Professional Documents

Culture Documents

Ijert Ijert: Electric Power Generation Using Roller Mechanism

Ijert Ijert: Electric Power Generation Using Roller Mechanism

Uploaded by

Mayur Madhukar MankarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijert Ijert: Electric Power Generation Using Roller Mechanism

Ijert Ijert: Electric Power Generation Using Roller Mechanism

Uploaded by

Mayur Madhukar MankarCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 2, February - 2014

Electric Power Generation Using Roller

Mechanism

*B. Santosh sarma* B.Udaya Kumar

*Student,*Associate Professor,Department of Electronics and Instrumentation Engineering,GITAM University, Visakhapatnam,

Andhra Pradesh

Abstract--In this Project we are generating electrical power as

non-conventional method by simply passing vehicles on to the rotational energy and thereby rotating the generator, to

specially designed Roller Setup. This method of Electrical power produce the electrical power.

generation needs no input power. This Project is implemented by

using simple drive mechanism such as Roller, some interfaced

Electrical components and chain drive Mechanism. The basic

principle is simple energy conversion form mechanical to

electrical energy by using the vehicles weight (potential energy)

& motion (kinetic energy).

I. INTRODUCTION

This road track generates free electricity as vehicles pass over

and they are not like conventional speed bumps. They don't

damage your car or waste petrol when you drive over them -

and they have the added advantage that they produce energy

free of charge. The Electro-Kinetic power generator is capable

RT

of generating around 10kW of electricity which can then be

used to power road signs, traffic lights and street lights or Figure: Design 1

stored in batteries for future use.

IJE

The track is made up of metal rollers that rotate by IV. EQUIPMENT:

using the pressure exerted by vehicles passing over it. The

movement of the rollers drives a specially developed design, A. Rollers:

which in turn drives a generator to produce electricity. The

repeated rotations from the rollers, which is further attached to

another free wheel allowing it to spin freely in-between while

vehicles passes over the track.

II. HISTORY

The ramp was invented by Peter Hughes, in the year 2002 an

electrical and mechanical engineer who is employed by

Highway Energy Systems Ltd. The company says that under

normal traffic conditions, the apparatus will produce 30 kW of

electricity. Other proposed applications for the road ramps

heating roads in the winter to prevent ice forming and

Figure 2

ventilating tunnels to reduce pollution. "The full potential of

Material used: hardened EN8

this is absolutely enormous." Hughes claims that 10 ramps

could generate the same power as one wind turbine. Properties of EN8:

EN8 is an unalloyed medium carbon steel with good tensile

III. THE ROLLER MECHANISM

strength. It is normally supplied in cold drawn or as rolled.

In this project we replaced the ramps with the Tensile properties can vary but are usually between 500-800

specially designed rollers which directly absorbs the kinetic N/mm2. EN8 is available from stock in bar and can be cut to

energy of the moving vehicles and converts them to your requirements.

Hardening:

To be heated uniformly to 830/860°C until heated

through & Quench in oil or water. Can also be induction or

flame hardened.

IJERTV3IS20870 www.ijert.org 1423

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 2, February - 2014

B. Bearings: one direction, the saw teeth of the drive disc lock with the

teeth of the driven disc, making it rotate at the same speed. If

the drive disc slows down or stops rotating, the teeth of the

driven disc slip over the drive disc teeth and continue rotating,

producing a characteristic clicking sound proportionate to the

speed difference of the driven gear relative to that of the

(slower) driving gear.

4.4 Hubs:

Figure: 3

A bearing is a device to allow constrained relative

motion between two or more parts, typically rotation or linear

movement. Bearings may be classified broadly according to

the motions they allow and according to their principle of Figure: 5

operation as well as by the directions of applied loads they can

handle. The type of bearing used here is rolling element type These hubs are specially designed for holding the

bearing which is widely used, relatively high friction, suffers free wheels. Two free wheels will be seated on this hub. One

from station in some applications. Depending upon the the primary free wheel the chain from the rollers will be used

application, lifetime can be higher or lower than rolling whereas the secondary is used to transmit the energy to the

element bearings. alternator.

C. Free Wheels: D. Generator (Dynamo):

RT

In mechanical or automotive engineering, a free

wheel or overrunning clutch is a device in a transmission that

disengages the driveshaft from the driven shaft when the

IJE

driven shaft rotates faster than the driveshaft. An overdrive is

sometimes mistakenly called a free wheel, but is otherwise

unrelated.

Figure: 6

Figure: 4

The dynamo uses rotating coils of wire and magnetic fields to

convert mechanical rotation into a pulsing direct electric

The condition of a driven shaft spinning faster than current through Faraday's law of induction. A dynamo

its driveshaft exists in most bicycles when the rider holds his machine consists of a stationary structure, called the stator,

or her feet still, no longer pushing the pedals. In a fixed-gear which provides a constant magnetic field, and a set of rotating

bicycle, without a free wheel, the rear wheel would drive the windings called the armature which turn within that field. The

pedals around. motion of the wire within the magnetic field causes the field to

An analogous condition exists in an automobile with push on the electrons in the metal, creating an electric current

a manual transmission going downhill or any situation where in the wire. On small machines the constant magnetic field

the driver takes his foot off the gas pedal, closing the throttle; may be provided by one or more permanent magnets; larger

the wheels want to drive the engine, possibly at a higher RPM. machines have the constant magnetic field provided by one or

The simplest freewheel device consists of two saw-toothed, more electromagnets, which are usually called field coils.

spring-loaded discs pressing against each other with the

toothed sides together, somewhat like a ratchet. Rotating in

IJERTV3IS20870 www.ijert.org 1424

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 2, February - 2014

The commutator was needed to produce direct Constant-resistance load testing (18 ohms)

current. When a loop of wire rotates in a magnetic field, the

potential induced in it reverses with each half turn, generating

an alternating current. However, in the early days of electric Output Output Output

experimentation, alternating current generally had no known speed(km/h)

use. The few uses for electricity, such as electroplating, used power(W) volt(V) current(A)

direct current provided by messy liquid batteries. Dynamos

were invented as a replacement for batteries. The commutator

is essentially a rotary switch. It consists of a set of contacts 5 0.45 2.45 0.115

mounted on the machine's shaft, combined with graphite-block

stationary contacts, called "brushes", because the earliest such

fixed contacts were metal brushes. The commutator reverses

the connection of the windings to the external circuit when the 15 1.89 5.78 0.325

potential reverses, so instead of alternating current, a pulsing

direct current is produced.

30 3.21 7.23 0.435

V. EXPECTED RESULTS:

Temperature test :

Surroundings Shell Temp.

Remarks

temp. temp. rise

keep 30cm

RT

20℃ 55.2℃ 32.2℃

distances test

Figure: 7

Speed versusPower

IJE

When the vehicle moves on the roller setup we may get the

1) Technical parameters

results as shown in the graphs for the speed

Output power test under constant voltage

No of dynamos used: 8

Power of the dynamo: 3Watts

Output Output Output RPM : 10/ dynamo

Speed(km/h) Torque going to obtain : (HP X 5252)/N

power(W) volt(V) current(A)

(0.004 * 5252)/ 10

2.1 N-M

Voltage going to Produce : 6Volts/dynamo

5 0.56 6.00 0.126 Current going to produce : 0.5amps/dynamo

VI. CONCLUSION:

No one is happy with current situation of electricity in India

15 1.89 6.00 0.369 We need electricity for every small thing. More suitable and

compact mechanisms to enhance efficiency. Although we get

less electrical output, this is a simple idea for generating

electricity from kinetic energy of the moving vehicles. If this

30 4.09 6.00 0.560 concept is further developed and is produced in high

potential, I am confident that enormous amount of power can

be developed. These rollers can be designed for heavy

vehicles, thus increasing input torque and ultimately output

of generator by using the multiple transmission system which

is more efficient method

IJERTV3IS20870 www.ijert.org 1425

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 2, February - 2014

VII. REFERENCES

[1] http://en.wikipedia.org/wiki/Bottle_dynamo

[2] S. T. Yusuf, A. S. Samosir, M. Abdulkadir Simplified Model of a

DC Rotating Machine for Mechanical Energy Generationusing

9001:2008 Certified International Journal of Engineering and

Innovative Technology (IJEIT) Volume 2, Issue 6, December

2012

[3] Rajat Gupta, Suyash Sharma, Saurabh Gaykawad

A Revolutionary Technique of Power Generation through

Speed Breaker Power Generators International Journal of

Engineering Research & Technology (IJERT) ISSN: 2278-0181

Vol. 2 Issue 8,Augus – 2013

[4] ChristophValerius, J6rg Krupar and Wolfgang Schwarz Electronic

Power Management for Bicycles

RT

IJE

IJERTV3IS20870 www.ijert.org 1426

You might also like

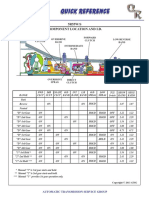

- 4L60 4l60-E 4l65-E 4l70-E QR PDFDocument10 pages4L60 4l60-E 4l65-E 4l70-E QR PDFHumberto100% (8)

- ZF4hp22 Automatic FejlfindingDocument74 pagesZF4hp22 Automatic Fejlfindingvolv8100% (5)

- Speed Breaker 1Document6 pagesSpeed Breaker 1AbhishekNo ratings yet

- Design and Fabrication of Gravity Power GenerationDocument5 pagesDesign and Fabrication of Gravity Power GenerationGhafar HassanNo ratings yet

- Flywheel GeneratorDocument3 pagesFlywheel GeneratorVenu GopalNo ratings yet

- Design and Development of Gap SensorDocument14 pagesDesign and Development of Gap SensorJagannath Prasad SahooNo ratings yet

- Car GenDocument4 pagesCar GenharshaNo ratings yet

- Design & Analysis of Steering System For Solar VehicleDocument4 pagesDesign & Analysis of Steering System For Solar VehicleYesh100% (1)

- Design and Fabrication of A Magnetic Prime Mover For Electric Power GenerationDocument4 pagesDesign and Fabrication of A Magnetic Prime Mover For Electric Power GenerationJerome GalleonNo ratings yet

- Design and Fabrication of Multi Process Machine Using Scotsh Yoke Mechanism IJERTCONV7IS06031Document2 pagesDesign and Fabrication of Multi Process Machine Using Scotsh Yoke Mechanism IJERTCONV7IS06031Sushant GhurupNo ratings yet

- Ijiset V2 I5 45 PDFDocument6 pagesIjiset V2 I5 45 PDFmanuelNo ratings yet

- IJCRT2210185Document5 pagesIJCRT2210185arainshoaib6671No ratings yet

- Analytic Synthesis of Hysteresis MotorDocument8 pagesAnalytic Synthesis of Hysteresis MotorEugene AgbachiNo ratings yet

- Generation of Electricity Through Rack and Pinion: Laxmi Gupta Ankita BhartiDocument3 pagesGeneration of Electricity Through Rack and Pinion: Laxmi Gupta Ankita BhartisandyyansikuNo ratings yet

- Power Generation Using Vehicle SuspensionDocument3 pagesPower Generation Using Vehicle SuspensionAnonymous 83DtcmB1nGNo ratings yet

- 38 DesignDocument8 pages38 Designarainshoaib6671No ratings yet

- Motors For Ship Propulsion - 11 - 30 - 14Document12 pagesMotors For Ship Propulsion - 11 - 30 - 14Madalin NeculacheNo ratings yet

- ENLILDocument8 pagesENLILnayenzaman6No ratings yet

- Linear Actuator Re GenerationDocument6 pagesLinear Actuator Re GenerationEr Chetan BachhavNo ratings yet

- Motors For Ship Propulsion - 11 - 30 - 14Document12 pagesMotors For Ship Propulsion - 11 - 30 - 14Andres Camilo Salazar Latorre.No ratings yet

- Irjet V5i5220Document4 pagesIrjet V5i5220afaq AhmadNo ratings yet

- 1667 PDFDocument3 pages1667 PDFrajNo ratings yet

- Tidal Energy SSIP ScreeningDocument12 pagesTidal Energy SSIP ScreeningLalu PatelNo ratings yet

- Power Generation Using Vehicle Suspension: July 2018Document4 pagesPower Generation Using Vehicle Suspension: July 2018Kiran PatilNo ratings yet

- Gearless Power Transmission: TRANSMISSION" Being Compact andDocument5 pagesGearless Power Transmission: TRANSMISSION" Being Compact andMectrosoft Creative technologyNo ratings yet

- IJSRDV6I50382Document4 pagesIJSRDV6I50382asborade04No ratings yet

- Design and Construction of Low Speed Axial Flux Generator With Stationary BikeDocument5 pagesDesign and Construction of Low Speed Axial Flux Generator With Stationary Bikemuhamad otongNo ratings yet

- Power Generation Using Speed Breaker IJERTV10IS090084Document3 pagesPower Generation Using Speed Breaker IJERTV10IS090084Nilli BilliNo ratings yet

- Report Nippon SteelDocument5 pagesReport Nippon SteelBiraj SahooNo ratings yet

- Power Generation Using Speed Breaker With Auto Street Light: ISO 9001:2008 CertifiedDocument4 pagesPower Generation Using Speed Breaker With Auto Street Light: ISO 9001:2008 CertifiedChetan Sanikoppa AkkisNo ratings yet

- Electric Grass CutterDocument6 pagesElectric Grass CuttervinaybgodaraNo ratings yet

- DRWT Journal by Joel Varughese K 2Document11 pagesDRWT Journal by Joel Varughese K 2Anonymous Kt9Us6100% (1)

- IjsrrDocument2 pagesIjsrrapi-469687913No ratings yet

- Review Paper On Gearless Power Transmission Offset Parallel Shaft Coupling IJERTV3IS030168Document4 pagesReview Paper On Gearless Power Transmission Offset Parallel Shaft Coupling IJERTV3IS030168Siddhartha JainNo ratings yet

- Eco Friendly BikeDocument3 pagesEco Friendly BikeInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Nternational Ournal of Ngineering Ciences & Esearch EchnologyDocument10 pagesNternational Ournal of Ngineering Ciences & Esearch EchnologyArchan rajNo ratings yet

- A Revolutionary Technique of Power Generation Through Speed Breaker Power Generators IJERTV2IS80596Document5 pagesA Revolutionary Technique of Power Generation Through Speed Breaker Power Generators IJERTV2IS80596hasan bishNo ratings yet

- Power Generation by Foot Step Method - Rack and PinionDocument13 pagesPower Generation by Foot Step Method - Rack and Pinionprem53100% (2)

- Report Nippon 2019Document5 pagesReport Nippon 2019Biraj SahooNo ratings yet

- In-Wheel Motor Design For Electric VehiclesDocument7 pagesIn-Wheel Motor Design For Electric VehiclesHuNo ratings yet

- Fabrication of Special Purpose Machine: R Kumar, Hemanth Kumar J, Chethan KumarDocument4 pagesFabrication of Special Purpose Machine: R Kumar, Hemanth Kumar J, Chethan KumarMikyas BelayNo ratings yet

- Wind Turbine Building For Saving Home Electricity: Mohammed Jasim Mohammed, Salam MohammedDocument8 pagesWind Turbine Building For Saving Home Electricity: Mohammed Jasim Mohammed, Salam MohammedyunanNo ratings yet

- Development of An Economical Solar Powered Lawn MoverDocument7 pagesDevelopment of An Economical Solar Powered Lawn MoverIJRASETPublicationsNo ratings yet

- Design and Optimization of Drive Shaft With Composite Materials IJERTV1IS7080Document9 pagesDesign and Optimization of Drive Shaft With Composite Materials IJERTV1IS7080Mule Venkateswara reddyNo ratings yet

- Design and Analysis of Drive Shaft For Heavy Duty TruckDocument4 pagesDesign and Analysis of Drive Shaft For Heavy Duty TruckSanzhar Rakhimkul0% (1)

- Small Power Generation Vertical Axis Wind Turbine (VAWT) SystemDocument3 pagesSmall Power Generation Vertical Axis Wind Turbine (VAWT) SystemDhika WidayanaNo ratings yet

- FinalDocument20 pagesFinalvedant kapseNo ratings yet

- Design and Fabrication of Hybrid Solar CarDocument6 pagesDesign and Fabrication of Hybrid Solar CarPradeepNo ratings yet

- Ijser: Power Generation From Train TrackDocument8 pagesIjser: Power Generation From Train TrackChanduNo ratings yet

- Pipe Rolling MachineDocument5 pagesPipe Rolling MachineJovelyn VistanNo ratings yet

- Chapter 5 Synchronous Machines and FHP MachinesDocument68 pagesChapter 5 Synchronous Machines and FHP Machinesmebrahten100% (1)

- GEA-820A Vertical Water Wheel Driven Generators 62 A 3000 KVA. OCRDocument8 pagesGEA-820A Vertical Water Wheel Driven Generators 62 A 3000 KVA. OCRPablo ThomassetNo ratings yet

- IJCRT2106439Document6 pagesIJCRT2106439SrikanthNo ratings yet

- An Analysis of Bearingless AC MotorsDocument8 pagesAn Analysis of Bearingless AC Motorsalstn7906No ratings yet

- Characterization of Electromagnetic Rotor Material Properties and Their Impact On An Ultra-High Speed Spinning Ball MotorDocument4 pagesCharacterization of Electromagnetic Rotor Material Properties and Their Impact On An Ultra-High Speed Spinning Ball MotorSteve OoiNo ratings yet

- Design and Fabrication of Six Speed Constant Mesh Gear Box IJERTV3IS090520Document5 pagesDesign and Fabrication of Six Speed Constant Mesh Gear Box IJERTV3IS090520Atul DahiyaNo ratings yet

- Design and Fabrication of Shaft Driven Electric BicycleDocument5 pagesDesign and Fabrication of Shaft Driven Electric BicycleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Irjet V5i10168 PDFDocument6 pagesIrjet V5i10168 PDFRahul GargNo ratings yet

- Chapter 3Document24 pagesChapter 3Kapeel KumarNo ratings yet

- Paper 16Document5 pagesPaper 16Mark Nicko Yabut ZablanNo ratings yet

- Multi-Hundred Horsepower Permanent Magnet Brushless Disc MotorsDocument5 pagesMulti-Hundred Horsepower Permanent Magnet Brushless Disc MotorsaugustoNo ratings yet

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsFrom EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo ratings yet

- Power Generation by Stair CaseDocument26 pagesPower Generation by Stair CaseMayur Madhukar MankarNo ratings yet

- Report On Design of Flexible PavmentDocument32 pagesReport On Design of Flexible PavmentMayur Madhukar MankarNo ratings yet

- Spring Testing MachineDocument16 pagesSpring Testing MachineMayur Madhukar MankarNo ratings yet

- Emision Control SystemDocument22 pagesEmision Control SystemMayur Madhukar MankarNo ratings yet

- Suspension Test-Rig Project ReportDocument22 pagesSuspension Test-Rig Project ReportMayur Madhukar MankarNo ratings yet

- Wakchaure Presentation ProjectDocument16 pagesWakchaure Presentation ProjectMayur Madhukar MankarNo ratings yet

- 6sigma Implimentation in Construction IndustryDocument29 pages6sigma Implimentation in Construction IndustryMayur Madhukar MankarNo ratings yet

- A Fast Blind Detection Algorithm For Outdoor Visible Light CommunicationsDocument1 pageA Fast Blind Detection Algorithm For Outdoor Visible Light CommunicationsMayur Madhukar MankarNo ratings yet

- Abstract Emission Control SystemDocument1 pageAbstract Emission Control SystemMayur Madhukar MankarNo ratings yet

- Automobile PracticalDocument3 pagesAutomobile PracticalMayur Madhukar MankarNo ratings yet

- 5S Check List After 5SDocument12 pages5S Check List After 5SMayur Madhukar MankarNo ratings yet

- Experiment No 8Document1 pageExperiment No 8Mayur Madhukar MankarNo ratings yet

- 4992 Final Report 0951Document80 pages4992 Final Report 0951Mayur Madhukar MankarNo ratings yet

- Industrial Gear Box: Bhalerao Trupti Bhoir Pravin Bhor Sakshi Bodake ShubhamDocument15 pagesIndustrial Gear Box: Bhalerao Trupti Bhoir Pravin Bhor Sakshi Bodake ShubhamMayur Madhukar MankarNo ratings yet

- Concrete Project ReportDocument16 pagesConcrete Project ReportMayur Madhukar Mankar100% (1)

- Green Building Report FinalDocument31 pagesGreen Building Report FinalMayur Madhukar MankarNo ratings yet

- Biomedical Waste Disposal Report FinalDocument31 pagesBiomedical Waste Disposal Report FinalMayur Madhukar MankarNo ratings yet

- Making of Suspension SystemDocument15 pagesMaking of Suspension SystemMayur Madhukar MankarNo ratings yet

- Food Safety Practices and 5s Implementation in Storage Area of Foods Industry: A Case StudyDocument21 pagesFood Safety Practices and 5s Implementation in Storage Area of Foods Industry: A Case StudyMayur Madhukar MankarNo ratings yet

- Biogas Generation From Kitchen Waste FINALDocument34 pagesBiogas Generation From Kitchen Waste FINALMayur Madhukar MankarNo ratings yet

- Loknete Gopalraoji Gulve Polytechnic Vilholi, NashikDocument3 pagesLoknete Gopalraoji Gulve Polytechnic Vilholi, NashikMayur Madhukar MankarNo ratings yet

- Biogas Power GenerationDocument5 pagesBiogas Power GenerationMayur Madhukar MankarNo ratings yet

- The Implementation of Six Sigma in Construction in China: March 2016Document32 pagesThe Implementation of Six Sigma in Construction in China: March 2016Mayur Madhukar MankarNo ratings yet

- " '5S' Implementation in Food Industry ": Department of Mechanical EngineeringDocument39 pages" '5S' Implementation in Food Industry ": Department of Mechanical EngineeringMayur Madhukar MankarNo ratings yet

- IHP Control ValvesDocument22 pagesIHP Control ValvesMayur Madhukar MankarNo ratings yet

- Visveswaraya Technology University: Electromagnetic Braking System"Document51 pagesVisveswaraya Technology University: Electromagnetic Braking System"Mayur Madhukar MankarNo ratings yet

- SIX SIGMA REPORT MayuriDocument28 pagesSIX SIGMA REPORT MayuriMayur Madhukar MankarNo ratings yet

- Dafpr Final 2Document45 pagesDafpr Final 2Hemprakash PrasannaNo ratings yet

- Z3 TransmissionDocument503 pagesZ3 TransmissionSuministros Lago Suministros LagoNo ratings yet

- Auto Matic Gear BoxDocument3 pagesAuto Matic Gear BoxPubudu DhananjayaNo ratings yet

- SSP 040 Automatic Gearbox 001 FabiaDocument46 pagesSSP 040 Automatic Gearbox 001 FabiaKovács EndreNo ratings yet

- WT Vrijloopkoppeling PDFDocument28 pagesWT Vrijloopkoppeling PDFengfaridmalkNo ratings yet

- BlackBruin MotorsDocument8 pagesBlackBruin MotorsWilber RamirezNo ratings yet

- Lifting System Chapter 1: Eurocopter Deutschland GMBHDocument38 pagesLifting System Chapter 1: Eurocopter Deutschland GMBHOfelia Umpire RuizNo ratings yet

- Kubota G1700 G1800 G1900 G2000 Lawn Garden Tractor Workshop Maint Manual - 1Document392 pagesKubota G1700 G1800 G1900 G2000 Lawn Garden Tractor Workshop Maint Manual - 1bobthelaw3321No ratings yet

- Om. TS 142Document40 pagesOm. TS 142Frank ColaciuriNo ratings yet

- 2863 Piaggio x9 Full ManualDocument239 pages2863 Piaggio x9 Full ManualGábor Pásztor100% (1)

- Quick Reference: 5R55W/S Component Location and I.DDocument7 pagesQuick Reference: 5R55W/S Component Location and I.DAyhan Ümit100% (3)

- Technical Service Information: THM 4L80E/4L80EHDDocument5 pagesTechnical Service Information: THM 4L80E/4L80EHDAranza SuNo ratings yet

- 2008 690enduro Repair ManualDocument231 pages2008 690enduro Repair ManualAdam Polak100% (1)

- Clutch and Types of Clutches (C)Document11 pagesClutch and Types of Clutches (C)Rahul Kumar100% (1)

- Mitsubishi l200 26 Front AxleDocument71 pagesMitsubishi l200 26 Front Axlenikirafferty5453No ratings yet

- FLND CopDocument25 pagesFLND CopPankaj RaneNo ratings yet

- Minos User Manual Tot-370-9 424-11Document24 pagesMinos User Manual Tot-370-9 424-11Wendell AntonesNo ratings yet

- Koya Sprag Clutches PDFDocument19 pagesKoya Sprag Clutches PDFZahir KhiraNo ratings yet

- Craftsman 917276102 - Owners - ManualDocument60 pagesCraftsman 917276102 - Owners - ManualDude manNo ratings yet

- b100 b200 Series Product Manual Black Bruin enDocument59 pagesb100 b200 Series Product Manual Black Bruin enAhmed AliNo ratings yet

- Hydraulic Traction AssistantDocument4 pagesHydraulic Traction Assistantxxsh100% (1)

- DSGDocument66 pagesDSGTM12550% (2)

- Rovi X 3 Power Wheelchair User ManualDocument44 pagesRovi X 3 Power Wheelchair User ManualOsama QureshiNo ratings yet

- Enstrom 480B Pilot Training ManualDocument105 pagesEnstrom 480B Pilot Training Manuallgv9100% (2)

- Bucket Elevator Gear Units: Operating InstructionsDocument28 pagesBucket Elevator Gear Units: Operating Instructionssandip patelNo ratings yet

- Alternator Clutch Pulley Designs: ISSUE 03.2010 ISSUE 02.2011Document4 pagesAlternator Clutch Pulley Designs: ISSUE 03.2010 ISSUE 02.2011venothNo ratings yet

- Fundamentals and Types of MechanismDocument60 pagesFundamentals and Types of MechanismVaibhav Vithoba Naik88% (8)

- Borg Warner R10 Wiring Instruction: Originally Posted OnDocument5 pagesBorg Warner R10 Wiring Instruction: Originally Posted OnRob WolfeNo ratings yet