Professional Documents

Culture Documents

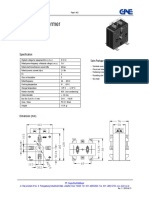

These Pictures Are Only Examples, Don't Use Them To Identify A Gage!

These Pictures Are Only Examples, Don't Use Them To Identify A Gage!

Uploaded by

Boby SaputraCopyright:

Available Formats

You might also like

- Den-Jet Ce20-500 - Master Mariner Manual - Dec 2017Document40 pagesDen-Jet Ce20-500 - Master Mariner Manual - Dec 2017First LastNo ratings yet

- A320 AMM ch11Document636 pagesA320 AMM ch11Larry Bogues0% (1)

- Swabbing With Braided Cable 1Document8 pagesSwabbing With Braided Cable 1Amrani Adel100% (2)

- A459 PDFDocument3 pagesA459 PDFRafael CossolinoNo ratings yet

- Ateq F420Pb - PrinterDocument4 pagesAteq F420Pb - PrinterMartin TomášekNo ratings yet

- Difference Between 0.2 & 0.2S Class Accuracy of CT & PTDocument1 pageDifference Between 0.2 & 0.2S Class Accuracy of CT & PTVikas Gupta100% (4)

- Matrics Printers Guides PrintheadsDocument6 pagesMatrics Printers Guides Printheadszocky74No ratings yet

- Score: General Luna Road, Baguio City Philippines 2600Document3 pagesScore: General Luna Road, Baguio City Philippines 2600kimNo ratings yet

- SES Current TransformerDocument6 pagesSES Current TransformerAmirul FazrinNo ratings yet

- Istek-Current Transformers CtsDocument30 pagesIstek-Current Transformers CtseyadNo ratings yet

- Aggregate Blending To Meet Specifications: Student's NameDocument6 pagesAggregate Blending To Meet Specifications: Student's NameAhmed S. ALhayek100% (1)

- 712 CastIron Flakes ISO-945.pdf ExtDocument1 page712 CastIron Flakes ISO-945.pdf ExtvictorNo ratings yet

- Basecourse TYpe A PT - GmjiDocument4 pagesBasecourse TYpe A PT - Gmjiagung gmjiNo ratings yet

- QC Tool - Control Chart Sieve Agg. 0.150mm 200diaDocument3 pagesQC Tool - Control Chart Sieve Agg. 0.150mm 200diachinhon0% (1)

- Sulfuric AcidDocument22 pagesSulfuric AcidEmmanuelNo ratings yet

- The Effects of B, C and AC Are Large and Significant.: Problem 6.6 A) Calculation of EffectDocument4 pagesThe Effects of B, C and AC Are Large and Significant.: Problem 6.6 A) Calculation of EffectBablu KumarNo ratings yet

- TABLE 2: PT1 Site Calibration Check: D Ma C Ma CDocument2 pagesTABLE 2: PT1 Site Calibration Check: D Ma C Ma Csyahirah shamsudinNo ratings yet

- Assignment #3-3 - Process Defect AnalysisDocument5 pagesAssignment #3-3 - Process Defect AnalysisʆƠƘЄƦ 6No ratings yet

- What's New Version 2.10: Votano 100Document7 pagesWhat's New Version 2.10: Votano 100JRACNo ratings yet

- Standard Sieve Opening Sizes Plot Data (In) (MM) % Passing Sieve Number Size (MM)Document5 pagesStandard Sieve Opening Sizes Plot Data (In) (MM) % Passing Sieve Number Size (MM)sandipNo ratings yet

- Auto CadDocument67 pagesAuto CadkltowerNo ratings yet

- Z-Score Ordinary (Or ModifiedDocument20 pagesZ-Score Ordinary (Or ModifiedLamiaNo ratings yet

- Evidencia FinalDocument7 pagesEvidencia FinalJesus ArellanoNo ratings yet

- Granulometria GravasDocument1 pageGranulometria GravasJose Tomas Castellani LemoineNo ratings yet

- Supplier Evaluation MatrixDocument1 pageSupplier Evaluation MatrixRanda S Jowa0% (1)

- 712 CastIron Flakes ASTM-A247.pdf ExtDocument1 page712 CastIron Flakes ASTM-A247.pdf ExtvictorNo ratings yet

- Selection of CT & PTDocument4 pagesSelection of CT & PTSwagat PradhanNo ratings yet

- Project Training in HmsiDocument38 pagesProject Training in HmsimohitNo ratings yet

- Rakesh Yadav 2017Document13 pagesRakesh Yadav 2017Avaneesh TripathiNo ratings yet

- Pie Chart To Drivers Who Are Distracted: Bar Graph of Distracted DrivingDocument8 pagesPie Chart To Drivers Who Are Distracted: Bar Graph of Distracted DrivingDavid ValenciaNo ratings yet

- Plot A Sieve Chart On ExcelDocument3 pagesPlot A Sieve Chart On ExcelSri RamNo ratings yet

- SAM 22, Section A, Session 7, 24010106Document4 pagesSAM 22, Section A, Session 7, 24010106Tooba ChaudharyNo ratings yet

- GRR Study MSA TemplateDocument20 pagesGRR Study MSA TemplateRuiz ManuelNo ratings yet

- Normal Probability Plot: Regression StatisticsDocument23 pagesNormal Probability Plot: Regression StatisticsShyamsunder SinghNo ratings yet

- GRR Study MSA TemplateDocument20 pagesGRR Study MSA Templateyusuf_jtNo ratings yet

- Sieve Analysis (Base Course Matl)Document2 pagesSieve Analysis (Base Course Matl)KaterzoNo ratings yet

- Six-Sigma and ReliabilityDocument37 pagesSix-Sigma and Reliabilitypanugantisameer468No ratings yet

- Installation and Calibration of Newly Installed X-Ray Machines - Anonas Diagnostic ClinicDocument3 pagesInstallation and Calibration of Newly Installed X-Ray Machines - Anonas Diagnostic ClinicTeresita AlcaideNo ratings yet

- Pelaksanaan Perkerasan: Ukuran Saringan Specification Range JMFDocument10 pagesPelaksanaan Perkerasan: Ukuran Saringan Specification Range JMFYudhirieza88100% (1)

- INFORME Alex PavDocument44 pagesINFORME Alex PavAngel Julisses Valderrama ReyesNo ratings yet

- Kuliah 3Document3 pagesKuliah 3Naufal AzraNo ratings yet

- Major ProjectDocument6 pagesMajor Projectgaurav kishoreNo ratings yet

- Visual Surface Distress Measurements & Rating For Flexible PavementDocument8 pagesVisual Surface Distress Measurements & Rating For Flexible PavementSasanka SekharNo ratings yet

- Combined Gradation of Coarse Aggregate - Astm C33-Size 67-1Document106 pagesCombined Gradation of Coarse Aggregate - Astm C33-Size 67-1Hasan al MahmudNo ratings yet

- GRR Study MSA TemplateDocument20 pagesGRR Study MSA TemplateRicardo VitorianoNo ratings yet

- Result Pressure Measurement (PART 2)Document2 pagesResult Pressure Measurement (PART 2)Noor FatihahNo ratings yet

- Mac Pherson GDSTDocument11 pagesMac Pherson GDSTdeportesaldia2014No ratings yet

- Assignment#1Document2 pagesAssignment#1Deema sultanNo ratings yet

- C) 1-Phase Differential Slope Test Procedure: The Relay Testing HandbookDocument2 pagesC) 1-Phase Differential Slope Test Procedure: The Relay Testing HandbooksameershahzanNo ratings yet

- 拋光等級Document1 page拋光等級ykc3850% (2)

- CT 50 - Window Detail55Document2 pagesCT 50 - Window Detail55sharing driveku1No ratings yet

- Data Sheet CT GAEDocument2 pagesData Sheet CT GAEsharing driveku1No ratings yet

- Current Transformer: CT 50 - WindowDocument2 pagesCurrent Transformer: CT 50 - Windowari firmanNo ratings yet

- UBE Automotive MSA System Bias and Linearity StudiesDocument6 pagesUBE Automotive MSA System Bias and Linearity StudiesNarayanKavitakeNo ratings yet

- DCPTR No. 19P-042 - NONGA X WATER SUPPLY Pipeline Geotech Sites, ENBDocument3 pagesDCPTR No. 19P-042 - NONGA X WATER SUPPLY Pipeline Geotech Sites, ENBNathan JohnNo ratings yet

- FQFQFDocument2 pagesFQFQFBoogi Andika TamamiNo ratings yet

- AA1060 - Aluminum Alloy SheetDocument1 pageAA1060 - Aluminum Alloy SheettljytzNo ratings yet

- Part A - Ferrous Material Specifications: Table 2 Tensile RequirementsDocument1 pagePart A - Ferrous Material Specifications: Table 2 Tensile RequirementsriyyjuniorNo ratings yet

- Pozo A TierraDocument6 pagesPozo A TierraRay BandaNo ratings yet

- WC (Water Content) Totadan Pan (W1) Todan Pan + Material Bokon (W2) Todan Pan + Material Nebe Hatama Ona Formo (W3)Document18 pagesWC (Water Content) Totadan Pan (W1) Todan Pan + Material Bokon (W2) Todan Pan + Material Nebe Hatama Ona Formo (W3)Jerry GilNo ratings yet

- Ipjmbt 434Document2 pagesIpjmbt 434Deepak KumarNo ratings yet

- Catalog TurbineDocument6 pagesCatalog TurbinerezandriansyahNo ratings yet

- Zero Sampling Plan: "B" "C" & Self Certified "A"Document4 pagesZero Sampling Plan: "B" "C" & Self Certified "A"Pradeep AdhikariNo ratings yet

- Autodesk Fusion 360 Black Book (V 2.0.12670) - Part 2: Autodesk Fusion 360 Black Book (V 2.0.12670)From EverandAutodesk Fusion 360 Black Book (V 2.0.12670) - Part 2: Autodesk Fusion 360 Black Book (V 2.0.12670)No ratings yet

- DPPM Reduction %changeDocument3 pagesDPPM Reduction %changeBoby SaputraNo ratings yet

- 8D Process: D0: Prepare For Problem SolvingDocument4 pages8D Process: D0: Prepare For Problem SolvingBoby SaputraNo ratings yet

- Tolerance Analysis-6SigmaDocument22 pagesTolerance Analysis-6SigmaBoby SaputraNo ratings yet

- Mold Fixture & Jig CertificationDocument7 pagesMold Fixture & Jig CertificationBoby SaputraNo ratings yet

- Elsmar Software Build Defect RatesDocument6 pagesElsmar Software Build Defect RatesBoby SaputraNo ratings yet

- Example CP MouldingDocument1 pageExample CP MouldingBoby SaputraNo ratings yet

- Cost of Quality and ROI Form Nick R Rev 012721Document4 pagesCost of Quality and ROI Form Nick R Rev 012721Boby SaputraNo ratings yet

- Pandrol Memphis AAR QAPE ChecklistDocument31 pagesPandrol Memphis AAR QAPE ChecklistBoby SaputraNo ratings yet

- Procedure TemplateDocument3 pagesProcedure TemplateBoby SaputraNo ratings yet

- Must Obtain Approval: 812.35 (A) Changes in Investigational PlanDocument1 pageMust Obtain Approval: 812.35 (A) Changes in Investigational PlanBoby SaputraNo ratings yet

- CYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetBoby SaputraNo ratings yet

- Error Proofing TechniquesDocument140 pagesError Proofing TechniquesBoby SaputraNo ratings yet

- Material Control ProcessDocument9 pagesMaterial Control ProcessBoby SaputraNo ratings yet

- DRY PTFE Spray - GBDocument11 pagesDRY PTFE Spray - GBBoby SaputraNo ratings yet

- The Poka-Yoke System: Is Zero Defects A Reality?Document39 pagesThe Poka-Yoke System: Is Zero Defects A Reality?Boby SaputraNo ratings yet

- Lean Is The Way of Our WorkDocument16 pagesLean Is The Way of Our WorkBoby SaputraNo ratings yet

- DDC p2c3 Ug02 Ugs DR Sot 35101 03 Editing1Document40 pagesDDC p2c3 Ug02 Ugs DR Sot 35101 03 Editing1Devesh GuptaNo ratings yet

- Standard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and ArchesDocument17 pagesStandard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and Archesjun floresNo ratings yet

- Modular Multi-Position Air HandlerDocument16 pagesModular Multi-Position Air Handlerkothat82No ratings yet

- ESEDRA 2010 - CatalogueDocument226 pagesESEDRA 2010 - CatalogueWilliam Dante Mescco SaireNo ratings yet

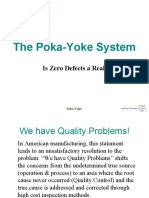

- Design of Baseplate (BP-1) - Without Shear Key - GRID 101 TO 104Document14 pagesDesign of Baseplate (BP-1) - Without Shear Key - GRID 101 TO 104prabhash kumarNo ratings yet

- DIY Miter Saw Station PDFDocument6 pagesDIY Miter Saw Station PDFNana Obiri Yeboa DarkoNo ratings yet

- Objective Question - Unit 1Document7 pagesObjective Question - Unit 1Parthiban PNNo ratings yet

- Surface Vehicle Standard: (R) Hydraulic Hose FittingsDocument34 pagesSurface Vehicle Standard: (R) Hydraulic Hose FittingsLUCIANO SOTONo ratings yet

- Department of Structural Engineering University of California San DiegoDocument6 pagesDepartment of Structural Engineering University of California San DiegomimiNo ratings yet

- Civil Engineering FormulaDocument4 pagesCivil Engineering Formulaanku4frenz100% (1)

- Bomba RL-20B (R) MancalDocument1 pageBomba RL-20B (R) Mancal47x996691523No ratings yet

- Drilling Machine Inspection ChecklistDocument1 pageDrilling Machine Inspection ChecklistKevin MichaelNo ratings yet

- 4 Hours / 70 Marks: Seat NoDocument8 pages4 Hours / 70 Marks: Seat Noadnan_ais123No ratings yet

- Poshs Metal Industries PVT - LTD: SR - No. Inspection Area Remark Required Lux Level (Min) Actual Lux LevelDocument2 pagesPoshs Metal Industries PVT - LTD: SR - No. Inspection Area Remark Required Lux Level (Min) Actual Lux LevelSafety Dept100% (1)

- MAN BASKET Inspection ReportDocument2 pagesMAN BASKET Inspection ReportbasdNo ratings yet

- Specs Conveyors BP 30-06-2022Document26 pagesSpecs Conveyors BP 30-06-2022Juan Jose Jimenez LopezNo ratings yet

- ISO-10664Document10 pagesISO-10664Daniel Quijada LucarioNo ratings yet

- 319 Equipment Installation Course DescriptionDocument2 pages319 Equipment Installation Course DescriptionAnonymous q9eCZHMuSNo ratings yet

- Chapter 9 - Solved ProblemsDocument11 pagesChapter 9 - Solved Problemshanihamoud05No ratings yet

- Centrifugal CompDocument100 pagesCentrifugal CompRiyadh Saleh100% (1)

- 1-Dimensions Are in '' M '' 1 - Elevation Levels Are in '' CM''Document1 page1-Dimensions Are in '' M '' 1 - Elevation Levels Are in '' CM''Nasser SabrNo ratings yet

- Heat Treatment To Anchor BoltsDocument4 pagesHeat Treatment To Anchor BoltsvishalnalwarNo ratings yet

- CTHS430-02 SPC R223.1394-02Document82 pagesCTHS430-02 SPC R223.1394-02Marcos GuardiaNo ratings yet

- AU TG Install GuideDocument5 pagesAU TG Install Guideguillote_666No ratings yet

- Collar BoltsDocument2 pagesCollar BoltsMahdi HocineNo ratings yet

- Fire Extinguisher Inspection Checklist Year - Fire Extinguisher Inspection Checklist YearDocument2 pagesFire Extinguisher Inspection Checklist Year - Fire Extinguisher Inspection Checklist YearteresaNo ratings yet

These Pictures Are Only Examples, Don't Use Them To Identify A Gage!

These Pictures Are Only Examples, Don't Use Them To Identify A Gage!

Uploaded by

Boby SaputraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

These Pictures Are Only Examples, Don't Use Them To Identify A Gage!

These Pictures Are Only Examples, Don't Use Them To Identify A Gage!

Uploaded by

Boby SaputraCopyright:

Available Formats

PRESSURE / VACUUM GAGE IDENTIFICATION

First: Look for a model number. This is important, because you cannot be sure what the accuracy of a gage is by looking at it, it's just a guess.

If you can find a model number, ask a technical person to look it up and find the grade / accuracy of the gage.

If no model or manufacturer is available we can make educated guesses:

If it is called a "Test" gage and is bigger than 4 1/2 inches diameter it is probably a Grade 3A (most gages bigger than 8 inches are Grade 4A)

If it is called a "Process" gage and is bigger than 2 1/2 inches it is probably a Grade 2A

"Industrial" gages are usually Grade 1A or Grade A

The chart below can help identify an unknown pressure or vacuum gage. First, find the range of the gage. Next find the resolution of the

smallest graduations on the dial. Match these to the chart to select the closest match, this is the grade we will use.

If the smallest graduations are larger than those in the chart it is probably a Grade A or Grade B gage. If it looks like a decent quality gage

call it a Grade A. If it is cheap (like one on a pool filter) then call it a Grade B.

Don't worry if you get it wrong - the technician can find out the correct grade and change the paperwork if necessary

These pictures are only examples, don't use them to identify a gage!

Gage Utility Industrial Process Test

Grade A Gage Gage Gage Gage

Grade B 1A 2A 3A

GAGE RANGE 15 30 60 100 160 200 300 400 600 800 1000 1500 2000 3000 5000

GRADE DIAL SIZE GRADUATION SIZE: (minor division)

4A (0.10%) > 8" 0.02 0.05 0.1 0.2 0.2 0.5 0.5 1 1 1 2 2 5 5 10

3A (0.25%) > 4.5" 0.05 0.1 0.2 0.2 0.5 0.5 1 1 2 2 2 5 5 10 10

2A (0.5%) > 2.5 " 0.1 0.2 0.5 1 2 2 2 5 5 10 10 20 20 20 20

1A (1%) > 1.5" 0.2 0.5 1 1 2 2 5 5 or 6 10 10 10 20 20 50 50

A (2-1-2%) ANY

B (3-2-3%) ANY

You might also like

- Den-Jet Ce20-500 - Master Mariner Manual - Dec 2017Document40 pagesDen-Jet Ce20-500 - Master Mariner Manual - Dec 2017First LastNo ratings yet

- A320 AMM ch11Document636 pagesA320 AMM ch11Larry Bogues0% (1)

- Swabbing With Braided Cable 1Document8 pagesSwabbing With Braided Cable 1Amrani Adel100% (2)

- A459 PDFDocument3 pagesA459 PDFRafael CossolinoNo ratings yet

- Ateq F420Pb - PrinterDocument4 pagesAteq F420Pb - PrinterMartin TomášekNo ratings yet

- Difference Between 0.2 & 0.2S Class Accuracy of CT & PTDocument1 pageDifference Between 0.2 & 0.2S Class Accuracy of CT & PTVikas Gupta100% (4)

- Matrics Printers Guides PrintheadsDocument6 pagesMatrics Printers Guides Printheadszocky74No ratings yet

- Score: General Luna Road, Baguio City Philippines 2600Document3 pagesScore: General Luna Road, Baguio City Philippines 2600kimNo ratings yet

- SES Current TransformerDocument6 pagesSES Current TransformerAmirul FazrinNo ratings yet

- Istek-Current Transformers CtsDocument30 pagesIstek-Current Transformers CtseyadNo ratings yet

- Aggregate Blending To Meet Specifications: Student's NameDocument6 pagesAggregate Blending To Meet Specifications: Student's NameAhmed S. ALhayek100% (1)

- 712 CastIron Flakes ISO-945.pdf ExtDocument1 page712 CastIron Flakes ISO-945.pdf ExtvictorNo ratings yet

- Basecourse TYpe A PT - GmjiDocument4 pagesBasecourse TYpe A PT - Gmjiagung gmjiNo ratings yet

- QC Tool - Control Chart Sieve Agg. 0.150mm 200diaDocument3 pagesQC Tool - Control Chart Sieve Agg. 0.150mm 200diachinhon0% (1)

- Sulfuric AcidDocument22 pagesSulfuric AcidEmmanuelNo ratings yet

- The Effects of B, C and AC Are Large and Significant.: Problem 6.6 A) Calculation of EffectDocument4 pagesThe Effects of B, C and AC Are Large and Significant.: Problem 6.6 A) Calculation of EffectBablu KumarNo ratings yet

- TABLE 2: PT1 Site Calibration Check: D Ma C Ma CDocument2 pagesTABLE 2: PT1 Site Calibration Check: D Ma C Ma Csyahirah shamsudinNo ratings yet

- Assignment #3-3 - Process Defect AnalysisDocument5 pagesAssignment #3-3 - Process Defect AnalysisʆƠƘЄƦ 6No ratings yet

- What's New Version 2.10: Votano 100Document7 pagesWhat's New Version 2.10: Votano 100JRACNo ratings yet

- Standard Sieve Opening Sizes Plot Data (In) (MM) % Passing Sieve Number Size (MM)Document5 pagesStandard Sieve Opening Sizes Plot Data (In) (MM) % Passing Sieve Number Size (MM)sandipNo ratings yet

- Auto CadDocument67 pagesAuto CadkltowerNo ratings yet

- Z-Score Ordinary (Or ModifiedDocument20 pagesZ-Score Ordinary (Or ModifiedLamiaNo ratings yet

- Evidencia FinalDocument7 pagesEvidencia FinalJesus ArellanoNo ratings yet

- Granulometria GravasDocument1 pageGranulometria GravasJose Tomas Castellani LemoineNo ratings yet

- Supplier Evaluation MatrixDocument1 pageSupplier Evaluation MatrixRanda S Jowa0% (1)

- 712 CastIron Flakes ASTM-A247.pdf ExtDocument1 page712 CastIron Flakes ASTM-A247.pdf ExtvictorNo ratings yet

- Selection of CT & PTDocument4 pagesSelection of CT & PTSwagat PradhanNo ratings yet

- Project Training in HmsiDocument38 pagesProject Training in HmsimohitNo ratings yet

- Rakesh Yadav 2017Document13 pagesRakesh Yadav 2017Avaneesh TripathiNo ratings yet

- Pie Chart To Drivers Who Are Distracted: Bar Graph of Distracted DrivingDocument8 pagesPie Chart To Drivers Who Are Distracted: Bar Graph of Distracted DrivingDavid ValenciaNo ratings yet

- Plot A Sieve Chart On ExcelDocument3 pagesPlot A Sieve Chart On ExcelSri RamNo ratings yet

- SAM 22, Section A, Session 7, 24010106Document4 pagesSAM 22, Section A, Session 7, 24010106Tooba ChaudharyNo ratings yet

- GRR Study MSA TemplateDocument20 pagesGRR Study MSA TemplateRuiz ManuelNo ratings yet

- Normal Probability Plot: Regression StatisticsDocument23 pagesNormal Probability Plot: Regression StatisticsShyamsunder SinghNo ratings yet

- GRR Study MSA TemplateDocument20 pagesGRR Study MSA Templateyusuf_jtNo ratings yet

- Sieve Analysis (Base Course Matl)Document2 pagesSieve Analysis (Base Course Matl)KaterzoNo ratings yet

- Six-Sigma and ReliabilityDocument37 pagesSix-Sigma and Reliabilitypanugantisameer468No ratings yet

- Installation and Calibration of Newly Installed X-Ray Machines - Anonas Diagnostic ClinicDocument3 pagesInstallation and Calibration of Newly Installed X-Ray Machines - Anonas Diagnostic ClinicTeresita AlcaideNo ratings yet

- Pelaksanaan Perkerasan: Ukuran Saringan Specification Range JMFDocument10 pagesPelaksanaan Perkerasan: Ukuran Saringan Specification Range JMFYudhirieza88100% (1)

- INFORME Alex PavDocument44 pagesINFORME Alex PavAngel Julisses Valderrama ReyesNo ratings yet

- Kuliah 3Document3 pagesKuliah 3Naufal AzraNo ratings yet

- Major ProjectDocument6 pagesMajor Projectgaurav kishoreNo ratings yet

- Visual Surface Distress Measurements & Rating For Flexible PavementDocument8 pagesVisual Surface Distress Measurements & Rating For Flexible PavementSasanka SekharNo ratings yet

- Combined Gradation of Coarse Aggregate - Astm C33-Size 67-1Document106 pagesCombined Gradation of Coarse Aggregate - Astm C33-Size 67-1Hasan al MahmudNo ratings yet

- GRR Study MSA TemplateDocument20 pagesGRR Study MSA TemplateRicardo VitorianoNo ratings yet

- Result Pressure Measurement (PART 2)Document2 pagesResult Pressure Measurement (PART 2)Noor FatihahNo ratings yet

- Mac Pherson GDSTDocument11 pagesMac Pherson GDSTdeportesaldia2014No ratings yet

- Assignment#1Document2 pagesAssignment#1Deema sultanNo ratings yet

- C) 1-Phase Differential Slope Test Procedure: The Relay Testing HandbookDocument2 pagesC) 1-Phase Differential Slope Test Procedure: The Relay Testing HandbooksameershahzanNo ratings yet

- 拋光等級Document1 page拋光等級ykc3850% (2)

- CT 50 - Window Detail55Document2 pagesCT 50 - Window Detail55sharing driveku1No ratings yet

- Data Sheet CT GAEDocument2 pagesData Sheet CT GAEsharing driveku1No ratings yet

- Current Transformer: CT 50 - WindowDocument2 pagesCurrent Transformer: CT 50 - Windowari firmanNo ratings yet

- UBE Automotive MSA System Bias and Linearity StudiesDocument6 pagesUBE Automotive MSA System Bias and Linearity StudiesNarayanKavitakeNo ratings yet

- DCPTR No. 19P-042 - NONGA X WATER SUPPLY Pipeline Geotech Sites, ENBDocument3 pagesDCPTR No. 19P-042 - NONGA X WATER SUPPLY Pipeline Geotech Sites, ENBNathan JohnNo ratings yet

- FQFQFDocument2 pagesFQFQFBoogi Andika TamamiNo ratings yet

- AA1060 - Aluminum Alloy SheetDocument1 pageAA1060 - Aluminum Alloy SheettljytzNo ratings yet

- Part A - Ferrous Material Specifications: Table 2 Tensile RequirementsDocument1 pagePart A - Ferrous Material Specifications: Table 2 Tensile RequirementsriyyjuniorNo ratings yet

- Pozo A TierraDocument6 pagesPozo A TierraRay BandaNo ratings yet

- WC (Water Content) Totadan Pan (W1) Todan Pan + Material Bokon (W2) Todan Pan + Material Nebe Hatama Ona Formo (W3)Document18 pagesWC (Water Content) Totadan Pan (W1) Todan Pan + Material Bokon (W2) Todan Pan + Material Nebe Hatama Ona Formo (W3)Jerry GilNo ratings yet

- Ipjmbt 434Document2 pagesIpjmbt 434Deepak KumarNo ratings yet

- Catalog TurbineDocument6 pagesCatalog TurbinerezandriansyahNo ratings yet

- Zero Sampling Plan: "B" "C" & Self Certified "A"Document4 pagesZero Sampling Plan: "B" "C" & Self Certified "A"Pradeep AdhikariNo ratings yet

- Autodesk Fusion 360 Black Book (V 2.0.12670) - Part 2: Autodesk Fusion 360 Black Book (V 2.0.12670)From EverandAutodesk Fusion 360 Black Book (V 2.0.12670) - Part 2: Autodesk Fusion 360 Black Book (V 2.0.12670)No ratings yet

- DPPM Reduction %changeDocument3 pagesDPPM Reduction %changeBoby SaputraNo ratings yet

- 8D Process: D0: Prepare For Problem SolvingDocument4 pages8D Process: D0: Prepare For Problem SolvingBoby SaputraNo ratings yet

- Tolerance Analysis-6SigmaDocument22 pagesTolerance Analysis-6SigmaBoby SaputraNo ratings yet

- Mold Fixture & Jig CertificationDocument7 pagesMold Fixture & Jig CertificationBoby SaputraNo ratings yet

- Elsmar Software Build Defect RatesDocument6 pagesElsmar Software Build Defect RatesBoby SaputraNo ratings yet

- Example CP MouldingDocument1 pageExample CP MouldingBoby SaputraNo ratings yet

- Cost of Quality and ROI Form Nick R Rev 012721Document4 pagesCost of Quality and ROI Form Nick R Rev 012721Boby SaputraNo ratings yet

- Pandrol Memphis AAR QAPE ChecklistDocument31 pagesPandrol Memphis AAR QAPE ChecklistBoby SaputraNo ratings yet

- Procedure TemplateDocument3 pagesProcedure TemplateBoby SaputraNo ratings yet

- Must Obtain Approval: 812.35 (A) Changes in Investigational PlanDocument1 pageMust Obtain Approval: 812.35 (A) Changes in Investigational PlanBoby SaputraNo ratings yet

- CYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetBoby SaputraNo ratings yet

- Error Proofing TechniquesDocument140 pagesError Proofing TechniquesBoby SaputraNo ratings yet

- Material Control ProcessDocument9 pagesMaterial Control ProcessBoby SaputraNo ratings yet

- DRY PTFE Spray - GBDocument11 pagesDRY PTFE Spray - GBBoby SaputraNo ratings yet

- The Poka-Yoke System: Is Zero Defects A Reality?Document39 pagesThe Poka-Yoke System: Is Zero Defects A Reality?Boby SaputraNo ratings yet

- Lean Is The Way of Our WorkDocument16 pagesLean Is The Way of Our WorkBoby SaputraNo ratings yet

- DDC p2c3 Ug02 Ugs DR Sot 35101 03 Editing1Document40 pagesDDC p2c3 Ug02 Ugs DR Sot 35101 03 Editing1Devesh GuptaNo ratings yet

- Standard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and ArchesDocument17 pagesStandard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and Archesjun floresNo ratings yet

- Modular Multi-Position Air HandlerDocument16 pagesModular Multi-Position Air Handlerkothat82No ratings yet

- ESEDRA 2010 - CatalogueDocument226 pagesESEDRA 2010 - CatalogueWilliam Dante Mescco SaireNo ratings yet

- Design of Baseplate (BP-1) - Without Shear Key - GRID 101 TO 104Document14 pagesDesign of Baseplate (BP-1) - Without Shear Key - GRID 101 TO 104prabhash kumarNo ratings yet

- DIY Miter Saw Station PDFDocument6 pagesDIY Miter Saw Station PDFNana Obiri Yeboa DarkoNo ratings yet

- Objective Question - Unit 1Document7 pagesObjective Question - Unit 1Parthiban PNNo ratings yet

- Surface Vehicle Standard: (R) Hydraulic Hose FittingsDocument34 pagesSurface Vehicle Standard: (R) Hydraulic Hose FittingsLUCIANO SOTONo ratings yet

- Department of Structural Engineering University of California San DiegoDocument6 pagesDepartment of Structural Engineering University of California San DiegomimiNo ratings yet

- Civil Engineering FormulaDocument4 pagesCivil Engineering Formulaanku4frenz100% (1)

- Bomba RL-20B (R) MancalDocument1 pageBomba RL-20B (R) Mancal47x996691523No ratings yet

- Drilling Machine Inspection ChecklistDocument1 pageDrilling Machine Inspection ChecklistKevin MichaelNo ratings yet

- 4 Hours / 70 Marks: Seat NoDocument8 pages4 Hours / 70 Marks: Seat Noadnan_ais123No ratings yet

- Poshs Metal Industries PVT - LTD: SR - No. Inspection Area Remark Required Lux Level (Min) Actual Lux LevelDocument2 pagesPoshs Metal Industries PVT - LTD: SR - No. Inspection Area Remark Required Lux Level (Min) Actual Lux LevelSafety Dept100% (1)

- MAN BASKET Inspection ReportDocument2 pagesMAN BASKET Inspection ReportbasdNo ratings yet

- Specs Conveyors BP 30-06-2022Document26 pagesSpecs Conveyors BP 30-06-2022Juan Jose Jimenez LopezNo ratings yet

- ISO-10664Document10 pagesISO-10664Daniel Quijada LucarioNo ratings yet

- 319 Equipment Installation Course DescriptionDocument2 pages319 Equipment Installation Course DescriptionAnonymous q9eCZHMuSNo ratings yet

- Chapter 9 - Solved ProblemsDocument11 pagesChapter 9 - Solved Problemshanihamoud05No ratings yet

- Centrifugal CompDocument100 pagesCentrifugal CompRiyadh Saleh100% (1)

- 1-Dimensions Are in '' M '' 1 - Elevation Levels Are in '' CM''Document1 page1-Dimensions Are in '' M '' 1 - Elevation Levels Are in '' CM''Nasser SabrNo ratings yet

- Heat Treatment To Anchor BoltsDocument4 pagesHeat Treatment To Anchor BoltsvishalnalwarNo ratings yet

- CTHS430-02 SPC R223.1394-02Document82 pagesCTHS430-02 SPC R223.1394-02Marcos GuardiaNo ratings yet

- AU TG Install GuideDocument5 pagesAU TG Install Guideguillote_666No ratings yet

- Collar BoltsDocument2 pagesCollar BoltsMahdi HocineNo ratings yet

- Fire Extinguisher Inspection Checklist Year - Fire Extinguisher Inspection Checklist YearDocument2 pagesFire Extinguisher Inspection Checklist Year - Fire Extinguisher Inspection Checklist YearteresaNo ratings yet