Professional Documents

Culture Documents

Life Line System

Life Line System

Uploaded by

Ranjit S KashyapCopyright:

Available Formats

You might also like

- Installation Reference, DPI Transom ShieldDocument2 pagesInstallation Reference, DPI Transom ShieldSON100% (1)

- CS101 Current Mid-Term Solved Papers 2022 BY M ZAMANDocument44 pagesCS101 Current Mid-Term Solved Papers 2022 BY M ZAMANNabil AhmedNo ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- CH 10Document30 pagesCH 10Narendran KumaravelNo ratings yet

- College Pretest PE 1Document7 pagesCollege Pretest PE 1Jelyn Racel Agundo ElmedulanNo ratings yet

- Lesson Plan 3 2D Shape With ReflectionDocument7 pagesLesson Plan 3 2D Shape With ReflectionfatimaNo ratings yet

- MINI Cooper Service Manual: 2002-2006 - Table of ContentsDocument2 pagesMINI Cooper Service Manual: 2002-2006 - Table of ContentsBentley Publishers40% (5)

- Berchtesgaden 2001 16 Eur Use Conf Paper - 61aDocument14 pagesBerchtesgaden 2001 16 Eur Use Conf Paper - 61aengineeringmteNo ratings yet

- Tyco TY5522 TFP250 - 08 - 2022Document5 pagesTyco TY5522 TFP250 - 08 - 2022First LAstNo ratings yet

- Installation Guidelines For Users of Outdoor Magnum DS Low-Voltage Switchgear Assemblies For Seismic ApplicationsDocument2 pagesInstallation Guidelines For Users of Outdoor Magnum DS Low-Voltage Switchgear Assemblies For Seismic ApplicationspandiNo ratings yet

- Oleo Buffer Stop Fixed HydraulicDocument2 pagesOleo Buffer Stop Fixed HydraulicShahryarNo ratings yet

- AFG-1038 RetlockClampConnectors Brochure HiResDocument4 pagesAFG-1038 RetlockClampConnectors Brochure HiResMiguel CardosoNo ratings yet

- ADAPT PT 2014 Cracked Version DownloadDocument2 pagesADAPT PT 2014 Cracked Version DownloadSamang Hai100% (4)

- MPX3500Document2 pagesMPX3500Karun KumarNo ratings yet

- GE - Bently Nevada 3300 - 55 Dual Velocity Monitor DatasheetDocument11 pagesGE - Bently Nevada 3300 - 55 Dual Velocity Monitor Datasheetalvaro reisNo ratings yet

- Uni Anchor Plate With Tie Down: Instruction ManualDocument8 pagesUni Anchor Plate With Tie Down: Instruction ManualLUIS GUSTAVO PILCO GARCIANo ratings yet

- Computational Fluid Dynamics: Accurate Performance PredictionDocument3 pagesComputational Fluid Dynamics: Accurate Performance PredictionPhilippe LAVOISIERNo ratings yet

- M39n Frame and Underbody PDFDocument6 pagesM39n Frame and Underbody PDFNenad MisicNo ratings yet

- Wabco Valves-Brake SystemDocument76 pagesWabco Valves-Brake Systemabdulrahman elsaied100% (1)

- 8000 Falling Weight Deflectometer (FWD) - WebDocument2 pages8000 Falling Weight Deflectometer (FWD) - WebCarlos Guillermo Somoza AlvarengaNo ratings yet

- 8081 Heavy Weight Deflectometer (HWD) - A4 - WebDocument2 pages8081 Heavy Weight Deflectometer (HWD) - A4 - WebCarlos Augusto Sánchez RondónNo ratings yet

- TFP260 05 2022Document4 pagesTFP260 05 2022antonio tafollaNo ratings yet

- DUCO Stab PlateDocument4 pagesDUCO Stab PlateProcurement PardisanNo ratings yet

- Accepted Safety Barriers V1Document19 pagesAccepted Safety Barriers V1Henry TuganoNo ratings yet

- STRUCTURE 2011-09 September (Concrete)Document52 pagesSTRUCTURE 2011-09 September (Concrete)symon ellimacNo ratings yet

- CGC Shaft Wall Systems SA-926: CGC Interior Panel & Finishing SolutionsDocument44 pagesCGC Shaft Wall Systems SA-926: CGC Interior Panel & Finishing SolutionsIranga RatnayakeNo ratings yet

- Fall Protection Rule (OR-OSHA) Changes in Oregon: Competent PersonsDocument11 pagesFall Protection Rule (OR-OSHA) Changes in Oregon: Competent PersonsEtibar AliyevNo ratings yet

- Lisega - 1 - Constant Hangers PDFDocument27 pagesLisega - 1 - Constant Hangers PDFMiguelNo ratings yet

- Alimak Super Scando FC Manual Elevator Cable PDFDocument71 pagesAlimak Super Scando FC Manual Elevator Cable PDFBoruida MachineryNo ratings yet

- Fall Arrest Anchor Devices Type and Class EN795Document4 pagesFall Arrest Anchor Devices Type and Class EN795roshanNo ratings yet

- EPX1250Document2 pagesEPX1250adventius S.SNo ratings yet

- Tower Structural Engineering: Technical PaperDocument5 pagesTower Structural Engineering: Technical PapertriboniNo ratings yet

- AtlasDocument44 pagesAtlasmpedraza-1No ratings yet

- Luminaria Emergencia PluraluceDocument2 pagesLuminaria Emergencia PluraluceChristian Llerena CayetanoNo ratings yet

- AS Interface - 2005 2006Document356 pagesAS Interface - 2005 2006Zulfiqar ZaidiNo ratings yet

- Alimak APF ManualDocument153 pagesAlimak APF Manualإيليس غابرييل كاديناس شيا100% (1)

- Catálogo Interruptor Siemens GMI PDFDocument20 pagesCatálogo Interruptor Siemens GMI PDFhesse21No ratings yet

- JHET Fan CoilDocument14 pagesJHET Fan CoilCharlie MartinezNo ratings yet

- ALIMAK-Scando 650 Tech Desc 9104228-107 USDocument117 pagesALIMAK-Scando 650 Tech Desc 9104228-107 USramtsanNo ratings yet

- (Brief Report) : Abaqus Fe-SafeDocument3 pages(Brief Report) : Abaqus Fe-SafeDigantNo ratings yet

- Ashrae 2019Document50 pagesAshrae 2019Poovelan ViswanathanNo ratings yet

- 2009 MAPA Install StructuralSupportsDocument7 pages2009 MAPA Install StructuralSupportslsaishankarNo ratings yet

- Powerflex 523 Adjustable Frequency Ac Drive: Product InformationDocument2 pagesPowerflex 523 Adjustable Frequency Ac Drive: Product Informationelecrical gresikNo ratings yet

- Catálogo de Bombas de Diafragma - ARODocument52 pagesCatálogo de Bombas de Diafragma - AROIvan RodrigoNo ratings yet

- P-50Ia Series: IaisaDocument2 pagesP-50Ia Series: IaisaDenilson MarinhoNo ratings yet

- H-E Parts Flyer Lifting SafetyDocument3 pagesH-E Parts Flyer Lifting SafetyJorge VillalobosNo ratings yet

- M4U-20A Rugged 901D Qualified Rackmount ComputerDocument4 pagesM4U-20A Rugged 901D Qualified Rackmount ComputerDavid LippincottNo ratings yet

- Alimak Scando - 650 - SeriesDocument148 pagesAlimak Scando - 650 - SeriesmoiburNo ratings yet

- Screenranger SaDocument2 pagesScreenranger Saelsieazcuna024No ratings yet

- Curc™: Range of Single Cartridge Mechanical SealsDocument8 pagesCurc™: Range of Single Cartridge Mechanical SealsSulaiman Kadher KNo ratings yet

- Optimum Stress Analysis of Crane Hook With The Help of Finite ElementDocument3 pagesOptimum Stress Analysis of Crane Hook With The Help of Finite ElementGogy100% (1)

- Ace Main Catalogue en 04 2009 PDFDocument164 pagesAce Main Catalogue en 04 2009 PDFKrishna TiruvedulaNo ratings yet

- Product Description RailPipe System With EBA CertificationDocument16 pagesProduct Description RailPipe System With EBA Certificationjpantazis1975No ratings yet

- Schletter Productsheet FlatRoof FlatGrid - Pro ENDocument4 pagesSchletter Productsheet FlatRoof FlatGrid - Pro ENf789sgacanonNo ratings yet

- KeeLine Life Line Technical Manual SGDocument30 pagesKeeLine Life Line Technical Manual SGKho Chin NganNo ratings yet

- Ace KatalogDocument100 pagesAce KatalogMehmetGörkemDemir100% (1)

- TFP140 08 2018Document4 pagesTFP140 08 201817souravNo ratings yet

- DPC BUS BRO S Series BrochureDocument4 pagesDPC BUS BRO S Series Brochurevishnu_victoryNo ratings yet

- NEMO-CPro 0313 ENDocument4 pagesNEMO-CPro 0313 ENrosario medinaNo ratings yet

- Catalog Cuplaje Braflex Eng-Rom 2002Document16 pagesCatalog Cuplaje Braflex Eng-Rom 2002Anonymous 4MwmDaNbNo ratings yet

- Vibration Analysis in Reciprocating Compressors - Vassillaq Kacani, Ernst HuttarDocument8 pagesVibration Analysis in Reciprocating Compressors - Vassillaq Kacani, Ernst HuttarConradodaMatta0% (1)

- VP Groundforce Technical BrochureDocument146 pagesVP Groundforce Technical BrochureAhsan MushtaqNo ratings yet

- ACB - Selection & Discrimination (Apr - Jun 02)Document4 pagesACB - Selection & Discrimination (Apr - Jun 02)santhoshNo ratings yet

- H-E Parts White Paper MP1000 BoddingtonDocument3 pagesH-E Parts White Paper MP1000 BoddingtonJorge VillalobosNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

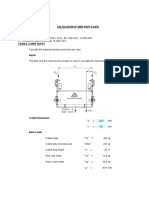

- DLF 2Document2 pagesDLF 2Ranjit S KashyapNo ratings yet

- UB 203x102x23: Cross-Section PropertiesDocument2 pagesUB 203x102x23: Cross-Section PropertiesRanjit S KashyapNo ratings yet

- Holding Down Bolt Design SteetDocument18 pagesHolding Down Bolt Design SteetRanjit S KashyapNo ratings yet

- Warning-Entry Sign Data SheetDocument1 pageWarning-Entry Sign Data SheetRanjit S KashyapNo ratings yet

- Track Calc - Staircase - 152X152X23Document13 pagesTrack Calc - Staircase - 152X152X23Ranjit S KashyapNo ratings yet

- Base Plate Design - SectionDocument6 pagesBase Plate Design - SectionRanjit S KashyapNo ratings yet

- Baby Cage Cradle (Self Powered)Document1 pageBaby Cage Cradle (Self Powered)Ranjit S KashyapNo ratings yet

- ATECH-KLJ-Anchor ReportDocument6 pagesATECH-KLJ-Anchor ReportRanjit S KashyapNo ratings yet

- Davit Trolley - Validation of Davit & Support BracketDocument17 pagesDavit Trolley - Validation of Davit & Support BracketRanjit S KashyapNo ratings yet

- Dw3605 T Abcd Cal Davit 01 Rev.1 Design InputDocument6 pagesDw3605 T Abcd Cal Davit 01 Rev.1 Design InputRanjit S KashyapNo ratings yet

- RF97 R57 DIBE71M4 - BE05A - HR - GM020132.00.3 - 23-ModelDocument1 pageRF97 R57 DIBE71M4 - BE05A - HR - GM020132.00.3 - 23-ModelRanjit S KashyapNo ratings yet

- Building Maintenance Unit - Study Referance Docs For DavitDocument2 pagesBuilding Maintenance Unit - Study Referance Docs For DavitRanjit S KashyapNo ratings yet

- Bmu-Technical Specifications Gind DJ Models BuildingDocument6 pagesBmu-Technical Specifications Gind DJ Models BuildingRanjit S KashyapNo ratings yet

- Greenberry Hotel and Resorts-Monorail SectionDocument1 pageGreenberry Hotel and Resorts-Monorail SectionRanjit S KashyapNo ratings yet

- Ginder-08 (Horizontal Static Line Traveller)Document3 pagesGinder-08 (Horizontal Static Line Traveller)Ranjit S KashyapNo ratings yet

- Design Calculations Steel Wire and CradleDocument2 pagesDesign Calculations Steel Wire and CradleRanjit S KashyapNo ratings yet

- Greenberry Hotel and Resorts-Monorail Track Layout PlanDocument1 pageGreenberry Hotel and Resorts-Monorail Track Layout PlanRanjit S KashyapNo ratings yet

- BUILDING MAINTENANCE UNIT - STUDY REFERANCE DOCS - Manual TrolleyDocument10 pagesBUILDING MAINTENANCE UNIT - STUDY REFERANCE DOCS - Manual TrolleyRanjit S KashyapNo ratings yet

- Advancetech Products Data SheetDocument3 pagesAdvancetech Products Data SheetRanjit S KashyapNo ratings yet

- BUILDING MAINTENANCE UNIT - Davit With WinchDocument1 pageBUILDING MAINTENANCE UNIT - Davit With WinchRanjit S KashyapNo ratings yet

- FrogLine Surface Mounted Lifeline S5 Data SheetDocument1 pageFrogLine Surface Mounted Lifeline S5 Data SheetRanjit S KashyapNo ratings yet

- Building Maintenance Unit - Study Referance DocsDocument34 pagesBuilding Maintenance Unit - Study Referance DocsRanjit S KashyapNo ratings yet

- Coffee Shop Business PlanDocument35 pagesCoffee Shop Business PlanKryon Cloud67% (3)

- Lesson 1 - Traditions and Locations - The Filipino PoemDocument8 pagesLesson 1 - Traditions and Locations - The Filipino Poemdes oro100% (1)

- S3F94xx BatteryCharger An REV000 060109-0Document40 pagesS3F94xx BatteryCharger An REV000 060109-0Jack ChanNo ratings yet

- Consequences of Stress: Kushaal Saraf Luv Kumar Jain Shivank Kedia Himashu RawtaniDocument21 pagesConsequences of Stress: Kushaal Saraf Luv Kumar Jain Shivank Kedia Himashu RawtaniSaraf KushalNo ratings yet

- Indirani College of Nursing: Level of Student - B.SC (N) Ii Yrs TractionDocument7 pagesIndirani College of Nursing: Level of Student - B.SC (N) Ii Yrs TractiondhanasundariNo ratings yet

- Phi Theta Kappa Sued by HonorSociety - Org Lawsuit Details 2024 False AdvertisingDocument47 pagesPhi Theta Kappa Sued by HonorSociety - Org Lawsuit Details 2024 False AdvertisinghonorsocietyorgNo ratings yet

- Sooceal ProjectDocument40 pagesSooceal ProjectSushil ShresthaNo ratings yet

- Tyrant's Grasp - 06 - Midwives To Death - Interactive MapsDocument5 pagesTyrant's Grasp - 06 - Midwives To Death - Interactive MapsRémi RNo ratings yet

- Qualitative Research NotesDocument8 pagesQualitative Research NotesAnanta SinhaNo ratings yet

- Psycosocial Activities Day 3Document40 pagesPsycosocial Activities Day 3John Briane CapiliNo ratings yet

- Journaling PDFDocument1 pageJournaling PDFMargarita Maria Botero PerezNo ratings yet

- Porter's Five Forces Model of Competition-1Document14 pagesPorter's Five Forces Model of Competition-1Kanika RustagiNo ratings yet

- Nmindrf 1Document6 pagesNmindrf 1Rama ChandranNo ratings yet

- Formulas To Know For Exam PDocument4 pagesFormulas To Know For Exam Pkevin.nguyen268998No ratings yet

- Spotter - S Guide To Plastic Pollution Trawls PDFDocument2 pagesSpotter - S Guide To Plastic Pollution Trawls PDFwilly paceteNo ratings yet

- L - Logistic and Exponential Graphs WorksheetDocument2 pagesL - Logistic and Exponential Graphs WorksheetHexagon LyricsNo ratings yet

- Effective Written CommunicationDocument3 pagesEffective Written CommunicationSudeb SarkarNo ratings yet

- S Geo ProDocument22 pagesS Geo ProMathews SikasoteNo ratings yet

- Jeetendra Sharma ResumeDocument6 pagesJeetendra Sharma Resumer_awadhiyaNo ratings yet

- Week 5 Spain & The ReconquistaDocument6 pagesWeek 5 Spain & The ReconquistaABigRedMonsterNo ratings yet

- Mechanical Waves Class 11 JEE Handwritten NotesDocument66 pagesMechanical Waves Class 11 JEE Handwritten Notessmeet mehtaNo ratings yet

- Media Converter Datasheet: HighlightsDocument2 pagesMedia Converter Datasheet: HighlightsJames JamesNo ratings yet

- New TIP Course 1 DepEd Teacher PDFDocument89 pagesNew TIP Course 1 DepEd Teacher PDFLenie TejadaNo ratings yet

- Manual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Document338 pagesManual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Joel Carvajal ArayaNo ratings yet

- Cara Membaca Analisis Gas Darah Arteri (AGDA)Document27 pagesCara Membaca Analisis Gas Darah Arteri (AGDA)Martin Susanto, MD67% (3)

Life Line System

Life Line System

Uploaded by

Ranjit S KashyapCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Life Line System

Life Line System

Uploaded by

Ranjit S KashyapCopyright:

Available Formats

TRAVSPRING® ref.

: T-4666

permanent single-cable revision: 4

technical sheet horizontal lifeline system date: 03/2018

The travspring®is a horizontal lifeline system that is easy to install and can allow up to five users. These systems can be permanent

or temporary and no special training or tools are required to install.

It comes with a visual tension indicator and a new in-line energy absorber. This in-line energy absorber look like a big spring hence

the name travspring®. This is a proximity horizontal lifeline system meaning that you must manipulate your lanyard when traversing

through anchor points.

As with all fall protection systems, a professional engineer or a qualified person must certify the design and installation of them.

These systems can be mounted on the wall or on ground. They must not be used as an overhead system.

When a fall occurs, the energy absorber deploys or un-winds acting as the visual indicator that something has happened.

BENEFITS APPLICABLE STANDARDS

The travspring® system can be permanently or temporarily OSHA 1910, subpart D: Walking and working surfaces

installed. The system can be portable. OSHA 1926, subpart M: Fall protection

The system length is unlimited and it can go around corners ANSI Z359.6-2016: Specifications and design

Maximum spacing between anchor points is 50 ft. (15 m) requirements for active fall protection systems

Up to five users on one system ANSI A10.32-2012: Personal fall protection used in

Easy to install with common tools construction and demolition operations

CSA Z259.13-04 (2009): Flexible horizontal lifeline system

FEATURES CSA Z259.16-04 (2009): Design of active fall protection

Can be used for fall arrest or fall restraint systems

Components are stainless steel and non corrosive materials

with the option of ordering galvanized wire rope WARNING

Lightweight components

When using a horizontal lifeline as a fall arrest system, you

Comes with a tension indicator and tensioner

must ensure that there is enough space below the walking/

Sold in component parts

working surface to fall and not hit anything. Tractel® Ltd.

Visual impact indicator (energy absorber un-winds)

can supply you with system deflection if you contact us.

Inexpensive connectors required

When used as a permanent installation the travspring®

Cooper aluminum anchors prevent fusing of the wire rope

horizontal lifeline system is an engineered designed

No need of dismantle the entire system in the event of a

system. This means that before any installation

fall. Individual components can be replaced commences, a specific technical study of the site must be

undertaken. This would include a shop drawing showing

APPLICATIONS

the system layout, general notes, connection details and

Construction sites

expected loading. These shop drawings are to be reviewed

Steel erection

by a professional engineer licensed to work in the state or

Pipe racks

province that the project is in. A site study may be required

Concrete structures

if drawings are not available to use when preparing these

Roof work

shop drawing. The shop drawings will also show the total

Manufacturing plants

fall height required if the system is designed for fall arrest.

Tractel® Ltd. or the Tractel® Ltd. computer loading program

COMPATIBLE PERSONAL FALL PROTECTION

will determine system loading. (Tractel® also recommends

EQUIPMENT ALSO REQUIRED

that similar steps be taken for temporary installations.)

Full-body harness

Shock-absorbing lanyard or self-retracting device

www.tractel.com Page 1/7

TRAVSPRING® ref.: T-4666

permanent single-cable revision: 4

technical sheet horizontal lifeline system date: 03/2018

TRAVSPRING® COMPONENTS

PLAN VIEW

H

B

A B C D E F G

J A

B

H

WALL APPLICATION

A B C D E F G K H I K H K A

J B L

K

B B H G K I

O K

E F H B

D J

C

L

M

M

B B

B N

N

N

N

N

POST APPLICATION

A. End anchor F. Wedge socket K. O-ring

B. Connector G. Wire rope cable L. End plate

C. Turnbuckle tensioner H. Corner kit M. Corner plate

D. Tension indicator I. Intermediate anchor N. Post

E. INRS energy absorber J. Wire rope clip O. Information plate

www.tractel.com Page 2/7

TRAVSPRING® ref.: T-4666

permanent single-cable revision: 4

technical sheet horizontal lifeline system date: 03/2018

END ANCHOR – J3666848

The end anchors are designed to be attached to the supporting structure with

two bolts (specifications to be set by prior study) through the holes shown on

the adjoining drawing.

Material: Stainless steel – 304L

Size: 6.7 x 4 x 3.3 in. (170 x 104 x 84 mm)

Minimum breaking strength: 6,744 lbs. (30 kN) End anchor

Centre distance: 5.1 in. (130 mm)

Net weight: 1.2 lbs. (544 g)

TURNBUCKLE TENSIONER – J3640742

The tensioner enables adjustment of the wire rope tension to the required value.

Material: Stainless steel – 316L

Minimum breaking strength: 6,744 lbs. (30 kN)

Extends from 10 to 16 in. (270 to 400 mm)

Net weight: 1.3 lbs. (580 g)

Turnbuckle tensioner

TENSION INDICATOR – J3666858

The tension indicator enables to check that the wire rope pre-tension is at 224 lbs.

(100 daN) by simply aligning a hole and a notch. Correct wire rope tension ensures

correct operation of all the system components in the event of a fall.

Material: Stainless steel – 316L

Size: 5.7 x 2 in. (144 x 50 mm)

Minimum breaking strength: 6,744 lbs. (30 kN)

Net weight: 2 lbs. (900 g) Tension indicator

INRS ENERGY ABSORBER – J3666688

The INRS energy absorber is designed to dissipate the energy transmitted

to the supporting structure by the fall of a user connected to the system. Quick-link

It is disposable (used once). It does not negate the necessity of equipping connector

every user with personal fall arrest equipment. Each INRS energy absorber is

supplied with a quick-link connector.

Material: Stainless steel – 304L

Size: 7.5 x 4.3 in. (190 x 110 mm)

Minimum breaking strength: 6,744 lbs. (30 kN)

Net weight: 0.9 lbs. (400 g)

Quick-link connector: Stainless steel – 316L

Shock absorber

See performance certificate

Maximum arrest force: 600 daN (1,350 lbs.)

Average dynamic pull out: 500 daN (1,124 lbs.)

Maximum deployment: 905 mm (35.63 in.)

www.tractel.com Page 3/7

TRAVSPRING® ref.: T-4666

permanent single-cable revision: 4

technical sheet horizontal lifeline system date: 03/2018

INTERMEDIATE ANCHOR – J3666868

With its unique design, the travspring® intermediate anchor enables each user to

cross over throughout the intermediate anchors using O-rings supplied with the

system in which the PPE is connected without having to unhook from the lifeline.

The intermediate anchors must be set up so that the maximum interval between

anchors should never exceed 50 ft. (15 m).

Material: copper-aluminum

Size: 2.3 x 3 x 3 in. (60 x 80 x 80 mm)

Minimum breaking strength: 3,697 lbs. (12 kN)

Net weight: 1.2 lbs. (544 g) Intermediate anchor

INFORMATION PLATE – JNP1

Comes with a mounting bolt hole for a 1⁄2 in. (12 mm) fastener.

Size: 71⁄2 x 81⁄2 in. (190 x 216 mm)

WIRE ROPE

GALVANIZED STEEL – J37009000 Information plate

STAINLESS STEEL – J37009000S

This makes up the retaining cable, which is sleeved, looped and fitted with a

thimble at one end. The other end is brazed and ground smooth in the factory.

It is available in stainless steel or galvanized.

5⁄16 in. (8 mm) diameter

Wire rope

cable

WEDGE SOCKET – J30193837

The wedge socket is formed by five (5) parts:

1. A casing

2. A wedge

3. A securing pin

4. Two (2) split rings to lock the securing pin on the casing

The wedge socket is used to secure the free end of the wire rope to the energy

absorber.

Material: copper-aluminum/aluminium and stainless steel

Minimum breaking strength: 6,744 lbs. (30 kN) when used with Tractel® Wedge socket

specified wire rope

Net weight: 0.9 lb. (430 g)

www.tractel.com Page 4/7

TRAVSPRING® ref.: T-4666

permanent single-cable revision: 4

technical sheet horizontal lifeline system date: 03/2018

CORNER KIT – J3666878

This sub-assembly is only used when the system has corners with a standard

angle of 90°. Each corner kit acts as an intermediate anchor*. The kits are

supplied for assembly by the installer only on internal or external 90° corners.

Corner kits are formed by two parts: Corner kit

1. Two corner anchors

2. Corner tube

Material: copper-aluminum and stainless steel

Net weight: 2.8 lbs. (1.27 g)

*A two-arm lanyard must be used to travel along the corners.

ANCHOR POST

Anchor posts are designed to be installed on a concrete or metal support. The cap

plate allows to fix directly the end anchors, the intermediates and corner plates.

Material: Galvanized steel

Breaking strength: up to 5,000 lbs. (22.2 kN)

Size: 12, 18 or 24 in. x ø4 in. (305, 457 or 610 mm x ø102 mm)

Shear resistance: >6,744 lbs. (>30 kN)

Net weight: from 13 lbs. (5.9 kg)

Anchor post

* Base plate configuration is up to/depends on fixing requirements and installation

conditions.

END PLATE – J366698

Comes with two holes for 1⁄2 in. (12 mm) fasteners. Supplied with a quick-link

connector.

Material: Stainless steel – 316L

Size: 4 x 1.2 x 0.2 in. (100 x 30 x 4 mm)

Centre distance: 2.6 in. (65 mm)

Net weight: 1.3 lbs. (580 g)

End plate

CORNER PLATE – J300266998

The corner plate is used to suit the corner anchor assembly which will be on a

regular anchor post for angles from 75 to 105° using the oblong holes in the

plate.

Each corner plate includes:

1. One plate

2. Two HM12 x 45 mm (1⁄2 x 13⁄4 in.) bolts

3. Four washers M12 Corner plate

4. Two locknuts

Material: Galvanized and stainless steel – 316L

Size: 2 x 11 in. (50 x 342 mm)

Net weight: 3.8 lbs. (1,705 kg)

www.tractel.com Page 5/7

TRAVSPRING® ref.: T-4666

permanent single-cable revision: 4

technical sheet horizontal lifeline system date: 03/2018

CARABINER – PM11Z

The carabiner is used only to connect the user’s lanyard to the Travsmart

traveler.

Material: Alloy steel

Opening: 3⁄4 in. (19 mm) opening

Size: 4.2 x 2.4 in. (107 x 60 mm)

Net weight: 0.4 lbs. (202 g) Carabiner

PULLEY – J300268478

A pulley replaces a corner kit when in a post system, an angle is different

to 90°. A pulley is able to direct the cable with angles from 0° to 160°.

Material: Stainless steel and copper-aluminum/aluminium

Net weight: 2.1 lbs. (953 g)

Pulley

O-RING – 47700

The O-ring is designed to connect a lanyard to the system which works as a

traveler found permanentely in the wire rope intervals which number depends

on the number of users.

Material: Alloy steel

Size: 37⁄8 in. (98 mm)

Net weight: 0.35 lbs. (159 g)

O-ring

www.tractel.com Page 6/7

TRAVSPRING® ref.: T-4666

permanent single-cable revision: 4

technical sheet horizontal lifeline system date: 03/2018

SYSTEM LOADING AND DEFLECTION

If you design, install and use this system according to the manual, the maximum force on any end and intermediate anchor will

not be greater than 2,922 lbs. (13 kN). The maximum force on corner anchors will not be greater than 3,147 lbs. (14 kN). Contact

Tractel® for system deflection and site-specific loading.

HOW THE CONNECTOR NAVIGATES THROUGH INTERMEDIATE ANCHORS

Specifications are subject to change without notice. Images are for illustrative purposes only.

www.tractel.com Page 7/7

You might also like

- Installation Reference, DPI Transom ShieldDocument2 pagesInstallation Reference, DPI Transom ShieldSON100% (1)

- CS101 Current Mid-Term Solved Papers 2022 BY M ZAMANDocument44 pagesCS101 Current Mid-Term Solved Papers 2022 BY M ZAMANNabil AhmedNo ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- CH 10Document30 pagesCH 10Narendran KumaravelNo ratings yet

- College Pretest PE 1Document7 pagesCollege Pretest PE 1Jelyn Racel Agundo ElmedulanNo ratings yet

- Lesson Plan 3 2D Shape With ReflectionDocument7 pagesLesson Plan 3 2D Shape With ReflectionfatimaNo ratings yet

- MINI Cooper Service Manual: 2002-2006 - Table of ContentsDocument2 pagesMINI Cooper Service Manual: 2002-2006 - Table of ContentsBentley Publishers40% (5)

- Berchtesgaden 2001 16 Eur Use Conf Paper - 61aDocument14 pagesBerchtesgaden 2001 16 Eur Use Conf Paper - 61aengineeringmteNo ratings yet

- Tyco TY5522 TFP250 - 08 - 2022Document5 pagesTyco TY5522 TFP250 - 08 - 2022First LAstNo ratings yet

- Installation Guidelines For Users of Outdoor Magnum DS Low-Voltage Switchgear Assemblies For Seismic ApplicationsDocument2 pagesInstallation Guidelines For Users of Outdoor Magnum DS Low-Voltage Switchgear Assemblies For Seismic ApplicationspandiNo ratings yet

- Oleo Buffer Stop Fixed HydraulicDocument2 pagesOleo Buffer Stop Fixed HydraulicShahryarNo ratings yet

- AFG-1038 RetlockClampConnectors Brochure HiResDocument4 pagesAFG-1038 RetlockClampConnectors Brochure HiResMiguel CardosoNo ratings yet

- ADAPT PT 2014 Cracked Version DownloadDocument2 pagesADAPT PT 2014 Cracked Version DownloadSamang Hai100% (4)

- MPX3500Document2 pagesMPX3500Karun KumarNo ratings yet

- GE - Bently Nevada 3300 - 55 Dual Velocity Monitor DatasheetDocument11 pagesGE - Bently Nevada 3300 - 55 Dual Velocity Monitor Datasheetalvaro reisNo ratings yet

- Uni Anchor Plate With Tie Down: Instruction ManualDocument8 pagesUni Anchor Plate With Tie Down: Instruction ManualLUIS GUSTAVO PILCO GARCIANo ratings yet

- Computational Fluid Dynamics: Accurate Performance PredictionDocument3 pagesComputational Fluid Dynamics: Accurate Performance PredictionPhilippe LAVOISIERNo ratings yet

- M39n Frame and Underbody PDFDocument6 pagesM39n Frame and Underbody PDFNenad MisicNo ratings yet

- Wabco Valves-Brake SystemDocument76 pagesWabco Valves-Brake Systemabdulrahman elsaied100% (1)

- 8000 Falling Weight Deflectometer (FWD) - WebDocument2 pages8000 Falling Weight Deflectometer (FWD) - WebCarlos Guillermo Somoza AlvarengaNo ratings yet

- 8081 Heavy Weight Deflectometer (HWD) - A4 - WebDocument2 pages8081 Heavy Weight Deflectometer (HWD) - A4 - WebCarlos Augusto Sánchez RondónNo ratings yet

- TFP260 05 2022Document4 pagesTFP260 05 2022antonio tafollaNo ratings yet

- DUCO Stab PlateDocument4 pagesDUCO Stab PlateProcurement PardisanNo ratings yet

- Accepted Safety Barriers V1Document19 pagesAccepted Safety Barriers V1Henry TuganoNo ratings yet

- STRUCTURE 2011-09 September (Concrete)Document52 pagesSTRUCTURE 2011-09 September (Concrete)symon ellimacNo ratings yet

- CGC Shaft Wall Systems SA-926: CGC Interior Panel & Finishing SolutionsDocument44 pagesCGC Shaft Wall Systems SA-926: CGC Interior Panel & Finishing SolutionsIranga RatnayakeNo ratings yet

- Fall Protection Rule (OR-OSHA) Changes in Oregon: Competent PersonsDocument11 pagesFall Protection Rule (OR-OSHA) Changes in Oregon: Competent PersonsEtibar AliyevNo ratings yet

- Lisega - 1 - Constant Hangers PDFDocument27 pagesLisega - 1 - Constant Hangers PDFMiguelNo ratings yet

- Alimak Super Scando FC Manual Elevator Cable PDFDocument71 pagesAlimak Super Scando FC Manual Elevator Cable PDFBoruida MachineryNo ratings yet

- Fall Arrest Anchor Devices Type and Class EN795Document4 pagesFall Arrest Anchor Devices Type and Class EN795roshanNo ratings yet

- EPX1250Document2 pagesEPX1250adventius S.SNo ratings yet

- Tower Structural Engineering: Technical PaperDocument5 pagesTower Structural Engineering: Technical PapertriboniNo ratings yet

- AtlasDocument44 pagesAtlasmpedraza-1No ratings yet

- Luminaria Emergencia PluraluceDocument2 pagesLuminaria Emergencia PluraluceChristian Llerena CayetanoNo ratings yet

- AS Interface - 2005 2006Document356 pagesAS Interface - 2005 2006Zulfiqar ZaidiNo ratings yet

- Alimak APF ManualDocument153 pagesAlimak APF Manualإيليس غابرييل كاديناس شيا100% (1)

- Catálogo Interruptor Siemens GMI PDFDocument20 pagesCatálogo Interruptor Siemens GMI PDFhesse21No ratings yet

- JHET Fan CoilDocument14 pagesJHET Fan CoilCharlie MartinezNo ratings yet

- ALIMAK-Scando 650 Tech Desc 9104228-107 USDocument117 pagesALIMAK-Scando 650 Tech Desc 9104228-107 USramtsanNo ratings yet

- (Brief Report) : Abaqus Fe-SafeDocument3 pages(Brief Report) : Abaqus Fe-SafeDigantNo ratings yet

- Ashrae 2019Document50 pagesAshrae 2019Poovelan ViswanathanNo ratings yet

- 2009 MAPA Install StructuralSupportsDocument7 pages2009 MAPA Install StructuralSupportslsaishankarNo ratings yet

- Powerflex 523 Adjustable Frequency Ac Drive: Product InformationDocument2 pagesPowerflex 523 Adjustable Frequency Ac Drive: Product Informationelecrical gresikNo ratings yet

- Catálogo de Bombas de Diafragma - ARODocument52 pagesCatálogo de Bombas de Diafragma - AROIvan RodrigoNo ratings yet

- P-50Ia Series: IaisaDocument2 pagesP-50Ia Series: IaisaDenilson MarinhoNo ratings yet

- H-E Parts Flyer Lifting SafetyDocument3 pagesH-E Parts Flyer Lifting SafetyJorge VillalobosNo ratings yet

- M4U-20A Rugged 901D Qualified Rackmount ComputerDocument4 pagesM4U-20A Rugged 901D Qualified Rackmount ComputerDavid LippincottNo ratings yet

- Alimak Scando - 650 - SeriesDocument148 pagesAlimak Scando - 650 - SeriesmoiburNo ratings yet

- Screenranger SaDocument2 pagesScreenranger Saelsieazcuna024No ratings yet

- Curc™: Range of Single Cartridge Mechanical SealsDocument8 pagesCurc™: Range of Single Cartridge Mechanical SealsSulaiman Kadher KNo ratings yet

- Optimum Stress Analysis of Crane Hook With The Help of Finite ElementDocument3 pagesOptimum Stress Analysis of Crane Hook With The Help of Finite ElementGogy100% (1)

- Ace Main Catalogue en 04 2009 PDFDocument164 pagesAce Main Catalogue en 04 2009 PDFKrishna TiruvedulaNo ratings yet

- Product Description RailPipe System With EBA CertificationDocument16 pagesProduct Description RailPipe System With EBA Certificationjpantazis1975No ratings yet

- Schletter Productsheet FlatRoof FlatGrid - Pro ENDocument4 pagesSchletter Productsheet FlatRoof FlatGrid - Pro ENf789sgacanonNo ratings yet

- KeeLine Life Line Technical Manual SGDocument30 pagesKeeLine Life Line Technical Manual SGKho Chin NganNo ratings yet

- Ace KatalogDocument100 pagesAce KatalogMehmetGörkemDemir100% (1)

- TFP140 08 2018Document4 pagesTFP140 08 201817souravNo ratings yet

- DPC BUS BRO S Series BrochureDocument4 pagesDPC BUS BRO S Series Brochurevishnu_victoryNo ratings yet

- NEMO-CPro 0313 ENDocument4 pagesNEMO-CPro 0313 ENrosario medinaNo ratings yet

- Catalog Cuplaje Braflex Eng-Rom 2002Document16 pagesCatalog Cuplaje Braflex Eng-Rom 2002Anonymous 4MwmDaNbNo ratings yet

- Vibration Analysis in Reciprocating Compressors - Vassillaq Kacani, Ernst HuttarDocument8 pagesVibration Analysis in Reciprocating Compressors - Vassillaq Kacani, Ernst HuttarConradodaMatta0% (1)

- VP Groundforce Technical BrochureDocument146 pagesVP Groundforce Technical BrochureAhsan MushtaqNo ratings yet

- ACB - Selection & Discrimination (Apr - Jun 02)Document4 pagesACB - Selection & Discrimination (Apr - Jun 02)santhoshNo ratings yet

- H-E Parts White Paper MP1000 BoddingtonDocument3 pagesH-E Parts White Paper MP1000 BoddingtonJorge VillalobosNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- DLF 2Document2 pagesDLF 2Ranjit S KashyapNo ratings yet

- UB 203x102x23: Cross-Section PropertiesDocument2 pagesUB 203x102x23: Cross-Section PropertiesRanjit S KashyapNo ratings yet

- Holding Down Bolt Design SteetDocument18 pagesHolding Down Bolt Design SteetRanjit S KashyapNo ratings yet

- Warning-Entry Sign Data SheetDocument1 pageWarning-Entry Sign Data SheetRanjit S KashyapNo ratings yet

- Track Calc - Staircase - 152X152X23Document13 pagesTrack Calc - Staircase - 152X152X23Ranjit S KashyapNo ratings yet

- Base Plate Design - SectionDocument6 pagesBase Plate Design - SectionRanjit S KashyapNo ratings yet

- Baby Cage Cradle (Self Powered)Document1 pageBaby Cage Cradle (Self Powered)Ranjit S KashyapNo ratings yet

- ATECH-KLJ-Anchor ReportDocument6 pagesATECH-KLJ-Anchor ReportRanjit S KashyapNo ratings yet

- Davit Trolley - Validation of Davit & Support BracketDocument17 pagesDavit Trolley - Validation of Davit & Support BracketRanjit S KashyapNo ratings yet

- Dw3605 T Abcd Cal Davit 01 Rev.1 Design InputDocument6 pagesDw3605 T Abcd Cal Davit 01 Rev.1 Design InputRanjit S KashyapNo ratings yet

- RF97 R57 DIBE71M4 - BE05A - HR - GM020132.00.3 - 23-ModelDocument1 pageRF97 R57 DIBE71M4 - BE05A - HR - GM020132.00.3 - 23-ModelRanjit S KashyapNo ratings yet

- Building Maintenance Unit - Study Referance Docs For DavitDocument2 pagesBuilding Maintenance Unit - Study Referance Docs For DavitRanjit S KashyapNo ratings yet

- Bmu-Technical Specifications Gind DJ Models BuildingDocument6 pagesBmu-Technical Specifications Gind DJ Models BuildingRanjit S KashyapNo ratings yet

- Greenberry Hotel and Resorts-Monorail SectionDocument1 pageGreenberry Hotel and Resorts-Monorail SectionRanjit S KashyapNo ratings yet

- Ginder-08 (Horizontal Static Line Traveller)Document3 pagesGinder-08 (Horizontal Static Line Traveller)Ranjit S KashyapNo ratings yet

- Design Calculations Steel Wire and CradleDocument2 pagesDesign Calculations Steel Wire and CradleRanjit S KashyapNo ratings yet

- Greenberry Hotel and Resorts-Monorail Track Layout PlanDocument1 pageGreenberry Hotel and Resorts-Monorail Track Layout PlanRanjit S KashyapNo ratings yet

- BUILDING MAINTENANCE UNIT - STUDY REFERANCE DOCS - Manual TrolleyDocument10 pagesBUILDING MAINTENANCE UNIT - STUDY REFERANCE DOCS - Manual TrolleyRanjit S KashyapNo ratings yet

- Advancetech Products Data SheetDocument3 pagesAdvancetech Products Data SheetRanjit S KashyapNo ratings yet

- BUILDING MAINTENANCE UNIT - Davit With WinchDocument1 pageBUILDING MAINTENANCE UNIT - Davit With WinchRanjit S KashyapNo ratings yet

- FrogLine Surface Mounted Lifeline S5 Data SheetDocument1 pageFrogLine Surface Mounted Lifeline S5 Data SheetRanjit S KashyapNo ratings yet

- Building Maintenance Unit - Study Referance DocsDocument34 pagesBuilding Maintenance Unit - Study Referance DocsRanjit S KashyapNo ratings yet

- Coffee Shop Business PlanDocument35 pagesCoffee Shop Business PlanKryon Cloud67% (3)

- Lesson 1 - Traditions and Locations - The Filipino PoemDocument8 pagesLesson 1 - Traditions and Locations - The Filipino Poemdes oro100% (1)

- S3F94xx BatteryCharger An REV000 060109-0Document40 pagesS3F94xx BatteryCharger An REV000 060109-0Jack ChanNo ratings yet

- Consequences of Stress: Kushaal Saraf Luv Kumar Jain Shivank Kedia Himashu RawtaniDocument21 pagesConsequences of Stress: Kushaal Saraf Luv Kumar Jain Shivank Kedia Himashu RawtaniSaraf KushalNo ratings yet

- Indirani College of Nursing: Level of Student - B.SC (N) Ii Yrs TractionDocument7 pagesIndirani College of Nursing: Level of Student - B.SC (N) Ii Yrs TractiondhanasundariNo ratings yet

- Phi Theta Kappa Sued by HonorSociety - Org Lawsuit Details 2024 False AdvertisingDocument47 pagesPhi Theta Kappa Sued by HonorSociety - Org Lawsuit Details 2024 False AdvertisinghonorsocietyorgNo ratings yet

- Sooceal ProjectDocument40 pagesSooceal ProjectSushil ShresthaNo ratings yet

- Tyrant's Grasp - 06 - Midwives To Death - Interactive MapsDocument5 pagesTyrant's Grasp - 06 - Midwives To Death - Interactive MapsRémi RNo ratings yet

- Qualitative Research NotesDocument8 pagesQualitative Research NotesAnanta SinhaNo ratings yet

- Psycosocial Activities Day 3Document40 pagesPsycosocial Activities Day 3John Briane CapiliNo ratings yet

- Journaling PDFDocument1 pageJournaling PDFMargarita Maria Botero PerezNo ratings yet

- Porter's Five Forces Model of Competition-1Document14 pagesPorter's Five Forces Model of Competition-1Kanika RustagiNo ratings yet

- Nmindrf 1Document6 pagesNmindrf 1Rama ChandranNo ratings yet

- Formulas To Know For Exam PDocument4 pagesFormulas To Know For Exam Pkevin.nguyen268998No ratings yet

- Spotter - S Guide To Plastic Pollution Trawls PDFDocument2 pagesSpotter - S Guide To Plastic Pollution Trawls PDFwilly paceteNo ratings yet

- L - Logistic and Exponential Graphs WorksheetDocument2 pagesL - Logistic and Exponential Graphs WorksheetHexagon LyricsNo ratings yet

- Effective Written CommunicationDocument3 pagesEffective Written CommunicationSudeb SarkarNo ratings yet

- S Geo ProDocument22 pagesS Geo ProMathews SikasoteNo ratings yet

- Jeetendra Sharma ResumeDocument6 pagesJeetendra Sharma Resumer_awadhiyaNo ratings yet

- Week 5 Spain & The ReconquistaDocument6 pagesWeek 5 Spain & The ReconquistaABigRedMonsterNo ratings yet

- Mechanical Waves Class 11 JEE Handwritten NotesDocument66 pagesMechanical Waves Class 11 JEE Handwritten Notessmeet mehtaNo ratings yet

- Media Converter Datasheet: HighlightsDocument2 pagesMedia Converter Datasheet: HighlightsJames JamesNo ratings yet

- New TIP Course 1 DepEd Teacher PDFDocument89 pagesNew TIP Course 1 DepEd Teacher PDFLenie TejadaNo ratings yet

- Manual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Document338 pagesManual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Joel Carvajal ArayaNo ratings yet

- Cara Membaca Analisis Gas Darah Arteri (AGDA)Document27 pagesCara Membaca Analisis Gas Darah Arteri (AGDA)Martin Susanto, MD67% (3)