Professional Documents

Culture Documents

50V/1.5A Step-Down High Brightness LED Driver: General Description Features

50V/1.5A Step-Down High Brightness LED Driver: General Description Features

Uploaded by

Kwun Hok ChongCopyright:

Available Formats

You might also like

- Tachosoft Mileage Calculator 23.1 Free DownloadAuto Repair Technician HomeDocument62 pagesTachosoft Mileage Calculator 23.1 Free DownloadAuto Repair Technician HomeKwun Hok ChongNo ratings yet

- Module Content: Unit of Competency: Install PV System Module Title: Installing PV System Module DescriptorDocument33 pagesModule Content: Unit of Competency: Install PV System Module Title: Installing PV System Module DescriptorJohn Rey Alaza100% (2)

- High Voltage Linear LED Driver Description Features: Is A High Current PrecisionDocument6 pagesHigh Voltage Linear LED Driver Description Features: Is A High Current PrecisionEzequiel A O VillegasNo ratings yet

- Battery Charger: Standard EquipmentDocument2 pagesBattery Charger: Standard EquipmentlejocolsaNo ratings yet

- Ac Ripple Effects On Lead Acid BatteriesDocument8 pagesAc Ripple Effects On Lead Acid BatteriesRichard Flynn0% (1)

- PT4115 LED Step-DownDocument18 pagesPT4115 LED Step-DownNandor KermeciNo ratings yet

- 30V, 1.2A Step-Down High Brightness LED Driver With 5000:1 DimmingDocument18 pages30V, 1.2A Step-Down High Brightness LED Driver With 5000:1 DimmingJaPan LifeNo ratings yet

- PT4205 PowTechDocument18 pagesPT4205 PowTechJose ReyesNo ratings yet

- Pt4103e PDFDocument7 pagesPt4103e PDFM'handAyoubiNo ratings yet

- Features Description: LT3755/LT3755-1/LT3755-2 40V, 75V LED ControllersDocument28 pagesFeatures Description: LT3755/LT3755-1/LT3755-2 40V, 75V LED ControllersMick Thomson RcNo ratings yet

- Description: 1A LED Driver With Internal SwitchDocument15 pagesDescription: 1A LED Driver With Internal SwitchSergio BarbozaNo ratings yet

- TD1410 TechcodeDocument15 pagesTD1410 TechcodegrooyoNo ratings yet

- pt1301 r3.2 PowtechDocument9 pagespt1301 r3.2 PowtechOscar Caetano FontNo ratings yet

- Preliminary: TE CHDocument8 pagesPreliminary: TE CHhsuhsu仔No ratings yet

- TRIAC Dimmable Offline LED Driver: TechnologyDocument8 pagesTRIAC Dimmable Offline LED Driver: TechnologyCanerNo ratings yet

- RT8577ADocument18 pagesRT8577ASamuel SamTechNo ratings yet

- TD1583 TechcodeDocument13 pagesTD1583 Techcodedavid.gjeorgevskiNo ratings yet

- lt8356 1-2955993Document27 pageslt8356 1-2955993chawkigenieNo ratings yet

- A6211 Datasheet PDFDocument18 pagesA6211 Datasheet PDFNestor GlezNo ratings yet

- Tle 4260Document15 pagesTle 4260Didier DoradoNo ratings yet

- Features Description: Ltc4290/Ltc4271 8-Port Poe/Poe+ Pse ControllerDocument32 pagesFeatures Description: Ltc4290/Ltc4271 8-Port Poe/Poe+ Pse ControllerVladimir MartynovNo ratings yet

- CN 5722Document8 pagesCN 5722vibhanshuNo ratings yet

- AC-DC LED Driver MT7930Document8 pagesAC-DC LED Driver MT7930Daniel GonzálezNo ratings yet

- LP 8545Document46 pagesLP 8545NalsonNo ratings yet

- PT4115EDocument18 pagesPT4115Edragom2No ratings yet

- Al8860 1019719Document18 pagesAl8860 1019719hansNo ratings yet

- Datasheet 0.4A 150Khz 80V Buck DC To DC Converter Xl7005A Features General DescriptionDocument10 pagesDatasheet 0.4A 150Khz 80V Buck DC To DC Converter Xl7005A Features General DescriptionAyu NilamNo ratings yet

- AL5815EV1 User GuideDocument8 pagesAL5815EV1 User GuideJuan Vicente Hernandez LogytelNo ratings yet

- AL8862QDocument17 pagesAL8862QIvo MatosNo ratings yet

- AL8861EV1 User GuideDocument8 pagesAL8861EV1 User GuideHans ClarinNo ratings yet

- LED DRIVER - DP830xDocument10 pagesLED DRIVER - DP830xHenryNo ratings yet

- AL8812Document11 pagesAL8812julio cesar calveteNo ratings yet

- Bd9423efv e 1223519 PDFDocument61 pagesBd9423efv e 1223519 PDFVươngNo ratings yet

- BD9423EFVDocument61 pagesBD9423EFVIoan TivgaNo ratings yet

- AD52580B Audio AmplifierDocument3 pagesAD52580B Audio Amplifierhamada13No ratings yet

- Datasheet 2A 150Khz 40V Buck DC/DC Converter With Constant Current Loop Xl4001Document7 pagesDatasheet 2A 150Khz 40V Buck DC/DC Converter With Constant Current Loop Xl4001CandNo ratings yet

- DAEWOO Dal 22v1wcDocument61 pagesDAEWOO Dal 22v1wcMarco Antonio100% (2)

- Cat4101 DDocument9 pagesCat4101 DArdvaakNo ratings yet

- 4260 2s PDFDocument15 pages4260 2s PDFmarce822No ratings yet

- TLE4260Document15 pagesTLE4260NoelNo ratings yet

- TD7590 PDFDocument13 pagesTD7590 PDFandibdgNo ratings yet

- 24-Bit Analog-to-Digital Converter (ADC) With Built-In Temperature SensorDocument8 pages24-Bit Analog-to-Digital Converter (ADC) With Built-In Temperature SensorFabricio AmaguañaNo ratings yet

- SONY,,: For The Availability of This Product, Please Contact The Sales OfficeDocument8 pagesSONY,,: For The Availability of This Product, Please Contact The Sales OfficeERNANIPARNOWNo ratings yet

- Led Driver - BP3315Document14 pagesLed Driver - BP3315HenryNo ratings yet

- OB2530P On BrightElectronicsDocument10 pagesOB2530P On BrightElectronicsrrNo ratings yet

- 2SD 718 - IscDocument4 pages2SD 718 - IscStevenNo ratings yet

- LT3743 Demo Board Rev2Document6 pagesLT3743 Demo Board Rev2tosraj7001No ratings yet

- TDAX023100Document3 pagesTDAX023100Abdul KurniadiNo ratings yet

- Silergy Corp SY8213FCC - C178246Document9 pagesSilergy Corp SY8213FCC - C178246Thai LamNo ratings yet

- Hx712 English Datasheet PDFDocument9 pagesHx712 English Datasheet PDFkibriaNo ratings yet

- Ipd 66031Document42 pagesIpd 66031HannOtto StoreNo ratings yet

- MT7842 MaxicTechnologyDocument6 pagesMT7842 MaxicTechnologyHeart of mountainNo ratings yet

- Ait Semiconductor Inc.: Description FeaturesDocument11 pagesAit Semiconductor Inc.: Description FeaturesSamerNo ratings yet

- Description Features: Maximizing IC PerformanceDocument6 pagesDescription Features: Maximizing IC PerformanceHernan De OtoNo ratings yet

- DP9127V DPDocument11 pagesDP9127V DPGustavo AlonsoNo ratings yet

- TSCR420CX6 / TSCR421CX6: Taiwan SemiconductorDocument11 pagesTSCR420CX6 / TSCR421CX6: Taiwan SemiconductorJuan CecconiNo ratings yet

- General Description Features: 2A 150Khz PWM Buck DC/DC Converter Td1509Document16 pagesGeneral Description Features: 2A 150Khz PWM Buck DC/DC Converter Td1509Vasil StoianovNo ratings yet

- RT8537 RichtekDocument17 pagesRT8537 Richtekodonelb9No ratings yet

- DW 8501Document8 pagesDW 8501مصعب بابكرNo ratings yet

- FAN7340 LED Backlight Driving Boost Switch: Features DescriptionDocument16 pagesFAN7340 LED Backlight Driving Boost Switch: Features DescriptionEnrile Labiano BaduaNo ratings yet

- PT4115 89eDocument15 pagesPT4115 89eAnonymous aDAfzvNo ratings yet

- HP 23 (22) Xi Backlight Driver EUP2589 PDFDocument12 pagesHP 23 (22) Xi Backlight Driver EUP2589 PDFmariusvNo ratings yet

- P50NF06 InchangeDocument2 pagesP50NF06 InchangeKwun Hok ChongNo ratings yet

- SS5P5, SS5P6: Vishay General SemiconductorDocument5 pagesSS5P5, SS5P6: Vishay General SemiconductorKwun Hok ChongNo ratings yet

- Waja Elec Wiring 26112013165107Document132 pagesWaja Elec Wiring 26112013165107Kwun Hok ChongNo ratings yet

- 绅宝车系正时图Document4 pages绅宝车系正时图Kwun Hok ChongNo ratings yet

- Max16833 Max16833gDocument25 pagesMax16833 Max16833gKwun Hok ChongNo ratings yet

- 17 最新汽车电脑维修彩色图解电子书Document210 pages17 最新汽车电脑维修彩色图解电子书Kwun Hok ChongNo ratings yet

- RJK0632JPD RenesasDocument7 pagesRJK0632JPD RenesasKwun Hok ChongNo ratings yet

- 路虎车系正时图Document4 pages路虎车系正时图Kwun Hok ChongNo ratings yet

- 欧宝车系正时图Document12 pages欧宝车系正时图Kwun Hok ChongNo ratings yet

- 15.汽车电控单元端子检测速查手册 下Document498 pages15.汽车电控单元端子检测速查手册 下Kwun Hok ChongNo ratings yet

- 93L56R RohmDocument42 pages93L56R RohmKwun Hok ChongNo ratings yet

- TM161A (16 Chars X 1 Row) LCD DatasheetDocument30 pagesTM161A (16 Chars X 1 Row) LCD DatasheetKwun Hok ChongNo ratings yet

- 307B液压图2Document2 pages307B液压图2Kwun Hok ChongNo ratings yet

- TM12864G Graphic Mode 128 X 64 LCD DatasheetDocument28 pagesTM12864G Graphic Mode 128 X 64 LCD DatasheetKwun Hok ChongNo ratings yet

- 03 大众车系与自主品牌汽车电脑维修图集Document64 pages03 大众车系与自主品牌汽车电脑维修图集Kwun Hok ChongNo ratings yet

- A6261 DatasheetDocument20 pagesA6261 DatasheetKwun Hok ChongNo ratings yet

- Supporting IV INM2303 001Document2 pagesSupporting IV INM2303 001Kwun Hok ChongNo ratings yet

- ELEC3300 02a-Student ProjectsDocument38 pagesELEC3300 02a-Student ProjectsKwun Hok ChongNo ratings yet

- MAX232 - TTL Convertor DatasheetDocument16 pagesMAX232 - TTL Convertor DatasheetKwun Hok ChongNo ratings yet

- MINI V3 Development BoardDocument5 pagesMINI V3 Development BoardKwun Hok ChongNo ratings yet

- ELEC3300 08-Series CommunicationDocument43 pagesELEC3300 08-Series CommunicationKwun Hok ChongNo ratings yet

- MINI V3 SchematicsDocument6 pagesMINI V3 SchematicsKwun Hok ChongNo ratings yet

- C-9 ENGINE系统运行测试与调整Document96 pagesC-9 ENGINE系统运行测试与调整Kwun Hok ChongNo ratings yet

- ELEC3300 - 01 Introduction To Embedded SystemsDocument21 pagesELEC3300 - 01 Introduction To Embedded SystemsKwun Hok ChongNo ratings yet

- ELEC3300 - 03-Embedded System StructureDocument27 pagesELEC3300 - 03-Embedded System StructureKwun Hok ChongNo ratings yet

- Elec3300 09-DmaDocument21 pagesElec3300 09-DmaKwun Hok ChongNo ratings yet

- ELEC3300 04 InterruptDocument28 pagesELEC3300 04 InterruptKwun Hok ChongNo ratings yet

- Immobilizer System TutorialDocument18 pagesImmobilizer System TutorialKwun Hok ChongNo ratings yet

- MA29Document1 pageMA29Kwun Hok ChongNo ratings yet

- 1951-Jacobsen-Hydrodynamic Experiments With Rigid Cylindrical Tanks Subjected To Transient MontionsDocument34 pages1951-Jacobsen-Hydrodynamic Experiments With Rigid Cylindrical Tanks Subjected To Transient MontionsEuge CompagnoniNo ratings yet

- Wind SensorDocument2 pagesWind SensorDerek YoungNo ratings yet

- Renewable Energy': and Its Impact On Environment and Human LifeDocument11 pagesRenewable Energy': and Its Impact On Environment and Human LifeAnushka BhaveNo ratings yet

- Volume Correction Factors - Diesel Fuel: Issued: July 2018Document5 pagesVolume Correction Factors - Diesel Fuel: Issued: July 2018ساهر رباطهNo ratings yet

- BẢNG TÍNH TẠO ÁP CẦU THANG 5Document10 pagesBẢNG TÍNH TẠO ÁP CẦU THANG 5Huỳnh Đức ThiệnNo ratings yet

- STTH 102Document12 pagesSTTH 102Abel GaunaNo ratings yet

- HIPOTDocument5 pagesHIPOTHARIHARANNo ratings yet

- Jawapan Gerak Gempur IIDocument4 pagesJawapan Gerak Gempur IIrenuNo ratings yet

- Opportunities For CCUS in Southeast Asia - DR Raimund MalischekDocument17 pagesOpportunities For CCUS in Southeast Asia - DR Raimund MalischekEconomic Research Institute for ASEAN and East Asia100% (1)

- Colegio de Montalban San Jose, Rodriguez, Rizal: Institute of EducationDocument4 pagesColegio de Montalban San Jose, Rodriguez, Rizal: Institute of EducationVOLANTE, EDLYN JOYCENo ratings yet

- Electrical Works - Package 2B Addendum BoQ Synefra EstimateDocument46 pagesElectrical Works - Package 2B Addendum BoQ Synefra Estimatemsdixit2006100% (4)

- Compressor Technical DataDocument3 pagesCompressor Technical DataGabriel RodriguezNo ratings yet

- Deney 3Document22 pagesDeney 3baratniloy1No ratings yet

- Design & Development of Multi-Evaporative Refrigeration SystemDocument4 pagesDesign & Development of Multi-Evaporative Refrigeration SystemAnonymous izrFWiQNo ratings yet

- PBL 2Document21 pagesPBL 2Sheratul AshikinNo ratings yet

- G12MEC21220802 - Connected ParticlesDocument25 pagesG12MEC21220802 - Connected ParticlesBerniceNo ratings yet

- Ordering Information: Power PCB RelayDocument12 pagesOrdering Information: Power PCB RelayDemóstenes Moraes OlintoNo ratings yet

- Amplificador de 00006WRms Com TDA 2003Document3 pagesAmplificador de 00006WRms Com TDA 2003EVERALDO AMORIMNo ratings yet

- EmtlDocument62 pagesEmtlsiri.pogulaNo ratings yet

- KTG & ThermodynamicsDocument38 pagesKTG & ThermodynamicsSesha Sai KumarNo ratings yet

- Energy Efficiency and CO2 Emission Comparison of Alternative PowertrainDocument11 pagesEnergy Efficiency and CO2 Emission Comparison of Alternative PowertrainVc CvNo ratings yet

- Four-Junction Wafer-Bonded Concentrator Solar CellsDocument7 pagesFour-Junction Wafer-Bonded Concentrator Solar CellsFerdi PratamaNo ratings yet

- Cooling Load CalculationsDocument6 pagesCooling Load CalculationssamuelNo ratings yet

- 8080 - PDF - 2019 12 14 19 09 36 PDFDocument32 pages8080 - PDF - 2019 12 14 19 09 36 PDFRashi RaiNo ratings yet

- Saturated Steam Metal Wall 1 Outer Asbestos 3Document8 pagesSaturated Steam Metal Wall 1 Outer Asbestos 3raras atiNo ratings yet

- CEC Inverters ListDocument11 pagesCEC Inverters ListSolarShop AustraliaNo ratings yet

- Electricity and Magnetism Handouts 1Document5 pagesElectricity and Magnetism Handouts 1Homo CiderNo ratings yet

50V/1.5A Step-Down High Brightness LED Driver: General Description Features

50V/1.5A Step-Down High Brightness LED Driver: General Description Features

Uploaded by

Kwun Hok ChongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

50V/1.5A Step-Down High Brightness LED Driver: General Description Features

50V/1.5A Step-Down High Brightness LED Driver: General Description Features

Uploaded by

Kwun Hok ChongCopyright:

Available Formats

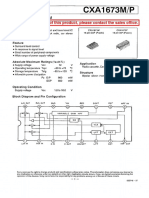

PT4115E

50V/1.5A Step-down High Brightness

LED Driver

GENERAL DESCRIPTION FEATURES

The PT4115E is a continuous conduction mode Simple low parts count

inductive step-down converter, designed for driving Wide input voltage range: 6V to 50V

High efficiency (up to 97%)

single or multiple series connected LED efficiently

Up to 1.5A output current

from a voltage source higher than the total LED chain Single pin on/off and brightness control using DC

voltage. The device operates from an input supply voltage or PWM

between 6V and 50V and provides an externally Up to 1MHz switching frequency

adjustable output current of up to 1.5A. Typical 3% output current accuracy

The PT4115E includes the power switch and a Inherent open-circuit LED protection

Inherent Rcs open protection

high-side output current sensing circuit, which uses an High-Side Current Sense

external resistor to set the nominal average output Hysteretic Control: No need compensation

current, and a dedicated DIM input accepts either a DC Adjustable Constant LED Current

voltage or a wide range of pulsed dimming. Applying a Thermal shutdown

voltage of 0.3V or lower to the DIM pin turns the

output off and switches the device into a low current

APPLICATIONS

standby state. Low voltage halogen replacement LEDs

The PT4115E is available in SOT89-5 package. Automotive lighting

Low voltage industrial lighting

LED back-up lighting

Illuminated signs

SELV lighting

LCD TV backlighting

ORDERING INFORMATION

TEMPERATURE ORDERING PART TRANSPORT

PACKAGE MARKING

RANGE NUMBER MEDIA

Tape and Reel PT4115E

SOT89-5 -40 oC to 85 oC PT4115EE89E xxxxxX

1000 units

Note:

xxxxxX

Assembly Factory Code

Lot Number

TYPICAL APPLICATION CIRCUIT

RS

DC6-50V

VIN

LED

L

D

CIN

AC12-24V VIN CSN SW

DIM PT4115E

GND

CR POWTECH (SHANGHAI) CO., LTD. WWW.CRPOWTECH.COM Page 1

PT4115E_DS_Rev EN 1.0

PT4115E

50V/1.5A Step-down High Brightness

LED Driver

PIN ASSIGNMENT

PIN DESCRIPTIONS

SOT89-5 PIN

PIN NAMES DESCRIPTION

No.

Switch Output. SW is the drain of the internal N-Ch MOSFET

1 SW

switch.

2 GND Signal and power ground. Connect directly to ground plane.

Logic level dimming input. Drive DIM low to turn off the current

3 DIM

regulator. Drive DIM high to enable the current regulator.

4 CSN Current sense input

5 VIN Input Supply Pin. Must be locally bypassed.

Internally connected to GND. Mount on board for lower thermal

Exposed PAD

resistance.

ABSOLUTE MAXIMUM RATINGS (note1)

SYMBOL ITEMS VALUE UNIT

VIN Supply Voltage -0.3~55 V

SW Drain of the internal power switch -0.3~55 V

CSN Current sense input (Respect to VIN) +0.3~(-6.0) V

DIM Logic level dimming input -0.3~6 V

ISW Switch output current 1.5 A

PDMAX Power Dissipation (Note 2) 1.5 W

PTR Thermal Resistance, SOT89-5 θJA 45 o

C /W

Operation Junction Temperature Range -40 to 150 o

TJ C

o

TSTG Storage Temperature -55 to 150 C

ESD Susceptibility (Note 3) 2 kV

CR POWTECH (SHANGHAI) CO., LTD. WWW.CRPOWTECH.COM Page 2

PT4115E_DS_Rev EN 1.0

PT4115E

50V/1.5A Step-down High Brightness

LED Driver

RECOMMENDED OPERATING RANGE

SYMBOL ITEMS VALUE UNIT

VIN VDD Supply Voltage 6 ~ 50 V

o

TOPT Operating Temperature -40 to +85 C

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Recommended

Operating Range indicates conditions for which the device is functional, but do not guarantee specific performance

limits. Electrical Characteristics state DC and AC electrical specifications under particular test conditions which

guarantee specific performance limits. This assumes that the device is within the Operating Range. Specifications are

not guaranteed for parameters where no limit is given, however, the typical value is a good indication of device

performance.

Note 2: The maximum power dissipation must be derated at elevated temperatures and is dictated by TJMAX, θJA, and

the ambient temperature TA. The maximum allowable power dissipation is PDMAX = (TJMAX - TA)/ θJA or the number

given in Absolute Maximum Ratings, whichever is lower.

Note 3: Human body model, 100pF discharged through a 1.5kΩ resistor.

CR POWTECH (SHANGHAI) CO., LTD. WWW.CRPOWTECH.COM Page 3

PT4115E_DS_Rev EN 1.0

PT4115E

50V/1.5A Step-down High Brightness

LED Driver

ELECTRICAL CHARACTERISTICS (Note 4, 5)

The following specifications apply for VIN=24V, TA=25 oC, unless specified otherwise.

SYMBOL ITEMS CONDITIONS Min. Typ. Max. UNIT

VIN Input Voltage 6 50 V

VUVLO Under voltage lock out VIN rising 4.5 V

VUVLO_HYS UVLO hysterisis VIN falling 0.3 V

FSW Max. Switching Frequency 1 MHz

Current Sense

Mean current sense

VCSN VIN-VCSN 194 200 206 mV

threshold voltage

VCSN_hys Sense threshold hysteresis ±15 %

ICSN CSN Pin Input Current VIN-VCSN=50mV 8 µA

Operating Current

ISD Shutdown supply current 60 100 µA

Quiescent supply current

IOFF No Switching 0.16 0.3 mA

with output off

DIM Input

VDIM Internal supply voltage DIM floating 4.2 V

VDIM_H DIM input voltage High 0.3 0.35 V

VDIM_HYS DIM input voltage hysterisis 20 50 80 mV

VDIM_DC DC brightness control 0.5 2.5 V

FDIM_MIN Min. DIM Frequency 0.1 kHz

FDIM_MAX Max. DIM Frequency 20 kHz

RDIM DIM pull up resistor to

200 KΩ

Internal supply voltage

IDIM_H DIM input leakage high VDIM = 5.0V 2.8 µA

IDIM_L DIM input leakage low VDIM = 0 22 µA

Output Switch

RSW SW On Resistance VIN=6V~50V 0.4 Ω

ISWmean Continuous SW Current 1.5 A

ILEAK SW Leakage Current 0.5 5 µA

Thermal Shutdown

TSD Thermal Shutdown 155 ℃

Threshold

TSD_HYS Thermal Shutdown 20 ℃

hysteresis

Note 4: Typical parameters are measured at 25˚C and represent the parametric norm.

Note 5: Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

CR POWTECH (SHANGHAI) CO., LTD. WWW.CRPOWTECH.COM Page 4

PT4115E_DS_Rev EN 1.0

PT4115E

50V/1.5A Step-down High Brightness

LED Driver

SIMPLIFIED BLOCK DIAGRAM

OPERATION DESCRIPTION

The PT4115E in conjunction with current sense resistor (RCS),the inductor (L1), and MOSFET forms a self

oscillating continuous-mode buck converter.

When input voltage VIN is first applied, the initial current in L1 and R CS is zero and there is no output from the

current sense circuit. Under this condition, the output of CS comparator is high. This turns on switch, causing

current to flow from VIN to ground, via RCS, the LED(s),L1 and internal MOSFET. The current rises at a rate

determined by VIN and L1 to produce a voltage ramp (VCSN) across RCS. When (VIN-VCSN) > 230mV, the

output of CS comparator switches low and the switch turns off. The current flowing on the RCS decreases at

another rate. When (VIN-VCSN) < 170mV, the switch turns on again and the mean current on the LED is

determined by 200mV/RCS.

The high-side current-sensing scheme and on-board current-setting circuitry minimize the number of external

components while delivering LED current with ±3% accuracy, using a 1% sense resistor. The PT4115E

allows dimming with a PWM signal at the DIM input. A logic level below 0.3V at DIM forces PT4115E to turn

off the LED and the logic level at DIM must be at least 2.5V to turn on the full LED current. The frequency of

PWM dimming ranges from 100Hz to 20 kHz.

The DIM pin can be driven by an external DC voltage (VDIM) to adjust the output current to a value below the

nominal average value defined by RCS. The DC voltage is valid from 0.5V to 2.5V. When the DC voltage is

higher than 2.5V, the output current keeps constant.

Additionally, to ensure the reliability, the PT4115E is built with a thermal shutdown (TSD) protection. The TSD

protests the IC from over temperature (155℃).

CR POWTECH (SHANGHAI) CO., LTD. WWW.CRPOWTECH.COM Page 5

PT4115E_DS_Rev EN 1.0

PT4115E

50V/1.5A Step-down High Brightness

LED Driver

TYPICAL PERFORMANCE CHARACTERASTICS

VIN=24V,3LEDs,IOUT=1A,TA=25℃,unless otherwise noted.

Efficiency Steady State

2µS/div

Input Power On Input Power Off

2mS/div 100mS/div

EN Power On EN Power Off

400µS/div 200µS/div

CR POWTECH (SHANGHAI) CO., LTD. WWW.CRPOWTECH.COM Page 6

PT4115E_DS_Rev EN 1.0

PT4115E

50V/1.5A Step-down High Brightness

LED Driver

TYPICAL PERFORMANCE CHARACTERASTICS(continued)

VIN=24V,3LEDs,IOUT=1A,TA=25℃,unless otherwise noted.

PWM Dimming PWM Dimming

(2KHz,50%) (2KHz,1%)

400µS/div 400µS/div

Short LED+ to LED- Protection Short LED+ to LED- Recovery

20µS/div 20µS/div

Open LED Load Protection Open LED Load Recovery

2mS/div 40µS/div

CR POWTECH (SHANGHAI) CO., LTD. WWW.CRPOWTECH.COM Page 7

PT4115E_DS_Rev EN 1.0

PT4115E

50V/1.5A Step-down High Brightness

LED Driver

TYPICAL PERFORMANCE CHARACTERASTICS(continued)

VIN=24V,3LEDs,IOUT=1A,TA=25℃,unless otherwise noted.

Open RCS Protection

2S/div

APPLICATION NOTES

Setting nominal average output current Output current adjustment by PWM

with external resistor RCS control

The nominal average output current in the LED(s) A Pulse Width Modulated (PWM) signal with duty

is determined by the value of the external current cycle PWM can be applied to the DIM pin, to adjust

sense resistor (RCS) connected between VIN and the output current to a value below the nominal

CSN and is given by: average value set by resistor RCS:

IOUT=0.2/RCS

0.2 D

This equation is valid when DIM pin is float or I OUT

applied with a voltage higher than 2.5V (must be

RCS

less than 5V). Actually, RCS sets the maximum (0≤D≤100%,2.5V<VPULSE<5.0V)

average current which can be adjusted to a less

0.2 D V PULSE

one by dimming. I OUT

2.5 RCS

Output current adjustment by external DC (0≤D≤100%,0<VPULSE<2.5V)

control voltage PWM dimming provides reduced brightness by

The DIM pin can be driven by an external DC modulating the LED’s forward current between 0%

voltage (VDIM), to adjust the output current to a and 100%. The LED brightness is controlled by

value below the nominal average value defined by adjusting the relative ratios of the on time to the off

RCS.The average output current is given by: time. A 25% brightness level is achieved by turning

0.2 V DIM the LED on at full current for 25% of one cycle. To

I OUT (0.5V≤VDIM≤2.5V)

2.5 RCS ensure this switching process between on and off

state is invisible by human eyes, the switching

Note that 100% brightness setting corresponds to: frequency must be greater than 100 Hz. Above 100

(2.5V≤VDIM≤5V) Hz, the human eyes average the on and off times,

CR POWTECH (SHANGHAI) CO., LTD. WWW.CRPOWTECH.COM Page 8

PT4115E_DS_Rev EN 1.0

PT4115E

50V/1.5A Step-down High Brightness

LED Driver

seeing only an effective brightness that is switching loss. Choose a switch frequency

proportional to the LED’s on-time duty cycle. The between 100kHz to 500kHz for most

advantage of PWM dimming is that the forward application.According to switching frequency,

current is always constant, therefore the LED color inductor value can be estimated as:

does not vary with brightness as it does with

(1 V OUT / V IN ) V OUT

analog dimming. Pulsing the current provides L

0.3 I LED fsw

precise brightness control while preserving the

color purity. The dimming frequency of PT4115E For higher efficiency, choose an inductor with a DC

can be as high as 20 kHz. resistance as small as possible.

Soft-start Output capacitor selection

An external capacitor from the DIM pin to ground For most applications,the output capacitor is not

will provide additional soft-start delay, by necessary. Peak to peak ripple current in the

increasing the time taken for the voltage on this pin LED(s) can be reduced below 30% of the average

to rise to the turn-on threshold and by slowing current, if required, by adding a capacitor across

down the rate of rise of the control voltage at the the LED(s).A value of 2.2µF will meet most

input of the comparator. requirements. Proportionally lower ripple can be

achieved with higher capacitor values. Note that

Input capacitor selection the capacitor will not affect operating frequency or

A low ESR capacitor should be used for input efficiency, but it will increase start-up delay and

decoupling, as the ESR of this capacitor appears in reduce the frequency of dimming, by reducing the

series with the supply source impedance and rate of rise of LED voltage.

lowers overall efficiency. This capacitor has to

supply the relatively high peak current to the coil Thermal considerations

and smooth the current ripple on the input supply. When the device operates at high ambient

A minimum value of 10µF is acceptable if the DC temperature, or when driving maximum load

input source is close to the device, but higher current, care must be taken to avoid exceeding the

values will improve performance at lower input package power dissipation limits.

voltages, especially when the source impedance is

high. The voltage rating should be greater than the Layout considerations

input voltage. The input capacitor should be placed Pay careful attention to the PCB layout and

as close as possible to the IC. For maximum component placement. RCS should be placed close

stability over temperature and voltage, capacitors to the VIN pin and CSN pin in order to minimize

with X7R, X5R, or better dielectric are current sense error. The input loop including input

recommended. Capacitors with Y5V dielectric are capacitor,Schottky diode, and MOSFET which

not suitable for decoupling in this application and should be as short as possible.

should not be used.

Inductor selection

Lower value of inductance can result in a higher

switching frequency, which causes a larger

CR POWTECH (SHANGHAI) CO., LTD. WWW.CRPOWTECH.COM Page 9

PT4115E_DS_Rev EN 1.0

PT4115E

50V/1.5A Step-down High Brightness

LED Driver

PACKAGE INFORMATION

SOT89-5 Package

D1 A

E

E1

b1

b c

e

L

e1

MILLIMETERS INCHES

SYMBOL

MIN MAX MIN MAX

A 1.400 1.600 0.055 0.063

b 0.320 0.520 0.013 0.020

b1 0.360 0.560 0.014 0.022

c 0.350 0.440 0.014 0.017

D 4.400 4.600 0.173 0.181

D1 1.400. 1.800 0.055 0.071

E 2.300 2.600 0.091 0.102

E1 3.940 4.250 0.155 0.167

e 1.500 TYP. 0.060 TYP.

e1 2.900 3.100 0.114 0.122

L 0.900 1.100 0.035 0.043

CR POWTECH (SHANGHAI) CO., LTD. WWW.CRPOWTECH.COM Page 10

PT4115E_DS_Rev EN 1.0

PT4115E

50V/1.5A Step-down High Brightness

LED Driver

IMPORTANT NOTICE

POWTWCH (SHANGHAI) CO., LTD. reserves the right to make corrections, enhancements, improvements and other changes to its

semiconductor products and services and to discontinue any product or service. Buyers should obtain the latest relevant information

before placing orders and should verify that such information is current and complete. All semiconductor products (also referred to

herein as “components”) are sold subject to POWTECH’s terms and conditions of sale supplied at the time of order acknowledgment.

POWTECH warrants performance of its components to the specifications applicable at the time of sale, in accordance with the

warranty in POWTECH’s terms and conditions of sale of semiconductor products. Testing and other quality control techniques are used

to the extent POWTECH deems necessary to support this warranty. Except where mandated by applicable law, testing of all parameters

of each component is not necessarily performed.

POWTECH assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their

products and applications using POWTECH components. To minimize the risks associated with Buyers’ products and applications,

Buyers should provide adequate design and operating safeguards.

No POWTECH components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized

officers of the parties have executed a special agreement specifically governing such use.

Only those POWTECH components which POWTECH has specifically designated as military grade or “enhanced plastic” are

designed and intended for use in military/aerospace applications or environments. Buyer acknowledges and agrees that any military or

aerospace use of POWTECH components which have not been so designated is solely at the Buyer's risk, and that Buyer is solely

responsible for compliance with all legal and regulatory requirements in connection with such use

Unless POWTECH has specifically designated certain components which meet ISO/TS16949 requirements, mainly for automotive

use, POWTECH will not be responsible for any failure of such components to meet such requirements.

CR POWTECH (SHANGHAI) CO., LTD. WWW.CRPOWTECH.COM Page 11

PT4115E_DS_Rev EN 1.0

You might also like

- Tachosoft Mileage Calculator 23.1 Free DownloadAuto Repair Technician HomeDocument62 pagesTachosoft Mileage Calculator 23.1 Free DownloadAuto Repair Technician HomeKwun Hok ChongNo ratings yet

- Module Content: Unit of Competency: Install PV System Module Title: Installing PV System Module DescriptorDocument33 pagesModule Content: Unit of Competency: Install PV System Module Title: Installing PV System Module DescriptorJohn Rey Alaza100% (2)

- High Voltage Linear LED Driver Description Features: Is A High Current PrecisionDocument6 pagesHigh Voltage Linear LED Driver Description Features: Is A High Current PrecisionEzequiel A O VillegasNo ratings yet

- Battery Charger: Standard EquipmentDocument2 pagesBattery Charger: Standard EquipmentlejocolsaNo ratings yet

- Ac Ripple Effects On Lead Acid BatteriesDocument8 pagesAc Ripple Effects On Lead Acid BatteriesRichard Flynn0% (1)

- PT4115 LED Step-DownDocument18 pagesPT4115 LED Step-DownNandor KermeciNo ratings yet

- 30V, 1.2A Step-Down High Brightness LED Driver With 5000:1 DimmingDocument18 pages30V, 1.2A Step-Down High Brightness LED Driver With 5000:1 DimmingJaPan LifeNo ratings yet

- PT4205 PowTechDocument18 pagesPT4205 PowTechJose ReyesNo ratings yet

- Pt4103e PDFDocument7 pagesPt4103e PDFM'handAyoubiNo ratings yet

- Features Description: LT3755/LT3755-1/LT3755-2 40V, 75V LED ControllersDocument28 pagesFeatures Description: LT3755/LT3755-1/LT3755-2 40V, 75V LED ControllersMick Thomson RcNo ratings yet

- Description: 1A LED Driver With Internal SwitchDocument15 pagesDescription: 1A LED Driver With Internal SwitchSergio BarbozaNo ratings yet

- TD1410 TechcodeDocument15 pagesTD1410 TechcodegrooyoNo ratings yet

- pt1301 r3.2 PowtechDocument9 pagespt1301 r3.2 PowtechOscar Caetano FontNo ratings yet

- Preliminary: TE CHDocument8 pagesPreliminary: TE CHhsuhsu仔No ratings yet

- TRIAC Dimmable Offline LED Driver: TechnologyDocument8 pagesTRIAC Dimmable Offline LED Driver: TechnologyCanerNo ratings yet

- RT8577ADocument18 pagesRT8577ASamuel SamTechNo ratings yet

- TD1583 TechcodeDocument13 pagesTD1583 Techcodedavid.gjeorgevskiNo ratings yet

- lt8356 1-2955993Document27 pageslt8356 1-2955993chawkigenieNo ratings yet

- A6211 Datasheet PDFDocument18 pagesA6211 Datasheet PDFNestor GlezNo ratings yet

- Tle 4260Document15 pagesTle 4260Didier DoradoNo ratings yet

- Features Description: Ltc4290/Ltc4271 8-Port Poe/Poe+ Pse ControllerDocument32 pagesFeatures Description: Ltc4290/Ltc4271 8-Port Poe/Poe+ Pse ControllerVladimir MartynovNo ratings yet

- CN 5722Document8 pagesCN 5722vibhanshuNo ratings yet

- AC-DC LED Driver MT7930Document8 pagesAC-DC LED Driver MT7930Daniel GonzálezNo ratings yet

- LP 8545Document46 pagesLP 8545NalsonNo ratings yet

- PT4115EDocument18 pagesPT4115Edragom2No ratings yet

- Al8860 1019719Document18 pagesAl8860 1019719hansNo ratings yet

- Datasheet 0.4A 150Khz 80V Buck DC To DC Converter Xl7005A Features General DescriptionDocument10 pagesDatasheet 0.4A 150Khz 80V Buck DC To DC Converter Xl7005A Features General DescriptionAyu NilamNo ratings yet

- AL5815EV1 User GuideDocument8 pagesAL5815EV1 User GuideJuan Vicente Hernandez LogytelNo ratings yet

- AL8862QDocument17 pagesAL8862QIvo MatosNo ratings yet

- AL8861EV1 User GuideDocument8 pagesAL8861EV1 User GuideHans ClarinNo ratings yet

- LED DRIVER - DP830xDocument10 pagesLED DRIVER - DP830xHenryNo ratings yet

- AL8812Document11 pagesAL8812julio cesar calveteNo ratings yet

- Bd9423efv e 1223519 PDFDocument61 pagesBd9423efv e 1223519 PDFVươngNo ratings yet

- BD9423EFVDocument61 pagesBD9423EFVIoan TivgaNo ratings yet

- AD52580B Audio AmplifierDocument3 pagesAD52580B Audio Amplifierhamada13No ratings yet

- Datasheet 2A 150Khz 40V Buck DC/DC Converter With Constant Current Loop Xl4001Document7 pagesDatasheet 2A 150Khz 40V Buck DC/DC Converter With Constant Current Loop Xl4001CandNo ratings yet

- DAEWOO Dal 22v1wcDocument61 pagesDAEWOO Dal 22v1wcMarco Antonio100% (2)

- Cat4101 DDocument9 pagesCat4101 DArdvaakNo ratings yet

- 4260 2s PDFDocument15 pages4260 2s PDFmarce822No ratings yet

- TLE4260Document15 pagesTLE4260NoelNo ratings yet

- TD7590 PDFDocument13 pagesTD7590 PDFandibdgNo ratings yet

- 24-Bit Analog-to-Digital Converter (ADC) With Built-In Temperature SensorDocument8 pages24-Bit Analog-to-Digital Converter (ADC) With Built-In Temperature SensorFabricio AmaguañaNo ratings yet

- SONY,,: For The Availability of This Product, Please Contact The Sales OfficeDocument8 pagesSONY,,: For The Availability of This Product, Please Contact The Sales OfficeERNANIPARNOWNo ratings yet

- Led Driver - BP3315Document14 pagesLed Driver - BP3315HenryNo ratings yet

- OB2530P On BrightElectronicsDocument10 pagesOB2530P On BrightElectronicsrrNo ratings yet

- 2SD 718 - IscDocument4 pages2SD 718 - IscStevenNo ratings yet

- LT3743 Demo Board Rev2Document6 pagesLT3743 Demo Board Rev2tosraj7001No ratings yet

- TDAX023100Document3 pagesTDAX023100Abdul KurniadiNo ratings yet

- Silergy Corp SY8213FCC - C178246Document9 pagesSilergy Corp SY8213FCC - C178246Thai LamNo ratings yet

- Hx712 English Datasheet PDFDocument9 pagesHx712 English Datasheet PDFkibriaNo ratings yet

- Ipd 66031Document42 pagesIpd 66031HannOtto StoreNo ratings yet

- MT7842 MaxicTechnologyDocument6 pagesMT7842 MaxicTechnologyHeart of mountainNo ratings yet

- Ait Semiconductor Inc.: Description FeaturesDocument11 pagesAit Semiconductor Inc.: Description FeaturesSamerNo ratings yet

- Description Features: Maximizing IC PerformanceDocument6 pagesDescription Features: Maximizing IC PerformanceHernan De OtoNo ratings yet

- DP9127V DPDocument11 pagesDP9127V DPGustavo AlonsoNo ratings yet

- TSCR420CX6 / TSCR421CX6: Taiwan SemiconductorDocument11 pagesTSCR420CX6 / TSCR421CX6: Taiwan SemiconductorJuan CecconiNo ratings yet

- General Description Features: 2A 150Khz PWM Buck DC/DC Converter Td1509Document16 pagesGeneral Description Features: 2A 150Khz PWM Buck DC/DC Converter Td1509Vasil StoianovNo ratings yet

- RT8537 RichtekDocument17 pagesRT8537 Richtekodonelb9No ratings yet

- DW 8501Document8 pagesDW 8501مصعب بابكرNo ratings yet

- FAN7340 LED Backlight Driving Boost Switch: Features DescriptionDocument16 pagesFAN7340 LED Backlight Driving Boost Switch: Features DescriptionEnrile Labiano BaduaNo ratings yet

- PT4115 89eDocument15 pagesPT4115 89eAnonymous aDAfzvNo ratings yet

- HP 23 (22) Xi Backlight Driver EUP2589 PDFDocument12 pagesHP 23 (22) Xi Backlight Driver EUP2589 PDFmariusvNo ratings yet

- P50NF06 InchangeDocument2 pagesP50NF06 InchangeKwun Hok ChongNo ratings yet

- SS5P5, SS5P6: Vishay General SemiconductorDocument5 pagesSS5P5, SS5P6: Vishay General SemiconductorKwun Hok ChongNo ratings yet

- Waja Elec Wiring 26112013165107Document132 pagesWaja Elec Wiring 26112013165107Kwun Hok ChongNo ratings yet

- 绅宝车系正时图Document4 pages绅宝车系正时图Kwun Hok ChongNo ratings yet

- Max16833 Max16833gDocument25 pagesMax16833 Max16833gKwun Hok ChongNo ratings yet

- 17 最新汽车电脑维修彩色图解电子书Document210 pages17 最新汽车电脑维修彩色图解电子书Kwun Hok ChongNo ratings yet

- RJK0632JPD RenesasDocument7 pagesRJK0632JPD RenesasKwun Hok ChongNo ratings yet

- 路虎车系正时图Document4 pages路虎车系正时图Kwun Hok ChongNo ratings yet

- 欧宝车系正时图Document12 pages欧宝车系正时图Kwun Hok ChongNo ratings yet

- 15.汽车电控单元端子检测速查手册 下Document498 pages15.汽车电控单元端子检测速查手册 下Kwun Hok ChongNo ratings yet

- 93L56R RohmDocument42 pages93L56R RohmKwun Hok ChongNo ratings yet

- TM161A (16 Chars X 1 Row) LCD DatasheetDocument30 pagesTM161A (16 Chars X 1 Row) LCD DatasheetKwun Hok ChongNo ratings yet

- 307B液压图2Document2 pages307B液压图2Kwun Hok ChongNo ratings yet

- TM12864G Graphic Mode 128 X 64 LCD DatasheetDocument28 pagesTM12864G Graphic Mode 128 X 64 LCD DatasheetKwun Hok ChongNo ratings yet

- 03 大众车系与自主品牌汽车电脑维修图集Document64 pages03 大众车系与自主品牌汽车电脑维修图集Kwun Hok ChongNo ratings yet

- A6261 DatasheetDocument20 pagesA6261 DatasheetKwun Hok ChongNo ratings yet

- Supporting IV INM2303 001Document2 pagesSupporting IV INM2303 001Kwun Hok ChongNo ratings yet

- ELEC3300 02a-Student ProjectsDocument38 pagesELEC3300 02a-Student ProjectsKwun Hok ChongNo ratings yet

- MAX232 - TTL Convertor DatasheetDocument16 pagesMAX232 - TTL Convertor DatasheetKwun Hok ChongNo ratings yet

- MINI V3 Development BoardDocument5 pagesMINI V3 Development BoardKwun Hok ChongNo ratings yet

- ELEC3300 08-Series CommunicationDocument43 pagesELEC3300 08-Series CommunicationKwun Hok ChongNo ratings yet

- MINI V3 SchematicsDocument6 pagesMINI V3 SchematicsKwun Hok ChongNo ratings yet

- C-9 ENGINE系统运行测试与调整Document96 pagesC-9 ENGINE系统运行测试与调整Kwun Hok ChongNo ratings yet

- ELEC3300 - 01 Introduction To Embedded SystemsDocument21 pagesELEC3300 - 01 Introduction To Embedded SystemsKwun Hok ChongNo ratings yet

- ELEC3300 - 03-Embedded System StructureDocument27 pagesELEC3300 - 03-Embedded System StructureKwun Hok ChongNo ratings yet

- Elec3300 09-DmaDocument21 pagesElec3300 09-DmaKwun Hok ChongNo ratings yet

- ELEC3300 04 InterruptDocument28 pagesELEC3300 04 InterruptKwun Hok ChongNo ratings yet

- Immobilizer System TutorialDocument18 pagesImmobilizer System TutorialKwun Hok ChongNo ratings yet

- MA29Document1 pageMA29Kwun Hok ChongNo ratings yet

- 1951-Jacobsen-Hydrodynamic Experiments With Rigid Cylindrical Tanks Subjected To Transient MontionsDocument34 pages1951-Jacobsen-Hydrodynamic Experiments With Rigid Cylindrical Tanks Subjected To Transient MontionsEuge CompagnoniNo ratings yet

- Wind SensorDocument2 pagesWind SensorDerek YoungNo ratings yet

- Renewable Energy': and Its Impact On Environment and Human LifeDocument11 pagesRenewable Energy': and Its Impact On Environment and Human LifeAnushka BhaveNo ratings yet

- Volume Correction Factors - Diesel Fuel: Issued: July 2018Document5 pagesVolume Correction Factors - Diesel Fuel: Issued: July 2018ساهر رباطهNo ratings yet

- BẢNG TÍNH TẠO ÁP CẦU THANG 5Document10 pagesBẢNG TÍNH TẠO ÁP CẦU THANG 5Huỳnh Đức ThiệnNo ratings yet

- STTH 102Document12 pagesSTTH 102Abel GaunaNo ratings yet

- HIPOTDocument5 pagesHIPOTHARIHARANNo ratings yet

- Jawapan Gerak Gempur IIDocument4 pagesJawapan Gerak Gempur IIrenuNo ratings yet

- Opportunities For CCUS in Southeast Asia - DR Raimund MalischekDocument17 pagesOpportunities For CCUS in Southeast Asia - DR Raimund MalischekEconomic Research Institute for ASEAN and East Asia100% (1)

- Colegio de Montalban San Jose, Rodriguez, Rizal: Institute of EducationDocument4 pagesColegio de Montalban San Jose, Rodriguez, Rizal: Institute of EducationVOLANTE, EDLYN JOYCENo ratings yet

- Electrical Works - Package 2B Addendum BoQ Synefra EstimateDocument46 pagesElectrical Works - Package 2B Addendum BoQ Synefra Estimatemsdixit2006100% (4)

- Compressor Technical DataDocument3 pagesCompressor Technical DataGabriel RodriguezNo ratings yet

- Deney 3Document22 pagesDeney 3baratniloy1No ratings yet

- Design & Development of Multi-Evaporative Refrigeration SystemDocument4 pagesDesign & Development of Multi-Evaporative Refrigeration SystemAnonymous izrFWiQNo ratings yet

- PBL 2Document21 pagesPBL 2Sheratul AshikinNo ratings yet

- G12MEC21220802 - Connected ParticlesDocument25 pagesG12MEC21220802 - Connected ParticlesBerniceNo ratings yet

- Ordering Information: Power PCB RelayDocument12 pagesOrdering Information: Power PCB RelayDemóstenes Moraes OlintoNo ratings yet

- Amplificador de 00006WRms Com TDA 2003Document3 pagesAmplificador de 00006WRms Com TDA 2003EVERALDO AMORIMNo ratings yet

- EmtlDocument62 pagesEmtlsiri.pogulaNo ratings yet

- KTG & ThermodynamicsDocument38 pagesKTG & ThermodynamicsSesha Sai KumarNo ratings yet

- Energy Efficiency and CO2 Emission Comparison of Alternative PowertrainDocument11 pagesEnergy Efficiency and CO2 Emission Comparison of Alternative PowertrainVc CvNo ratings yet

- Four-Junction Wafer-Bonded Concentrator Solar CellsDocument7 pagesFour-Junction Wafer-Bonded Concentrator Solar CellsFerdi PratamaNo ratings yet

- Cooling Load CalculationsDocument6 pagesCooling Load CalculationssamuelNo ratings yet

- 8080 - PDF - 2019 12 14 19 09 36 PDFDocument32 pages8080 - PDF - 2019 12 14 19 09 36 PDFRashi RaiNo ratings yet

- Saturated Steam Metal Wall 1 Outer Asbestos 3Document8 pagesSaturated Steam Metal Wall 1 Outer Asbestos 3raras atiNo ratings yet

- CEC Inverters ListDocument11 pagesCEC Inverters ListSolarShop AustraliaNo ratings yet

- Electricity and Magnetism Handouts 1Document5 pagesElectricity and Magnetism Handouts 1Homo CiderNo ratings yet