in FoundationDocument1 pageBackfilling in Foundationm.rehanhseNo ratings yet

- Jsa-013 Well DevelopmentDocument2 pagesJsa-013 Well DevelopmentRehman Muzaffar100% (2)

- CraneOperations PDFDocument2 pagesCraneOperations PDFIrshad AkhterNo ratings yet

- JSA - Backfilling at The Side of Retaining WallDocument2 pagesJSA - Backfilling at The Side of Retaining WallNFRNNo ratings yet

- Backfilling in Foundation - Plinth JSA HSE ProfessionalsDocument1 pageBackfilling in Foundation - Plinth JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Shuttering in Foundation HSE ProfessionalsDocument1 pageShuttering in Foundation HSE Professionalsalaa_2305No ratings yet

- Jsa For Installation of Additional Storm Down Ties and Stow Pin Slots On Crane Rail at West Pier of City Comercial PortDocument7 pagesJsa For Installation of Additional Storm Down Ties and Stow Pin Slots On Crane Rail at West Pier of City Comercial PortSebin VargheseNo ratings yet

- Pit Cleaning HSE ProfessionalsDocument1 pagePit Cleaning HSE ProfessionalsSamadov 13No ratings yet

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- Jsa Ground Grid MocksvilleDocument2 pagesJsa Ground Grid MocksvilleChristopher NewbyNo ratings yet

- Jsa Roof Sheeting & Wall CladdingDocument23 pagesJsa Roof Sheeting & Wall Claddingsamir ranjan dhalNo ratings yet

- Critical Steps Hazard(s) Controls/Recommended Action: Concrete Cutting & Breaking Core Cutting On Existing Man HoleDocument5 pagesCritical Steps Hazard(s) Controls/Recommended Action: Concrete Cutting & Breaking Core Cutting On Existing Man HoleSrikanth GandepalliNo ratings yet

- 02 Job Hazard Analysis For Deep Excavation & TrenchingDocument3 pages02 Job Hazard Analysis For Deep Excavation & TrenchingAmanNo ratings yet

- Hira For Esp Outlet PannalDocument5 pagesHira For Esp Outlet Pannalshahhussain1031100% (1)

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- PTW Jha Air PipeDocument3 pagesPTW Jha Air PipePHH9834No ratings yet

- JSA 004 Sand Blasting of Exposed RebarDocument1 pageJSA 004 Sand Blasting of Exposed RebarRyanNo ratings yet

- JSA-009a Drilling and Mon Well Construction-Sonic - 2Document4 pagesJSA-009a Drilling and Mon Well Construction-Sonic - 2sudarmanNo ratings yet

- AHAa RoofingDocument7 pagesAHAa RoofingjunomarsNo ratings yet

- AGF-01-115 62 Job Safety Analysis - INTAKE PIT ASPIRATION SYSTEM - GFMDocument1 pageAGF-01-115 62 Job Safety Analysis - INTAKE PIT ASPIRATION SYSTEM - GFMArslanNo ratings yet

- Risk Assessment For Demolishing of Burnt Ware of Procurement DepartmentDocument10 pagesRisk Assessment For Demolishing of Burnt Ware of Procurement DepartmentEdmund KonoteyNo ratings yet

- Pole Unit Install JhaDocument2 pagesPole Unit Install JhafatimahNo ratings yet

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- JSA For HP and LP Piping ErectionDocument1 pageJSA For HP and LP Piping ErectionAmit SinghNo ratings yet

- Jsa For Scafolding ErectionDocument1 pageJsa For Scafolding ErectionKoneti Janardhanarao100% (1)

- Tower CarneDocument2 pagesTower CarnenabeelNo ratings yet

- HIRA For Machanical WorkDocument8 pagesHIRA For Machanical Workshahhussain1031No ratings yet

- PCW Pipe Installation JhaDocument2 pagesPCW Pipe Installation Jhafatimah100% (1)

- Job Safety Analysis (JSA) - Earthworks DateDocument1 pageJob Safety Analysis (JSA) - Earthworks DatenabeelNo ratings yet

- SSSP Site Inspection Checklist Generic InteractiveDocument2 pagesSSSP Site Inspection Checklist Generic InteractivehaziqNo ratings yet

- A. Identify Task/Job Description B. Identify Lifesavers InvolvedDocument3 pagesA. Identify Task/Job Description B. Identify Lifesavers InvolvedPaul TamayoNo ratings yet

- 5B High Rise Building Summary of FindingsDocument3 pages5B High Rise Building Summary of FindingsJholo LopezNo ratings yet

- Hira For Kiln - 8Document6 pagesHira For Kiln - 8shahhussain1031No ratings yet

- Risk Mitigation Plan 1Document25 pagesRisk Mitigation Plan 1Omar BahakimNo ratings yet

- WMS Summary EnglishDocument1 pageWMS Summary EnglishKarthik babuNo ratings yet

- Safe Work Method - PilingDocument6 pagesSafe Work Method - PilingJustin RanjitNo ratings yet

- Risk AssessmentDocument5 pagesRisk AssessmentDurga PrasadNo ratings yet

- Method StatementsDocument5 pagesMethod Statementsjogesh sharmaNo ratings yet

- JSA For Replacement of Metal Roofsheet (East) .AB.1Document4 pagesJSA For Replacement of Metal Roofsheet (East) .AB.1hse2No ratings yet

- Jsa For - SRPDocument3 pagesJsa For - SRPVijay chauhanNo ratings yet

- Tool Box Talk For Block Works MasdarDocument2 pagesTool Box Talk For Block Works MasdarRyan PertezNo ratings yet

- Method Statement For Transmission Line Lanco PDFDocument37 pagesMethod Statement For Transmission Line Lanco PDFAmar Wadood100% (1)

- JSA-010 Excavation Sampling PDFDocument5 pagesJSA-010 Excavation Sampling PDFArgaYurIstiawanNo ratings yet

- Risk Assessment Form WSHDocument29 pagesRisk Assessment Form WSHDynamic ramNo ratings yet

- Bombers' Training, and Application of Same in Trench WarfareFrom EverandBombers' Training, and Application of Same in Trench WarfareNo ratings yet

- Guide For Officer and AdvisersDocument58 pagesGuide For Officer and AdvisersLane RandallNo ratings yet

- Online Polynomial Regression: Regressiontools: The ProgramDocument2 pagesOnline Polynomial Regression: Regressiontools: The Programsepideh rajaeiradNo ratings yet

- Unit 2 Evolution of Industrial Relations and Current DevelopmentsDocument10 pagesUnit 2 Evolution of Industrial Relations and Current DevelopmentsSatyam mishra100% (2)

- Group 5 PRACTICAL RESEARCHDocument28 pagesGroup 5 PRACTICAL RESEARCHJefford Vinson ValdehuezaNo ratings yet

- Fire SafetyDocument14 pagesFire SafetySubadharshiniNo ratings yet

- Cisco Systems, Inc.: Implementing ERP: - Submitted by Group 2Document5 pagesCisco Systems, Inc.: Implementing ERP: - Submitted by Group 2Aditya Vidolkar100% (1)

- Manual de Instalacion Marmita F-GL (20-100) - Man PDFDocument12 pagesManual de Instalacion Marmita F-GL (20-100) - Man PDFPitter M Montilla NNo ratings yet

- Hydraulic System 1Document28 pagesHydraulic System 1Udhaya Kumar100% (1)

- PaySlip-34 (LANKALAPALLI DURGA PRASAD) - JUN - 2022Document2 pagesPaySlip-34 (LANKALAPALLI DURGA PRASAD) - JUN - 2022Durga PrasadNo ratings yet

- Ra 11549Document6 pagesRa 11549Joemar Manaois TabanaoNo ratings yet

- Music Analysis, Retrieval and Synthesis of Audio Signals MARSYAS (George Tzanetakis)Document2 pagesMusic Analysis, Retrieval and Synthesis of Audio Signals MARSYAS (George Tzanetakis)emad afifyNo ratings yet

- Internal Audit Report FormatDocument3 pagesInternal Audit Report FormatSaket TibrewalNo ratings yet

- Status of Value Addition and Export of Moringa Produce in Tamil Nadu A Case StudyDocument14 pagesStatus of Value Addition and Export of Moringa Produce in Tamil Nadu A Case StudyvarunbeNo ratings yet

- ICI Pakistan LimitedDocument74 pagesICI Pakistan LimitedZeeshan GillNo ratings yet

- PIIS2589750020301606Document3 pagesPIIS2589750020301606Sadaf QasimNo ratings yet

- Overtourism Causes Implications and Solutions 1St Ed Edition Hugues Seraphin Full ChapterDocument67 pagesOvertourism Causes Implications and Solutions 1St Ed Edition Hugues Seraphin Full Chapterevelyn.kennedy635100% (6)

- Energy Auditing Proposal Scope of WorkDocument19 pagesEnergy Auditing Proposal Scope of WorkOmar Bilal AkashNo ratings yet

- 6in TBRS613Document1 page6in TBRS613pendexxNo ratings yet

- IBPS PO Main Exam PDF by AffairsCloud 1Document268 pagesIBPS PO Main Exam PDF by AffairsCloud 1Pranalee DhamaneNo ratings yet

- Maniego v. People: (The Law On Public Officers, Civil Service Laws, Election Laws)Document1 pageManiego v. People: (The Law On Public Officers, Civil Service Laws, Election Laws)Cari Mangalindan Macaalay100% (1)

- Electrical Submersible Pump (Esp)Document88 pagesElectrical Submersible Pump (Esp)kuldeepNo ratings yet

- Bonds Payable 2023Document59 pagesBonds Payable 2023Kirstine SanchezNo ratings yet

- Osh Accident Investigation Study CaseDocument23 pagesOsh Accident Investigation Study CaseMinho OnionsNo ratings yet

- TEIP 11-PS ABB I-P Conveter ManualDocument16 pagesTEIP 11-PS ABB I-P Conveter ManualsatindiaNo ratings yet

- The WCUDocument8 pagesThe WCUPatrick GroenNo ratings yet

- A Guide To Using The 100 Home Based Businesses For Malaysians ManualDocument63 pagesA Guide To Using The 100 Home Based Businesses For Malaysians ManualMohd Afif Sukri100% (1)

- Assignment 4 Unit 4Document4 pagesAssignment 4 Unit 4Maharshi Sanand Yadav TNo ratings yet

- Man BL 982411Document2 pagesMan BL 982411lordsethdarknessNo ratings yet

- Grade 8 - Criteria B and C Factors Affecting Rocket Performance AssessmentDocument8 pagesGrade 8 - Criteria B and C Factors Affecting Rocket Performance Assessmentapi-291745547No ratings yet