Professional Documents

Culture Documents

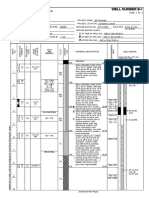

Thompson'S Station - Regional Wastewater Treatment Plant Upgrades

Thompson'S Station - Regional Wastewater Treatment Plant Upgrades

Uploaded by

Ly Duc TrungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thompson'S Station - Regional Wastewater Treatment Plant Upgrades

Thompson'S Station - Regional Wastewater Treatment Plant Upgrades

Uploaded by

Ly Duc TrungCopyright:

Available Formats

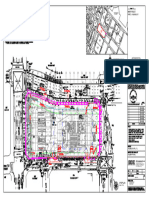

THOMPSON'S STATION - REGIONAL JUNE, 2020

PROJECT No.

36724-03

WASTEWATER TREATMENT PLANT UPGRADES

THOMPSON'S STATION, TENNESSEE

TOWN OF THOMPSON'S STATION

248

N

D

RYR

ER

DB

SE

TREATMENT PLANT UPGRADES

TOLLGATE

BLVD

REGIONAL WASTEWATER

THOMPSON'S STATION, TENNESSEE

DECLARATIO

N WAY

PROJECT TEAM

30% DESIGN REVIEW

840

OWNER

TOWN OF THOMPSON'S STATION

PROJECT P.O. BOX 100

SITE THOMPSON'S STATION, TN 37179

SEDBERRY

RD

PHONE: (615) 794-4333

31

CRITZ LN

ENGINEER

BARGE DESIGN SOLUTIONS, INC.

615 3RD AVENUE SOUTH, SUITE 700

THOMPSO NASHVILLE, TENNESSEE, 37210

N'S STAT

ION RD W PHONE: (615) 252-4236

THOMPSON'S

CONTACT: MATTHEW JOHNSON, PE

STATION

LOCATION MAP

NOT TO SCALE

30% DESIGN REVIEW

JUNE 2020

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210 00-G000 PROJECT No.

PHONE (615) 254-1500 // FAX (615) 255-6572

36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

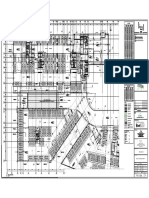

00-G000 COVER SHEET 24-D302 INTERMEDIATE LIFT STATIONS SECTION - LAGOON PUMP

00-G001 INDEX OF SHEETS 24-E101 INTERMEDIATE LIFT STATIONS ELECTRICAL PLAN

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

00-G002 STANDARD ABBREVIATIONS

GENERAL LEGEND

PHONE (615) 254-1500 // FAX (615) 255-6572

00-G003 35-D101 OPERATIONS/UV BUILDING PLAN

00-G004 GENERAL NOTES

35-D301 OPERATIONS/UV BUILDING SECTIONS

00-G201 HYDRAULIC PROFILE - PROCESS

35-D501 OPERATIONS/UV BUILDING DETAILS

00-G601 PROCESS FLOW DIAGRAM

35-ED101 OPERATIONS/UV BUILDING ELECTRICAL DEMOLITION PLAN

00-S001 STRUCTURAL GENERAL NOTES AND DESIGN CRITERIA

35-E101 OPERATIONS/UV BUILDING ELECTRICAL PLAN

00-S002 STRUCTURAL INSPECTIONS

35-E102 OPERATIONS/UV BUILDING ELECTRICAL DETAILS

00-M001 MECHANICAL GENERAL NOTES & DESIGN CRITERIA

00-P001 PLUMBING GENERAL NOTES AND LEGENDS

00-E001 ELECTRICAL LEGEND AND GENERAL NOTES 63-E101 STANDBY POWER GENERATOR PLAN

00-E002 ELECTRICAL ONE-LINE DIAGRAMS 63-S101 STANDBY POWER GENERATOR PLAN

00-E003 ELECTRICAL ONE-LINE DIAGRAMS

80-S101 AEROBIC DIGESTER STRUCTURAL PLAN

01-C101 OVERALL SITE PLAN 80-S301 AEROBIC DIGESTER STRUCTURAL SECTIONS

01-C102 SITE DEMOLITION PLAN 80-S701 AEROBIC DIGESTER STRUCTURAL DETAILS

01-C103 STAKING PLAN 80-D101 AEROBIC DIGESTER PLAN

01-C110 GRADING AND EROSION CONTROL PLAN 80-D301 AEROBIC DIGESTER SECTIONS

01-C120 SITE PIPING PLAN

80-E101 AEROBIC DIGESTER ELECTRICAL PLAN

01-C501 SITE DETAILS

01-ES101 ELECTRICAL SITE PLAN

85-S100 SLUDGE DEWATERING BUILDING - FOUNDATION PLAN

01-ES102 ELECTRICAL LIGHTING PLAN

85-S110 SLUDGE DEWATERING BUILDING - ROOF FRAMING PLAN

85-S301 SLUDGE DEWATERING BUILDING - FOUNDATION SECTIONS & DETAILS

03-DI001 P&ID - PROCESS SYMBOLS LEGEND

85-M101 SLUDGE DEWATERING BUILDING - MECHANICAL PLAN

03-DI002 P&ID - INSTRUMENTATION LEGEND

P&ID - ABBREVIATIONS 85-M701 SLUDGE DEWATERING BUILDING - MECHANICAL DETAILS & SCHEDULES

03-DI003

85-P101 SLUDGE DEWATERING BUILDING - PLUMBING PLAN

TREATMENT PLANT UPGRADES

03-DI201 P&ID - INFLUENT PUMP STATION

P&ID - INFLUENT SCREENING 85-P701 SLUDGE DEWATERING BUILDING - PLUMBING DETAILS & SCHEDULES

REGIONAL WASTEWATER TREATMENT PLANT

03-DI202

03-DI203 P&ID - AERATION 85-D101 SLUDGE DEWATERING BUILDING - PLAN

03-DI204 P&ID - MEMBRANE BIOREACTORS 85-D301 SLUDGE DEWATERING BUILDING - SECTIONS

03-DI205 P&ID - MEMBRANE BIOREACTORS 85-E101 SLUDGE DEWATERING BUILDING - ELECTRICAL PLAN

03-DI206 P&ID - MEMBRANE BIOREACTORS 85-E301 SLUDGE DEWATERING BUILDING - LIGHTING PLAN

03-DI207 P&ID - FILTERS 85-E601 SLUDGE DEWATERING BUILDING - RISER DIAGRAM

INDEX OF DRAWINGS

THOMPSON'S STATION, TENNESSEE

03-DI208 P&ID - UV DISINFECTION

03-DI209 P&ID - IRRIGATION PUMPING

95-E701 ELECTRICAL DETAILS

03-DI210 P&ID - AEROBIC DIGESTION

95-E702 ELECTRICAL DETAILS

03-DI211 P&ID - BIOSOLIDS DEWATERING

95-E703 ELECTRICAL DETAILS

95-E901 ELECTRICAL SCHEDULES

07-S101 INFLUENT LIFT STATION STRUCTURAL PLAN

07-S301 INFLUENT LIFT STATION STRUCTURAL SECTIONS

INFLUENT LIFT STATION STRUCTURAL SECTIONS & DETAILS

99-S701 GENERAL FOUNDATION SECTIONS & DETAILS

07-S701

07-D101 INFLUENT LIFT STATION PLAN 99-S711 GENERAL WALL SECTIONS & DETAILS

07-D301 INFLUENT LIFT STATION SECTIONS 99-S712 GENERAL FRAMING SECTIONS & DETAILS

07-E101 INFLUENT LIFT STATION ELECTRICAL PLAN

99-D501 STANDARD DETAILS

09-S101 INFLUENT SCREENING STRUCTURAL PLAN 99-D502 STANDARD DETAILS

09-S301 INFLUENT SCREENING STRUCTURAL SECTIONS 99-D503 STANDARD DETAILS

09-S701 INFLUENT SCREENING STRUCTURAL SECTIONS & DETAILS 99-D504 STANDARD DETAILS

09-D101 INFLUENT SCREENING PLAN 99-D505 STANDARD DETAILS

09-D301 INFLUENT SCREENING SECTIONS

09-E101 INFLUENT SCREENING ELECTRICAL PLAN

15-S101 AERATION BASINS STRUCTURAL PLAN

15-S301 AERATION BASINS STRUCTURAL SECTIONS

15-S302 AERATION BASINS STRUCTURAL SECTIONS & DETAILS

15-D101 AERATION BASINS PLAN

15-D301 AERATION BASINS SECTIONS

15-E101 AERATION BASINS SYSTEM ELECTRICAL PLAN

DESCRIPTION

REVISION INFORMATION

23-S101 MEMBRANE BIOREACTOR SYSTEM STRUCTURAL PLAN

FILE:F:\36\36724\3672403\04_CAD\GENL\3672403_00-G001_v18.dwg

23-S301 MEMBRANE BIOREACTOR SYSTEM STRUCTURAL SECTIONS

23-S302 MEMBRANE BIOREACTOR SYSTEM STRUCTURAL SECTIONS & DETAILS

MEMBRANE BIOREACTOR PLAN

DATE

23-D101

23-D301 MEMBRANE BIOREACTOR SECTIONS

CHK.

23-E101 MEMBRANE BIOREACTOR SYSTEM ELECTRICAL PLAN

DR.

24-D101 INTERMEDIATE LIFT STATIONS PLAN - PS-1 AND PS-2

24-D102 INTERMEDIATE LIFT STATIONS PLAN - LAGOON PUMP

REV.

24-D301 INTERMEDIATE LIFT STATIONS SECTIONS - PS-1 AND PS-2

PLOTTED:6/9/2020

00-G001

SAVED:6/9/2020

USER:CNDAVIS

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

ABBREVIATIONS

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

GENERAL ABBREVIATIONS GSKT GASKET RED REDUCER OTE OXIDATION TOWER EFFLUENT

H HIGH REF REFRIGERATOR OR REFERENCE PROCESS FLUIDS OTI OXIDATION TOWER INFLUENT

PHONE (615) 254-1500 // FAX (615) 255-6572

AB ANCHOR BOLTS HB HOSE BIBB REINF REINFORCE PIPE MATERIALS PCE PRIMARY CLARIFIER EFFLUENT

ABAN ABANDON HGR HANGER REM REMOVABLE ACS CARBON SLURRY PCI PRIMARY CLARIFIER INFLUENT

ABC AGGREGATE BASE COURSE HOA HAND-OFF-AUTOMATIC REP REPAIR ABS ACRYLONITRILE BUTADIENE STYRENE PIPE AER AERATION PCS PRIMARY CLARIFIER SOLIDS

ABS ACRYLONITRILE BUTADIENE STYRENE HORIZ HORIZONTAL REPL REPLACE ACP ASBESTOS CEMENT PIPE AHP HIGH PRESSURE AIR

AC ASBESTOS CEMENT HP HIGH POINT REQD REQUIRED BSP BLACK STEEL PIPE PDFS PRIMARY DIGESTER FEED SOLIDS

ALP LOW PRESSURE AIR PDS PRIMARY DIGESTED SOLIDS

ACST ACOUSTIC HS HIGH SERVICE RESIL RESILIENT CIP CAST IRON PIPE

ADDL ADDITIONAL HT HEIGHT RM ROOM CISP CAST IRON SOIL PIPE ALUM ALUM PDSP PRIMARY DIGESTER SUPERNATANT

ADJ ADJUSTABLE HWA HIGH WATER ALARM RND ROUND CMP CORRUGATED METAL PIPE ANE ANAEROBIC EFFLUENT PDXS PRIMARY DIGESTER TRANSFER SOLIDS

ADPT ADAPTER HWL HIGH WATER LEVEL ROW RIGHT OF WAY CP CONCRETE PIPE ANI ANAEROBIC INFLUENT PO4 PHOSPHATE COMPOUNDS

AFF ABOVE FINISHED FLOOR HWY HIGHWAY RPM REVOLUTIONS PER MINUTE CPP CONCRETE PRESSURE PIPE ARCY ANOXIC RECYCLE POLY SOL POLYMER SOLUTION

ALT ALTERNATE HYD HYDRANT OR HYDRAULIC RPZ REDUCED PRESSURE ZONE CPVC CHLORINATED POLYVINYL CHLORIDE PIPE ARE AERATION EFFLUENT PP POTASSIUM PERMANGANATE

ALUM ALUMINUM Hz HERTZ RR RAILROAD CU P COPPER PIPE/TUBING ARI AERATION INFLUENT

ASH INCINERATOR ASH PW POTABLE WATER

APPROX APPROXIMATE ID INSIDE DIAMETER S SOUTH DIP DUCTILE IRON PIPE

ASCE AMERICAN SOCIETY OF CIVIL ENGINEERS IN INCH S/S START/STOP FRP FIBERGLASS REINFORCED PLASTIC PIPE ASR AERATED SUPERNATANT RETURN RAS RETURN ACTIVATED SLUDGE

ASPH ASPHALT IND INDICATOR SALV SALVAGE GSP GALVANIZED STEEL PIPE AWR ACID WASH RETURN RCYW RECYCLE WATER

ASSY ASSEMBLY INF INFLUENT SAN SANITARY HDPE HIGH DENSITY POLYETHYLENE PIPE AWS ACID WASH SUPPLY RD ROOF DRAIN

AUTO AUTOMATIC INFO INFORMATION SCFM STANDARD CUBIC FEET PER MINUTE PE POLYETHYLENE (PLASTIC) PIPE AXE ANOXIC EFFLUENT RWI RAW WATER INFLUENT

AUX AUXILIARY INSTR INSTRUMENT SCHED SCHEDULE PVC POLYVINYL CHLORIDE (PLASTIC) PIPE AXI ANOXIC INFLUENT RWW RAW WASTEWATER INFLUENT

AVE AVENUE INSUL INSULATION SD STORM DRAIN PVF POLYVINYL FLUORIDE (PLASTIC) PIPE BISULFITE SODIUM BISULFITE SBD SCRUBBER BLOWDOWN

AVG AVERAGE INV INVERT SDMH STORM DRAIN MANHOLE RCCP REINFORCED CONCRETE CYLINDER PIPE SCB SCUM CONCENTRATOR SUBNATANT

BISULFITE SOL SODIUM BISULFITE SOLUTION

BC BACK OF CURB INV EL INVERT ELEVATION SECT SECTION RCP REINFORCED CONCRETE PIPE

BWS BACKWASH SUPPLY SCE SECONDARY CLARIFIER EFFLUENT

BKGD BACKGROUND IP IRON PIN SEG SEGMENT SSP STAINLESS STEEL PIPE

BLT BUILT IR IRON ROD SF SQUARE FOOT (FEET) STL STEEL PIPE BWW BACKWASH WASTE SCF SCRUBBER CHEMICAL FEED

BM BENCHMARK JCT JUNCTION SGL SINGLE VCP VITRIFIED CLAY PIPE CCK CENTRIFUGE BIOSOLIDS CAKE SCI SECONDARY CLARIFIER INFLUENT

BM BLOWOFF JT JOINT SHLDR SHOULDER CEN CENTRATE SCRUB EXH SCRUBBER EXHAUST

BOT BOTTOM KWY KEY WAY SHV SHELVING VALVES AND JOINTS CFS CENTRIFUGE FEED SOLIDS SCRUB INTK SCRUBBER INTAKE

BTWN BETWEEN L ANGLE SIM SIMILAR CIP CLEAN-IN PIPE SCUM SCUM

BYP BY PASS LAB LABORATORY SL SLUDGE AC CHKV AIR CUSHION CHECK VALVE CL2 CHLORINE GAS SDS SECONDARY DIGESTED SOLIDS

C&G CURB AND GUTTER LAT LATITUDE SLDR SOLDER ARV AIR RELEASE VALVE CLO2 CHLORINE DIOXIDE SDSP SECONDARY DIGESTER SUPERNATANT

CAP CAPACITY LATL LATERAL SLNT SEALANT B CHKV BALL CHECK VALVE CLS CHLORINE SOLUTION SE SCREENED EFFLUENT

CAT CATALOG LBS POUND SLV SLEEVE BF BLIND FLANGE CN SCUM CONCENTRATED SCUM

CB CATCH BASIN LF LINEAR FEET (FOOT) SOLN SOLUTION BFP BACKFLOW PREVENTER SE SCRUBBER EXHAUST

CNFS CONDITIONING TANK FEED SOLIDS SEPT UNLDG SEPTIC TANK UNLOADING

CCW COUNTER CLOCKWISE LH LEFT HAND SOLV SOLENOID VALVE BFV BUTTERFLY VALVE

CER CERAMIC LIM SW LIMIT SWITCH SPEC SPECIFICATION BO BURIED GEAR OPERATOR CON CONCENTRATE SO SULFUR DIOXIDE

CFM CUBIC FEET PER MINUTE LIN LINEAR SQ SQUARE BV BALL VALVE CRW CLARIFIED RAW WATER SOA SULFURIC ACID

CFS CUBIC FEET PER SECOND LIQ LIQUID SQ IN SQUARE INCH C COMPRESSION JOINT CS CONDITIONED SLUDGE SPD SUMP PUMP DISCHARGE

CHKR CHECKER LLH LONG LEG HORIZONTAL SQ YD SQUARE YARD C CHKV CUSHION CHECK VALVE CTE DISINFECTION CONTACT TANK EFFLUENT SPRAY SPRAY WATER

CJ CONSTRUCTION JOINT LLV LONG LEG VERTICAL SST STAINLESS STEEL CHKV CHECK VALVE CTS CENTRIFUGE THICKENED BIOSOLIDS SRC SCRUBBER RECIRCULATION CLEANING

CL CENTER LINE LNG LONGITUDE STA STATION DMJ DISMANTLING JOINT CW COLD WATER (POTABLE) SRD SCRUBBER RECIRCULATION DISCHARGE

CL2 CHLORINE LOC LOCATION STD STANDARD EJ EXPANSION JOINT CYCL INF CYCLONE INFLUENT

CLG CEILING LOG LOGARITHM STIF STIFFENER EL VA ELECTRIC VALVE ACTUATOR SRS SCRUBBER RECIRCULATION SUCTION

CYCL RCY CYCLONE RECYCLE SS SANITARY SEWER

CLR CLEAR LONG LONGITUDINAL STK STOCK FAC FLANGED ADAPTER COUPLING

D AL DISSOLVED ALUM SSFM SANITARY SEWER FORCE MAIN

CM CONCRETE MONUMENT LP LIGHT POLE STRUCT STRUCTURAL FH FIRE HYDRANT

CMU CONCRETE MASONRY UNIT LT LIGHT SWD SIDE WATER DEPTH FLG FLANGED DA POLYMER DRY AIR STM STEAM

CO CLEAN OUT LVR LOUVER SWR SEWER GR GROOVED END DEC DECANT STORM STORM DRAIN

COL COLUMN LW LOW WATER SYM SYMBOL GTV GATE VALVE DF DIESEL FUEL SW SEAL WATER

TREATMENT PLANT UPGRADES

COM COMMON LWA LOW WATER ALARM SYMM SYMMETRICAL HU HUB AND SPIGOT DFR DIESEL FUEL RETURN V VENT

CONC CONCRETE LWL LOW WATER LEVEL T TREAD K GTV KNIFE GATE VALVE DFS DIESEL FUEL SUPPLY VAC VACUUM

REGIONAL WASTEWATER TREATMENT PLANT

CONC FLR CONCRETE FLOOR M METER T&B TOP AND BOTTOM LR LONG RADIUS DGAS DIGESTER GAS

CONN CONNECT MACH MACHINE TAN TANGENT MJ MECHANICAL JOINT WAS WASTE ACTIVATED SLUDGE

DGR DEWATERED GRIT ANTISCALANT

CONSTR CONSTRUCT MAINT MAINTENANCE TBM TEMPORARY BENCHMARK NV NEEDLE VALVE

DPOLY DRY POLYMER SODA ASH/SODIUM CARBONATE NA2CO3

CONT CONTINUOUS MAN MANUAL TDH TOTAL DYNAMIC HEAD OC CHKV OIL CUSHIONED CHECK VALVE

CP CONTROL PANEL MATL MATERIAL TECH TECHNICAL P CHKV PRESSURE CHECK VALVE DPSD DRAINAGE PUMP STATION DISCHARGE

CPLG COUPLING MAX MAXIMUM TEL TELEPHONE PE PLAIN END DR DRAIN

CTR CENTER MCC MOTOR CONTROL CENTER TEMP TEMPERATURE PHV PINCH VALVE DRS DIGESTER RECIRCULATION SOLIDS

CU COPPER MEAS MEASURE TEMP TEMPORARY PNEU VA PNEUMATIC VALVE ACTUATOR DS DIGESTED SLUDGE

STANDARD ABBREVIATIONS

CU FT CUBIC FEET MECH MECHANICAL THK THICKNESS PO PUSH ON JOINT DSR DECANT SUPERNATANT RETURN

CU IN CUBIC INCHES MED MEDIUM TOB TOP OF BERM PRV PRESSURE REGULATING VALVE DW FL DEWATERING FLOCCULATION

CU YD CUBIC YARD MFD MANUFACTURED TOS TOP OF SLAB PV PLUG VALVE DWS DEWATERED SLUDGE

THOMPSON'S STATION, TENNESSEE

CW CLOCKWISE MFG MANUFACTURING TOW TOP OF WALL RJ RESTRAINED JOINT

EI EQUALIZATION INFLUENT

dB DECIBEL MFR MANUFACTURER TYP TYPICAL RS GTV RESILIENT SEAT GATE VALVE

dBA UNIT OF SOUND LEVEL MFR REC MANUFACTURER'S RECOMMENDATION UGND UNDERGROUND S SOLDERED JOINT ER EQUALIZATION RETURN

DBL DOUBLE MGD MILLION GALLONS PER DAY UNO UNLESS NOTED OTHERWISE SAV SURGE ANTICIPATOR VALVE F FILTRATE

DEG DEGREE MG/L MILLIGRAMS PER LITER UV ULTRAVIOLET SOLV SOLENOID VALVE FD FLOOR DRAIN

DEMO DEMOLITION MH MANHOLE V VENT SW SOLVENT WELDED FD SCUM FEED SCUM

DHW DESIGN HIGH WATER MID MIDDLE VA VOLT AMPERE THD THREADED FE FINAL EFFLUENT

DIA DIAMETER MIN MINIMUM VAC VACUUM TS&V TAPPING SLEEVE AND VALVE FECL FERRIC CHLORIDE

DIAG DIAGONAL MISC MISCELLANEOUS VAR VARIES W WELDED FES FERROUS SULFATE

DIM DIMENSION MON MONUMENT VB VACUUM BREAKER WSLV WALL SLEEVE

FIRE FIRE PROTECTION

DISC DISCONNECT MOT MOTOR VB VALVE BOX

DISCH DISCHARGE MSL MEAN SEA LEVEL VERT VERTICAL FLS FOREIGN BIOSOLIDS LOADING

DIST DISTANCE MTD MOUNTED VOC VOLATILE ORGANIC COMPOUND FO FUEL OIL

DN DOWN MTL METAL VOL VOLUME FOR FUEL OIL RETURN

DWG DRAWING N NORTH VTR VENT THROUGH ROOF FOS FUEL OIL SUPPLY

E EAST NA NOT APPLICABLE W WEST FOV FUEL OIL VENT

EA EACH NC NORMALLY CLOSED W/ WITH FSB FLOTATION THICKENER SUBNATANT

ECC ECCENTRIC NEC NATIONAL ELECTRIC CODE W/O WITHOUT FTFS FLOTATION THICKENER FEED SOLIDS

ECC RDCR ECCENTRIC REDUCER NIC NOT IN CONTRACT WAS WASTE ACTIVATED SLUDGE

FTRCY FLOTATION THICKENER RECYCLE

ED EQUIPMENT DRAIN NO NORMALLY OPEN WD WOOD

EF EACH FACE NO NUMBER WL WATER LINE FTS FLOTATION THICKENED SOLIDS

EFF EFFLUENT NOM NOMINAL WLD WELDED FUS FOREIGN BIOSOLIDS UNLOADING

EJ EXPANSION JOINT NORM NORMAL WM WATER METER GBFL GRAVITY BELT THICKENER FILTRATE

EL ELEVATION NTS NOT TO SCALE WT WATER TABLE GBFS GRAVITY BELT THICKENER FEED SOLIDS

ELEC ELECTRIC NUM NUMERAL WW WASTE WATER GBTS GRAVITY BELT THICKENED SOLIDS

ELEC DR OP ELECTRIC DOOR OPENER OA OVERALL XFER TRANSFER GRIT GRIT

EMER SHR EMERGENCY SHOWER OC ON CENTER XFMR TRANSFORMER GSP GRAVITY THICKENER OVERFLOW/SUPERNATANT

ENCL ENCLOSURE OC EW ON CENTER EACH WAY YD YARD DRAIN GTFS GRAVITY THICKENER FEED SOLIDS

EP EDGE OF PAVEMENT (PAVING) OD OUTSIDE DIAMETER YH YARD HYDRANT GTS GRAVITY THICKENED SOLIDS

EQ EQUAL O/E OR EQUAL YI YARD INLET

H2O2 PEROXIDE

EQUIP EQUIPMENT OH OVERHEAD YR YEAR

EQUIV EQUIVALENT OHE OVERHEAD ELECTRIC HCL HYDROCHLORIC ACID

ESMT EASEMENT OL OVERLOAD HDO HYDRAULIC OIL

ET ELAPSED TIME OPNG OPENING HF FLUORIDE

EW EACH WAY OPP OPPOSITE HPSA SERVICE AIR (HIGH PRESSURE)

EXP EXPANSION OPT OPTIONAL HPW HOT POTABLE WATER

EXST EXISTING ORIG ORIGINAL HTFS HOLDING TANK FEED SOLIDS

EXST GR EXISTING GRADE OVFL OVERFLOW HVAC HVAC

EXT EXTERNAL PC POINT OF CURVE

HW HOT WATER (POTABLE)

F FAHRENHEIT PERF PERFORATED

FB FLAT BAR PERIM PERIMETER HW REV RET HOT WATER REVERSE RETURN

FCO FLOOR CLEANOUT PERM PERMANENT HWR HOT WATER RETURN

FD FLOOR DRAIN PERP PERPENDICULAR HWS HOT WATER SUPPLY

FE FIRE EXTINGUISHER pH ACID/ALKALINE SCALE HYPO SODIUM HYPOCHLORITE

FF EL FINISHED FLOOR ELEVATION PI POINT OF INTERSECTION HYPO SOL SODIUM HYPOCHLORITE SOLUTION

FH FIRE HYDRANT PKG PACKAGE ICE INTERMEDIATE CLARIFIER EFFLUENT

FIG FIGURE PL PROPERTY LINE OR PLATE ICI INTERMEDIATE CLARIFIER INFLUENT

DESCRIPTION

FIN FLR FINISH FLOOR PLAT PLATFORM

REVISION INFORMATION

IFC INCINERATOR FEED CAKE

FIN GR FINISH GRADE POS POSITIVE

FLEX FLEXIBLE PPM PARTS PER MILLION INS INTERMEDIATE BIOSOLIDS

FLL FLOW LINE PR PAIR ISE INCINERATOR SCRUBBER WATER EFFLUENT

FLR FLOOR PRESS PRESSURE LO LUBE OIL

FILE:F:\36\36724\3672403\04_CAD\GENL\3672403_00-G002_v18.dwg

FN FENCE PREV PREVIOUS LP PROPANE

FRP FIBER REINFORCED PLASTIC PRI PRIMARY LPOLY LIQUID POLYMER

FT FEET PRKG PARKING LPSA SERVICE AIR (LOW PRESSURE)

FT FOOT PSI POUNDS PER SQUARE INCH

DATE

LS LIME SLURRY

FTG FOOTING PSIA POUNDS PER SQUARE INCH ABSOLUTE

ML MIXED LIQUOR

G NATURAL GAS PSIG POUNDS PER SQUARE INCH, GAUGE

GA GAUGE PSL PIPE SLEEVE NAOH CAUSTIC

CHK.

GAL GALLON PT POINT OF TANGENCY NAOH SOL CAUSTIC SOLUTION

GALV GALVANIZED PVG PAVING NAT GAS NATURAL GAS

GBT GRAVITY BELT THICKENER PWR POWER NG NATURAL GAS

GEN GENERAL Q RATE OF FLOW NH4 AMMONIA

DR.

GL GLASS QTR QUARTER NPW NON POTABLE WATER

GPD GALLONS PER DAY QTY QUANTITY NPWW NON POTABLE WELL WATER

GPH GALLONS PER HOUR R RADIUS

NRCY NITRIFIED RECYCLE

REV.

GPM GALLONS PER MINUTE RD ROAD

GRD SEWAGE GRINDER RECD RECEIVED O3 OZONE

GRTG GRATING RECM RECOMMENDATION OA ODOROUS AIR

USER:ATLUTTRULL

PLOTTED:6/2/2020

00-G002

SAVED:5/21/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

VALVE DESIGNATIONS JOINT DESIGNATIONS SITE PLAN LEGEND

SYMBOLS TYPE SYMBOL TYPE NEW BUILDING

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

DOUBLE SINGLE EXISTING BUILDING

PHONE (615) 254-1500 // FAX (615) 255-6572

LINE LINE

FLANGED JOINT

NEW STRUCTURE (TANKS, ETC.)

FOOT VALVE

EXISTING STRUCTURE (TANKS, ETC.)

MECHANICAL JOINT

VACUUM RELIEF VALVE FUTURE STRUCTURE

THREADED JOINT

NEW PIPING SINGLE LINE

PRESSURE RELEASE VALVE

NEW PIPING DOUBLE LINE

PUSH ON JOINT

HOSE BIBB

EXISTING PIPING SINGLE LINE

BOLTED FLEXIBLE COUPLING

GATE VALVE EXISTING PIPING DOUBLE LINE

NEW MANHOLE

GROOVED COUPLING

ALTITUDE VALVE, PRESSURE CONTROL

REGULATING VALVE, SURGE OR PRESSURE RELIEF EXISTING MANHOLE

SHOP WELDED JOINT (STEEL PIPE)

BUTTERFLY VALVE NEW VALVE BOX

EXISTING VALVE BOX

FIELD WELDED JOINT (STEEL PIPE)

BALL CONTROL VALVE

A-1-2 MH NEW VALVE MANHOLE AND NUMBER

SOCKET TYPE JOINT (FRP OR PVC PIPE) MH

BALL VALVE EXISTING VALVE MANHOLE

YH

NEW YARD HYDRANT ASSEMBLY

EXPANSION JOINT

DIAPHRAGM VALVE

NEW FIRE HYDRANT ASSEMBLY

FLANGE ADAPTER COUPLING

FLOODWATER (DUCKBILL) VALVE EXISTING FIRE HYDRANT ASSEMBLY

NEW UNDERGROUND ELECTRICAL CONDUIT

TREATMENT PLANT UPGRADES

BLIND FLANGE

CHECK VALVE

REGIONAL WASTEWATER TREATMENT PLANT

EXISTING UNDERGROUND ELECTRICAL CONDUIT

DISMANTLING JOINT

WAFER CHECK VALVE NEW CATCH BASIN

EXISTING CATCH BASIN

RESTRAINED FLANGE ADAPTOR

CONE VALVE

PIPING OR EQUIPMENT TO BE DEMOLISHED

PIPE DESIGNATIONS

THOMPSON'S STATION, TENNESSEE

GLOBE VALVE

STRUCTURE (TANKS, ETC.) OR

GENERAL LEGEND

PAVEMENT TO BE REMOVED

SYMBOL TYPE

PLUG VALVE

STRUCTURE/ BUILDING TO BE RENOVATED

SECTION PLAN

MUD VALVE ABANDON PIPE

CORED HOLE IN EXISTING WALL

PINCH VALVE NEW CONCRETE PAVEMENT

WALL SLEEVE W/ WATER COLLAR (STANDARD) EXISTING CONCRETE PAVEMENT

TAPPING SLEEVE AND VALVE

NEW ASPHALT PAVEMENT

VERTICAL AXIS

FLANGE X FLANGE WALL PIPE

TELESCOPIC VALVE EXISTING ASPHALT PAVEMENT

FLANGE X PLAIN END WALL PIPE

NEW GRAVEL DRIVE

FLANGE X PLAIN END WALL PIPE (TAPPED FOR STUDS) EXISTING GRAVEL DRIVE

SYMBOL LEGEND

STRAW BALES

DOUBLE SINGLE MECHANICAL JOINT X MECHANICAL JOINT WALL PIPE (TAPPED FOR STUDS)

LINE LINE

RIP-RAP

MECHANICAL JOINT X PLAIN END WALL PIPE (TAPPED FOR STUDS)

90° FLANGE BEND 1894 NEW CONTOURS

PUSH ON BELL JOINT X PLAIN END WALL PIPE 1895 EXISTING CONTOURS

FLANGE TEE

NEW FENCE

REDUCER CONCENTRIC

EXISTING FENCE

DESCRIPTION

REVISION INFORMATION

M FLOW METER PROPERTY LINE

PIPING AND VALVES GENERAL NOTES

FILE:F:\36\36724\3672403\04_CAD\GENL\3672403_00-G003_v18.dwg

FLEXIBLE CONNECTION NEW POWER POLE

1. INSTALL ALL PIPING SUPPORTS AND PIPING IN ACCORDANCE WITH THE LATEST EDITION OF THE ASME ANSI POWER

PIPING CODE B 31.1.

DATE

2. LOCATE PRESSURE TAPS ON THE TOP OF PROCESS PIPES, UNLESS OTHERWISE INDICATED ON DWGS. EXISTING POWER POLE

PI PRESSURE INDICATOR

CHK.

3. LOCATE SAMPLE TAPS ON THE SIDE OF PROCESS PIPES.

S SOLENOID OPERATED

4. LOCATE DRAIN TAPS ON THE BOTTOM OF PROCESS PIPES.

00 STRUCTURE IDENTIFIER

DR.

5. UNLESS OTHERWISE NOTED, PIPE ELEVATIONS SHOWN ON PIPING DRAWINGS REFER TO CENTERLINE OF THE PIPE.

6. ALL GROUND BURIED PIPING TO HAVE A MINIMUM OF 36" OF EARTH COVER OR AS DETAILED ON THE DRAWINGS.

REV.

MAINTAIN MINIMUM CLEARANCE BETWEEN PIPES OF 6". SILT FENCE

M MOTOR OPERATED

7. INSTALL ALL PLUG, BUTTERFLY AND BALL VALVES WITH THE SHAFT IN THE HORIZONTAL POSITION, UNLESS

OTHERWISE DIRECTED.

USER:ATLUTTRULL

PLOTTED:6/2/2020

QUICK CONNECT COUPLING

00-G003

SAVED:5/21/2020

EASEMENT BOUNDARY

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

PEAK DAY PEAK DAY

718.50 775.34 774.98 773.10 773.10 771.00

(3.0 MGD) (XX.X MGD)

DESIGN FLOW DESIGN FLOW

(1.0 MGD) 716.50 774.87 774.83 773.05 773.05 765.00 (XX.X MGD)

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

OPS BLDG

PHONE (615) 254-1500 // FAX (615) 255-6572

780 780

TOP EL 776.0

TOP EL 778.5

TOP EL 776.50

TOP EL 774.5

770 16" MLSS 770

14" SE 8" SS

20" PTE 20" PTE 6" SS

8" SS

TOP EL. 763.50

760 760

BOTTOM EL 755.92

750 BOTTOM EL 750.50 750

DRIP IRRIGATION

740 740

TOP OF CONCRETE 14" RWW

EL 735.25

730 730

18" RWW

720 720

TREATMENT PLANT UPGRADES

INV EL 719.5

REGIONAL WASTEWATER TREATMENT PLANT

BOTTOM EL 708.00

710 710

INFLUENT FLOW

FINE AERATION UV LAND APPLICATION

PUMPING SPLITTER MBRS

SCREENS BASINS DISINFECTION WET WELL

STATION BOX

HYDRAULIC PROFILE

THOMPSON'S STATION, TENNESSEE

700 700

PEAK DAY PEAK DAY

755.00

(3.0 MGD) (XX.X MGD)

DESIGN FLOW DESIGN FLOW

(1.0 MGD) 755.00 (XX.X MGD)

780 780

770 770

760 760

TOP EL 757.25

750 750

740 740

DESCRIPTION

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\GENL\3672403_00-G201_v18.dwg

730 730

DATE CHK.

720 720

DR.

REV.

710 710

PLOTTED:6/11/2020

00-G201

SAVED:6/11/2020

USER:CNDAVIS

SLUDGE FEED FLOCCULATION SCREW BIOSOLIDS

DIGESTER PUMPS TANK PRESS DUMPSTER

700 700

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

LEGEND

EXISTING FLOW

EXISTING FILTER

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

NEW FLOW

PHONE (615) 254-1500 // FAX (615) 255-6572

MEMBRANE

FUTURE MEMBRANE SYSTEM

BLOWERS

EXISTING STRUCTURE

NEW STRUCTURE

LAGOON PUMP

CELL 2

FUTURE STRUCTURE

PLANT DRAIN OPERATIONS BUILDING

MEMBRANE SYSTEM 1

D

UV TRAIN 1 IRRIGATION PUMP 1

TO DRIP FIELDS

PROCESS

BLOWERS

CLEARWELL

UV TRAIN 2 IRRIGATION PUMP 2

D TO DRIP FIELDS

MEMBRANE SYSTEM 2

TREATMENT PLANT UPGRADES

REGIONAL WASTEWATER TREATMENT PLANT

OVERFLOW

PROCESS FLOW DIAGRAM

AERATION AERATION PS-2

AEROBIC AEROBIC

BASIN 1 BASIN 2

THOMPSON'S STATION, TENNESSEE

D

TO TOLLGATE

ANOXIC ANOXIC FORCE MAIN

DIGESTER BLOWERS

D D

NOTES: PS-1

1. SEE P&IDS FOR PIPE SIZES,

VALVE AND GATE LOCATIONS.

DRUM SCREEN 1 DRUM SCREEN 2

SCREW PRESS

TO DISPOSAL

SCREENINGS SCREENINGS SLUDGE PUMP

CONTAINER 1 CONTAINER 2

TOLLGATE SCUM PUMP DIGESTER

FORCE MAIN STATION FLOCCULATION

TANK

MH-1

POLYMER

M INFLUENT METER

INFLUENT LIFT STATION

BIOSOLIDS DEWATERING BUILDING

DESCRIPTION

INFLUENT

REVISION INFORMATION

SANITARY MH-A MH-B

SEWER

FILE:F:\36\36724\3672403\04_CAD\GENL\3672403_00-G601_v18.dwg

DATE CHK.

DR.

REV.

MH-C

USER:ATLUTTRULL

PLOTTED:6/11/2020

00-G601

SAVED:6/11/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

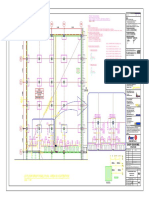

SITE PLAN LEGEND 35

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

00 STRUCTURE IDENTIFIER

PHONE (615) 254-1500 // FAX (615) 255-6572

PROPOSED STRUCTURE

(TANKS, BASINS, ETC.)

FUTURE STRUCTURE

(TANKS, BASINS, ETC.) 24 PS-1

PS-2 24

PROPOSED BUILDING

OPERATIONS/UV BUILDING

EXISTING 200' RAILROAD

CHARTER R.O.W.

TREATMENT PLANT UPGRADES

REGIONAL WASTEWATER TREATMENT PLANT

CELL 2

OVERALL SITE PLAN

THOMPSON'S STATION, TENNESSEE

20' X 20' CHEMICAL

MBR SYSTEM STORAGE BUILDING

23

INFLUENT SCREENS

09

MH 1 EXTENDED BERM

15'-0" GRAVEL ACCESS

AEROBIC DIGESTER EXISTING LIFT STATION #2

45'-0" DIA CONC TANK TO BE DEMOLISHED

15

14' X 12' VALVE VAULT

EXISTING TOE BIOSOLIDS DEWATERING BUILDING

OF BERM

15' REQUIRED

FOR CONSTRUCTION

BENCHMARK

P.K. NAIL IN POWER POLE 80

ELEV. 761.49 (NAVD88)

(GEOID03) 07 85

AERATION BASIN

35' DIAMETER TANK (TYP 2) FLOW SPLITTER INFLUENT

BOX LIFT STATION

MH A

DESCRIPTION

MH B

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_01-C101_v18.dwg

CELL 1

EXISTING EASEMENT

APPROXIMATE LOCATION

DATE CHK.

EXISTING SANITARY SEWER MANHOLES

APPROXIMATE LOCATION

DR.

EXISTING EASEMENT

REV.

APPROXIMATE LOCATION

N

OVERALL SITE PLAN

PLOTTED:6/11/2020

USER:DGBOWERS

01-C101

SAVED:6/11/2020

SCALE: 1" = 50' 50' 25' 0' 50' 100'

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

EXISTING 14"

IRRIGATION

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

16" SE - DIP FORCE MAIN

PHONE (615) 254-1500 // FAX (615) 255-6572

EXISTING 12"

FORCE MAIN FROM

TOLLGATE VILLAGE

PS-1 PS-2

OPERATIONS/UV BUILDING

LAGOON PUMP

EXISTING 200' RAILROAD

CHARTER R.O.W.

TREATMENT PLANT UPGRADES

16" SE - DIP

REGIONAL WASTEWATER TREATMENT PLANT

CELL 2

16" PD - DIP

THOMPSON'S STATION, TENNESSEE

SITE PIPING PLAN

20' X 20' CHEMICAL

STORAGE BUILDING

MBR SYSTEM

16" MLSS - DIP

INFLUENT SCREENS

14" RS - DIP

16" PTE - DIP

20" PTE - DIP 10" ALP - DIP

EXTENDED BERM

VALVE VAULT

45'-0" DIA CONC TANK

3" PW - DIP

8" TDS - DIP

14" RS - DIP

BIOSOLIDS DEWATERING BUILDING

15' REQUIRED FOR

CONSTRUCTION EXISTING TOE

BENCHMARK OF BERM AEROBIC 4" PW - DIP

P.K. NAIL IN POWER POLE DIGESTER

ELEV. 761.49 (NAVD88)

(GEOID03) 6" PW - DIP

AERATION BASIN

DESCRIPTION

35' DIAMETER TANK (TYP 2) FLOW SPLITTER

REVISION INFORMATION

BOX

4" WAS - DIP

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_01-C120_v18.dwg

MH A

INFLUENT LIFT

STATION

DATE

MH B

CELL 1

CHK.

EXISTING LIFT STATION #2

TO BE DEMOLISHED

DR.

REV.

N

SITE PIPING PLAN

PLOTTED:6/11/2020

USER:DGBOWERS

01-C120

SAVED:6/10/2020

SCALE: 1" = 50' 50' 25' 0' 50' 100'

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

VALVES GATES PRIMARY ELEMENT PUMP & BLOWER SYMBOLS

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

GATE VALVE OR OTHER IN-LINE TYPE OR SLIDE M ELECTROMAGNETIC FLOWMETER CENTRIFUGAL PUMP

NOT OTHERWISE IDENTIFIED OR OTHER TYPE NOT SUBMERSIBLE AXIAL

XX SPECIFIED FLOW PUMP

BALL

PARSHALL FLUME XX

WEIR

BUTTERFLY PISTON PUMP PROGRESSIVE CAVITY

PROPELLER OR TURBINE FLOW METER

PUMP

XX XX

FLAP

PLUG

ULTRASONIC FLOW METER (CLAMP-ON)

GEAR OR ROTARY PUMP

CHECK OR BLOWER

VENTURI TUBE VERTICAL PUMP (POSITIVE DISPLACEMENT)

XX

WAFER CHECK

FITTING SYMBOLS XX

VORTEX FLOWMETER

NEEDLE AIR COMPRESSOR (2 STAGE SHOWN)

ROTAMETER

REDUCER - CONCENTRIC METERING PUMP

XX

DIAPHRAGM

FLOAT SWITCH

REDUCER - ECCENTRIC

CENTRIFUGAL BLOWER OR FAN

GLOBE XX SUBMERSIBLE PUMP

BUBBLER TUBE XX

PIPE CLEANOUT PORT

PINCH

UNION

SCREW PUMP

ANGLE XX

FLANGE

XX:

THREE WAY AS ADJUSTABLE SPEED

PIPE BREAK CS-1 CONSTANT SPEED (SINGLE)

CS-2 CONSTANT SPEED (TWO)

FOUR WAY

CAP

TREATMENT PLANT UPGRADES

BACKFLOW PREVENTER

REGIONAL WASTEWATER TREATMENT PLANT

PLUG

MISCELLANEOUS SYMBOLS WASTEWATER PROCESS SYMBOLS

KNIFE

P&ID - STANDARD SYMBOLS

D DRAIN - BELL UP

MUD FILTER BELT WEIGH SCALE MIXER OR SURFACE ASPIRATOR UV BANK

PLAN SECT DRAIN - FUNNEL

D

THOMPSON'S STATION, TENNESSEE

SILENCER

DIFFUSER

WEIGH SCALE

PRESSURE REDUCING VALVE FLEXIBLE TUBING

DRAFT TUBE AERATOR

PRESSURE RELEASE VALVE EXPANSION JOINT

QUICK CONNECT

VACUUM RELIEF VALVE

STRAINER - WYE TYPE SOLIDS HANDLING EQUIPMENT SYMBOLS

TELESCOPING

STRAINER - BASKET TYPE

SCREW CONVEYOR OR

ROTARY SCREEN SCREW PRESS

DIAPHRAGM SEAL

BELT CONVEYOR

CYCLONE SEPARATOR

INLINE GRINDER

VALVE & GATE ACTUATOR SYMBOLS CHEMICAL FEED EQUIPMENT SYMBOLS

CHANNEL MTD GRINDER

CHLORINE CYLINDER EDUCTOR GRIT COLLECTOR: HYDRAULIC TYPE

M MOTOR OPERATOR THE FOLLOWING ADDITIONAL DESIGNATIONS

MAY BE UTILIZED ADJACENT TO SOME VALVE BAR SCREEN: MANUAL

OR GATE SYMBOLS.

DESCRIPTION

REVISION INFORMATION

S SOLENOID OPERATOR XX: INJECTOR

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_03-DI001_v18.dwg

XX NC NORMALLY CLOSED

NO NORMALLY OPEN

CHEMICAL STORAGE

FC FAILS CLOSED BAR SCREEN: MECHANICAL

FO FAILS OPEN GRIT COLLECTOR: VORTEX TYPE

P PNEUMATIC OPERATOR

CALIBRATION COLUMN

FIP FAILS IN LAST POSITION

XX

DATE CHK.

STATIC IN-LINE MIXER

POLYMER BLENDER FEEDER

GRIT CONCENTRATOR & DEWATERING

DR.

SCREW

REV.

USER:DGBOWERS

03-DI001

PLOTTED:6/5/2020

SAVED:6/5/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

SYMBOL LINE DESCRIPTION

PRIMARY AUXILIARY

LOCATION FIELD LOCATION FI FE FT

NORMALLY MOUNTED NORMALLY 8 FE FURNISHED BY OTHERS, INSTALLED BY CONTRACTOR

5 7

ACCESSIBLE TO (NOTE 2) ACCESSIBLE TO 10

ORIFICE PLATE WITH VC INSTRUMENT SUPPLY OR CONNECTION TO PROCESS

OPERATOR OPERATOR FLANGE OR CORNER TAPS ORIFICE PLATE WITH VENA

DIAPHRAGM, SPRING-OPPOSED ORIFICE PLATE WITH CONTRACTA, RADIUS, OR

(NOTE 1) (NOTE 1) DIAPHRAGM, CONNECTED TO PIPE TAPS CONNECTED TO ORIFICE PLATE IN

SPRING-OPPOSED

PRESSURE- SINGLE-ACTING DOUBLE-ACTING DIFFERENTIAL-PRESSURE VENA CONTRACTA DIFFERENTIAL-PRESSURE-

UNDEFINED SIGNAL

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

BALANCED CYLINDER CYLINDER TAPS QUICK-CHANGE FITTING

TYPE FLOW INDICATOR TYPE FLOW TRANSMITTER

I PNEUMATIC SIGNAL

P

PHONE (615) 254-1500 // FAX (615) 255-6572

XY TY

S E ELECTRIC SIGNAL

H FE FE FE FE

DISCRETE

11 12 13 14 ELECTRONIC SIGNAL

INSTRUMENTS

VALVE ACTUATOR SINGLE PORT PITOT A A ANALOG SIGNAL

CYLINDER WITH W/ ATTACHED ELECTRO- TUBE OR PITOT- AVERAGING

SOLENOID ELECTROHYDRAULIC VENTURI TUBE FLUME

POSITIONER PNEUMATIC CONVERTER VENTURI TUBE PITOT TUBE

L L HYDRAULIC SIGNAL

FI X X CAPILLARY TUBE

FI FG

FO 17

SHARED DISPLAY, 3 23 FE FQI ELECTROMAGNETIC OR SONIC SIGNAL (GUIDED)

22 FE

SHARED CONTROL 16 18

15

(SCADA) INDICATING VARIABLE RESTRICTION ORIFICE DRILLED ELECTROMAGNETIC OR SONIC SIGNAL (NOT GUIDED)

AREA METER W/ FLOW SIGHT GLASS,

IN VALVE (INSTRUMENT TAG PLAIN OR W/ PADDLE VARIABLE AREA POSITIVE-DISPLACEMENT-

HAND ACTUATOR INTEGRAL MANUAL TURBINE-OR PROPELLER-

OR HANDWHEEL THROTTLE VALVE

NO. MAY BE OMITTED IF VALVE WHEEL, FLAPPER, ETC. WEIR TYPE PRIMARY ELEMENT FLOW INDICATOR TYPE FLOW TOTALIZING INTERNAL SYSTEM LINK (SOFTWARE OR DATA LINK)

IS OTHERWISE IDENTIFIED) INDICATOR

FX PCV

MECHANICAL LINK

HV LCV FT

24 1 1 1 20 PNEUMATIC BINARY SIGNAL

TANK FE FE FE

COMPUTER

FLOW STRAIGHTENING VANE 25 26 27 ELECTRIC BINARY SIGNAL

FUNCTION PRESSURE-REDUCING

(TAG NUMBER IS OPTIONAL.

THE LOOP NUMBER MAY BE REGULATOR, SELF- PRIMARY PROCESS LINE

THE SAME AS THAT OF THE HAND CONTROL VALVE LEVEL REGULATOR W/ CONTAINED, WITH

MECHANICAL LINKAGE FLOW ELEMENT INTEGRAL VORTEX SENSOR TARGET TYPE SENSOR FLOW NOZZLE

ASSOCIATED PRIMARY HANDWHEEL ADJUSTABLE WITH TRANSMITTER

ELEMENT) SET POINT PROCESS OR MECHANICAL EQUIPMENT

PCV PDCV PCV PCV FT FE IE LIMITS OF EQUIPMENT SUPPLIED BY MANUFACTURE

2 3 4 5 29 30 1

PROGRAMMABLE PROCESS SECONDARY LINE

M PI

LOGIC CONTROL

17

(PLC) E E ELECTRICALLY TRACED AND INSULATED LINE

PRESSURE-REDUCING DIFFERENTIAL-PRESSURE- BACKPRESSURE PRESSURE INSTRUMENT

BACKPRESSURE MAGNETIC FLOWMETER SONIC FLOWMETER CURRENT TRANSFORMER

REGULATOR WITH REDUCING REGULATOR REGULATOR INDICATOR CONNECTED TO

REGULATOR, WITH INTEGRAL "DOPPLER" OR "TRANSIT MEASURING CURRENT OF DOUBLE CONTAINMENT LINE

EXTERNAL PRESSURE WITH INTERNAL AND WITH EXTERNAL DIAPHRAGM SEAL WITH FILLED

SELF-CONTAINED TRANSMITTER TIME" MAY BE ADDED ELECTRIC MOTOR

TAP EXTERNAL PRESSURE TAPS PRESSURE TAP SYSTEM WITH LEAD LINE

PDCV PCV

EXISTING LINE OR DEVICE

PI PSV PSV

6 7 8 9

TW TE TE TI

P

PRESSURE-REDUCING 4 6 7 8

REGULATOR W/ INTEGRAL

OUTLET PRESSURE RELIEF PRESSURE RELIEF OR

INSTRUMENT PURGE OR PRESSURE RELIEF OR SAFETY VALVE, STRAIGHT- FILLED-SYSTEM-TYPE

INSTRUMENT WITH PILOT VALVE, AND OPTIONAL VACUUM RELIEF VALVE, TEMPERATURE TEMPERATURE ELEMENT TEMPERATURE ELEMENT

TREATMENT PLANT UPGRADES

SHARING FLUSHING SAFETY VALVE, THROUGH PATTERN, SPRING- TEMPERATURE INDICATOR

LONG TAG NUMBER LIGHT PRESSURE INDICATOR GENERAL SYMBOL CONNECTION WITH WELL WITHOUT WELL WITH WELL

GENERAL SYMBOL WITH WELL

COMMON HOUSING DEVICE (TYPICAL AIR SET) OR WITH INTEGRAL PILOT

REGIONAL WASTEWATER TREATMENT PLANT

PSV S PSE PSE INSTRUMENT IDENTIFICATION LETTERS

TE LIT LE

P&ID - INSTRUMENTATION LEGEND

10 PS 13 14

22 16 27

NOTE 4 12 FIRST-LETTER SUCCEEDING-LETTERS

R I

NOTE 3 FE

PROCESS MODIFIER READOUT OR OUTPUT MODIFIER

PRESSURE AND VACUUM PRESSURE RELIEF OR 19

RESET FOR UNDEFINED RELIEF VALVE, SPRING- SAFETY VALVE, ANGLE RUPTURE DISK OR RUPTURE DISK OR VARIABLE PASSIVE FUNCTION FUNCTION

DIAPHRAGM TOTAL SAFETY HEAD FOR SAFETY HEAD FOR SURFACE-MOUNTED BUBBLER TYPE

LATCH-TYPE INTERLOCK OR WEIGHT-LOADED, OR PATTERN, TRIPPED BY TEMPERATURE SENSOR ADJUSTABLE WEIR

SEAL PRESSURE RELIEF VACUUM RELIEF LEVEL TRANSMITTER RADAR ELEMENT ANALYSIS ALARM

ACTUATOR LOGIC

WITH INTEGRAL PILOT INTEGRAL SOLENOID A

TANK BURNER USER'S CHOICE USER'S CHOICE USER'S CHOICE

TCV

LI LT LT B

THOMPSON'S STATION, TENNESSEE

A B

NOTES 1 LE

T T

14 15 15 C CONDUCTIVITY CONTROL CLOSED

LCV LCV C 33

1. NORMALLY INACCESSIBLE TO BEHIND-THE-PANEL DEVICES OR 4 D DENSITY DIFFERENTIAL

FUNCTIONS ARE DEPICTED BY USING THE SAME SYMBOLS BUT 5

WITH DASHED HORIZONTAL BARS, I.E.: TEMPERATURE E VOLTAGE SENSOR PRIMARY ELEMENT

THREE-WAY VALVE,

REGULATOR, ALL TRAPS TRAP WITH EQUALIZING FAIL OPEN TO PATH FLOAT TYPE DUAL PROBE SINGLE PROBE

FILLED-SYSTEM TYPE CONNECTION ULTRASONIC ELEMENT LEVEL INDICATOR LEVEL TRANSMITTER LEVEL TRANSMITTER F FLOW RATE RATIO

A-C

G USER'S CHOICE GLASS

2. SUPERSCRIPT DENOTES ADDITIONAL FUNCTIONAL DESCRIPTION A

OF INSTRUMENT. SEE INSTRUMENT DESIGNATIONS FOR B H HAND (MANUAL) HIGH

DEFINITIONS. C

D I CURRENT INDICATE

3. SUBSCRIPT DENOTES PANEL OR CABINET I.D.

J POWER SCAN

FOUR-WAY VALVE,

4. SUPERSCRIPT REFERS TO INTERLOCK SPECIFICATION. FAIL OPEN TO PATHS K TIME / SCHEDULE CONTROL STATION

A-C AND D-B

TIME RATE OF CHANGE

L LEVEL LIGHT LOW

M MOISTURE MOMENTARY MIDDLE

N USER'S CHOICE USER'S CHOICE USER'S CHOICE USER'S CHOICE

INSTRUMENT DESIGNATIONS

O USER'S CHOICE ORIFICE (RESTRICTION) OPEN

CL2 CHLORINE RESIDUAL P PRESSURE, VACUUM POINT (TEST) CONNECTION

CO2 CARBON DIOXIDE Q QUANTITY TOTALIZE

DO DISSOLVED OXYGEN

R RADIATION RECORD

LEL LOWER EXPLOSIVE LIMIT

S SPEED / FREQ. SAFETY SWITCH

MCC MOTOR CONTROL CENTER

T TEMPERATURE TRANSMIT

MLSS MIXED LIQUOR SUSPENDED SOLIDS

U MULTIVARIABLE MULTIFUNCTION MULTIFUNCTION MULTIFUNCTION

O2 OXYGEN (PURITY)

VIBRATION, MECHANICAL VALVE, DAMPER

ORP OXIDATION REDUCTION POTENTIAL V ANALYSIS

OVLD OVERLOAD W WEIGHT / FORCE WELL

pH pH CELL X UNCLASSIFIED X-AXIS UNCLASSIFIED UNCLASSIFIED UNCLASSIFIED

SD SLUDGE DENSITY EVENT, STATE, Y-AXIS RELAY/COMPUTE

Y PREFERENCE

TURB TURBIDITY Z POSITION Z-AXIS DRIVER/ACTUATOR

TO PROCESS LINE CONTINUED ON

08-DI-251 A

UV UV TRANSMITTANCE STRUCTURE ANOTHER SHEET

DESCRIPTION

LOR LOCAL - OFF - REMOTE

REVISION INFORMATION

EOT END OF TRAVEL STREAM DESIGNATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_03-DI002_v18.dwg

RM REVERSE MOTION

FLOW INDICATION

REFERENCE SHEET

DATE

TO PROCESS LINE COMING FROM ANOTHER

08-DI-251 A

CHK.

STRUCTURE SHEET

NOTES:

1. THIS IS A GENERAL LEGEND SHEET. SOME SYMBOLS AND

DR.

ABBREVIATIONS MAY NOT BE UTILIZED ON THIS SPECIFIC PROJECT.

FLOW ARROW FOR PROCESS PIPING

2. PIPING AND EQUIPMENT LEGEND APPLIES TO PROCESS AND

INSTRUMENTATION SHEETS ONLY AND MAY DIFFER FROM LEGENDS

REV.

ON OTHER SHEETS.

PROCESS LINE CROSSING (NOT CONNECTED)

USER:DGBOWERS

03-DI002

PLOTTED:6/2/2020

SAVED:5/18/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

EQUIPMENT IDENTIFICATION DESCRIPTION PIPELINE IDENTIFICATION DESCRIPTION

FFF- ## # #

PIPE SIZE - INCHES UNLESS OTHERWISE NOTED

SEQUENCE CODE - SEQUENTIAL NUMBER PROCESS CODE - DENOTES ASSOCIATED PROCESS STREAM

SEQUENCE CODE - SEQUENTIAL NUMBER MATERIAL OF CONSTRUCTION - DENOTES ASSOCIATED MATERIAL ABBREVIATION

SEQUENCE CODE - STRUCTURE IDENTIFIER

FUNCTION CODE - DENOTES ASSOCIATED EQUIPMENT ABBREVIATION ##-PPP-MTL

FUNCTION CODE ABBREVIATIONS PROCESS CODE ABBREVIATIONS PIPELINE MATERIAL OF CONSTRUCTION

AER AERATOR / AERATION

ABBREVIATIONS

ASP SURFACE ASPIRATOR AER AERATION HW HOT WATER ACP ASBESTOS CEMENT PIPE

ASU AUTOMATIC SWITCHOVER UNIT AHP AIR HIGH PRESSURE LP LIQUID PETROLEUM GAS (PROPANE) BSP BLACK STEEL PIPE

BLR BLOWER ALP AIR LOW PRESSURE ML MIXED LIQUOR CI CAST IRON

BSN BASIN BWS BACKWASH SUPPLY NG NATURAL GAS CISP CAST IRON SOIL PIPE

CLR CLARIFIER BWW BACKWASH WASTE NPW NON POTABLE WATER CMP CORRUGATED METAL PIPE

CMP COMPRESSOR CEN CENTRATE OF OVERFLOW CPP CONCRETE PRESSURE PIPE

CNV CONVEYOR CIP CLEAN-IN PIPE PA PROCESS AIR CPVC CHLORINATED POLY (VINYL CHLORIDE) PIPE

COB CONVEYOR: BELT CL2 CHLORINE GAS PD PLANT DRAIN CU COPPER PIPE

CRN CRANE

TREATMENT PLANT UPGRADES

CLS CHLORINE SOLUTION PE PRIMARY EFFLUENT CUP COPPER TUBING

DEC SLUDGE DECANTER CMS COMPRESSED AIR-SERVICE PFM PLANT FORCE MAIN DIP DUCTILE IRON PIPE

DIF DIFFUSER

REGIONAL WASTEWATER TREATMENT PLANT

CON CONCENTRATE PI PRIMARY INFLUENT FRH FLEXIBLE RUBBER HOSE

DWS DEWATERING SCREW PRESS CS CONDITIONED SLUDGE POL POLYMER (NEAT) FRP FIBERGLASS REINFORCED PIPE

DWB DEWATERING BOX CW COLD WATER (POTABLE) POLD POLYMER (DILUTED) GSP GALVANIZED STEEL PIPE

EDC EDUCTOR DAL DISSOLVED ALUM PS PRIMARY SLUDGE HDPE HIGH DENSITY POLYETHYLENE PIPE

FIL FILTER DEC DECANT PTE SCREENED SEWAGE PE POLYETHYLENE PIPE

G GATE DF DIESEL FUEL PW POTABLE WATER PP SANTOPRENE TUBING

GF GAS FEEDER DG DIGESTER GAS RAS RETURN ACTIVATED SLUDGE PVC POLY (VINYL CHLORIDE) PIPE

GRB GRIT BASIN DR DRAIN RCS RECIRCULATED SLUDGE PVT PVC TUBING

P&ID - ABBREVIATIONS

GRT GRIT DS DIGESTED SLUDGE RS RAW SEWAGE RCP REINFORCED CONCRETE PIPE

HST HOIST DWFL DEWATERING FLOCCULATION S SAMPLE STL STEEL PIPE

INJ INJECTOR

THOMPSON'S STATION, TENNESSEE

EI EQUALIZATION TANK INFLUENT SC SCUM SST STAINLESS STEEL PIPE

MXR MIXER ER EQUALIZATION TANK RETURN SCR SCREENINGS VCP VITRIFIED CLAY PIPE

P PUMP F FILTRATE SD STORM DRAIN (HT/INS) HEAT TRACED AND INSULATED LINE

PMX POLYMER MIX SKID FACD FACILITY DRAIN SE SECONDARY EFFLUENT

SB SPLITTER BOX FE FINAL EFFLUENT SEP SEPTAGE

SC SCUM COLLECTOR FM FORCE MAIN SNT SUPERNATANT

SCL SCALE FO FUEL OIL SS SANITARY SEWER

SCR SCREEN FOV FUEL OIL VENT TDS THICKENED DIGESTED SLUDGE

SLC SLUDGE COLLECTOR FOGS FATS, OILS, GREASE & SEPTAGE TWAS THICKENED WASTE ACTIVATED SLUDGE

SRS SEPTAGE RECEIVING STATION FS FINAL TANK SLUDGE UW UTILITY WATER

TNK TANK FW FILTERED WASTEWATER V VENT

UV ULTRAVIOLET GRT GRIT WAS WASTE ACTIVATED SLUDGE

V VALVE IA INSTRUMENT AIR WW WASTE WATER

WCMP WASHER/COMPACTOR IR IRRIGATION

DESCRIPTION

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_03-DI003_v18.dwg

DATE CHK.

DR.

REV.

PLOTTED:6/11/2020

USER:DGBOWERS

03-DI003

SAVED:6/8/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

TREATMENT PLANT UPGRADES

REGIONAL WASTEWATER TREATMENT PLANT

P&ID - INFLUENT LIFT STATION

FIT

0701

THOMPSON'S STATION, TENNESSEE

14" RS-DIP TO INFLUENT

M 03-DI202

SCREENING

A

V-0701 V-0702

TOLLGATE 12" RS-DIP

12" FORCE MAIN

V-0712 V-0722 V-0732

V-0703

V-0711 V-0721 V-0731

INFLUENT METER VAULT

PI PI PI

MH A

12" SANITARY 12" RS-PVC 0711 0712 0713

SEWER

LSHHH

EL 717.50

0404

10" RS-DIP

10" RS-DIP

10" RS-DIP

FROM AEROBIC 8" SNT-DIP

03-DI209

DIGESTER LSHH

EL 716.50

0405

LSH

EL 715.50

0406

MH B

15" RS-PVC 18" RS-DIP LSL TE ME TE ME TE ME

15" SANITARY EL 714.50

SEWER 0407 0711 0711 0721 0721 0731 0731

GRD-0701 AS AS AS

8" DR-DIP

P-0710 P-0720 P-0730

FROM AEROBIC 8" TDS-DIP

03-DI209 B MH C

DIGESTER

DESCRIPTION

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_03-DI201_v18.dwg

T-1010

4" DR-DIP

DATE

FROM BIOSOLIDS

03-DI210

DEWATERING

CHK.

DR.

REV.

PLOTTED:6/10/2020

USER:DGBOWERS

03-DI201

SAVED:6/9/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

USER:ATLUTTRULL

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_03-DI202_v18.dwg

SAVED:6/11/2020

PLOTTED:6/11/2020

03-DI201

SUPPLY

LIFT STATION

FROM WATER

FROM INFLUENT 16" RS-DIP

20" RS-DIP

2" NPW-PVC

V-0901

LS

0901

SCR0901

SCREEN 1

ROTARY DRUM

V-0902

1" NPW-PVC

SCREEN CONTROL PANEL

15.25" SCR-DIP

HS

0901

SCREENING

CONTAINER 1

LS

0902

SCR0902

SCREEN 2

ROTARY DRUM

V-0903

1" NPW-PVC

SCREEN CONTROL PANEL

15.25" SCR-DIP

HS

0902

SCREENING

CONTAINER 2

24" PTE-SST

24" PTE-SST

20" PTE-DIP

20" PTE-DIP

03-DI203

TO FLOW SPLITTER BOX

A

REVISION INFORMATION

REV. DR. CHK. DATE DESCRIPTION

P&ID - INFLUENT SCREENING

FILE NO.

REGIONAL WASTEWATER TREATMENT PLANT

TREATMENT PLANT UPGRADES 615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

36724-03

THOMPSON'S STATION, TENNESSEE PHONE (615) 254-1500 // FAX (615) 255-6572

03-DI202

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

6" PA-DIP FROM SUEZ PID

03-DI204

326838-AA-01, SHT 4 OF 13

20" PTE-DIP

AIT AIT AIT

1511 1512 1513

DO DO DO

TREATMENT PLANT UPGRADES

REGIONAL WASTEWATER TREATMENT PLANT

V1501

16" MLSS-DIP TO SUEZ PID

ANOXIC ZONE AEROBIC ZONE 03-DI204 A

326838-AA-01, SHT 7 OF 13

THOMPSON'S STATION, TENNESSEE

G-1511

P&ID - AERATION

FLOW

FROM INFLUENT

03-DI203 A SPLITTER AER-1511 AER-1512

SCREENING

BOX

V1502

G-1512

8" PD-DIP

AERATION BASIN 1

6" PA-DIP FROM SUEZ PID

03-DI204

326838-AA-01, SHT 4 OF 13

20" PTE-DIP

AIT AIT AIT

1521 1522 1523

DO DO DO

V1503

16" MLSS-DIP TO SUEZ PID

ANOXIC ZONE AEROBIC ZONE 03-DI204 B

326838-AA-01, SHT 7 OF 13

DESCRIPTION

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_03-DI203_v18.dwg

AER-1521 AER-1522

DATE CHK.

8" PD-DIP

DR.

AERATION BASIN 2

REV.

USER:ATLUTTRULL

PLOTTED:6/11/2020

03-DI203

D

SAVED:6/11/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

FROM SUEZ PID

03-DI206 A

326838-AA-01, SHT 9 OF 13

8" SE-CS (BYPASS LINE) MASTER

TREATMENT PLANT UPGRADES

CONTROL/IRRIGATION

CONTROL PLC/HMI

REGIONAL WASTEWATER TREATMENT PLANT

HS HOA

111

THOMPSON'S STATION, TENNESSEE

P&ID - FILTERS

FROM PS-2 8" SE-CS 8" SE-CS TO UV DISINFECTION

03-DI209 03-DI208 A

TRAINS

SP

0.5

PSIG

P-2401

FILTER PACKAGE

CELL 2

FE

2401

3" PD-DIP

12" PD-DIP

DESCRIPTION

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_03-DI207_v18.dwg

FROM SUEZ PID 8" PD-DIP 16" PD-DIP

03-DI206 B

326838-AA-01, SHT 9 OF 13

DATE CHK.

MH

PS-1

DR.

REV.

TO TOLLGATE VILLAGE

USER:ATLUTTRULL

PLOTTED:6/11/2020

03-DI201

FORCE MAIN

03-DI207

SAVED:6/11/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

MASTER

CONTROL/IRRIGATION

CONTROL PLC/HMI

TREATMENT PLANT UPGRADES

REGIONAL WASTEWATER TREATMENT PLANT

LOCAL HS HOA

CONTROL

PANEL 113

15 PSIG

P&ID - UV DISINFECTION

SET

THOMPSON'S STATION, TENNESSEE

POINT

FILTERS AND 8" IR-CS TO LAND APPLICATION

03-DI206 A 03-DI209 A

MEMBRANES WET WELL

V-3501

PI

101

UV DISINFECTION BANK 1

LOCAL HS HOA

CONTROL

PANEL 113

15 PSIG

SET

POINT

DESCRIPTION

8" IR-CS TO LAND APPLICATION

REVISION INFORMATION

03-DI209 B

WET WELL

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_03-DI208_v18.dwg

V-3502

PI

102

DATE CHK.

UV DISINFECTION BANK 2

DR.

REV.

USER:ATLUTTRULL

PLOTTED:6/11/2020

03-DI208

SAVED:6/11/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

MASTER

CONTROL/IRRIGATION

CONTROL PLC/HMI

TREATMENT PLANT UPGRADES

REGIONAL WASTEWATER TREATMENT PLANT

LOCAL CONTROL PANEL

FROM UV DISINFECTION 8" IR-CS

03-DI208 A

TRAIN 1 HOA

HS PC PC

107 107 107

P&ID - IRRIGATION PUMPING

PT

THOMPSON'S STATION, TENNESSEE

107 14" IR-PVC TO DRIP

M IRRIGATION

P-107

FROM UV DISINFECTION 8" IR-CS

03-DI208 B

TRAIN 2 LOCAL CONTROL PANEL

HS HOA PC PC

108 108 108

PT

108 14" IR-PVC TO DRIP

M IRRIGATION

P-108

LSL

108

LSL

107

DESCRIPTION

12" OF-PVC

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_03-DI209_v18.dwg

LAND APPLICATION

IRRIGATION PUMPS

WET WELL

DATE

TO CELL 2

CHK.

03-DI207

DR.

PS-2

REV.

USER:ATLUTTRULL

PLOTTED:6/11/2020

03-DI209

SAVED:6/11/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

DIPGESTER CONTROL PANEL

"DCP"

AIR LIR

8001 8011

1A 1A

TREATMENT PLANT UPGRADES

REGIONAL WASTEWATER TREATMENT PLANT

1A 1A

P&ID - AEROBIC DIGESTION

THOMPSON'S STATION, TENNESSEE

FROM MEMBRANE 4"-WAS-DIP

03-DI206

BIOREACTOR

AIT LIT

120V 120V

8001 8001

V-8001

FROM 10"-ALP-DIP

03-DI211 M M

BLOWERS

TLV-8002

DO

AE LE

8001 8011

V-8003

8"-SNT-DIP

03-DI201 TO INFLUENT

LIFT STATION

DRAFT TUBE

AERATOR

DESCRIPTION

V-8004

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_03-DI210_v18.dwg

DIPGESTER

V-8005

8"-TDS-DIP

03-DI-211 TO BIOSOLIDS

DEWATERING

DATE

8"-TDS-DIP

CHK.

V-8006

DR.

03-DI-201 TO INFLUENT B

LIFT STATION

REV.

PLOTTED:6/10/2020

USER:DGBOWERS

03-DI210

SAVED:6/9/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

TREATMENT PLANT UPGRADES

REGIONAL WASTEWATER TREATMENT PLANT

P&ID - BIOSOLIDS DEWATERING

THOMPSON'S STATION, TENNESSEE

POTABLE 2" PW-PVC

WATER

M

LIT S S S

8510

VS DRUM DRUM HEADBOX

SHOWER SHOWER SHOWER

FCV-8511 FCV-8512 FCV-8513

8" DS - SS

LT LSH

P-8511 8510 8510

ZS

PSH

FLOC TANK 8510

AS 8511 SCREW

FIT T-8510

8510 SCREW PRESS CONVEYOR

DWS-8510 M CNV-8510

AS

FROM 8" TDS - DIP 4" TDS - DIP

03-DI210 DIGESTER A SLUDGE M

V-8510 FEED PUMPS

3" DR-DIP

FE

8510 M

1" POLS-PVC

PSH

P-8512 8512

3" DR-DIP

TO DISPOSAL

AS

DESCRIPTION

REVISION INFORMATION

4" DR - DIP TO INFLUENT

POLYMER 03-DI201

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_03-DI211_v18.dwg

TOTE LIFT STATION

POLYMER MAKEDOWN

SYSTEM

1" POL-PVT

PMX-8510

DATE CHK.

1" POL-PVC

DR.

POTABLE 1" PW-PVC

WATER

REV.

PLOTTED:6/10/2020

USER:DGBOWERS

03-DI211

SAVED:6/9/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

48" X 30" EQUIPMENT HATCH

W/ FALL PROTECTION

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

DAVIT CRANE

MOUNT NOTE: INFLUENT PIPE

SHOWN FOR CLARITY.

4" VENT PIPE DI W/ INSECT SCREEN.

SEE PLAN FOR LOCATION

4" FLG X PE WALL PIPE THROUGH SLAB

14" RS-DI

1" DRAIN FROM ARV

10" RESTRAINED

DISMANTLING

JOINT (TYP)

T/SLAB EL 735.50

48" X 30" EQUIPMENT

HATCH (TYP) F.G. EL 735.00

14" X 10" TEE DI

(TYP)

4" VENT PIPE DI W/

INSECT SCREEN

10" RS-DI

CL EL 731.00

3'-2"

12' DIAMETER PRECAST

CONCRETE WET WELL

A

70-D101

3'-2"

DAVIT CRANE

MOUNT

PIPE SUPPORT (TYP)

SS GUIDE RAILS

PIPE SUPPORT INV 719.50

(TYP)

TREATMENT PLANT UPGRADES

10" CHECK

18" RS-DI

REGIONAL WASTEWATER TREATMENT PLANT

VALVE (TYP)

10" PLUG VALVE (TYP)

14" BLIND FLANGE DI

INFLUENT LIFT STATION

HIGH LEVEL ALARM

EL 718.50

THOMPSON'S STATION, TENNESSEE

N

2'-0" MAX LAG PUMP ON

1 INFLUENT LIFT STATION - UPPER PLAN EL 717.50

LEAD PUMP ON

07-D101 SCALE: 3/8" = 1'-0" 0 6" 1' 2' 4' EL 716.50

LOW LEVEL ALARM

EL 714.50

GROUT

(TYP)

10" X 6" REDUCER DI

EL 709.50

3'-2"

A

1'-6" 1'-6"

70-D101

12" MIN ASTM #57 STONE UNDISTURBED GROUND PRECAST

KOR-N-SEAL FOUNDATION

3'-2"

A INFLUENT LIFT STATION - SECTION

07-D101 SCALE: 3/8" = 1'-0" 0 6" 1' 2' 4'

DESCRIPTION

2 3/4"

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_07-D101_v18.dwg

18" RS-DI

DATE CHK.

DR.

REV.

N

PLOTTED:6/11/2020

USER:DGBOWERS

07-D101

SAVED:6/11/2020

2 INFLUENT LIFT STATION - LOWER PLAN

07-D101 SCALE: 3/8" = 1'-0" 0 6" 1' 2' 4'

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

USER:ATLUTTRULL

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_09-D101_v18.dwg

SAVED:6/10/2020

PLOTTED:6/10/2020

22'-8"

SCALE: 1/2" = 1'-0"

DRUM SCREEN SCR-0902

DRUM SCREEN SCR-0901

20" RS-DIP

20" RS-DIP

0

6" 1'

2'

4'

INFLUENT SCREENING PLAN

3'-0" TYP 5'-0"

HANDRAIL

REMOVABLE

GRATING

24" TEE, FLG

15'-0"

A

4'-0"

09-D301

5'-0"

24"x20" MJ RED

15'-0"

20" PTE-DIP

TO FLOW

SPLITTER BOX

4 CY DUMPSTER (TYP)

B

09-D301

REVISION INFORMATION

REV. DR. CHK. DATE DESCRIPTION

INFLUENT SCREENING PLAN

FILE NO.

REGIONAL WASTEWATER TREATMENT PLANT

TREATMENT PLANT UPGRADES 615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

36724-03

THOMPSON'S STATION, TENNESSEE PHONE (615) 254-1500 // FAX (615) 255-6572

09-D101

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

CYLINDER CYLINDER

DRUM SCREEN SCR-0902 ROTATION ROTATION

DRUM SCREEN SCR-0901

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

HANDRAIL

ELEVATED CONCRETE PLATFORM

5'-0"

TOP EL 766.63

1'-3"

24" BASE BEND,

FLG (TYP)

PIPE SUPPORT

(TYP)

24" TEE, FLG

TOP OF BERM EL 760.80

TREATMENT PLANT UPGRADES

24" PTE-DIP

REGIONAL WASTEWATER TREATMENT PLANT

INFLUENT SCREENING SECTIONS

24" 90° MJ BEND

THOMPSON'S STATION, TENNESSEE

DRUM SCREEN SCR-0902

A SECTION

09-D101 SCALE: 1/2" = 1'-0"

0 6" 1' 2' 4'

20" RS-DIP INFLUENT

SOLIDS

DISCHARGE

EMERGENCY

ELEVATED CONCRETE PLATFORM

HANDRAIL

EFFLUENT 4 CY DUMPSTER (TYP)

PIPE SUPPORT

(TYP)

TOP EL 766.63

DESCRIPTION

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_09-D301_v18.dwg

TOP OF BERM EL 760.80

DATE CHK.

DR.

REV.

20" PTE-DIP

B SECTION TO AERATION BASINS

USER:ATLUTTRULL

PLOTTED:6/10/2020

09-D301

CL EL 755.80

SAVED:6/10/2020

09-D101 SCALE: 1/2" = 1'-0"

0 6" 1' 2' 4'

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

20" INFLUENT

FROM SCREENS

16" 45° MJ BEND (TYP)

OA D

RK R

" WO

15'-0

TO MBR 16" EFF-DIP

4' SQ CONC LANDING SYSTEM

FINE BUBBLE DIFFUSERS

20" INF-DIP

CANTILEVER PLATFORM -

4' WIDTH

METAL STAIRS

WEIR

HANDRAIL

TREATMENT PLANT UPGRADES

REGIONAL WASTEWATER TREATMENT PLANT

AERATION BASINS PLAN

NK

NK

R TA

TA

TO MBR

THOMPSON'S STATION, TENNESSEE

16" EFF-DIP 3'-0"

R

SYSTEM

E

TE

MET

ME

DIA

" DIA

-0"

35'-0

35'

AEROBIC ZONE ANOXIC ZONE

(75% CAPACITY) (25% CAPACITY)

9'x4' ELEVATED FLOW

DISTRIBUTION BOX WITH

2-90° V-NOTCH WEIRS

8" THICK CMU BAFFLE WALL

AERATION BASIN 1 AERATION BASIN 2

DESCRIPTION

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_15-D101_v18.dwg

DATE CHK.

DR.

N

REV.

AERATION BASINS - PLAN

SCALE: 1/4" = 1'-0"

USER:ATLUTTRULL

PLOTTED:6/10/2020

0 1' 2' 4' 8'

15-D101

SAVED:6/10/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

USER:CNDAVIS

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_23-D101_v18.dwg

SAVED:6/11/2020

PLOTTED:6/11/2020

CONCRETE PAD

16" MLSS-DIP

22'-0"

16" MLSS-DIP

SCALE: 1/2" = 1'-0"

PLAN VIEW

37'-6 1/2"

FUTURE MEMBRANE TRAIN 3

MEMBRANE TANK TRAIN 2

MEMBRANE TANK TRAIN 1

DRAIN

DRAIN

12" SE-DIP

12" SE-DIP

REVISION INFORMATION

REV. DR. CHK. DATE DESCRIPTION

MBR PLAN

FILE NO.

REGIONAL WASTEWATER TREATMENT PLANT

TREATMENT PLANT UPGRADES 615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

36724-03

THOMPSON'S STATION, TENNESSEE PHONE (615) 254-1500 // FAX (615) 255-6572

23-D101

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

12" BLIND FLANGE

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

NOTES:

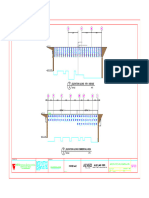

1. CONTRACTOR SHALL PROVIDE A MINIMUM 40 MIL

PHONE (615) 254-1500 // FAX (615) 255-6572

PVC LINER SEPARATION PIECE BETWEEN

2" PVC QUICK

CONCRETE COLLARS AND EXISTING LINER.

CONNECT UNION

CONCRETE PIPE CRADLE

4"x2" PVC RED

4" PVC BV

12" STEEL CARRIER PIPE

FLEX HOSE (BY PUMP MFR)

GRADE EL 761.00

1

LINER PROTECTION -

SEE NOTE 1

12" PIPE COLLAR (SQUARE) -

MIN 3" CONCRETE COVER

TREATMENT PLANT UPGRADES

OVER PIPE

CL EL 758.00

REGIONAL WASTEWATER TREATMENT PLANT

HWL EL 758.00

EXISTING HDPE LINER

INTERMEDIATE LIFT STATIONS

SECTION - LAGOON PUMP

PUMP CABLE (BY PUMP MFR)

THOMPSON'S STATION, TENNESSEE

SLIDE SLOPE PUMP

8 FT LENGTH WELL SCREEN PIPE

12" PIPE SLEEVE WELDED

12" STEEL PIPE W/CONCRETE

FOOT STRAPPED TO PIPE

MIN ONE PIECE 40 MIL PVC

MATERIAL BETWEEN CONCRETE

SPLASH BLOCK AND LINER

EL 729.00

DESCRIPTION

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_24-D302_v18.dwg

LAGOON PUMP - SECTION

DATE

SCALE: 3/4" = 1'-0"

0 6" 1' 2'

CHK.

DR.

REV.

USER:ATLUTTRULL

PLOTTED:6/5/2020

24-D302

SAVED:6/5/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

EXISTING BLOWER #2

EXISTING BLOWER #1

COAGULANT

BLOWER ROOM

ROOM

TO LAGOON CELLS

NEW UV TRAIN 2

8" GV, FLG (TYP)

3'-0"

MIN

EXISTING IRRIGATION

PUMP #2

8" 90° BEND, CS (TYP)

TREATMENT PLANT UPGRADES

REGIONAL WASTEWATER TREATMENT PLANT

TO DRIP FIELDS

OPERATIONS/UV BUILDING PLAN

8" F-CS

4'-7"

OFFICE

B

LAND 35-D301

THOMPSON'S STATION, TENNESSEE

APPLICATION

WET WELL

8" TEE, CS

TO DRIP FIELDS

3'-3"

NEW UV TRAIN 1

EXISTING IRRIGATION

PUMP #1

STORAGE

3'-11" ROOM

DESCRIPTION

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_35-D101_v18.dwg

DATE

A

CHK.

35-D301

DR.

REV.

N

OPERATIONS/UV BUILDING - PLAN VIEW

USER:ATLUTTRULL

PLOTTED:6/11/2020

35-D101

SAVED:6/11/2020

SCALE: 1/4" = 1'-0"

0 1' 2' 4' 8'

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

EXISTING FILTER

EXISTING BLOWER

NEW UV TRAIN 2

NEW UV TRAIN 1

12'-0"

6'-3"

3'-9"

3'-9"

F/F EL 763.50

GRADE EL 763.00

EXISTING

CONCRETE TANK

INV EL 760.00

7'-6"

EXISTING 12" PVC

TO BE RE-ROUTED

TO PS-2

BOTTOM EL 755.92 EXISTING 8" PVC

TO CELL 2

EXISTING 8" CS FROM PS-1

TREATMENT PLANT UPGRADES

REGIONAL WASTEWATER TREATMENT PLANT

OPERATIONS/UV BUILDING SECTIONS

21'-9" 15'-3" 23'-0"

60'-0"

THOMPSON'S STATION, TENNESSEE

A OPERATIONS/UV BUILDING - SECTION

35-D101 SCALE: 1/4" = 1'-0"

0 1' 2' 4' 8'

10'-2" 6'-2"

8" BFV, FLG (TYP)

EXISTING IRRIGATION PUMP UNIT NEW UV

8" 90° BEND, CS TRAIN 2

8" CS PIPING FROM UV TRAIN 1

DESCRIPTION

REVISION INFORMATION

PIPE SUPPORT

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_35-D301_v18.dwg

EXISTING 12" PVC TO BE

RE-ROUTED TO PS-2

DATE CHK.

DR.

8'-5"

REV.

USER:ATLUTTRULL

PLOTTED:6/11/2020

OPERATIONS/UV BUILDING - SECTION

B

35-D301

SAVED:6/2/2020

35-D101 SCALE: 1/4" = 1'-0"

0 1' 2' 4' 8'

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

10" 90° BEND (TYP)

10" ALP-DIP FROM BLOWERS

SEE SHEET 01-C120

FOR CONTINUATION

10" BUTTERFLY VALVE

8" TDS-DIP

TO BIOSOLIDS DEWATERING BUILDING

SEE SHEET 01-C120 FOR CONTINUATION

8" FLG PLUG VALVE

2" AIR DROP PIPES

TREATMENT PLANT UPGRADES

W/ DIFFUSERS (TYP 12)

REGIONAL WASTEWATER TREATMENT PLANT

7'-6" DIA ENERGY

RECOVERY BAFFLE

45'-0"

AEROBIC DIGESTER - PLAN

DIAM 8" FLG PLUG VALVE

ETER WITH 2" NUT

TANK 8" MUD VALVE W/

MANUAL OPERATOR

THOMPSON'S STATION, TENNESSEE

5' X 4' PRECAST VALVE

VAULT W/ 5' X 4'

ACCESS HATCH

8" DR-DIP

TO INFLUENT LIFT STATION

SEE SHEET 01-C120

1" AIR DROP PIPES FOR CONTINUATION

W/ DIFFUSERS (TYP 6)

4"-WAS-DIP 15'-0"

FROM MBR W

ALL A ORK RO

SEE SHEET 01-C120 14" SHEAR ROUN AD

D TA

FOR CONTINUATION TUBES (TYP 6) NK

5'-6" DIA DRAFT TUBE INFLUENT LIFT STATION

AIR BRIDGE SUPPORT VALVE VAULT

(TYP)

4" 90° BEND (TYP)

4" TELESCOPING VALVE

DESCRIPTION

8" SNT - DIP

REVISION INFORMATION

TO INFLUENT LIFT STATION

INFLUENT LIFT STATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_80-D101_v18.dwg

8" 90° BEND (TYP) SEE SHEET 01-C120 FOR

CONTINUATION

DATE CHK.

DR.

N

REV.

AEROBIC DIGESTER - PLAN

SCALE: 1/4" = 1'-0" 0 1' 2' 4' 8'

PLOTTED:6/11/2020

USER:DGBOWERS

80-D101

SAVED:6/10/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

PHONE (615) 254-1500 // FAX (615) 255-6572

9"

4" 90° BEND FLG

(TYP) PIPE SUPPORT

PIPE SUPPORT HWL ELEV 755.00

AND ANCHOR

TREATMENT PLANT UPGRADES

6"

4" WAS-DI

REGIONAL WASTEWATER TREATMENT PLANT

AEROBIC DIGESTER - SECTION

THOMPSON'S STATION, TENNESSEE

8" MUD VALVE

6'-0"

ELEV 735.25

8" PLUG VALVE W/ 1'-4"

FLOOR STAND 4" 90° BEND DI/FLG

(TYP)

6'-6"

1'-0"

TO DEWATERING BOX

ELEV 735.00

8" TDS-DI

CL ELEV 729.75

ELEV 728.75

CL ELEV 731.83

TO PLANT DRAIN

CONCRETE ENCASEMENT

OF ALL LINES UNDER TANK

A AEROBIC DIGESTER - SECTION B AEROBIC DIGESTER - SECTION

80-D101 SCALE: 1/4" = 1'-0" 0 1' 2' 4' 8' 80-D101 SCALE: 1/4" = 1'-0" 0 1' 2' 4' 8'

DESCRIPTION

REVISION INFORMATION

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_80-D301_v18.dwg

DATE CHK.

DR.

REV.

PLOTTED:6/10/2020

USER:DGBOWERS

80-D301

SAVED:6/4/2020

FILE NO. 36724-03

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

USER:DGBOWERS

FILE:F:\36\36724\3672403\04_CAD\WATR\PLOT\3672403_85-D101_v18.dwg

SAVED:5/26/2020

PLOTTED:6/10/2020

36'-0"

17'-6" 10'-0" 7'-6"

(TYP)

BLOWER

PAD (TYP)

2'-0" MIN CLEARANCE

3'-0"

7'-6"

WASHROOM

9'-6"

BLOWER ROOM

16'-0"

ROOM

ELECTRICAL

8'-6"

AREA

11'-0" 6'-0"

CONTROL

OPERATOR

N

TOTE

TOTE

FUTURE

POLYMER

POLYMER

SCALE:3/8" = 1'-0"

48'-6"

PRESS

FUTURE

1'-0"

0 6" 1'

2'

8'-0" 20'-0" 7'-0"

SLUDGE DEWATERING BUILDING - PLAN

4'

8'-0"

SKID

SCREW PRESS

2'-0"

SCREW CONVEYOR

8'-0"

10' ROLLUP DOOR (TYP)

SCREW CONVEYOR DROP

REVISION INFORMATION

REV. DR. CHK. DATE DESCRIPTION

SLUDGE DEWATERING BUILDING - PLAN

FILE NO.

REGIONAL WASTEWATER TREATMENT PLANT

TREATMENT PLANT UPGRADES 615 3rd Avenue South // Suite 700 // Nashville, Tennessee 37210

36724-03

THOMPSON'S STATION, TENNESSEE PHONE (615) 254-1500 // FAX (615) 255-6572

85-D101

Copyright 2020, Barge Design Solutions, Inc. ALL RIGHTS RESERVED

You might also like

- Plans For Acton HillDocument16 pagesPlans For Acton Hillwillhofmann2100% (1)

- Charge Air Cooler Pressure Drop MeasurementDocument12 pagesCharge Air Cooler Pressure Drop MeasurementMuhammad Waleed Tariq100% (1)

- MTO For Piping MaterialDocument15 pagesMTO For Piping MaterialNguyen VHNo ratings yet

- Answers - Questionnaire-Bonder06-TT+LaminationDocument6 pagesAnswers - Questionnaire-Bonder06-TT+Laminationchandana kumarNo ratings yet

- NPCDocument32 pagesNPCKhristine Lerie PascualNo ratings yet

- Siteplan Hikmah Sapphire HospitalDocument8 pagesSiteplan Hikmah Sapphire Hospitalrahmat hidayatNo ratings yet

- Bore Log Si-02Document2 pagesBore Log Si-02Jody WyvrnsNo ratings yet

- PS 585Document3 pagesPS 585ilham robbyNo ratings yet

- Gint STD A4 Astm LabDocument32 pagesGint STD A4 Astm LabDiego Alexis CalloNo ratings yet

- BH 04Document3 pagesBH 04Rillo MaulanaNo ratings yet

- Det Kuda2 RevisiDocument1 pageDet Kuda2 RevisiDeni Rizki SaputraNo ratings yet

- 40485Document2 pages40485naveenNo ratings yet

- Soil Boring 1Document3 pagesSoil Boring 1Vaibhav SharmaNo ratings yet

- Perspective: This SiteDocument1 pagePerspective: This Sitekim aurinoNo ratings yet

- Swert PDFDocument1 pageSwert PDFAkhil MpNo ratings yet

- Shop Sivan Lalitha ModelDocument1 pageShop Sivan Lalitha ModelAkhil MpNo ratings yet

- Swert PDFDocument1 pageSwert PDFAkhil MpNo ratings yet

- Daily Drilling Report RPT No: 6 Date: 23-Apr-20 Job: Rig No: 25Document2 pagesDaily Drilling Report RPT No: 6 Date: 23-Apr-20 Job: Rig No: 25Thế Tài HoàngNo ratings yet

- Sa203 Structural DrawingDocument50 pagesSa203 Structural DrawingChime MornNo ratings yet

- Daily Drilling Report RPT No: 5 Date: 22-Apr-20 Job: Rig No: 25Document2 pagesDaily Drilling Report RPT No: 5 Date: 22-Apr-20 Job: Rig No: 25Thế Tài HoàngNo ratings yet

- (R.0) L2 Floor Area W.H Extention FIX-1Document1 page(R.0) L2 Floor Area W.H Extention FIX-1richter marlandohemNo ratings yet

- Larsen & Toubro Limited: Distribution Transformer Sizing CalculationDocument33 pagesLarsen & Toubro Limited: Distribution Transformer Sizing CalculationEngr. Nabid Rayhan KhalequeNo ratings yet

- PS 566Document3 pagesPS 566ilham robbyNo ratings yet

- Pu 537Document3 pagesPu 537ilham robbyNo ratings yet

- To Kalimati To Tripureshwor: 22M Wide Access RoadDocument1 pageTo Kalimati To Tripureshwor: 22M Wide Access RoadHritika GurungNo ratings yet

- Data Tanah ThesisDocument2 pagesData Tanah ThesisESTU EMMA APRILIANANo ratings yet

- Asd Tank: Inlet Pipe (By Plumbing)Document1 pageAsd Tank: Inlet Pipe (By Plumbing)Angel RoaringNo ratings yet

- Stevens Animal Hospital Architectural Drawings 12-18-19Document34 pagesStevens Animal Hospital Architectural Drawings 12-18-19Alyssa Joy Finca100% (1)

- Sample Town CommitteeDocument1 pageSample Town CommitteeSimantaSonowalNo ratings yet

- First Floor Plan Part-1Document1 pageFirst Floor Plan Part-1Harini hariniNo ratings yet

- Daily Drilling Report RPT No: 3 Date: 20-Apr-20 Job: Rig No: 25Document2 pagesDaily Drilling Report RPT No: 3 Date: 20-Apr-20 Job: Rig No: 25Thế Tài HoàngNo ratings yet

- Daftar GambarDocument1 pageDaftar GambarRofa UdinNo ratings yet

- Denah ApotekDocument3 pagesDenah Apotekairohaeni073No ratings yet

- 003Document1 page003Rhowelle TibayNo ratings yet

- Mezzanine FloorDocument1 pageMezzanine FloorLewis HamiltonNo ratings yet

- DED-Model 2Document1 pageDED-Model 2KhaerulAjiNo ratings yet

- Bore Log Si-06Document3 pagesBore Log Si-06Jody WyvrnsNo ratings yet

- Iiit - NR - 20190211 - 14C - Door Schedule-16120-I-Td-14c-305-07Document1 pageIiit - NR - 20190211 - 14C - Door Schedule-16120-I-Td-14c-305-07Sohan KhobragadeNo ratings yet

- Soil Boring 2Document3 pagesSoil Boring 2Vaibhav SharmaNo ratings yet

- Hydraulic Drawings - 1670 Pacific Highway WahroongaDocument4 pagesHydraulic Drawings - 1670 Pacific Highway Wahroongalearning.aat100% (1)

- LV Ph2020 - Bid Set - PlumbingDocument14 pagesLV Ph2020 - Bid Set - Plumbingart cafeNo ratings yet

- Steel Structure Access Bridge #2 Ciliwung StationDocument28 pagesSteel Structure Access Bridge #2 Ciliwung StationRillo MaulanaNo ratings yet

- Peta Pra Site Plan SaluranDocument1 pagePeta Pra Site Plan SaluranRoestantyo Eka SeptianNo ratings yet

- Staff Statement1Document1 pageStaff Statement1Naser KpkNo ratings yet

- PCC ECOLAND AS-BUILT PLANS (Occupancy)Document17 pagesPCC ECOLAND AS-BUILT PLANS (Occupancy)jossan doplaynaNo ratings yet

- Daily Drilling Report RPT No: 2 Date: 19-Apr-20 Job: Rig No: 25Document2 pagesDaily Drilling Report RPT No: 2 Date: 19-Apr-20 Job: Rig No: 25Thế Tài HoàngNo ratings yet

- Daily Drilling Report RPT No: 4 Date: 21-Apr-20 Job: Rig No: 25Document2 pagesDaily Drilling Report RPT No: 4 Date: 21-Apr-20 Job: Rig No: 25Thế Tài HoàngNo ratings yet

- Ceklis Pekerjaan Renovasi RukoDocument4 pagesCeklis Pekerjaan Renovasi Rukomrdongdongg92No ratings yet

- Detail Perspektif Pump House: PT - Kartanegara Energi PerkasaDocument1 pageDetail Perspektif Pump House: PT - Kartanegara Energi PerkasaRully SaputraNo ratings yet

- LAY OUT PIPA CO2 RISE FLOOR Rev.1Document1 pageLAY OUT PIPA CO2 RISE FLOOR Rev.1dyashuntingNo ratings yet

- TMP - Mah Sing - 01 - Rev01 - JKR RoadDocument4 pagesTMP - Mah Sing - 01 - Rev01 - JKR Roadaliff suhaimi100% (2)

- Bricklink Engineers & Consultants: Structural DrawingDocument6 pagesBricklink Engineers & Consultants: Structural DrawingMayil Vahanan TNo ratings yet

- Admin & Tourism Center 1Document1 pageAdmin & Tourism Center 1Lovely BautistaNo ratings yet

- LAY OUT PIPA CO2 ELEKTRIKAL ROOM Rev.1Document1 pageLAY OUT PIPA CO2 ELEKTRIKAL ROOM Rev.1dyashuntingNo ratings yet

- Teachers in Hubli.01-.02-2022Document15 pagesTeachers in Hubli.01-.02-2022arbaz khanNo ratings yet

- Preliminary Borlog SBZ-01Document1 pagePreliminary Borlog SBZ-01benayaNo ratings yet

- Layout3Document1 pageLayout3janzcorpuz26No ratings yet

- Location PlanDocument1 pageLocation PlanJinxian XuNo ratings yet

- Site Development Plan: Rizal Technological UniversityDocument1 pageSite Development Plan: Rizal Technological UniversityLigaya Delos SantosNo ratings yet

- Skystream Segmented Tower ManualDocument76 pagesSkystream Segmented Tower Manualudaykiranorange1986No ratings yet

- Directory Map01Document1 pageDirectory Map01Gelyn RabanesNo ratings yet

- Side Ditch: Impact Box 3Document5 pagesSide Ditch: Impact Box 3ade indraNo ratings yet

- Construction of Cast-Insitu Bored PileDocument193 pagesConstruction of Cast-Insitu Bored PileTirthajit RoyNo ratings yet

- Chem Oil - Check Valve PDFDocument204 pagesChem Oil - Check Valve PDFClemente Rafael Marval EscalonaNo ratings yet

- BS en 489-2003Document28 pagesBS en 489-2003Wyllton CandidoNo ratings yet

- Master Diploma in Piping Design and Stress AnalysisDocument2 pagesMaster Diploma in Piping Design and Stress Analysissalith100% (1)

- Saep 57 PDFDocument30 pagesSaep 57 PDFRami ElloumiNo ratings yet

- Specification Sheet: 2 7/8" P 110 7.90 LBS/FT, PH 6 HYDRIL TUBINGDocument1 pageSpecification Sheet: 2 7/8" P 110 7.90 LBS/FT, PH 6 HYDRIL TUBINGAlberto CárdenasNo ratings yet

- Spe 184193Document13 pagesSpe 184193HSEQ AZUL ENERGYNo ratings yet

- Dim3225blsst Rev A, B, CDocument31 pagesDim3225blsst Rev A, B, CCarolinaNo ratings yet

- Seaharvest BrochureDocument6 pagesSeaharvest BrochurealaddinNo ratings yet