Professional Documents

Culture Documents

Colour Erythrosine supraSTP

Colour Erythrosine supraSTP

Uploaded by

shakt londaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Colour Erythrosine supraSTP

Colour Erythrosine supraSTP

Uploaded by

shakt londaCopyright:

Available Formats

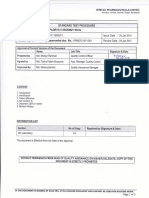

YASH PHARMA LABORATORIES PVT.

LTD

Khasra No.19M, Village: Raipur, Pargana: Bhagwanpur,Tehsil– Roorkee,

Distt: - Haridwar, Uttarakhand

Department Quality control Document Type Standard testing procedure

Material Name Colour erythrosine supra Page No. Page 1 of 3

STP No. YPR/STP/RM/134 Pharm. Ref. IHS

Effective From Document validity

1. Description: A pink coloured powder.

2. Solubility: Freely soluble in water and in dilute acids & in dilute alkali.

3. Identification:

A By Assay: The final solution obtained in the assay gives maximum absorbance at 428 nm.

4. pH :Weight 1.0 g of the sample in 100 ml volumetric flask and dissolve in water produce the 100 ml

with water and check the pH of these solutions.Limit:5.00 to 8.50

5. Heavy metals:

Standard solution: Into a 50 ml Nessler Cylinder pipette 1.0 ml of Lead Standard solution (40 ppm

pb) and dilute with water to 25 ml. Adjust with dilute Acetic Acid or dilute Ammonia solution to a

pH between 3.0 and 4.0 dilute with water to about 35 ml and mix.

Test solution: Weigh 1.0 g in a suitable crucible, add sufficient Sulphuric Acid to wet the sample,

ignite carefully at a low temperature until thoroughly charred. Add to the charred mass 2 ml of Nitric

Acid and 5 drops of Sulphuric Acid and heat cautiously until white fumes are no longer evolved.

Ignite, preferably in a muffle furnace, at 500° to 600°C, until the carbon is completely burnt off.

Cool, add 4 ml of Hydrochloric Acid, cover, digest on a water-bath for 15 minutes, uncover and

slowly evaporate to dryness on a water-bath. Moisten the residue with 1 drop of Hydrochloric Acid,

add 10 ml of hot water and digest for 2 minutes.

Add Ammonia solution to dropwise until the solution is just alkaline to litmus paper, dilute to 25 ml

with water and adjust with dilute Acetic Acid to a pH between 3.0 and 4.0. filter, if necessary,

rinse the crucible and the filter with 10 ml of water, combine the filtrate and washings in a 50 ml

Nessler Cylinder, dilute with water to about 35 ml and mix.

Procedure:

To each of the cylinders containing the standard solution and test solution respectively add 10 ml of

freshly prepared Hydrogen Sulphide solution. Mix, dilute to 50 ml with water, allow standing for 5

minutes and viewing downwards over a white surface; the colour produced with the test solution is

not more intense than that produced with the standard solution.

Limit: Not more than :40ppm.

Prepared by Checked by Approved by

Name

Designation

Sign. & Date

Format No :YPR/QC/081/F02-00

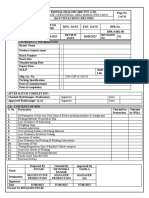

YASH PHARMA LABORATORIES PVT.LTD

Khasra No.19M, Village: Raipur, Pargana: Bhagwanpur,Tehsil– Roorkee,

Distt: - Haridwar, Uttarakhand

Department Quality control Document Type Standard testing procedure

Material Name Colour erythrosine supra Page No. Page 2 of 3

STP No. YPR/STP/RM/134 Pharm. Ref. IHS

Effective From Document validity

6. Arsenic: Dissolve 5.0 g. in 10 ml of Bromine solution and evaporate to dryness on a water – bath.

Ignite gently, dissolve the cooled residue, ignoring any carbon, in 50 ml of water and 14 ml of

Brominated Hydrochloric Acid AsT and remove the excess of bromine with a few drops of Stannous

Chloride solution AsT.

Into the bottle or conical flask introduce the test solution prepared as directed above; add 5 ml of 1 M

Potassium Iodide and 10 g of Zinc AsT. Immediately assemble the apparatus and immerse the flask

in a water-bath at the temperature such that a uniform evolution of gas is maintained. After 40

minutes any stain produced on the Mercuric Chloride paper is not more intense than that obtained by

treating in the same manner 1 ml of Arsenic Standard solution (10 ppm As) diluted to 50 ml with

water.

Limit: Not more than 3 PPM

7. Water Insoluble Matter: Weigh accurately about 2 g of sample and shake with 100 ml of distilled

water for 5 minutes and filter through sintered glass crucible G4 (previously dried & weighed). Dry

the crucible at 105oC to the constant weight and find out the weight of insoluble matter.

Calculation:

Weight of Insoluble matter

% of Insoluble matter = --------------------------------------- X 100

Weight of sample

=……………………….%

Limit :Not more than :Not more than 0.5%

8. Loss on drying:

Place the 1 g of the substance to be examined in a weighing bottle previously dried under the

conditions. Dry the substance for the 2 hours in 1100C.after drying the sample cooled in desiccators

and weighing the bottle.

Weight of weighing bottle = ____________g (A)

Weight of weighing bottle + sample = ____________g (B)

Weight of sample (B-A) = ____________g (C)

Weight of weighing bottle + sample = ___________g (D) (After drying at110 oC. for 2hrs)

Loss in weight (B-D) = ________________g (E)

(E)

Prepared by Checked by Approved by

Name

Designation

Sign. & Date

Format No :YPR/QC/081/F02-00

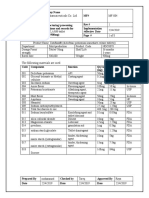

YASH PHARMA LABORATORIES PVT.LTD

Khasra No.19M, Village: Raipur, Pargana: Bhagwanpur,Tehsil– Roorkee,

Distt: - Haridwar, Uttarakhand

Department Quality control Document Type Standard testing procedure

Material Name Colour erythrosine supra Page No. Page 3 of 3

STP No. YPR/STP/RM/134 Pharm. Ref. IHS

Effective From Document validity

Loss on drying -------------------------- X100 = _________________%

(C

Limit:Not more than 20.0%

9. Total dye content: Weigh accurately about 100 mg of the sample and transfer into 200 ml

volumetric flask. Add 20 ml of Water and dissolve. Make up the volume with same water. Dilute

2.0 ml to 100.0 ml ml with same solvent. Read the absorbance of final solution at 527 nm using

water as blank. Calculate the assay taking value of A1% 1080

Calculation:

Abs. 200 100 1

% Dye Content = ------ X -------------------- X --------- X --------- X 100

520 Wt of sample (g) 2 100

Limit: Not less than 85.0%

Prepared by Checked by Approved by

Name

Designation

Sign. & Date

Format No :YPR/QC/081/F02-00

You might also like

- Preservative Efficacy Test - 1Document8 pagesPreservative Efficacy Test - 1SolomonNo ratings yet

- Equilibrium and Concentration 1234567Document11 pagesEquilibrium and Concentration 1234567GarnielNo ratings yet

- STP Opadry IIDocument2 pagesSTP Opadry IIShagorShagorNo ratings yet

- STP of Ambeet Syrup NSDocument6 pagesSTP of Ambeet Syrup NSBejoy KarimNo ratings yet

- STP of Ethifen SyrupDocument5 pagesSTP of Ethifen SyrupBejoy KarimNo ratings yet

- Excipient Compatibility PDFDocument28 pagesExcipient Compatibility PDFJitendra YadavNo ratings yet

- Cefpodoxime 200 Tab New 1Document25 pagesCefpodoxime 200 Tab New 1Gurdev SinghNo ratings yet

- Source Water STP 31-05-2019Document11 pagesSource Water STP 31-05-2019saptaksamadder4No ratings yet

- Mega Iron 1200.Document6 pagesMega Iron 1200.Muhammad ZubairNo ratings yet

- STP Avicel PH 102Document6 pagesSTP Avicel PH 102ShagorShagorNo ratings yet

- In-Process Testing of Infusions: Novamed Pharmaceutical Quality Control Department Standard Operating ProcedureDocument5 pagesIn-Process Testing of Infusions: Novamed Pharmaceutical Quality Control Department Standard Operating Procedurenaeem186No ratings yet

- GPM Guideline Inspect EngDocument96 pagesGPM Guideline Inspect EngDilawar BakhtNo ratings yet

- Manufacturing Formula: Product: Ctzine SyrupDocument6 pagesManufacturing Formula: Product: Ctzine SyrupMohammed Zubair100% (1)

- 01 Disintegration Test For Tablets and CapsulesDocument30 pages01 Disintegration Test For Tablets and CapsulesmefroNo ratings yet

- SOP For Destruction of Control Samples (Raw Material and Finished Product)Document3 pagesSOP For Destruction of Control Samples (Raw Material and Finished Product)Solomon100% (1)

- Alusim SuspensionDocument5 pagesAlusim SuspensionAhmad HussainNo ratings yet

- SMF Update SOLITAIRE PDFDocument35 pagesSMF Update SOLITAIRE PDFmaheshNo ratings yet

- Consern Pharma Limited, Ludhiana: Focal Point, V.P.O. Tibba, District Ludhiana-141120, (Punjab), India 1 of 7Document7 pagesConsern Pharma Limited, Ludhiana: Focal Point, V.P.O. Tibba, District Ludhiana-141120, (Punjab), India 1 of 7ASHIMA SHARMANo ratings yet

- Sop For Package Integrity - Leak TestDocument4 pagesSop For Package Integrity - Leak TestMusyoka UrbanusNo ratings yet

- PRODUCT: Mediplex-L Syrup: Manufacturing FormulaDocument7 pagesPRODUCT: Mediplex-L Syrup: Manufacturing FormulaMohammed Zubair100% (1)

- BPR TABLET JarDocument16 pagesBPR TABLET JarBIONIAL HEALTHCARENo ratings yet

- QA005-04 Vendor Qualification-IM & PMKDocument9 pagesQA005-04 Vendor Qualification-IM & PMKSagar ChavanNo ratings yet

- Procedure For Leak Testing of Strips - BlistersDocument7 pagesProcedure For Leak Testing of Strips - BlistersashishdrNo ratings yet

- Related Substances of Cefipime IPDocument4 pagesRelated Substances of Cefipime IPBhawani singhNo ratings yet

- BMR Calamine CreamDocument5 pagesBMR Calamine Creamzaraorganics99No ratings yet

- Formulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression MethodDocument5 pagesFormulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression Methodanto_pharma7784No ratings yet

- Helix Pharma (Private) Limited: Validation ProtocolDocument3 pagesHelix Pharma (Private) Limited: Validation Protocolziauddin bukhariNo ratings yet

- 36 Leak Test Apparatus 036Document2 pages36 Leak Test Apparatus 036ASHOK KUMAR LENKANo ratings yet

- 214.039 Operation of Sieve Shaker2012Document3 pages214.039 Operation of Sieve Shaker2012Pradeep KumarNo ratings yet

- MB-01-005-Procedure For Collection of Swab Samples From Equipments and FloorsDocument2 pagesMB-01-005-Procedure For Collection of Swab Samples From Equipments and FloorsmeghaNo ratings yet

- STP of Triben-L BolusDocument6 pagesSTP of Triben-L BolusBejoy Karim100% (1)

- 32 Prepare FP Specification 032Document2 pages32 Prepare FP Specification 032ASHOK KUMAR LENKANo ratings yet

- STP Aerosil 200Document3 pagesSTP Aerosil 200ShagorShagor100% (1)

- BMR - Reference - Moisturizing CreamDocument6 pagesBMR - Reference - Moisturizing CreamNIKHIL YEMUL100% (1)

- Nystatin Oral Suspension AMVDocument33 pagesNystatin Oral Suspension AMVOm PandeyNo ratings yet

- OOS InvestigationDocument5 pagesOOS Investigationmarkandey gupta100% (2)

- Sterille Production AreaDocument12 pagesSterille Production AreaNavdeep ChaudharyNo ratings yet

- A Product Which Has Completed All Stages of Manufacture, Including Final PackagingDocument4 pagesA Product Which Has Completed All Stages of Manufacture, Including Final Packagingom shankar JhaNo ratings yet

- Coding - of - Pipes - 20170611 - Purified WaterDocument3 pagesCoding - of - Pipes - 20170611 - Purified Waterreflectprakash3610No ratings yet

- Siddhi Vinayak Industries.: Batch Manufacturing RecordDocument11 pagesSiddhi Vinayak Industries.: Batch Manufacturing RecordPANKAJNo ratings yet

- PRODUCT: Medfen 100 MG / 5 ML (Ibuprofen U.S.P) : Potency OverageDocument7 pagesPRODUCT: Medfen 100 MG / 5 ML (Ibuprofen U.S.P) : Potency OverageMohammed ZubairNo ratings yet

- STP Montelukast Sa.Document6 pagesSTP Montelukast Sa.ShagorShagor100% (1)

- Issuance of DocumentsDocument2 pagesIssuance of DocumentsAshok KumarNo ratings yet

- 033 BOD IncubatorDocument4 pages033 BOD Incubatorbhavna sharmaNo ratings yet

- SOP For Karl Fisher Titration-Sophie - RadwanDocument3 pagesSOP For Karl Fisher Titration-Sophie - RadwanzhobeysNo ratings yet

- Standard Operating Procedure of Automatic Coating System Used For Coating On TabletDocument5 pagesStandard Operating Procedure of Automatic Coating System Used For Coating On TabletSolomonNo ratings yet

- Aromet ER 1000Document14 pagesAromet ER 1000HamidNo ratings yet

- Formulation of HERVEL SGC For WomenDocument2 pagesFormulation of HERVEL SGC For Womennaeem186No ratings yet

- Pure & Cure Healthcare Pvt. LTD.: Restricted CirculationDocument16 pagesPure & Cure Healthcare Pvt. LTD.: Restricted CirculationDarlenis RodriguezNo ratings yet

- Manufacturing Formula: Product: Univit SyrupDocument6 pagesManufacturing Formula: Product: Univit SyrupMohammed ZubairNo ratings yet

- OOT NWDocument2 pagesOOT NWSagar ChavanNo ratings yet

- Aroflam BPRDocument26 pagesAroflam BPRHamidNo ratings yet

- Raya Pharmaceuticals Co. LTD: Cataflam®Document8 pagesRaya Pharmaceuticals Co. LTD: Cataflam®Mayson BaliNo ratings yet

- Biobase Tht-2 Tablet Hardness TesterDocument2 pagesBiobase Tht-2 Tablet Hardness TesterWANDERA ROBERTNo ratings yet

- SOP For Calibration of FT-IR SpectrometerDocument8 pagesSOP For Calibration of FT-IR SpectrometerSolomon Gamanuel100% (1)

- Manufacturing Formula: PRODUCT: Enzovit SyrupDocument6 pagesManufacturing Formula: PRODUCT: Enzovit SyrupMohammed Zubair100% (1)

- Specification Eudragit L 30 D 55Document6 pagesSpecification Eudragit L 30 D 55Jivan Battu100% (1)

- Potassium Tetraiodomercurate Solution R.: Format No.: - YPR/QC/081/F02-00Document6 pagesPotassium Tetraiodomercurate Solution R.: Format No.: - YPR/QC/081/F02-00shakt londaNo ratings yet

- Itraconazole STPDocument5 pagesItraconazole STPshakt londaNo ratings yet

- STP of Ciprofloxacin HCL USPDocument7 pagesSTP of Ciprofloxacin HCL USPbejoykarim2022No ratings yet

- Itraconazole STP NEWDocument4 pagesItraconazole STP NEWshakt londaNo ratings yet

- Potassium Tetraiodomercurate Solution R.: Format No.: - YPR/QC/081/F02-00Document6 pagesPotassium Tetraiodomercurate Solution R.: Format No.: - YPR/QC/081/F02-00shakt londaNo ratings yet

- Benzyl Alcohol IP STP BPDocument5 pagesBenzyl Alcohol IP STP BPshakt londaNo ratings yet

- YASH Pharma Laboratories Pvt. LTD.: Certificate of AnalysisDocument1 pageYASH Pharma Laboratories Pvt. LTD.: Certificate of Analysisshakt londaNo ratings yet

- Citric Acid Anhydrous CoaDocument2 pagesCitric Acid Anhydrous Coashakt londaNo ratings yet

- Luliconazole Specs and STP - From DMF - Nosch LabsDocument22 pagesLuliconazole Specs and STP - From DMF - Nosch Labsshakt londaNo ratings yet

- Itraconazole STPDocument5 pagesItraconazole STPshakt londaNo ratings yet

- Itraconazole STP NEWDocument4 pagesItraconazole STP NEWshakt londaNo ratings yet

- Prepared by Checked by Approved by Sign: Date:: Format No.-YPR/QC/003/F08-00Document1 pagePrepared by Checked by Approved by Sign: Date:: Format No.-YPR/QC/003/F08-00shakt londaNo ratings yet

- Yrmg171143 .Document1 pageYrmg171143 .shakt londaNo ratings yet

- Chemical Bonding Mcqs Mdcat Nums Paid Test 2023 by Study CornerDocument7 pagesChemical Bonding Mcqs Mdcat Nums Paid Test 2023 by Study Cornerststa.2022No ratings yet

- Vegetable Oils: Composition and AnalysisDocument8 pagesVegetable Oils: Composition and AnalysisBianca AndreeaNo ratings yet

- Safety Data Sheet: According To Regulation (EC) No. 1907/2006Document12 pagesSafety Data Sheet: According To Regulation (EC) No. 1907/2006danielNo ratings yet

- Answer Key - Chemistry - Diagnostic ExamDocument2 pagesAnswer Key - Chemistry - Diagnostic ExamNiño Edrianne Nimo100% (2)

- Magnesium Alloys: Raw Material ProductionDocument25 pagesMagnesium Alloys: Raw Material Productionmohamad hafizNo ratings yet

- Explosives and Blasting in UG Coal MinesDocument12 pagesExplosives and Blasting in UG Coal Minespartha das sharma94% (16)

- RANGER - Rescue Davit Kit Shoring - Operating Manual CertificationDocument38 pagesRANGER - Rescue Davit Kit Shoring - Operating Manual CertificationAmr Adel HameedNo ratings yet

- 05.sulphur and Its Compounds (69-84)Document16 pages05.sulphur and Its Compounds (69-84)Vaibhav TripathiNo ratings yet

- Tablas Metalurgicas 2 PDFDocument40 pagesTablas Metalurgicas 2 PDFAnonymous CNormeuqWpNo ratings yet

- Particulate Preview Wrap-UpDocument11 pagesParticulate Preview Wrap-UpBunny SmithNo ratings yet

- APC - Chapter 5 - Part 3 SP23Document11 pagesAPC - Chapter 5 - Part 3 SP23iB13eNo ratings yet

- Co-Ordinated and Congruent Phosphate Treatments: AlkalinityDocument3 pagesCo-Ordinated and Congruent Phosphate Treatments: AlkalinityMeghanath AdkonkarNo ratings yet

- Chemistry 2Document14 pagesChemistry 2Marianne0% (1)

- Practical Guidebook Pharmacology and ToxicologyDocument107 pagesPractical Guidebook Pharmacology and ToxicologySamad KaziNo ratings yet

- Ozone Senitzer With Ozone FogerDocument2 pagesOzone Senitzer With Ozone Fogersaradhi sravan kumarNo ratings yet

- UraniumDocument19 pagesUraniumEdgar Apaza HuallpaNo ratings yet

- RRL: Soil Analyzer and Plant SuggestionDocument6 pagesRRL: Soil Analyzer and Plant SuggestionJhon Paul Gervacio100% (1)

- AnnexureDocument3 pagesAnnexureqamarNo ratings yet

- Chemisstry DPP # 2 (Alkyl Halide+alcDocument7 pagesChemisstry DPP # 2 (Alkyl Halide+alcmohitpatel18032003No ratings yet

- End of ReportDocument45 pagesEnd of ReportManthan GendleNo ratings yet

- Microsoft Word - DLL For July 16 2019Document2 pagesMicrosoft Word - DLL For July 16 2019Marilyn LaquindanumNo ratings yet

- Pengaruh Kombinasi Jenis Pelarut Dan Perbandingannya Terhadap KARAKTERISTIK EKSTRAK BUAH PANDAN (Pandanus Tectorius)Document12 pagesPengaruh Kombinasi Jenis Pelarut Dan Perbandingannya Terhadap KARAKTERISTIK EKSTRAK BUAH PANDAN (Pandanus Tectorius)Diannisa Mahiru Suryani 2005114296No ratings yet

- Chemical Kinetic Modelling of Ammonia or Hydrogen or Air Ignition, Premixed Premixed Flame Under Varying Pressure and Equivalence RatioDocument10 pagesChemical Kinetic Modelling of Ammonia or Hydrogen or Air Ignition, Premixed Premixed Flame Under Varying Pressure and Equivalence RatioSourav Sarkar MechanicalNo ratings yet

- 3 LAB ACTIVITY SHEET 3 Precipitation and Solubility 1Document3 pages3 LAB ACTIVITY SHEET 3 Precipitation and Solubility 1Jurel JohnNo ratings yet

- Use of Partial Dissolution Techniques in Geochemical ExplorationDocument35 pagesUse of Partial Dissolution Techniques in Geochemical ExplorationMiguel Angel Catunta ZarateNo ratings yet

- Assignment in Advance Chemistry (Hydrocarbons) : Frauline C. Tadle IV-Galileo Mr. Romel Condeza S.Y.: 2010-2011Document7 pagesAssignment in Advance Chemistry (Hydrocarbons) : Frauline C. Tadle IV-Galileo Mr. Romel Condeza S.Y.: 2010-2011Fraul TadleNo ratings yet

- Now Test Yourself Answers: 1 Engineering MaterialsDocument9 pagesNow Test Yourself Answers: 1 Engineering MaterialsSylvesterNo ratings yet

- Publishedbook InsulationMaterialsFundamentalsandApplications NewDocument199 pagesPublishedbook InsulationMaterialsFundamentalsandApplications NewClaudenise ClaudeniseNo ratings yet

- BIO 204 Current Final Term Fall 2020 by Amaan KhanDocument38 pagesBIO 204 Current Final Term Fall 2020 by Amaan KhanSharqaNo ratings yet