Professional Documents

Culture Documents

Mega White LED Calculos

Mega White LED Calculos

Uploaded by

Atemex OaxCopyright:

Available Formats

You might also like

- Aircraft Carrier Climate Control Investigation Team (ACCCIT) HVAC ManualDocument143 pagesAircraft Carrier Climate Control Investigation Team (ACCCIT) HVAC Manualezmerelda50% (2)

- Optimal Energy Management For Solar-Powered CarsDocument189 pagesOptimal Energy Management For Solar-Powered CarsMohammad Hafiz OthmanNo ratings yet

- CSL0406WBCW Series: Data SheetDocument10 pagesCSL0406WBCW Series: Data SheetpabloNo ratings yet

- SML-D14x (C) Series: Data SheetDocument10 pagesSML-D14x (C) Series: Data SheetKhadija EL ATRASSINo ratings yet

- High-Friquency General-Purpose Amplifier Applications: Package Dimensions FeaturesDocument5 pagesHigh-Friquency General-Purpose Amplifier Applications: Package Dimensions FeaturesArturo ArmuellesNo ratings yet

- 1 PDFDocument23 pages1 PDFRony panggabeanNo ratings yet

- Rt1N237X Series: 〈Transistor〉Document3 pagesRt1N237X Series: 〈Transistor〉Rodolfo AndradeNo ratings yet

- FA5301 DatasheetDocument5 pagesFA5301 DatasheetIvanBernalNo ratings yet

- Datasheet 2SC5376FVDocument5 pagesDatasheet 2SC5376FVTAOZ MNo ratings yet

- Apen A700000008823562Document5 pagesApen A700000008823562fabio coalaNo ratings yet

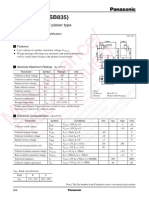

- Silicon NPN Epitaxial Planer Type: TransistorDocument2 pagesSilicon NPN Epitaxial Planer Type: TransistorStuxnetNo ratings yet

- RT1N141C (N1)Document3 pagesRT1N141C (N1)Homer Sadych Henao MarinNo ratings yet

- Rt1n141u-T150 (Aec) eDocument3 pagesRt1n141u-T150 (Aec) eHamza Abbasi AbbasiNo ratings yet

- RN2131FV, RN2132FV: Switching, Inverter Circuit, Interface Circuit and Driver Circuit ApplicationsDocument5 pagesRN2131FV, RN2132FV: Switching, Inverter Circuit, Interface Circuit and Driver Circuit ApplicationsIsaiasAvilesNo ratings yet

- FA531X Series: FA5310BP (S), FA5314P (S), FA5316P (S) FA5311BP (S), FA5315P (S), FA5317P (S)Document17 pagesFA531X Series: FA5310BP (S), FA5314P (S), FA5316P (S) FA5311BP (S), FA5315P (S), FA5317P (S)Djalma MoreiraNo ratings yet

- PD49PI/PD481PI: Photodiode High Speed, High SensitivityDocument3 pagesPD49PI/PD481PI: Photodiode High Speed, High SensitivityDavid Nasael VERGARANo ratings yet

- Maintenance/ Discontinued: Silicon PNP Epitaxial Planer TypeDocument3 pagesMaintenance/ Discontinued: Silicon PNP Epitaxial Planer TypeDaniela Estrella Elvira CastilloNo ratings yet

- Maintenance/ Discontinued: Silicon PNP Epitaxial Planer TypeDocument3 pagesMaintenance/ Discontinued: Silicon PNP Epitaxial Planer TypeDaniela Estrella Elvira CastilloNo ratings yet

- Specifications: A1251 SERIESDocument6 pagesSpecifications: A1251 SERIESEvgeniKosakovskiNo ratings yet

- Odd 12WDocument3 pagesOdd 12Woscar_sm77No ratings yet

- TOIR 50b94bCEaDocument2 pagesTOIR 50b94bCEaFaifai ChulanitaNo ratings yet

- Silicon NPN Triple Diffusion Planar Type Darlington: Power TransistorsDocument3 pagesSilicon NPN Triple Diffusion Planar Type Darlington: Power TransistorsVitorioNo ratings yet

- Specifications: AcrosentecDocument6 pagesSpecifications: AcrosentecIsra JanNo ratings yet

- SERIESDocument3 pagesSERIESJose Angel TorrealbaNo ratings yet

- General Purpose Low Leakage Diode: Absolute Maximum Ratings Sym Parameter Value UnitsDocument3 pagesGeneral Purpose Low Leakage Diode: Absolute Maximum Ratings Sym Parameter Value UnitsZoltán ÁgostonNo ratings yet

- DFBLaser FWHM 0.01nm 1570nmDocument1 pageDFBLaser FWHM 0.01nm 1570nmJ. M. M.No ratings yet

- 2SA1015Document2 pages2SA1015Thi NguyễnNo ratings yet

- CENTRIC DAYLIGHT Full Spectrum Flicker-Free A19 10W LED Bulb 4000K Photometric ReportDocument1 pageCENTRIC DAYLIGHT Full Spectrum Flicker-Free A19 10W LED Bulb 4000K Photometric ReportTonyNo ratings yet

- SunonDocument4 pagesSunonEmerson Müller Juarez AvilaNo ratings yet

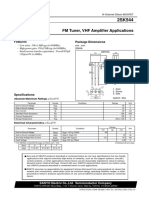

- FM Tuner, VHF Amplifier ApplicationsDocument5 pagesFM Tuner, VHF Amplifier ApplicationsEzequiel Cândido KelNo ratings yet

- 2 SK 546Document3 pages2 SK 546Joaquin Guzman murilloNo ratings yet

- High-Frequency Amplifier, Analog Switch Applications: Package Dimensions FeaturesDocument4 pagesHigh-Frequency Amplifier, Analog Switch Applications: Package Dimensions FeaturesAngel Simo MoralesNo ratings yet

- CNB1302 (ON2170) : Reflective PhotosensorDocument3 pagesCNB1302 (ON2170) : Reflective PhotosensorSébastien MahutNo ratings yet

- 090RDA1 sharpTV PDFDocument7 pages090RDA1 sharpTV PDFLui Drones100% (1)

- 117SIP, 107DIP, 171DIP PCB Mount Miniature Reed RelaysDocument5 pages117SIP, 107DIP, 171DIP PCB Mount Miniature Reed RelaysJose Manuel EscalanteNo ratings yet

- 2sc5585, 2sc5663 RohmDocument4 pages2sc5585, 2sc5663 RohmRe Ma (Master)No ratings yet

- RF-500TB: Output: 0.01W 2.0W (Approx)Document1 pageRF-500TB: Output: 0.01W 2.0W (Approx)luisfNo ratings yet

- Datos D Emotor DC WGMDocument1 pageDatos D Emotor DC WGMjosue perezNo ratings yet

- KTLP 3616Document10 pagesKTLP 3616Ismael silvaNo ratings yet

- Silicon PNP Epitaxial Planer Type: TransistorsDocument1 pageSilicon PNP Epitaxial Planer Type: Transistorsbusamawan wayanNo ratings yet

- SP20U80L: Low VF Schottky Barrier RectifierDocument3 pagesSP20U80L: Low VF Schottky Barrier RectifierRiad SalihNo ratings yet

- 20DL2CZ51A, 20FL2CZ51A: Switching Mode Power Supply Applications Converter & Chopper ApplicationsDocument5 pages20DL2CZ51A, 20FL2CZ51A: Switching Mode Power Supply Applications Converter & Chopper ApplicationsJuvenal David Hernández CórdovaNo ratings yet

- Motiongoo Stepper Motor Drawing-17HT19S4168C1Document1 pageMotiongoo Stepper Motor Drawing-17HT19S4168C1Make RownNo ratings yet

- Relee PlacaDocument1 pageRelee PlacaMarcelo ArtolaNo ratings yet

- 5.4 Applications 5.4.1 B: IosensingDocument3 pages5.4 Applications 5.4.1 B: IosensingThông NguyễnNo ratings yet

- Switching Diode: DatasheetDocument7 pagesSwitching Diode: DatasheetClément SaillantNo ratings yet

- En An Ce / Co Nti Nu Ed: Silicon PNP Epitaxial Planer TypeDocument4 pagesEn An Ce / Co Nti Nu Ed: Silicon PNP Epitaxial Planer TypeDaniela Estrella Elvira CastilloNo ratings yet

- DatasheetDocument6 pagesDatasheetGlaucio GomesNo ratings yet

- High-Frequency Low-Noise Amplifier Applications: Package Dimensions FeaturesDocument6 pagesHigh-Frequency Low-Noise Amplifier Applications: Package Dimensions FeaturesMarco Antonio Bolívar SuárezNo ratings yet

- PQ05RD08 Series/PQ3RD083/PQ6RD083: Features Outline DimensionsDocument8 pagesPQ05RD08 Series/PQ3RD083/PQ6RD083: Features Outline Dimensionsmitesh12123No ratings yet

- 070xna1 Panasonic IcDocument5 pages070xna1 Panasonic IcGeovanny SanJuanNo ratings yet

- Low-Frequency Amplifier Applications: Package Dimensions FeaturesDocument4 pagesLow-Frequency Amplifier Applications: Package Dimensions FeaturesautreraNo ratings yet

- An 0001Document5 pagesAn 0001Umar MajeedNo ratings yet

- Mb05Fa Thru Mb10Fa: FeaturesDocument2 pagesMb05Fa Thru Mb10Fa: FeaturesFox BenNo ratings yet

- LDR Orp12Document2 pagesLDR Orp12Faulhaber AdrianNo ratings yet

- Design of Source Degenerated Cascode Dual FunctionDocument25 pagesDesign of Source Degenerated Cascode Dual Functionmaia.df11No ratings yet

- Zener Diode-Load RegulatorDocument1 pageZener Diode-Load RegulatorKaushal Kumar GulatiNo ratings yet

- 2SK772Document4 pages2SK772Juan CarlosNo ratings yet

- The Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramDocument1 pageThe Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramJuan Carlos BarandicaNo ratings yet

- 504wc2e W6 1PC PDFDocument9 pages504wc2e W6 1PC PDFCris Yo SoyNo ratings yet

- Pulsed Laser Diode in Plastic Package 25 W Peak Power: FeaturesDocument6 pagesPulsed Laser Diode in Plastic Package 25 W Peak Power: FeaturesPraveen ShenolkarNo ratings yet

- Feasibility Study of Isoprene ProductionDocument4 pagesFeasibility Study of Isoprene ProductionIntratec SolutionsNo ratings yet

- Aritco Public Lift Access Datasheet-1Document2 pagesAritco Public Lift Access Datasheet-1Nancy StarryNo ratings yet

- P Series Ciac Service Manual 30,36K FVDocument108 pagesP Series Ciac Service Manual 30,36K FVAnthony Pineda ValenciaNo ratings yet

- 2.0 DCV-Brochure BV Valves (Pages) R01 PDFDocument12 pages2.0 DCV-Brochure BV Valves (Pages) R01 PDFAliZenatiNo ratings yet

- Metal CladdingDocument21 pagesMetal CladdingRoopali Gupta100% (2)

- Ornithopter: A Machine Designed To Achieve Flight by Means of Flapping WingsDocument61 pagesOrnithopter: A Machine Designed To Achieve Flight by Means of Flapping Wingsdavid hermawanNo ratings yet

- Alex Loyd Gift Secret Spiritual Laws of Nature Les CoreDocument25 pagesAlex Loyd Gift Secret Spiritual Laws of Nature Les CoreDr Ron100% (11)

- TDP InfoDocument7 pagesTDP InfoEN LeedNo ratings yet

- Latent Heat Worksheet 2016Document4 pagesLatent Heat Worksheet 2016Angelica Beltran LazagaNo ratings yet

- Chapter 10: Particle Size Reduction and SeparationDocument4 pagesChapter 10: Particle Size Reduction and SeparationYsabel Salvador DychincoNo ratings yet

- AMS1117ADJDocument5 pagesAMS1117ADJCharly FhNo ratings yet

- Solid-State Kinetic ModelsDocument14 pagesSolid-State Kinetic Modelsleizar_death64No ratings yet

- Lecture 2 Enzyme KineticsDocument31 pagesLecture 2 Enzyme KineticsCarinaJongLeeNo ratings yet

- Store Resp: Store Level Vending ResponsibilitiesDocument11 pagesStore Resp: Store Level Vending ResponsibilitiesDrahosDostalNo ratings yet

- WEG D and NH Fuses 50023628 Brochure EnglishDocument12 pagesWEG D and NH Fuses 50023628 Brochure EnglishRiza Agus FaisalNo ratings yet

- Ascorbic AcidDocument17 pagesAscorbic AcidNURUL SYAHIRAH BINTI ABDUL HALIMNo ratings yet

- Electrical Characterization of NanomaterialsDocument13 pagesElectrical Characterization of NanomaterialsNehal Aswani 19BEC1125No ratings yet

- Refinery OperationsDocument31 pagesRefinery OperationsGhilescu Daniil100% (1)

- Electric Oil - Filled Radiator: Owner'S ManualDocument12 pagesElectric Oil - Filled Radiator: Owner'S ManualjohnqevilNo ratings yet

- Rubber IndustryDocument13 pagesRubber IndustryMinjdeDiosNo ratings yet

- Ei1252 - Transducer EngineeringDocument18 pagesEi1252 - Transducer Engineeringguru.rjpmNo ratings yet

- Service Schedule For All MachinesDocument47 pagesService Schedule For All MachinesGENOVIC MPEMBANo ratings yet

- WI62EX: Model TypeDocument23 pagesWI62EX: Model TypePredrag MarkovicNo ratings yet

- Manual Excavadora 320dDocument982 pagesManual Excavadora 320dAlvaro Escalona Gtz100% (5)

- Uop-1 Mid Sem 2Document65 pagesUop-1 Mid Sem 2ShreyaDixitNo ratings yet

- Modicon X80 Modules - BMXCPS4002Document3 pagesModicon X80 Modules - BMXCPS4002Boris MoreiraNo ratings yet

- Pyro & Cooler Heat & Mass Balance Ed1Document2 pagesPyro & Cooler Heat & Mass Balance Ed1JCSNo ratings yet

- Cavalier 2.2Document42 pagesCavalier 2.2arche70No ratings yet

Mega White LED Calculos

Mega White LED Calculos

Uploaded by

Atemex OaxOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mega White LED Calculos

Mega White LED Calculos

Uploaded by

Atemex OaxCopyright:

Available Formats

MEC

Data Sheet For 5mm Super White LED

Part No: RF5A3SWG4-N1

Part No: RF5A3SWG4-N1 Page 1 of 6

Package Dimensions

Features

• Standard T-1 Diameter Type Package. 5.0

• General Purpose Leads

1.0

8.7

• Reliable and Rugged

5.8

Part No. RF5A3SWG4-N1

MIN26.5

Lens Color Water Clear

ANODE

Source Color Super White

0.5

2.54

1.5

Typical Characteristic

Spectrum

Forward Current vs.

Chromaticity Coordinate (λD)

Relative Emission Intensity (a.u.)

0.35 1.2

Ta = 25 C Ta = 25 C

1.0 IF = 20mA

0.34

1mA 0.8

0.33

5mA 0.6

y

0.32 20mA

0.4

0.31 50mA

0.2

100mA

0.30 0

0.29 0.30 0.31 0.32 0.33 0.34 350 450 550 650 750

x Wavelength λ(nm)

Ambient Temperature vs.

Chromaticity Coordinate (λD) Directivity (Angle : 20 )

0 10

0.35 1 20

IFP = 20mA Ta = 25 C 30

Relative Luminosity (a.u.)

IF = 20mA 40

0.34

50

0.33 0.5 60

-30 C

y 0 C 70

0.32 25 C 80

50 C

0.31 0

90

85 C 90 60 30 0 0.5 1

0.30 Radiation Angle

0.29 0.30 0.31 0.32 0.33 0.34

x

Part No: RF5A3SWG4-N1 Page 2 of 6

Typical Characteristic

F o rw ard V o ltag e v s. F o rw ard C u rren t v s.

F o rw ard C u rren t R elativ e L u m iin o sity

200

Ta = 25 C 4 .0

100 T a = 25 C

Relative Luminosity (a.u.)

3 .5

Forward Current IFP (mA)

50

3 .0

20

2 .5

2 .0

10

1 .5

5

1 .0

0 .5

1

0

2 .5 3 .0 3 .5 4 .0 4 .5 5 .0 0 20 40 60 80 100 1 20

F o rw ard C u rren t I F P (m A )

F o rw ard V o ltag e ( V )

A m b ie n t T em p e ratu re v s. A m b ie n t T em p era tu re v s.

F o rw ard V o ltag e R elativ e L u m in o sity

5 .4

I F P = 2 0m A 2 .0

5 .0 IF P = 2 0 m A

Relative Luminosity (a.u.)

4 .6

Forward Voltage VF (V)

1 .0

4 .2

3 .8 0 .5

3 .4

3 .0

2 .6 0 .2

-4 0 -20 0 20 40 60 80 100 -4 0 -20 0 20 40 60 80 1 00

A m b ien t T em p eratu re T a ( C ) A m b ien t T em p eratu re T a ( C )

D u ty R atio v s. A m b ien t T em p eratu re v s.

A llo w ab le F o rw ard C u rren t A llo w ab le F o rw ard C u rren t

200 40

Allowable Forward Current IFP (mA)

Ta = 25 C

Allowable Forward Current IFP (mA)

100

30

50

20

30

20

10

10

1 5 10 20 50 100 0

0 20 40 60 80 100

D u ty R atio ( % )

A m b ien t T em p eratu re ( C )

Part No: RF5A3SWG4-N1 Page 3 of 6

Absolute Maximum Ratings at Ta=25℃

Parameter MAX. Unit

Power Dissipation 100 mW

Peak Forward Current

100 mA

(1/10 Duty Cycle, 0.1ms Pulse Wide)

Continuous Forward Current 20 mA

Derating Linear From 50°C 0.4 mA/°C

Reverse Voltage 5 V

Operating Temperature Range -40°C to +80°C

Storage Temperature Range -40°C to +80°C

Lead Soldering Temperature

260°C for 3 Seconds

[ 4mm(.157”) From Body]

Electrical Optical Characteristics at Ta=25℃

Parameter Symbol Min. Typ. Max. Unit Test Condition

Luminous Intensity Iv 5000 --- 7000 mcd IF = 20mA (Note 7)

Viewing angle 2θ½ --- 20 --- Deg (Note 8)

X Re d

x= =

X + Y + Z Re d + Green + Blue x --- 0.29 --- --- IF = 20mA(Note 9)

Y Green

y= = Y --- 0.27 --- --- IF = 20mA(Note 9)

X + Y + Z Re d + Green + Blue

Forward Voltage VF 3.0 --- 4.0 V IF = 20mA

Reverse Current IR --- --- 50 µA VR = 5V

Notes:

1. All dimensions are in millimeter.

2. Tolerance is ±0.25mm(.01”) unless others otherwise noted.

3. Protruded resin under flanges is 1.0mm(0.4”) max.

4. Lead spacing is measured where the leads emerge from the package.

5. Specifications are subject to change without notice.

6. Caution in ESD: Static Electricity and surge damages the LED. lt is recommended to use

a wrist band or anti-electrostatic glove when handling the LED.All devices, equipment and

machinery must be properly grounded.

7. Luminous intensity is measured with a light sensor and filter combination that

approximates the CIE eye-response curve.

8. θ1/2 is the off-axis angle at which the luminous intensity is half the axial luminous intensity.

9. It use many parameters that correspond to the CIE 1931 2°

X,Y, and Z are CIE1931 2°values of Red, Green and Blue content of the measurement.

Part No: RF5A3SWG4-N1 Page 4 of 6

CAUTIONS- Super Bright LED

Because the white LEDs are make by combining Blue LEDs and special phosphors. Hence, the color of White LEDs is changed a little by an

operation current. Care should be taken after due consideration when using LEDs.

1. Lead Forming

a. At least 3mm from the base of the epoxy bulb should be keep when forming leads.

b. Do not use the base of the leadframe as a fulcrum during lead forming.

Lead forming should be done before soldering.

c. Because the stress to the base may damage the characteristics or it may break the LEDs, do not apply any bending stress to the

base of the lead

d. When mounting the LEDs onto a PCB, the holes on the circuit board should be exactly aligned with the leads of the LEDs. Stress at

the leads should be avoid when the LEDs are mounted on the PCB, because it causes damage to the epoxy resin and this will

degrade the LEDs.

(2) Storage

a. The LEDs should be stored at stored at 30 C or less and 70%RH or less after being shipped and the storage life limits are 3 months.

b. If the LEDs are stored more then 3 months, they can be stored for a year in a sealed container with a nitrogen atmosphere and

moisture absorbent material.

c. Please avoid rapid transitions in ambient temperature, especially, in high humidity environments where condensation can occur.

(3) Static Electricity

a. Static electricity or surge voltage damages the LEDs.

b. It is recommended that a wristband or an anti-electrostatic glove be used when handling the LEDs.

c. All devices, equipment and machinery must be properly grounded.

d. It is recommended that measures be taken against surge voltage to the equipment that mounts the LEDs.

e. Damaged LEDs will show some unusual characteristics such as the leak current remarkably increases, the forward voltage

becomes lower, or the LEDs do not light at the low current.

Criteria: (VF>2.0V at IF=0.5mA)

(5) Heat Generation

a. Thermal design of the end product was most importance. Please consider the heat generation of the LED when making the system

design.

b. The thermal resistance of the circuit board and density of LED placement on the board, as well as other components was the

important factor affecting the coefficient of temperature increase per input electric power. It must be avoid intense heat generation

and operate within the maximum ratings given in the specification.

c. The operating current should be decided after considering the ambient maximum temperature of LEDs.

(6) Cleaning

a. It is recommended that isopropyl alcohol be used as a solvent for cleaning the LEDs. When using other solvents, it should be

confirmed beforehand whether the solvents will dissolve the resin or not. Freon solvents should not be used to clean the LEDs

because of worldwide regulations.

b. Do not clean the LEDs by the ultrasonic. When it is absolutely necessary, the influence of ultrasonic cleaning on the LEDs depends

on factors such as ultrasonic power and the assembled condition. Before cleaning, a pre-test should be done to confirm whether any

damage to the LEDs would occur.

(7) Safety Guideline for Human Eyes

a. In 1993, the International Electric Committee (IEC) issued a standard concerning laser product safety (IEC 825-1).Since then, this

standard has been applied for diffused light sources (LEDs) as well as lasers.In 1998 IEC 60825-1 Edition 1.1 evaluated the

magnitude of the light source.

b. In 2001 IC 60825-1 Amendment 2 converted the laser class into 7 classes for end products.

c. Components are excluded from this system. Products which contain visible LEDs are now classified as class 1. Products containing

UV LEDs can be classified as class 2 in cases where viewing angles are narrow, optical manipulation intensifies the light, and/or the

energy emitted is high. For these systems it is recommended to avoid long term exposure. It is also recommended to follow the ICE

regulations regarding safety and labeling of products.

(8) Soldering Condition for LED Lamps

a. EPOXY RESIN of LED

Epoxy resin for LED need to be cured within some temperature range with enough time, otherwise it will not hard enough then and

moisture in the air will penetrate into epoxy day by day. After some period later, the epoxy of LED may crack inside and it will reduce

the lifetime of the LED lamps. Because of this reason, we REFOND had precisely controlled as in the 2nd Statement.

b. Temperature of Glass (Tg Point)

For ensure the epoxy resin is hard enough, a good process control for epoxy resin ENDCAP process was required, such as precise

temperature profile of the over, exactly time for curing and good selection for epoxy resin. After that we need to measure the Tg

point for checking the epoxy resin is hard enough or not. Tg point should be control in range 125-135 centi-grade, if Tg lower than

125degree, it will make the epoxy soft. When soldering higher than 135degree, it will make the epoxy too hard and the epoxy will

crack inside easily.

c. For Automatic Soldering

(a) All of soldering equipment needs to check temperature on top of PCB for soldering LED as record.

(b) Pre-heat temperature must below Tg point, otherwise LED will be soft soldering and broken the bonding gold wire inside.

(c) The soldering condition need to below 5 seconds with 260 centi-grade or lower of each soldering point.

Part No: RF5A3SWG4-N1 Page 5 of 6

(d) The soldering PCB with LED can’t have any vibration or shock after soldering because inside LED epoxy still soft, and this

action will cause gold wire broken inside. The best way is to have cooling fan for cooling down shortly.

d. For Manually soldering

(a) When use hand soldering with extension wire, it is suggested that a fixture for soldering is needed to prevent any strength inside

when head is transferring to epoxy through LED leads. Otherwise, it might have gold wire broken inside.

(b) When use hand soldering with PCB insertion, it must make sure the pitch of OCB for LED leads are the same as LED lead pitch.

Otherwise there might have strength transfer to inside epoxy broken gold wire when soldering.

e. The size of the PCB for automatic soldering

(a) It is very important that PCB will have a little bit bent when soldering, this phenomenon especially for large PCB size. When

there are some higher defect rate for LED after soldering, it must check the PCB size and the PCB is bent or not in this

soldering. If this phenomenon happen, the LED leads will be a little bit bent and the gold wire inside may be broken.

(b) It will be good for the LED circuit application if a small size PCB was used.

(c) Then larger size PCB was use; it needs to have special fixture to preventing PCB bending when soldering.

(9) Others

a. Care must be taken to ensure that the reverse voltage will not exceed the absolute maximum rating when using the LEDs with

matrix drive. Keeping the Normal Forward to 20 mA.

IF

Rx

VF

IF = V - VF

Rx

b. The LEDs described in this brochure are intended to be used for ordinary electronic equipment (such as office equipment,

communications equipment, measurement instruments and household appliances). Consult Refond’s sales staff in advance for

information on the applications in which exceptional quality and reliability are required, particularly when the failure or malfunction of

the LEDs may directly jeopardize life or health (such as for airplanes, aerospace, submersible repeaters, nuclear reactor control

systems, automobiles, traffic control equipment, life support systems and safety devices).

c. User shall not reverse engineer by disassembling or analysis of the LEDs without having prior written consent from Refond. When

defective LEDs are found, the User shall inform Refond directly before disassembling or analysis.

d. The formal specifications must be exchanged and signed by both parties before large volume purchase begins.

e. The appearance and specifications of the product may be modified for improvement without notice.

Part No: RF5A3SWG4-N1 Page 6 of 6

You might also like

- Aircraft Carrier Climate Control Investigation Team (ACCCIT) HVAC ManualDocument143 pagesAircraft Carrier Climate Control Investigation Team (ACCCIT) HVAC Manualezmerelda50% (2)

- Optimal Energy Management For Solar-Powered CarsDocument189 pagesOptimal Energy Management For Solar-Powered CarsMohammad Hafiz OthmanNo ratings yet

- CSL0406WBCW Series: Data SheetDocument10 pagesCSL0406WBCW Series: Data SheetpabloNo ratings yet

- SML-D14x (C) Series: Data SheetDocument10 pagesSML-D14x (C) Series: Data SheetKhadija EL ATRASSINo ratings yet

- High-Friquency General-Purpose Amplifier Applications: Package Dimensions FeaturesDocument5 pagesHigh-Friquency General-Purpose Amplifier Applications: Package Dimensions FeaturesArturo ArmuellesNo ratings yet

- 1 PDFDocument23 pages1 PDFRony panggabeanNo ratings yet

- Rt1N237X Series: 〈Transistor〉Document3 pagesRt1N237X Series: 〈Transistor〉Rodolfo AndradeNo ratings yet

- FA5301 DatasheetDocument5 pagesFA5301 DatasheetIvanBernalNo ratings yet

- Datasheet 2SC5376FVDocument5 pagesDatasheet 2SC5376FVTAOZ MNo ratings yet

- Apen A700000008823562Document5 pagesApen A700000008823562fabio coalaNo ratings yet

- Silicon NPN Epitaxial Planer Type: TransistorDocument2 pagesSilicon NPN Epitaxial Planer Type: TransistorStuxnetNo ratings yet

- RT1N141C (N1)Document3 pagesRT1N141C (N1)Homer Sadych Henao MarinNo ratings yet

- Rt1n141u-T150 (Aec) eDocument3 pagesRt1n141u-T150 (Aec) eHamza Abbasi AbbasiNo ratings yet

- RN2131FV, RN2132FV: Switching, Inverter Circuit, Interface Circuit and Driver Circuit ApplicationsDocument5 pagesRN2131FV, RN2132FV: Switching, Inverter Circuit, Interface Circuit and Driver Circuit ApplicationsIsaiasAvilesNo ratings yet

- FA531X Series: FA5310BP (S), FA5314P (S), FA5316P (S) FA5311BP (S), FA5315P (S), FA5317P (S)Document17 pagesFA531X Series: FA5310BP (S), FA5314P (S), FA5316P (S) FA5311BP (S), FA5315P (S), FA5317P (S)Djalma MoreiraNo ratings yet

- PD49PI/PD481PI: Photodiode High Speed, High SensitivityDocument3 pagesPD49PI/PD481PI: Photodiode High Speed, High SensitivityDavid Nasael VERGARANo ratings yet

- Maintenance/ Discontinued: Silicon PNP Epitaxial Planer TypeDocument3 pagesMaintenance/ Discontinued: Silicon PNP Epitaxial Planer TypeDaniela Estrella Elvira CastilloNo ratings yet

- Maintenance/ Discontinued: Silicon PNP Epitaxial Planer TypeDocument3 pagesMaintenance/ Discontinued: Silicon PNP Epitaxial Planer TypeDaniela Estrella Elvira CastilloNo ratings yet

- Specifications: A1251 SERIESDocument6 pagesSpecifications: A1251 SERIESEvgeniKosakovskiNo ratings yet

- Odd 12WDocument3 pagesOdd 12Woscar_sm77No ratings yet

- TOIR 50b94bCEaDocument2 pagesTOIR 50b94bCEaFaifai ChulanitaNo ratings yet

- Silicon NPN Triple Diffusion Planar Type Darlington: Power TransistorsDocument3 pagesSilicon NPN Triple Diffusion Planar Type Darlington: Power TransistorsVitorioNo ratings yet

- Specifications: AcrosentecDocument6 pagesSpecifications: AcrosentecIsra JanNo ratings yet

- SERIESDocument3 pagesSERIESJose Angel TorrealbaNo ratings yet

- General Purpose Low Leakage Diode: Absolute Maximum Ratings Sym Parameter Value UnitsDocument3 pagesGeneral Purpose Low Leakage Diode: Absolute Maximum Ratings Sym Parameter Value UnitsZoltán ÁgostonNo ratings yet

- DFBLaser FWHM 0.01nm 1570nmDocument1 pageDFBLaser FWHM 0.01nm 1570nmJ. M. M.No ratings yet

- 2SA1015Document2 pages2SA1015Thi NguyễnNo ratings yet

- CENTRIC DAYLIGHT Full Spectrum Flicker-Free A19 10W LED Bulb 4000K Photometric ReportDocument1 pageCENTRIC DAYLIGHT Full Spectrum Flicker-Free A19 10W LED Bulb 4000K Photometric ReportTonyNo ratings yet

- SunonDocument4 pagesSunonEmerson Müller Juarez AvilaNo ratings yet

- FM Tuner, VHF Amplifier ApplicationsDocument5 pagesFM Tuner, VHF Amplifier ApplicationsEzequiel Cândido KelNo ratings yet

- 2 SK 546Document3 pages2 SK 546Joaquin Guzman murilloNo ratings yet

- High-Frequency Amplifier, Analog Switch Applications: Package Dimensions FeaturesDocument4 pagesHigh-Frequency Amplifier, Analog Switch Applications: Package Dimensions FeaturesAngel Simo MoralesNo ratings yet

- CNB1302 (ON2170) : Reflective PhotosensorDocument3 pagesCNB1302 (ON2170) : Reflective PhotosensorSébastien MahutNo ratings yet

- 090RDA1 sharpTV PDFDocument7 pages090RDA1 sharpTV PDFLui Drones100% (1)

- 117SIP, 107DIP, 171DIP PCB Mount Miniature Reed RelaysDocument5 pages117SIP, 107DIP, 171DIP PCB Mount Miniature Reed RelaysJose Manuel EscalanteNo ratings yet

- 2sc5585, 2sc5663 RohmDocument4 pages2sc5585, 2sc5663 RohmRe Ma (Master)No ratings yet

- RF-500TB: Output: 0.01W 2.0W (Approx)Document1 pageRF-500TB: Output: 0.01W 2.0W (Approx)luisfNo ratings yet

- Datos D Emotor DC WGMDocument1 pageDatos D Emotor DC WGMjosue perezNo ratings yet

- KTLP 3616Document10 pagesKTLP 3616Ismael silvaNo ratings yet

- Silicon PNP Epitaxial Planer Type: TransistorsDocument1 pageSilicon PNP Epitaxial Planer Type: Transistorsbusamawan wayanNo ratings yet

- SP20U80L: Low VF Schottky Barrier RectifierDocument3 pagesSP20U80L: Low VF Schottky Barrier RectifierRiad SalihNo ratings yet

- 20DL2CZ51A, 20FL2CZ51A: Switching Mode Power Supply Applications Converter & Chopper ApplicationsDocument5 pages20DL2CZ51A, 20FL2CZ51A: Switching Mode Power Supply Applications Converter & Chopper ApplicationsJuvenal David Hernández CórdovaNo ratings yet

- Motiongoo Stepper Motor Drawing-17HT19S4168C1Document1 pageMotiongoo Stepper Motor Drawing-17HT19S4168C1Make RownNo ratings yet

- Relee PlacaDocument1 pageRelee PlacaMarcelo ArtolaNo ratings yet

- 5.4 Applications 5.4.1 B: IosensingDocument3 pages5.4 Applications 5.4.1 B: IosensingThông NguyễnNo ratings yet

- Switching Diode: DatasheetDocument7 pagesSwitching Diode: DatasheetClément SaillantNo ratings yet

- En An Ce / Co Nti Nu Ed: Silicon PNP Epitaxial Planer TypeDocument4 pagesEn An Ce / Co Nti Nu Ed: Silicon PNP Epitaxial Planer TypeDaniela Estrella Elvira CastilloNo ratings yet

- DatasheetDocument6 pagesDatasheetGlaucio GomesNo ratings yet

- High-Frequency Low-Noise Amplifier Applications: Package Dimensions FeaturesDocument6 pagesHigh-Frequency Low-Noise Amplifier Applications: Package Dimensions FeaturesMarco Antonio Bolívar SuárezNo ratings yet

- PQ05RD08 Series/PQ3RD083/PQ6RD083: Features Outline DimensionsDocument8 pagesPQ05RD08 Series/PQ3RD083/PQ6RD083: Features Outline Dimensionsmitesh12123No ratings yet

- 070xna1 Panasonic IcDocument5 pages070xna1 Panasonic IcGeovanny SanJuanNo ratings yet

- Low-Frequency Amplifier Applications: Package Dimensions FeaturesDocument4 pagesLow-Frequency Amplifier Applications: Package Dimensions FeaturesautreraNo ratings yet

- An 0001Document5 pagesAn 0001Umar MajeedNo ratings yet

- Mb05Fa Thru Mb10Fa: FeaturesDocument2 pagesMb05Fa Thru Mb10Fa: FeaturesFox BenNo ratings yet

- LDR Orp12Document2 pagesLDR Orp12Faulhaber AdrianNo ratings yet

- Design of Source Degenerated Cascode Dual FunctionDocument25 pagesDesign of Source Degenerated Cascode Dual Functionmaia.df11No ratings yet

- Zener Diode-Load RegulatorDocument1 pageZener Diode-Load RegulatorKaushal Kumar GulatiNo ratings yet

- 2SK772Document4 pages2SK772Juan CarlosNo ratings yet

- The Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramDocument1 pageThe Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramJuan Carlos BarandicaNo ratings yet

- 504wc2e W6 1PC PDFDocument9 pages504wc2e W6 1PC PDFCris Yo SoyNo ratings yet

- Pulsed Laser Diode in Plastic Package 25 W Peak Power: FeaturesDocument6 pagesPulsed Laser Diode in Plastic Package 25 W Peak Power: FeaturesPraveen ShenolkarNo ratings yet

- Feasibility Study of Isoprene ProductionDocument4 pagesFeasibility Study of Isoprene ProductionIntratec SolutionsNo ratings yet

- Aritco Public Lift Access Datasheet-1Document2 pagesAritco Public Lift Access Datasheet-1Nancy StarryNo ratings yet

- P Series Ciac Service Manual 30,36K FVDocument108 pagesP Series Ciac Service Manual 30,36K FVAnthony Pineda ValenciaNo ratings yet

- 2.0 DCV-Brochure BV Valves (Pages) R01 PDFDocument12 pages2.0 DCV-Brochure BV Valves (Pages) R01 PDFAliZenatiNo ratings yet

- Metal CladdingDocument21 pagesMetal CladdingRoopali Gupta100% (2)

- Ornithopter: A Machine Designed To Achieve Flight by Means of Flapping WingsDocument61 pagesOrnithopter: A Machine Designed To Achieve Flight by Means of Flapping Wingsdavid hermawanNo ratings yet

- Alex Loyd Gift Secret Spiritual Laws of Nature Les CoreDocument25 pagesAlex Loyd Gift Secret Spiritual Laws of Nature Les CoreDr Ron100% (11)

- TDP InfoDocument7 pagesTDP InfoEN LeedNo ratings yet

- Latent Heat Worksheet 2016Document4 pagesLatent Heat Worksheet 2016Angelica Beltran LazagaNo ratings yet

- Chapter 10: Particle Size Reduction and SeparationDocument4 pagesChapter 10: Particle Size Reduction and SeparationYsabel Salvador DychincoNo ratings yet

- AMS1117ADJDocument5 pagesAMS1117ADJCharly FhNo ratings yet

- Solid-State Kinetic ModelsDocument14 pagesSolid-State Kinetic Modelsleizar_death64No ratings yet

- Lecture 2 Enzyme KineticsDocument31 pagesLecture 2 Enzyme KineticsCarinaJongLeeNo ratings yet

- Store Resp: Store Level Vending ResponsibilitiesDocument11 pagesStore Resp: Store Level Vending ResponsibilitiesDrahosDostalNo ratings yet

- WEG D and NH Fuses 50023628 Brochure EnglishDocument12 pagesWEG D and NH Fuses 50023628 Brochure EnglishRiza Agus FaisalNo ratings yet

- Ascorbic AcidDocument17 pagesAscorbic AcidNURUL SYAHIRAH BINTI ABDUL HALIMNo ratings yet

- Electrical Characterization of NanomaterialsDocument13 pagesElectrical Characterization of NanomaterialsNehal Aswani 19BEC1125No ratings yet

- Refinery OperationsDocument31 pagesRefinery OperationsGhilescu Daniil100% (1)

- Electric Oil - Filled Radiator: Owner'S ManualDocument12 pagesElectric Oil - Filled Radiator: Owner'S ManualjohnqevilNo ratings yet

- Rubber IndustryDocument13 pagesRubber IndustryMinjdeDiosNo ratings yet

- Ei1252 - Transducer EngineeringDocument18 pagesEi1252 - Transducer Engineeringguru.rjpmNo ratings yet

- Service Schedule For All MachinesDocument47 pagesService Schedule For All MachinesGENOVIC MPEMBANo ratings yet

- WI62EX: Model TypeDocument23 pagesWI62EX: Model TypePredrag MarkovicNo ratings yet

- Manual Excavadora 320dDocument982 pagesManual Excavadora 320dAlvaro Escalona Gtz100% (5)

- Uop-1 Mid Sem 2Document65 pagesUop-1 Mid Sem 2ShreyaDixitNo ratings yet

- Modicon X80 Modules - BMXCPS4002Document3 pagesModicon X80 Modules - BMXCPS4002Boris MoreiraNo ratings yet

- Pyro & Cooler Heat & Mass Balance Ed1Document2 pagesPyro & Cooler Heat & Mass Balance Ed1JCSNo ratings yet

- Cavalier 2.2Document42 pagesCavalier 2.2arche70No ratings yet