Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

153 viewsHDLS Series Switches: Installation Instructions For The

HDLS Series Switches: Installation Instructions For The

Uploaded by

flasher_for_nokiaDoc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Truck Light Series 900 SwitchDocument5 pagesTruck Light Series 900 SwitchRoy Scott McNair100% (1)

- Weldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitDocument12 pagesWeldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitMark trahanNo ratings yet

- Inspection Checklist For Concrete Placement Pre & Post PlacementDocument4 pagesInspection Checklist For Concrete Placement Pre & Post PlacementUsman ShahidNo ratings yet

- Traffic Analysis - Express ElevatorDocument30 pagesTraffic Analysis - Express ElevatorIswadi Bin ZulkarnainNo ratings yet

- SN047a - Simplified Approach To The Selection of Equivalent Horizontal ForcesDocument10 pagesSN047a - Simplified Approach To The Selection of Equivalent Horizontal ForcesJohn WoodsNo ratings yet

- EN-12004 Impac On Adhesive Formulations PDFDocument28 pagesEN-12004 Impac On Adhesive Formulations PDFLucas Bissoli100% (2)

- MICRO SWITCH™ Heavy Duty Limit Switch Series: Installation Instructions For TheDocument8 pagesMICRO SWITCH™ Heavy Duty Limit Switch Series: Installation Instructions For TheAlex RamirezNo ratings yet

- Sps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Document7 pagesSps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Zahira Yadira Arévalo MéndezNo ratings yet

- Jabsco Zoeklicht 135 SL RCDocument5 pagesJabsco Zoeklicht 135 SL RCWillem LindenNo ratings yet

- ELS EtDocument12 pagesELS EtmanhngoducNo ratings yet

- Luminarias - HPS - Appleton - AreamasterDocument3 pagesLuminarias - HPS - Appleton - AreamasterJFPA2012No ratings yet

- MS50 ManualDocument16 pagesMS50 ManualROGELIO QUIJANONo ratings yet

- Elektrotechnische Werke Fritz Driescher & Söhne GMBHDocument4 pagesElektrotechnische Werke Fritz Driescher & Söhne GMBHEdgar BasilioNo ratings yet

- 555 Off-Circuit Tap-Changer An Instruction ManualDocument23 pages555 Off-Circuit Tap-Changer An Instruction Manualhendrias_budiNo ratings yet

- Uai B 0214Document4 pagesUai B 0214Jose Puc ManzanillaNo ratings yet

- How To Guide Auxiliary Switch Field InstallationDocument3 pagesHow To Guide Auxiliary Switch Field InstallationJuan CarlosNo ratings yet

- Temper Switch PDFDocument3 pagesTemper Switch PDFShoaib AhmedNo ratings yet

- Bobinas HansenDocument4 pagesBobinas HansenJose Ignacio Figueroa CortesNo ratings yet

- Type SG @su Auxiliary Relay: A Irii! P/IbuiDocument7 pagesType SG @su Auxiliary Relay: A Irii! P/IbuiImperial TranslationsNo ratings yet

- Robart Electric Retract Series Instruction Manual: Thank YouDocument2 pagesRobart Electric Retract Series Instruction Manual: Thank Yourob100% (1)

- Jabsco Search Light.Document4 pagesJabsco Search Light.ChrisNo ratings yet

- SD 15 Solenoid Valves InstallationDocument8 pagesSD 15 Solenoid Valves Installationjoel lozadaNo ratings yet

- TIG Welding in The Product Realization LabDocument12 pagesTIG Welding in The Product Realization LabFahmi HarisNo ratings yet

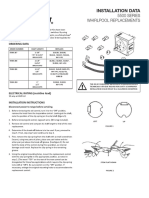

- Installation Data: 5500 Series Whirlpool ReplacementsDocument2 pagesInstallation Data: 5500 Series Whirlpool ReplacementsArio BharataNo ratings yet

- Electrical AccessoriesDocument14 pagesElectrical AccessoriesValar Mathei PadmanadhanNo ratings yet

- GFE H ManualDocument2 pagesGFE H Manualparallax1957No ratings yet

- 6-RELA-ABT Boton de AbortoDocument2 pages6-RELA-ABT Boton de AbortoAndres Rodriguez ArevaloNo ratings yet

- 6-RELA-ABT Boton de Aborto PDFDocument2 pages6-RELA-ABT Boton de Aborto PDFAndres Rodriguez ArevaloNo ratings yet

- BMRX ManualDocument10 pagesBMRX ManualIbarra Diego ONo ratings yet

- Isolator Installation Manual 2018ewDocument27 pagesIsolator Installation Manual 2018ewPablo Omar Luz PedemonteNo ratings yet

- Replacement of Voltage Transformer 4MT3 at The Feeder 8djh36Document6 pagesReplacement of Voltage Transformer 4MT3 at The Feeder 8djh36Rodolfo VázquezNo ratings yet

- Dynatek-S-Electronic-Ignition Dual FireDocument4 pagesDynatek-S-Electronic-Ignition Dual FireAdrián CasarrubiasNo ratings yet

- 47 XinstDocument2 pages47 XinstA330TurbinexNo ratings yet

- 54) - 56) J400K - (455,456,457)Document5 pages54) - 56) J400K - (455,456,457)cyrano1091No ratings yet

- Asco - Solenoide Ef8017g1 Red HatDocument4 pagesAsco - Solenoide Ef8017g1 Red HatMariano DomenechNo ratings yet

- 12V Monorail System Installation Guide: Getting StartedDocument4 pages12V Monorail System Installation Guide: Getting StartedAlaa ElelwanyNo ratings yet

- Aliner Ext Porch Light ProjectDocument5 pagesAliner Ext Porch Light ProjectthriftytravelNo ratings yet

- TG - NB326 - S - Smoke DetectorDocument2 pagesTG - NB326 - S - Smoke DetectordepozitankoNo ratings yet

- Operation Manual: 4bank, Double & SingleDocument16 pagesOperation Manual: 4bank, Double & SinglemeshcodeNo ratings yet

- Technics sl1200 Service ManualDocument6 pagesTechnics sl1200 Service ManualCarpet DriverNo ratings yet

- Instruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Document3 pagesInstruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Quang Pham100% (1)

- 30 11 Solenoid Valves InstallationDocument12 pages30 11 Solenoid Valves InstallationWitthaya ThanakhotNo ratings yet

- L4006A, B, E, H Aquastat® Controllers: ApplicationDocument8 pagesL4006A, B, E, H Aquastat® Controllers: ApplicationJimy Antony Perez CubaNo ratings yet

- Honeywell Humidity SensorDocument8 pagesHoneywell Humidity SensorDonny ZimmermanNo ratings yet

- Az1-L Service ManualDocument68 pagesAz1-L Service Manualdra6anNo ratings yet

- Msa 4 LDDocument1 pageMsa 4 LDdrmichael29No ratings yet

- Carrier Ducted Controller ManualDocument33 pagesCarrier Ducted Controller ManualMechanical PowerNo ratings yet

- Installation, Wiring and Operating Instructions For: Series 900 SwitchDocument5 pagesInstallation, Wiring and Operating Instructions For: Series 900 SwitchRob GustNo ratings yet

- Passive Infrared Motlon DetectorsDocument16 pagesPassive Infrared Motlon DetectorsmianarguNo ratings yet

- Pg05f05te PDFDocument8 pagesPg05f05te PDFa_salehiNo ratings yet

- 5500 M Series Infinite Switch Kit: Installation DataDocument2 pages5500 M Series Infinite Switch Kit: Installation DataToan TranNo ratings yet

- MAKITA - Llave Impacto 6905H - ManualDocument64 pagesMAKITA - Llave Impacto 6905H - Manualmarco antonio talavera salazarNo ratings yet

- SEM HDHR Service ManualDocument14 pagesSEM HDHR Service ManualAlexandre UltraleveNo ratings yet

- Rth6360d 5 2 Programmable Thermostat ManualDocument40 pagesRth6360d 5 2 Programmable Thermostat ManualcgedmanNo ratings yet

- Series 1204: Orange Research IncDocument3 pagesSeries 1204: Orange Research IncWilson VelásquezNo ratings yet

- ALS Series: Exd Limit Switch BoxDocument4 pagesALS Series: Exd Limit Switch BoxNabeel MohammedNo ratings yet

- Instructions - Lt8-Pro Tubo de LedDocument4 pagesInstructions - Lt8-Pro Tubo de LedcoptoforpyrosNo ratings yet

- Instruction Manual-Smc 33KVDocument9 pagesInstruction Manual-Smc 33KVRAKESH CHANDRA PATRANo ratings yet

- Proximity Switch InstallationDocument3 pagesProximity Switch InstallationSaleh AlomariNo ratings yet

- Abbeon Cal, Inc.: Model Bd-50E High Frequency Generator Operating ManualDocument7 pagesAbbeon Cal, Inc.: Model Bd-50E High Frequency Generator Operating ManualdanielvillagrapNo ratings yet

- How to Wire a Doll's House for Electricity - An Illustrated GuideFrom EverandHow to Wire a Doll's House for Electricity - An Illustrated GuideRating: 5 out of 5 stars5/5 (1)

- Laboport: Mini Diaphragm Vacuum Pumps and CompressorsDocument2 pagesLaboport: Mini Diaphragm Vacuum Pumps and Compressorsflasher_for_nokiaNo ratings yet

- LC1D115P7: Product Data SheetDocument3 pagesLC1D115P7: Product Data Sheetflasher_for_nokiaNo ratings yet

- Parts Manual For F1600 1300Document23 pagesParts Manual For F1600 1300flasher_for_nokiaNo ratings yet

- TD 670 676 680 8PG BW Oct2015Document8 pagesTD 670 676 680 8PG BW Oct2015flasher_for_nokiaNo ratings yet

- Thermowell For Thermometers ManualDocument40 pagesThermowell For Thermometers Manualflasher_for_nokiaNo ratings yet

- Sample Only: Api 6A, Api Q1Document6 pagesSample Only: Api 6A, Api Q1flasher_for_nokiaNo ratings yet

- Assessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density LogsDocument7 pagesAssessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density Logsflasher_for_nokiaNo ratings yet

- Doniflon 2010: Properties Appropriate Industries & ApplicationsDocument2 pagesDoniflon 2010: Properties Appropriate Industries & Applicationsflasher_for_nokiaNo ratings yet

- Data Sheet P 550: Technical InformationDocument1 pageData Sheet P 550: Technical Informationflasher_for_nokiaNo ratings yet

- rfb7 de en PDFDocument2 pagesrfb7 de en PDFflasher_for_nokiaNo ratings yet

- Twelve Point Flange Screws: Earnest Technical BulletinDocument1 pageTwelve Point Flange Screws: Earnest Technical Bulletinflasher_for_nokiaNo ratings yet

- Duraflo Composite Oemduea Mongoose PsDocument2 pagesDuraflo Composite Oemduea Mongoose Psflasher_for_nokiaNo ratings yet

- Mud Pump Consumables - enDocument24 pagesMud Pump Consumables - enflasher_for_nokia100% (1)

- Journal of Materials Processing Technology: Chen Hua, Hao Lu, Chun Yu, Jun-Mei Chen, Xiao Wei, Ji-Jin XuDocument11 pagesJournal of Materials Processing Technology: Chen Hua, Hao Lu, Chun Yu, Jun-Mei Chen, Xiao Wei, Ji-Jin Xuflasher_for_nokiaNo ratings yet

- HpuDocument1 pageHpuflasher_for_nokiaNo ratings yet

- Mabanol Xenon Alpha Synth 5W-40 EDocument12 pagesMabanol Xenon Alpha Synth 5W-40 Eflasher_for_nokiaNo ratings yet

- Chapter 3BDocument1 pageChapter 3Bflasher_for_nokiaNo ratings yet

- Wheel Track Suspension List USADocument29 pagesWheel Track Suspension List USAflasher_for_nokiaNo ratings yet

- Mabanol Xenon Alpha Synth 5W-40: Synthetic High Performance Engine OilDocument1 pageMabanol Xenon Alpha Synth 5W-40: Synthetic High Performance Engine Oilflasher_for_nokiaNo ratings yet

- Marco Material Datasheet B1001Document2 pagesMarco Material Datasheet B1001flasher_for_nokiaNo ratings yet

- Model 723 "Saddle-Let" Small Mechanical TeeDocument2 pagesModel 723 "Saddle-Let" Small Mechanical TeemiturraNo ratings yet

- Steel Beam With Detailed Computation RAM CONCEPTDocument210 pagesSteel Beam With Detailed Computation RAM CONCEPTWilbert ReuyanNo ratings yet

- ELECTRICITYDocument70 pagesELECTRICITYJean Rose BalbontinNo ratings yet

- Case Study On Infrastructure FinanceDocument10 pagesCase Study On Infrastructure FinanceRatnadeep MitraNo ratings yet

- Design Brief - Old Age HomeDocument3 pagesDesign Brief - Old Age HomeChaitrali PatilNo ratings yet

- RC Design U 2017 v13.2Document74 pagesRC Design U 2017 v13.2MazenMowafyNo ratings yet

- Estimate Gr4Document3 pagesEstimate Gr4dkhey02No ratings yet

- Bendigo Airport Strategic Plan June 2009Document38 pagesBendigo Airport Strategic Plan June 2009Terry LollbackNo ratings yet

- Waste Management PDFDocument240 pagesWaste Management PDFskilmagNo ratings yet

- Hard Turning: AISI 4340 High Strength Low Alloy Steel and AISI D2 Cold Work Tool SteelDocument8 pagesHard Turning: AISI 4340 High Strength Low Alloy Steel and AISI D2 Cold Work Tool Steelநந்த_குமார்No ratings yet

- Valves AssignmentDocument16 pagesValves AssignmentAdil Jutt GNo ratings yet

- Passive Fire ProtectionDocument21 pagesPassive Fire ProtectionZulHilmi ZakariaNo ratings yet

- GreenHouse StructuresDocument12 pagesGreenHouse Structurespipeds100% (2)

- Devils Slide Tunnel Factsheet1Document2 pagesDevils Slide Tunnel Factsheet1yuamarbasarahNo ratings yet

- Pamintuan Quiz Part 2 Ceqs0322Document4 pagesPamintuan Quiz Part 2 Ceqs0322Onel Rubiano BacilesNo ratings yet

- Project ModelsDocument5 pagesProject ModelsHARSH RANJANNo ratings yet

- KSOU Distance M Tech Civil Engineering Sem I SyllabusDocument7 pagesKSOU Distance M Tech Civil Engineering Sem I SyllabusSunil JhaNo ratings yet

- 02 Feb 2020Document21 pages02 Feb 2020Imran KhanNo ratings yet

- BoqDocument10 pagesBoqaylateNo ratings yet

- Lab TestsDocument4 pagesLab TestsDKHILLALI YAAKOUBNo ratings yet

- Leoni Sealine Cables For ShipbuildingDocument2 pagesLeoni Sealine Cables For ShipbuildingDenzo RyugaNo ratings yet

- Math PTDocument17 pagesMath PT• C O L E •No ratings yet

- Circuit Breaker GalilioDocument34 pagesCircuit Breaker GalilioMoaz KhursheedNo ratings yet

- Anneaux LevageDocument6 pagesAnneaux LevageANo ratings yet

- Assessment of Microestructure Degradation of Creep Exposed Boiler SteelsDocument4 pagesAssessment of Microestructure Degradation of Creep Exposed Boiler SteelsdantegimenezNo ratings yet

- GROHE Specification Sheet 27296001Document2 pagesGROHE Specification Sheet 27296001mikeNo ratings yet

HDLS Series Switches: Installation Instructions For The

HDLS Series Switches: Installation Instructions For The

Uploaded by

flasher_for_nokia0 ratings0% found this document useful (0 votes)

153 views4 pagesDoc

Original Title

honeywell-lsz7a1a-datasheets-9229

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDoc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

153 views4 pagesHDLS Series Switches: Installation Instructions For The

HDLS Series Switches: Installation Instructions For The

Uploaded by

flasher_for_nokiaDoc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

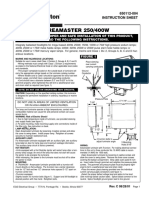

Installation Instructions for the ISSUE 2

HDLS Series Switches PK 81116

WARNING Sealing IP67/68

PERSONAL INJURY Enclosure Type 1, 3, 3R, 4, 4X, 6, 6P, 12, 13

DO NOT USE these products as safety or emergency

stop devices or in any other application where failure Rated Operational Voltages (Ue) and Currents (Ie)

of the product could result in personal injury. Ue Ie

Failure to comply with these instructions could 120 Vac 6A

result in death or serious injury. 600 Vac 1.2 A

125 Vdc 0.22 A

MOUNTING 250 Vdc 0.11 A

All Heavy Duty Limit Switches (HDLS) have exactly the

same mounting dimensions. Mount by either of two

methods: (a) use two #10 screws from the front, or (b)

WIRING

use two #10-32 UNF screws from the back. HDLS offers

Use size #12AWG or smaller solid or

the advantage of front mount construction. The

stranded wire to connect to the

electrician will find a complete switch, with no parts

pressure type connector terminals.

missing and ample wiring space.

Spades may be up to .312" wide,

rings up to .312" dia. With spade or

With plug-in construction, wiring and conduit connection ring type connections, preinsulated

is made to the base receptacle. This feature also connectors or heat-shrinkable tubing

reduces downtime, since plug-in unit can be removed should be used to provide insulation

without disconnecting wiring or conduit. between terminals. Circuit diagram is

shown on the nameplate.

To mount either switch, merely tighten mounting screws,

tighten plug-in unit or cover screws, and make sure It will be easier to wire the double-

conduit section is sealed. Use of sealant (teflon tape, pole units by connecting lead wires to

pipe dope, etc.) is recommended to seal conduit the terminals nearest the conduit opening first. A

connection. grounding screw is located in the housing near the

conduit opening.

Because of moisture condensation problems, it is not

good practice to mount the switch upside down or at the Switch units with an indicator light in the cover are

low point of conduit runs. furnished with the lead wires from the light connected to

the normally-open male terminals (#3 and #4) unless

otherwise specified on the order. Wires can be

unsoldered and reconnected to the normally-closed male

terminals or they can be ordered connected to the

normally-closed terminals by using a modification code

(refer to Catalog 40). Always connect these wires to the

same set of terminals used for the load. Across the

normally open male terminals (#3 and #4) the light will

be On (Fig. 1). Across the normally closed terminals (#1

and #2) the light will be Off.

Single-Pole – Plug-in Type Double-Pole – Non

Plug-in Type

Sensing and Control

HDLS Series Issue 2 81116

ADJUSTING INSTRUCTIONS 4. Using a screwdriver or similar tool, rotate cam to

Actuator head. For application desired actuating position (Fig. 4, 5, and 6.)

flexibility, actuator head may be 5. Slide cam all the way forward to its original position,

positioned in any of four and close hinged cover.

directions. Loosen the four captive 6. Replace operating head on switch housing and

head screws, place head in the securely tighten head screws.

desired position, and then securely

tighten the four screws. Figure 2

Reversing the roller lever.

Except for the offset roller levers,

the roller arm may be reversed to face the roller to the

inside or outside of the arm.

Teller Tab

Positioning Lever. Lever on rotary

actuated units is adjustable through 360°

around the shaft. Loosen the screw with a

9/64 inch hexagon key wrench, move

lever to desired position and securely Figure 3

tighten the screw until "teller tab" can no

Ionger be moved by hand. Then tighten

the screw another 1/8 to 1/4 turn to

assure lever is tight on the shaft.

Hexagon key wrenches are provided in

adjusting tool set LSZ4005 for this

purpose.

Adjustable Length Levers. A hexagon

key wrench is required to adjust length of adjustable Figure 4

levers.

Cam Lobes

Top Roller Plunger. Position top For CW

roller plunger in desired roller For CCW

plane by adjusting the head as

explained under Actuator Head.

Side Roller Plunger. Grasp roller

with pliers and rotate it to desired Figure 5

horizontal or vertical plane.

CHANGING DIRECTION OF Cam Lobe

ACTUATION For CW

Side Rotary. LSM (center neutral) and LSN

(maintained) listings operate in both directions and

cannot be changed. Listings with the first three letters

LSA, LSH, LSL, LSP, LSU, and LSR may be changed to

operate clockwise, counterclockwise or both. NOTE: Figure 6

Instructions for adjusting switch operation are cast into

the hinged cover (Fig. 2). To change, follow these steps: Cam Lobe

For CCW

1. Loosen the head screws and remove the head from

the switch housing.

2. On the bottom of the head, insert a screwdriver in

slot provided (Fig. 2) and lift open hinged cover.

3. Referring to Fig. 3, slide cam all the way back, so

cam is free to rotate on the shaft.

2 Honeywell • Sensing and Control

HDLS Series Issue 2 81116

Top Rotary. Follow these steps to change operating REPLACEMENT PARTS

direction of LSB type switches: Should your specific switch catalog listing not appear in

1. Loosen head screws and remove head from the this parts list, contact nearest MICRO SWITCH

switch housing. Authorized distributor or MICRO SWITCH sales office.

2. From bottom of head grasp end of pin plunger and

remove pin. It may be necessary to rotate actuating For ease of making switch adjustments which may be

shaft to expose end of pin plunger. necessary on various switch listings, order LSZ4005

3. Refer to Fig. 8 and select correct pin plunger (lever and switch adjusting tool set). This set consists of

position for desired direction of actuation. a special 3/32" open wrench and necessary hexagon

4. Insert the pin plunger in the position providing key wrenches to adjust all types of levers.

desired direction of actuation.

5. Replace the operating head on switch housing and Hex head screws. If you prefer to

securely tighten head screws. loosen and tighten lever with a

pliers or screwdriver, order

CW And CCW 15PA164-LS (packet of 50

hexhead screws with screwdriver

slot) to replace screws furnished

CCW Only with the lever.

Replacement Levers. To order

CW Only replacement levers, order the same part number that is

metal stamped on either lever or lever hub. For other

Plug-in Type lever variations, refer to HDLS in Catalog 40.

Catalog Complete Contact

Plug-inBase Operating

Listing* on Plug-in Unit Block (Basic Non Plug-in Type

Recept. Head

Switch Less Base Switch

Only Only Catalog Listing on Operating Head Only Contact Block (Basic

Nameplate Receptacle Only)

Switch Nameplate Switch Only)

LSA1A LSZ7A1A LSZ4001 LSZ1A LSZ3A LSA3K LSZ1A LSZ3K

LSA1J LSZ7A1J LSZ4001 LSZ1A LSZ3J LAS4L LSZ1A LSZ3L

LSA2B LSZ7A2B LSZ4002 LSZ1A LSZ3B LSB3K LSZ1B LSZ3K

LSB1A LSZ7B1A LSZ4001 LSZ1B LSZ3A LSB4L LSZ1B LSZ3L

LSC1A LSZ7C1A LSZ4001 LSZ1C LSZ3A LSC3K LSZ1C LSZ3K

LSC1J LSZ7C1J LSZ4001 LSZ1C LSZ3J LSC4L LSZ1C LSZ3L

LSD1A LSZ7D1A LSZ4001 LSZ1D LSZ3A LSD3K LSZ1D LSZ3K

LSD1J LSZ7D1J LSZ4001 LSZ1D LSZ3J LSD4L LSZ1D LSZ3L

LSD2B LSZ7D2B LSZ4002 LSZ1D LSZ3B LSE3K LSZ1E LSK3K

LSE1A LSZ7E1A LSZ4001 LSZ1E LSZ3A LSE4L LSZ1E LSZ3L

LSE1J LSZ7E1J LSZ4001 LSZ1E LSZ3J LSF3K LSZ1F LSZ3K

LSE2B LSZ7E2B LSZ4002 LSZ1E LSZ3B LSF4L LSZ1F LSZ3L

LSF1A LSZ7F1A LSZ4001 LSZ1F LSZ3A LSG3K LSF1G **

LSF1J LSZ7F1J LSZ4001 LSZ1F LSZ3J LSH3K LSZ1H LSZ3K

LSF2B LSZ7F2B LSZ4002 LSZ1F LSZ3B LSH4L LSZ1H LSZ3 L

LSH1A LSZ7H1A LSZ4001 LSZ1H LSZ3A LSJ3K-7A LSZ1JGA LSZ3 L

LSH1J LSZ7H1J LSZ4001 LSZ1H LSZ3J LSJ3K-7M LSZ1JGM LSZ3 K

LSH2B LSZ7H2B LSZ4002 LSZ1H LSZ3B LSJ4L-7A LSZ1JGA LSZ3 L

LSJ1A-7A LSZ7J1A-7A LSZ4001 LSZ1JGA LSZ3A LSJ4L-7M LSZ1JGM LSZ3 L

LSJ1A-7M LSZ7J1A-7M LSZ4001 LSZ1JGM LSZ3A LSK3K-8A LSZ1KHA LSZ3 K

LSJ2B-7A LSZ7J2B-7A LSZ4002 LSZ1JGA LSZ3B LSK4L-8A LSZ1KHA LSZ3 L

LSJ2B-7M LSZ7J2B-7M LSZ4002 LSZ1JGM LSZ3B LSL4M LSZ1L LSZ3 M

LSK1A-8A LSZ7K1A-8A LSZ4001 LSZ1KHA LSZ3A LSM4N LSZ1M LSZ3M

LSK2B-8A LSZ7K2B-8A LSZ4002 LSZ1KHA LSZ3B LSN3K LSZ1N **

LSL2C LSZ7L2C LSZ4002 LSZ1L LSZ3C LSN4L LSZ1N **

LSM2D LSZ7M2D LSZ4002 LSZ1M LSZ3C LSP3K LSZ1P LSZ3 K

LSN1A LSZ7N1A LSZ4001 LSZ1N ** LSP4L LSZ1P LSZ3 L

LSN2B LSZ7N2B LSZ4002 LSZ1N ** LSR3K LSZ1R LSZ3 K

LSP1A LSZ7P1A LSZ4001 LSZ1P LSZ3A LSR4L LSZ1R LSZ3 L

LSP1J LSZ7P1J LSZ4001 LSZ1P LSZ3J LSU3K LSZ1U LSZ3 K

LSP2B LSZ7P2B LSZ4002 LSZ1P LSZ3B *Only the listing portion which determines the replacement part is shown.

Listings with -7A, -7M, or -8A are complete listings.

LSR1A LSZ7R1A LSZ4001 LSZ1R LSZ3A

**Not user-replaceable.

LSR1J LSZ7R1A LSZ4001 LSZ1R LSZ3J

LSH2B LSZ7R2B LSZ4002 LSZ1R LSZ3B

LSU1A LSZ7U1A LSZ4001 LSZ1U LSZ3A

LSV1A LSZ7V1A LSZ4001 LSZ1V LSZ3J

LSV1J LSZ7V1J LSZ4001 LSZ1V LSZ3A

LSV5A LSZ7V5A LSZ4001 LSZ1V LSZ3A

LSV8A LSZ7V8A LSZ4001 LSZ1V LSZ3A

Honeywell • Sensing and Control 3

HDLS Series Issue 2 81116

REPLACEMENT PARTS - Continued GRAVITY RETURN HDLS

Listings beginning with LSS are gravity return devices. During

installation and setup, note the following:

1. Operate and release points exchange locations when

shaft is rotated 180° (Fig. 9).

2. Switch is near operate-release points when shaft slot is

parallel to switch's long axis (Fig. 9).

3. The switch should be installed so gravity return of the

actuator releases the switch.

Replacement Parts for gravity return LSS1H, extra/low torque

LST1H and two examples of a standard size rotary LSA1A

type (LSYAC1A with Viton seals and LSYAB1A low

temperature version) are listed below.

Catalog Plug-in Units Base Operating Contact

Listing Only Receptacle Head Block

LSS1H LSZ7S1H LSZ4001 LSZ1S LSZ3H

LST1H LSZ7T1H LSZ4001 LSZ1T LSZ3H

LSYAB1A LSZ7YAB1A LSZ4001 LSZ1AB LSZ3A

LSYAC1A LSZ7YAC1A LSA4001 LSZ1AC LSZ3A

PROPER APPLICATION OF LIMIT SWITCHES

To achieve greatest reliability and longest life possible, limit

switches should be installed as outlined in NEMA lCS2-225.

WARRANTY/REMEDY SALES AND SERVICE

Honeywell warrants goods of its manufacture as being free of defective materials and faulty Honeywell serves its customers through a worldwide network of sales offices,

workmanship. Honeywell’s standard product warranty applies unless agreed to otherwise by representatives and distributors. For application assistance, current specifications, pricing or

Honeywell in writing; please refer to your order acknowledgement or consult your local sales name of the nearest Authorized Distributor, contact your local sales office or:

office for specific warranty details. If warranted goods are returned to Honeywell during the E-mail: info.sc@honeywell.com

period of coverage, Honeywell will repair or replace, at its option, without charge those items it Internet: www.honeywell.com/sensing

finds defective. The foregoing is buyer’s sole remedy and is in lieu of all other warranties, Phone and Fax:

expressed or implied, including those of merchantability and fitness for a particular Asia Pacific +65 6355-2828

purpose. In no event shall Honeywell be liable for consequential, special, or indirect +65 6445-3033 Fax

damages. Europe +44 (0) 1698 481481

While we provide application assistance personally, through our literature and the +44 (0) 1698 481676 Fax

Honeywell web site, it is up to the customer to determine the suitability of the product in the Latin America +1-305-805-8188

application. +1-305-883-8257 Fax

Specifications may change without notice. The information we supply is believed to be USA/Canada +1-800-537-6945

accurate and reliable as of this printing. However, we assume no responsibility for its use. +1-815-235-6847

+1-815-235-6545 Fax

Automation and Control Solutions

Sensing and Control

Honeywell

1985 Douglas Drive North

Minneapolis, MN 55422 PK 81116 Issue 2 IL50 GLO Printed in USA

January 20064

www.honeywell.com/sensing © 2006 Honeywell International Inc.

You might also like

- Truck Light Series 900 SwitchDocument5 pagesTruck Light Series 900 SwitchRoy Scott McNair100% (1)

- Weldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitDocument12 pagesWeldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitMark trahanNo ratings yet

- Inspection Checklist For Concrete Placement Pre & Post PlacementDocument4 pagesInspection Checklist For Concrete Placement Pre & Post PlacementUsman ShahidNo ratings yet

- Traffic Analysis - Express ElevatorDocument30 pagesTraffic Analysis - Express ElevatorIswadi Bin ZulkarnainNo ratings yet

- SN047a - Simplified Approach To The Selection of Equivalent Horizontal ForcesDocument10 pagesSN047a - Simplified Approach To The Selection of Equivalent Horizontal ForcesJohn WoodsNo ratings yet

- EN-12004 Impac On Adhesive Formulations PDFDocument28 pagesEN-12004 Impac On Adhesive Formulations PDFLucas Bissoli100% (2)

- MICRO SWITCH™ Heavy Duty Limit Switch Series: Installation Instructions For TheDocument8 pagesMICRO SWITCH™ Heavy Duty Limit Switch Series: Installation Instructions For TheAlex RamirezNo ratings yet

- Sps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Document7 pagesSps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Zahira Yadira Arévalo MéndezNo ratings yet

- Jabsco Zoeklicht 135 SL RCDocument5 pagesJabsco Zoeklicht 135 SL RCWillem LindenNo ratings yet

- ELS EtDocument12 pagesELS EtmanhngoducNo ratings yet

- Luminarias - HPS - Appleton - AreamasterDocument3 pagesLuminarias - HPS - Appleton - AreamasterJFPA2012No ratings yet

- MS50 ManualDocument16 pagesMS50 ManualROGELIO QUIJANONo ratings yet

- Elektrotechnische Werke Fritz Driescher & Söhne GMBHDocument4 pagesElektrotechnische Werke Fritz Driescher & Söhne GMBHEdgar BasilioNo ratings yet

- 555 Off-Circuit Tap-Changer An Instruction ManualDocument23 pages555 Off-Circuit Tap-Changer An Instruction Manualhendrias_budiNo ratings yet

- Uai B 0214Document4 pagesUai B 0214Jose Puc ManzanillaNo ratings yet

- How To Guide Auxiliary Switch Field InstallationDocument3 pagesHow To Guide Auxiliary Switch Field InstallationJuan CarlosNo ratings yet

- Temper Switch PDFDocument3 pagesTemper Switch PDFShoaib AhmedNo ratings yet

- Bobinas HansenDocument4 pagesBobinas HansenJose Ignacio Figueroa CortesNo ratings yet

- Type SG @su Auxiliary Relay: A Irii! P/IbuiDocument7 pagesType SG @su Auxiliary Relay: A Irii! P/IbuiImperial TranslationsNo ratings yet

- Robart Electric Retract Series Instruction Manual: Thank YouDocument2 pagesRobart Electric Retract Series Instruction Manual: Thank Yourob100% (1)

- Jabsco Search Light.Document4 pagesJabsco Search Light.ChrisNo ratings yet

- SD 15 Solenoid Valves InstallationDocument8 pagesSD 15 Solenoid Valves Installationjoel lozadaNo ratings yet

- TIG Welding in The Product Realization LabDocument12 pagesTIG Welding in The Product Realization LabFahmi HarisNo ratings yet

- Installation Data: 5500 Series Whirlpool ReplacementsDocument2 pagesInstallation Data: 5500 Series Whirlpool ReplacementsArio BharataNo ratings yet

- Electrical AccessoriesDocument14 pagesElectrical AccessoriesValar Mathei PadmanadhanNo ratings yet

- GFE H ManualDocument2 pagesGFE H Manualparallax1957No ratings yet

- 6-RELA-ABT Boton de AbortoDocument2 pages6-RELA-ABT Boton de AbortoAndres Rodriguez ArevaloNo ratings yet

- 6-RELA-ABT Boton de Aborto PDFDocument2 pages6-RELA-ABT Boton de Aborto PDFAndres Rodriguez ArevaloNo ratings yet

- BMRX ManualDocument10 pagesBMRX ManualIbarra Diego ONo ratings yet

- Isolator Installation Manual 2018ewDocument27 pagesIsolator Installation Manual 2018ewPablo Omar Luz PedemonteNo ratings yet

- Replacement of Voltage Transformer 4MT3 at The Feeder 8djh36Document6 pagesReplacement of Voltage Transformer 4MT3 at The Feeder 8djh36Rodolfo VázquezNo ratings yet

- Dynatek-S-Electronic-Ignition Dual FireDocument4 pagesDynatek-S-Electronic-Ignition Dual FireAdrián CasarrubiasNo ratings yet

- 47 XinstDocument2 pages47 XinstA330TurbinexNo ratings yet

- 54) - 56) J400K - (455,456,457)Document5 pages54) - 56) J400K - (455,456,457)cyrano1091No ratings yet

- Asco - Solenoide Ef8017g1 Red HatDocument4 pagesAsco - Solenoide Ef8017g1 Red HatMariano DomenechNo ratings yet

- 12V Monorail System Installation Guide: Getting StartedDocument4 pages12V Monorail System Installation Guide: Getting StartedAlaa ElelwanyNo ratings yet

- Aliner Ext Porch Light ProjectDocument5 pagesAliner Ext Porch Light ProjectthriftytravelNo ratings yet

- TG - NB326 - S - Smoke DetectorDocument2 pagesTG - NB326 - S - Smoke DetectordepozitankoNo ratings yet

- Operation Manual: 4bank, Double & SingleDocument16 pagesOperation Manual: 4bank, Double & SinglemeshcodeNo ratings yet

- Technics sl1200 Service ManualDocument6 pagesTechnics sl1200 Service ManualCarpet DriverNo ratings yet

- Instruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Document3 pagesInstruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Quang Pham100% (1)

- 30 11 Solenoid Valves InstallationDocument12 pages30 11 Solenoid Valves InstallationWitthaya ThanakhotNo ratings yet

- L4006A, B, E, H Aquastat® Controllers: ApplicationDocument8 pagesL4006A, B, E, H Aquastat® Controllers: ApplicationJimy Antony Perez CubaNo ratings yet

- Honeywell Humidity SensorDocument8 pagesHoneywell Humidity SensorDonny ZimmermanNo ratings yet

- Az1-L Service ManualDocument68 pagesAz1-L Service Manualdra6anNo ratings yet

- Msa 4 LDDocument1 pageMsa 4 LDdrmichael29No ratings yet

- Carrier Ducted Controller ManualDocument33 pagesCarrier Ducted Controller ManualMechanical PowerNo ratings yet

- Installation, Wiring and Operating Instructions For: Series 900 SwitchDocument5 pagesInstallation, Wiring and Operating Instructions For: Series 900 SwitchRob GustNo ratings yet

- Passive Infrared Motlon DetectorsDocument16 pagesPassive Infrared Motlon DetectorsmianarguNo ratings yet

- Pg05f05te PDFDocument8 pagesPg05f05te PDFa_salehiNo ratings yet

- 5500 M Series Infinite Switch Kit: Installation DataDocument2 pages5500 M Series Infinite Switch Kit: Installation DataToan TranNo ratings yet

- MAKITA - Llave Impacto 6905H - ManualDocument64 pagesMAKITA - Llave Impacto 6905H - Manualmarco antonio talavera salazarNo ratings yet

- SEM HDHR Service ManualDocument14 pagesSEM HDHR Service ManualAlexandre UltraleveNo ratings yet

- Rth6360d 5 2 Programmable Thermostat ManualDocument40 pagesRth6360d 5 2 Programmable Thermostat ManualcgedmanNo ratings yet

- Series 1204: Orange Research IncDocument3 pagesSeries 1204: Orange Research IncWilson VelásquezNo ratings yet

- ALS Series: Exd Limit Switch BoxDocument4 pagesALS Series: Exd Limit Switch BoxNabeel MohammedNo ratings yet

- Instructions - Lt8-Pro Tubo de LedDocument4 pagesInstructions - Lt8-Pro Tubo de LedcoptoforpyrosNo ratings yet

- Instruction Manual-Smc 33KVDocument9 pagesInstruction Manual-Smc 33KVRAKESH CHANDRA PATRANo ratings yet

- Proximity Switch InstallationDocument3 pagesProximity Switch InstallationSaleh AlomariNo ratings yet

- Abbeon Cal, Inc.: Model Bd-50E High Frequency Generator Operating ManualDocument7 pagesAbbeon Cal, Inc.: Model Bd-50E High Frequency Generator Operating ManualdanielvillagrapNo ratings yet

- How to Wire a Doll's House for Electricity - An Illustrated GuideFrom EverandHow to Wire a Doll's House for Electricity - An Illustrated GuideRating: 5 out of 5 stars5/5 (1)

- Laboport: Mini Diaphragm Vacuum Pumps and CompressorsDocument2 pagesLaboport: Mini Diaphragm Vacuum Pumps and Compressorsflasher_for_nokiaNo ratings yet

- LC1D115P7: Product Data SheetDocument3 pagesLC1D115P7: Product Data Sheetflasher_for_nokiaNo ratings yet

- Parts Manual For F1600 1300Document23 pagesParts Manual For F1600 1300flasher_for_nokiaNo ratings yet

- TD 670 676 680 8PG BW Oct2015Document8 pagesTD 670 676 680 8PG BW Oct2015flasher_for_nokiaNo ratings yet

- Thermowell For Thermometers ManualDocument40 pagesThermowell For Thermometers Manualflasher_for_nokiaNo ratings yet

- Sample Only: Api 6A, Api Q1Document6 pagesSample Only: Api 6A, Api Q1flasher_for_nokiaNo ratings yet

- Assessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density LogsDocument7 pagesAssessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density Logsflasher_for_nokiaNo ratings yet

- Doniflon 2010: Properties Appropriate Industries & ApplicationsDocument2 pagesDoniflon 2010: Properties Appropriate Industries & Applicationsflasher_for_nokiaNo ratings yet

- Data Sheet P 550: Technical InformationDocument1 pageData Sheet P 550: Technical Informationflasher_for_nokiaNo ratings yet

- rfb7 de en PDFDocument2 pagesrfb7 de en PDFflasher_for_nokiaNo ratings yet

- Twelve Point Flange Screws: Earnest Technical BulletinDocument1 pageTwelve Point Flange Screws: Earnest Technical Bulletinflasher_for_nokiaNo ratings yet

- Duraflo Composite Oemduea Mongoose PsDocument2 pagesDuraflo Composite Oemduea Mongoose Psflasher_for_nokiaNo ratings yet

- Mud Pump Consumables - enDocument24 pagesMud Pump Consumables - enflasher_for_nokia100% (1)

- Journal of Materials Processing Technology: Chen Hua, Hao Lu, Chun Yu, Jun-Mei Chen, Xiao Wei, Ji-Jin XuDocument11 pagesJournal of Materials Processing Technology: Chen Hua, Hao Lu, Chun Yu, Jun-Mei Chen, Xiao Wei, Ji-Jin Xuflasher_for_nokiaNo ratings yet

- HpuDocument1 pageHpuflasher_for_nokiaNo ratings yet

- Mabanol Xenon Alpha Synth 5W-40 EDocument12 pagesMabanol Xenon Alpha Synth 5W-40 Eflasher_for_nokiaNo ratings yet

- Chapter 3BDocument1 pageChapter 3Bflasher_for_nokiaNo ratings yet

- Wheel Track Suspension List USADocument29 pagesWheel Track Suspension List USAflasher_for_nokiaNo ratings yet

- Mabanol Xenon Alpha Synth 5W-40: Synthetic High Performance Engine OilDocument1 pageMabanol Xenon Alpha Synth 5W-40: Synthetic High Performance Engine Oilflasher_for_nokiaNo ratings yet

- Marco Material Datasheet B1001Document2 pagesMarco Material Datasheet B1001flasher_for_nokiaNo ratings yet

- Model 723 "Saddle-Let" Small Mechanical TeeDocument2 pagesModel 723 "Saddle-Let" Small Mechanical TeemiturraNo ratings yet

- Steel Beam With Detailed Computation RAM CONCEPTDocument210 pagesSteel Beam With Detailed Computation RAM CONCEPTWilbert ReuyanNo ratings yet

- ELECTRICITYDocument70 pagesELECTRICITYJean Rose BalbontinNo ratings yet

- Case Study On Infrastructure FinanceDocument10 pagesCase Study On Infrastructure FinanceRatnadeep MitraNo ratings yet

- Design Brief - Old Age HomeDocument3 pagesDesign Brief - Old Age HomeChaitrali PatilNo ratings yet

- RC Design U 2017 v13.2Document74 pagesRC Design U 2017 v13.2MazenMowafyNo ratings yet

- Estimate Gr4Document3 pagesEstimate Gr4dkhey02No ratings yet

- Bendigo Airport Strategic Plan June 2009Document38 pagesBendigo Airport Strategic Plan June 2009Terry LollbackNo ratings yet

- Waste Management PDFDocument240 pagesWaste Management PDFskilmagNo ratings yet

- Hard Turning: AISI 4340 High Strength Low Alloy Steel and AISI D2 Cold Work Tool SteelDocument8 pagesHard Turning: AISI 4340 High Strength Low Alloy Steel and AISI D2 Cold Work Tool Steelநந்த_குமார்No ratings yet

- Valves AssignmentDocument16 pagesValves AssignmentAdil Jutt GNo ratings yet

- Passive Fire ProtectionDocument21 pagesPassive Fire ProtectionZulHilmi ZakariaNo ratings yet

- GreenHouse StructuresDocument12 pagesGreenHouse Structurespipeds100% (2)

- Devils Slide Tunnel Factsheet1Document2 pagesDevils Slide Tunnel Factsheet1yuamarbasarahNo ratings yet

- Pamintuan Quiz Part 2 Ceqs0322Document4 pagesPamintuan Quiz Part 2 Ceqs0322Onel Rubiano BacilesNo ratings yet

- Project ModelsDocument5 pagesProject ModelsHARSH RANJANNo ratings yet

- KSOU Distance M Tech Civil Engineering Sem I SyllabusDocument7 pagesKSOU Distance M Tech Civil Engineering Sem I SyllabusSunil JhaNo ratings yet

- 02 Feb 2020Document21 pages02 Feb 2020Imran KhanNo ratings yet

- BoqDocument10 pagesBoqaylateNo ratings yet

- Lab TestsDocument4 pagesLab TestsDKHILLALI YAAKOUBNo ratings yet

- Leoni Sealine Cables For ShipbuildingDocument2 pagesLeoni Sealine Cables For ShipbuildingDenzo RyugaNo ratings yet

- Math PTDocument17 pagesMath PT• C O L E •No ratings yet

- Circuit Breaker GalilioDocument34 pagesCircuit Breaker GalilioMoaz KhursheedNo ratings yet

- Anneaux LevageDocument6 pagesAnneaux LevageANo ratings yet

- Assessment of Microestructure Degradation of Creep Exposed Boiler SteelsDocument4 pagesAssessment of Microestructure Degradation of Creep Exposed Boiler SteelsdantegimenezNo ratings yet

- GROHE Specification Sheet 27296001Document2 pagesGROHE Specification Sheet 27296001mikeNo ratings yet