Professional Documents

Culture Documents

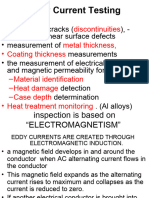

Head Shot Method:: Center For NDT P 00 RV 02 Self Study Material

Head Shot Method:: Center For NDT P 00 RV 02 Self Study Material

Uploaded by

Rajeev KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Head Shot Method:: Center For NDT P 00 RV 02 Self Study Material

Head Shot Method:: Center For NDT P 00 RV 02 Self Study Material

Uploaded by

Rajeev KumarCopyright:

Available Formats

Head shot Method:

The part is fixed between the heads ensuring good electrical

contact and the current is passed from end to end. A circular field

is developed in and around the part and the discontinuities oriented

along the length are indicated.

If the part contains more than one diameter, then the part is to be

tested separately for each diameter. The current applicable for each

diameter is applied and the corresponding section is tested. The

applicable currents are used in ascending order.

Central Conductor:

When current is passed through a hollow cylindrical conductor, the

magnetic field on the inner surface is zero. A component with a

continuous hole through it can be magnetized without contact by

means of a current carrying straight conductor passing through the

hole. The examination technique is often used in examination of

parts such as pipe connectors, hollow cylinders, gear wheels, springs

and large nuts.

For this technique, a central conductor is used to magnetize the

inner surface of the bore with a circumferential magnetic field.

Defect on the outer surface of a tubular can also be detected if

the wall thickness is not too large but there may be a large

difference in the magnetic field strength on the two surfaces.

When the axis of the central conductor is located near the central

axis of the test object, 12 to 31 amps current per mm of test

object diameter should be applied. The diameter to be used for

current computation is the largest distance between two points, 180

degrees apart on the inside circumference.

Alternating current is to be used only for surface discontinuities on

the inside surface of the test object. Where large diameter

cylindrical parts are to be examined, the conductor shall be

positioned close to the internal surface of the bore and the

circumference of the part shall be examined in increments. A

current of 12 to 31 amps per mm shall apply except that the

diameter shall be considered the sum of the diameter of the

conductor and twice the wall thickness of the part. The distance

along the test object circumference [ ID / OD ] which is effectively

magnetized is to be taken 4 times the diameter of the conductor.

The parts are the inspected in four quadrants or segments. This provides

a greater induced field for a lesser current value.

Bars or cables, passing through the bore of a cylindrical part, may

be used to induce circular magnetization.

Bars are usually made of copper to reduce heating. If a flexible cable

is used, several turns of cable may be passed through the bore

and the current reduced in proportion to the number of turns.

The magnetic field will increase in proportion to the number of

times the central conductor cable pass through the bore.

The magnetic field adequacy shall be verified using a field indicator.

The strength of the magnetic field around a magnetic or non

magnetic conductor decreases as the distance from the surface of

the conductor increases. The amount of decreases is dependent on

the conductor material, cross section and type of current.

Indications

produced by

central

conductor.

K. Chatterjee, 75643 Center for NDT P 00 Rv 02 Self study material.

You might also like

- Vanguard 37 Efi Repair ManualDocument150 pagesVanguard 37 Efi Repair ManualFrancis Kengne0% (2)

- Practice ExerciseDocument7 pagesPractice ExerciseRajeev KumarNo ratings yet

- Intro To Eddy Current (1) by Raj Deep GuptaDocument51 pagesIntro To Eddy Current (1) by Raj Deep GuptaRajdeep Gupta50% (2)

- Remote Field TestingDocument8 pagesRemote Field TestingEngr Arfan Ali DhamrahoNo ratings yet

- TUBE INSPECTION by RFETDocument8 pagesTUBE INSPECTION by RFETTusar Kole100% (1)

- Eddy Current SensorsDocument61 pagesEddy Current SensorsVhan DarshNo ratings yet

- YL620 A Inverter Manual PDFDocument26 pagesYL620 A Inverter Manual PDFIpan ArgonNo ratings yet

- Data Sheet Indirect Fired Heater NapkjsDocument12 pagesData Sheet Indirect Fired Heater Napkjsahmad santosoNo ratings yet

- Manual Del Variador de Frecuencia Baldor VS1MD21Document164 pagesManual Del Variador de Frecuencia Baldor VS1MD21Luis Orduña100% (1)

- Coil MagDocument1 pageCoil MagABC Any Body Can RelaxNo ratings yet

- Eddy Current and Non Contacting TransducerDocument10 pagesEddy Current and Non Contacting TransducerRam Krishna SinghNo ratings yet

- NDT Eddy CurrentsDocument13 pagesNDT Eddy Currentsyashwant verma100% (1)

- Electromagnetic Flow MeterDocument16 pagesElectromagnetic Flow MeterKashif AliNo ratings yet

- Eddy Current Testing: Presented To: Dr. Abhishek Kumar Presented By: Shivendra Kumar (2016MT06)Document18 pagesEddy Current Testing: Presented To: Dr. Abhishek Kumar Presented By: Shivendra Kumar (2016MT06)Shivam YadavNo ratings yet

- Current Sensors Using Magnetic MaterialsDocument7 pagesCurrent Sensors Using Magnetic MaterialsSuttisak SuriyachanhomNo ratings yet

- NDT Assignment (Q4)Document2 pagesNDT Assignment (Q4)AndyNo ratings yet

- Double Wall Single Image (DWSI)Document19 pagesDouble Wall Single Image (DWSI)vinod kumarNo ratings yet

- Circular Field:: Circular and Longitudinal Magnetic FieldsDocument1 pageCircular Field:: Circular and Longitudinal Magnetic FieldsRajeev KumarNo ratings yet

- S3 ME FEE Notes Mod 4 FINALDocument25 pagesS3 ME FEE Notes Mod 4 FINALAmal MonichanNo ratings yet

- Chapter 1Document3 pagesChapter 1vedant sawantNo ratings yet

- How Can You Use Eddy Current NDT For Tube InspectionDocument2 pagesHow Can You Use Eddy Current NDT For Tube InspectionWoodrow FoxNo ratings yet

- X RaysDocument5 pagesX RaysWardah ZahidNo ratings yet

- U2 - Eddy Current InspectionDocument73 pagesU2 - Eddy Current InspectionSuraj B SNo ratings yet

- NDT Remote Field TestingDocument7 pagesNDT Remote Field TestingKha MnNo ratings yet

- Rotor Degaussing Rev 1Document5 pagesRotor Degaussing Rev 1mariamalloney1730No ratings yet

- Induced Current Magnetization:: Quick BreakDocument1 pageInduced Current Magnetization:: Quick BreakDhaval PanchalNo ratings yet

- Advances in Superconducting Magnets For Particle Physics: Akira YamamotoDocument8 pagesAdvances in Superconducting Magnets For Particle Physics: Akira YamamotoAbid aliNo ratings yet

- Head Shot Method:: in Order To Indicate The Presence of All DiscontinuitiesDocument1 pageHead Shot Method:: in Order To Indicate The Presence of All DiscontinuitiesRajeev KumarNo ratings yet

- Remote Field TestingDocument8 pagesRemote Field TestingthinhlvtNo ratings yet

- Xavier University College of Engineering Cagayan de Oro City Electrical Engineering DepartmentDocument4 pagesXavier University College of Engineering Cagayan de Oro City Electrical Engineering DepartmentMark Julius CabasanNo ratings yet

- Alternating Current Field MeasurementDocument22 pagesAlternating Current Field Measurementabhi100% (2)

- Quiz MTDocument19 pagesQuiz MTReinaldo OrejuelaNo ratings yet

- Eddy Current InspectionDocument34 pagesEddy Current InspectionAlishia LoshNo ratings yet

- 21EES101T-EEE-Unit-2 NotesDocument35 pages21EES101T-EEE-Unit-2 Notessr1343No ratings yet

- ME 402 UNIT 4 IC Force Strain InstrumentsDocument43 pagesME 402 UNIT 4 IC Force Strain InstrumentsYASH KUMARNo ratings yet

- Eddy PiezoDocument19 pagesEddy Piezoshrish ukhalkarNo ratings yet

- NDT Eddy Current Testing ModuleDocument67 pagesNDT Eddy Current Testing Moduleyashwant vermaNo ratings yet

- S1 Slo1Document40 pagesS1 Slo1Vidhyalakshmi MNo ratings yet

- Electrical Strain GaugesDocument26 pagesElectrical Strain GaugesRivin LuciousNo ratings yet

- Concrete TestingDocument34 pagesConcrete TestingKamarajanNo ratings yet

- Design of Novel High - Factor Multipath Stacked On-Chip Spiral InductorsDocument8 pagesDesign of Novel High - Factor Multipath Stacked On-Chip Spiral InductorsSathyasree JayaramanNo ratings yet

- Design of Novel High - Factor Multipath Stacked On-Chip Spiral InductorsDocument8 pagesDesign of Novel High - Factor Multipath Stacked On-Chip Spiral InductorsSathyasree JayaramanNo ratings yet

- 7.1.eddy Current Testing-Part-1Document15 pages7.1.eddy Current Testing-Part-1Mohanad AlmalahNo ratings yet

- p5 En303 Sankalp Purwar 2Document14 pagesp5 En303 Sankalp Purwar 22K20 EN 63 Sankalp PurwarNo ratings yet

- Special DiodesDocument15 pagesSpecial DiodesKUMAR SNo ratings yet

- Basic Principles of Eddy Current InspectionDocument16 pagesBasic Principles of Eddy Current InspectionSiphesihle NkosiNo ratings yet

- p5 En303 Sankalp PurwarDocument14 pagesp5 En303 Sankalp Purwar2K20 EN 63 Sankalp PurwarNo ratings yet

- Elctronic Flo MTRSDocument14 pagesElctronic Flo MTRSShoeb ShaikhNo ratings yet

- EC Test StudentDocument27 pagesEC Test StudentCan BilgeNo ratings yet

- Eddy Current InspectionDocument23 pagesEddy Current InspectionDr. Akshay JainNo ratings yet

- Analog ElectronicsDocument431 pagesAnalog ElectronicsRaghvendra SahuNo ratings yet

- Magnetic Particle Testing. Presentation Krishnamoorthi. VDocument50 pagesMagnetic Particle Testing. Presentation Krishnamoorthi. VThe Engineers EDGE, CoimbatoreNo ratings yet

- Shielded vs. Unshielded Square Magnetic Field Loops For EMI-ESD Design and TroubleshootingDocument26 pagesShielded vs. Unshielded Square Magnetic Field Loops For EMI-ESD Design and Troubleshootingagmnm1962No ratings yet

- DemagDocument1 pageDemagDhaval PanchalNo ratings yet

- Displacement SensorsDocument32 pagesDisplacement SensorsMuhammad Qasim SajidNo ratings yet

- Active Electronic Devices 1: Unit 3Document52 pagesActive Electronic Devices 1: Unit 3Swapnil ThoratNo ratings yet

- Introto ACPDDocument11 pagesIntroto ACPDKittikun JitpairodNo ratings yet

- Eddy Probe System On The Basis of New Technology: FT L C L I T UDocument6 pagesEddy Probe System On The Basis of New Technology: FT L C L I T UNatthaphon NaosookNo ratings yet

- EE312L Research WorkDocument20 pagesEE312L Research WorkJohn Carl TiburcioNo ratings yet

- Four Point Probe: Dr. Shanti Swaroop Bhatnagar Uicet Panjab University, ChandigarhDocument15 pagesFour Point Probe: Dr. Shanti Swaroop Bhatnagar Uicet Panjab University, ChandigarhAditya KoulNo ratings yet

- Eddy Current TestingDocument43 pagesEddy Current TestingkongsakuaiphonNo ratings yet

- Calculation of InductorsDocument7 pagesCalculation of InductorsAnonymous DjWqKpZ1No ratings yet

- Presentation 30Document11 pagesPresentation 30Avi TiwariNo ratings yet

- Deperming Technology in Large Ferromagnetic PipesDocument3 pagesDeperming Technology in Large Ferromagnetic PipesAntonio PerezNo ratings yet

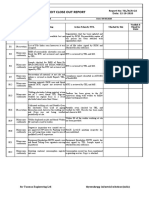

- Itp For MechDocument5 pagesItp For MechRajeev KumarNo ratings yet

- Itp Equipment (Static)Document5 pagesItp Equipment (Static)Rajeev KumarNo ratings yet

- Sect 11a P Welding DocumDocument31 pagesSect 11a P Welding DocumRajeev KumarNo ratings yet

- JP For Structural WorksDocument4 pagesJP For Structural WorksRajeev KumarNo ratings yet

- Format For Manufacturer Record of Welding Operator QualificationDocument1 pageFormat For Manufacturer Record of Welding Operator QualificationRajeev KumarNo ratings yet

- LHS Rev-1Document29 pagesLHS Rev-1Rajeev KumarNo ratings yet

- Hardness Ins ReportDocument2 pagesHardness Ins ReportRajeev KumarNo ratings yet

- INCDEX1Document2 pagesINCDEX1Rajeev KumarNo ratings yet

- Hydro TestDocument2 pagesHydro TestRajeev KumarNo ratings yet

- MCF Testing of PWHTDocument21 pagesMCF Testing of PWHTRajeev KumarNo ratings yet

- QDR Tel-04Document2 pagesQDR Tel-04Rajeev KumarNo ratings yet

- BSVITEL001Document1 pageBSVITEL001Rajeev KumarNo ratings yet

- Astm A217-2007Document6 pagesAstm A217-2007Rajeev KumarNo ratings yet

- Activity 016Document2 pagesActivity 016Rajeev KumarNo ratings yet

- Acr 002Document1 pageAcr 002Rajeev KumarNo ratings yet

- Walk Through - TEL-COMPO.22.12..2021Document3 pagesWalk Through - TEL-COMPO.22.12..2021Rajeev KumarNo ratings yet

- Structural Steel Received DetailsDocument16 pagesStructural Steel Received DetailsRajeev KumarNo ratings yet

- L-6699-Pins-tel-mei-0019 - Epcm QM Audit Report (Audit No. 6699-Iocl-bs-Vi-epcm-cons-006) For Bs-Vi Project at Paradip SiteDocument4 pagesL-6699-Pins-tel-mei-0019 - Epcm QM Audit Report (Audit No. 6699-Iocl-bs-Vi-epcm-cons-006) For Bs-Vi Project at Paradip SiteRajeev KumarNo ratings yet

- Qly Walkthrough 09-11-2022Document4 pagesQly Walkthrough 09-11-2022Rajeev KumarNo ratings yet

- Qwt-Tel-Compo-03 03 2022Document5 pagesQwt-Tel-Compo-03 03 2022Rajeev KumarNo ratings yet

- Training Calender 2020-21Document2 pagesTraining Calender 2020-21Rajeev KumarNo ratings yet

- Acr-001 (Draft)Document2 pagesAcr-001 (Draft)Rajeev KumarNo ratings yet

- HCDS Loop ListDocument20 pagesHCDS Loop ListRajeev KumarNo ratings yet

- U#2 W.V.Document52 pagesU#2 W.V.Rajeev KumarNo ratings yet

- Day Wise TO Plan For The Month of DEC.22Document56 pagesDay Wise TO Plan For The Month of DEC.22Rajeev KumarNo ratings yet

- H2 Balance Month Turn Over Plan - 11.11.2022Document4 pagesH2 Balance Month Turn Over Plan - 11.11.2022Rajeev KumarNo ratings yet

- Jsa IndexDocument6 pagesJsa IndexRajeev KumarNo ratings yet

- FINAL - Audit Report - Shailesh DongareDocument7 pagesFINAL - Audit Report - Shailesh DongareRajeev KumarNo ratings yet

- U-2 PWHT Charts SubmissionDocument102 pagesU-2 PWHT Charts SubmissionRajeev KumarNo ratings yet

- Eco CoolerDocument35 pagesEco Coolerjomark orayanNo ratings yet

- ELEPRA3 Assessment 2Document18 pagesELEPRA3 Assessment 2SBUSISONo ratings yet

- Boiler VMIDocument42 pagesBoiler VMIKỳ PhamNo ratings yet

- Heery's Zen Notes: Physics KSSM F5 2021Document12 pagesHeery's Zen Notes: Physics KSSM F5 2021Aideel zakwanNo ratings yet

- Introduction To TransformerDocument4 pagesIntroduction To TransformerKing EverestNo ratings yet

- Allen Leader DLP Ut 06 QP (E+h)Document48 pagesAllen Leader DLP Ut 06 QP (E+h)su1770083No ratings yet

- Timeline of Cosmological Theories - Wikipedia PDFDocument43 pagesTimeline of Cosmological Theories - Wikipedia PDFAnshu RetherNo ratings yet

- Yuasa NP10-6Document1 pageYuasa NP10-6Lumaksono WirastomoNo ratings yet

- Module-4a - Three Phase Induction Motor: By, Maria Sushma S Assistant Professor Dept of Eee, AtmeceDocument20 pagesModule-4a - Three Phase Induction Motor: By, Maria Sushma S Assistant Professor Dept of Eee, AtmeceDinesh Naik GNo ratings yet

- CFD Study For Assessment of Axial Thrust Balance in Centrifugal Multistage PumpsDocument9 pagesCFD Study For Assessment of Axial Thrust Balance in Centrifugal Multistage PumpsNavaneeth Krishnan NairNo ratings yet

- MassDocument2 pagesMassQambrani Shoaib AnwerNo ratings yet

- Duresca Make Bus Bar Type AllDocument40 pagesDuresca Make Bus Bar Type AllMutaharZahidNo ratings yet

- Tutorial 4Document1 pageTutorial 4sakinah azizanNo ratings yet

- Lesson 4Document11 pagesLesson 4Bonz AriolaNo ratings yet

- Field Density TestDocument2 pagesField Density TestPhilip SabadiNo ratings yet

- ABB Motor (IE4)Document1 pageABB Motor (IE4)Lee DerekNo ratings yet

- Title: Simple Pendulum: Name: Shreya KanwarDocument19 pagesTitle: Simple Pendulum: Name: Shreya KanwarShreya RathoreNo ratings yet

- Resonance Hyper PhysicsDocument3 pagesResonance Hyper Physicsmech.sasikumarNo ratings yet

- Physics Grade 9 - Lesson NoteDocument6 pagesPhysics Grade 9 - Lesson Notemicahx50% (2)

- Chapter 1-Part 1Document36 pagesChapter 1-Part 1Ammar FitriNo ratings yet

- Ch-9 Class-8 Q AnsDocument7 pagesCh-9 Class-8 Q AnsmeghaNo ratings yet

- D.E 6rd EditionDocument33 pagesD.E 6rd EditionkenNo ratings yet

- Transformer Class 12thDocument22 pagesTransformer Class 12thDeepanshu SharmaNo ratings yet

- Made Easy Online Test Series E&m-1Document11 pagesMade Easy Online Test Series E&m-1Aayush Patidar100% (2)

- Tolteq Iseries NXT Directional ModuleDocument1 pageTolteq Iseries NXT Directional ModuleBen PontierNo ratings yet

- Electric Current and Circuits PDFDocument8 pagesElectric Current and Circuits PDFB VIDATTE VILLANIEVANo ratings yet