Professional Documents

Culture Documents

HIRAC (Commissioning Operations)

HIRAC (Commissioning Operations)

Uploaded by

hendraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HIRAC (Commissioning Operations)

HIRAC (Commissioning Operations)

Uploaded by

hendraCopyright:

Available Formats

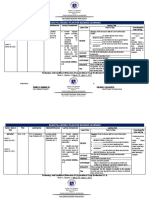

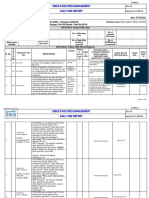

HAZARD IDENTIFICATION RISK ASSESMENT & CONTROL (HIRAC)

HIRA Registration No. : RDMP BALIKPAPAN PROJECT Prepared by: Reviewed by: Reviewed by: Approved by : Risk Category

Revision No. : 004

Revision Purpose : Change to activity wise High 15 - 25

Moderate to High 10 – 12

Node (Unit) : Commissioning/Operations (OPS) Moderate 5–9

Date : 30-May-20 Low to Moderate 4

Total Page Number : 2

I Wayan Sanbudi Nata John P Simanjuntak Yun Youngman M. Yuzar Virza Low 1–3

(JO HSE Engineer) (JO DHSEM) (JO DHSEM) (JO HSEM)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Risk Identification Legal Inherent Risk Residual Risk

Operation Potency of Major

Source of Hazard Accident Hazard Additional Control

No Process / Activities Condition No. Regulation Hierarcy of Control Existing Control Hierarcy of Control PIC

Introduced Hazard Category HS E Tot Tot Planned

(N/A/E) S P R S P R

Hazard/Aspect Detail Risk Explanation Consequency Consequency Category Hazard Code Score Score

H OS E PS S Y/N Y/N Y/N

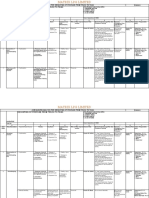

1 Flare startup N Area risk 1 Extreme Temperature from H 1 - Expose with heat from flare - Dehydration and illness 1 Health (H) OPS-H-1.1.1.1 Y 1. Manpower Minister Regulation 5 / 4 3 12 M-H N Elimination N/A 3 1 3 L Elimination N/A SM/CM

assessment/surveys flaring system when working inside flare heat 2018 Isolation N/A Isolation N/A

radiant 2. Health Minister Regulation 70 / Risk Reduction - N/A Risk Reduction - Substitution N/A

- Upset process condition at 2016 Substitution

existing plant will increase 3. Health Minister Regulation 48 / Risk Reduction - - Fire water Risk Reduction - Engineering N/A

flame and heat radius 2016 Engineering - Drinking water supply

- Flare pilot suddenly off, all 4. Local Regulation of Balikpapan - Existing FGS and Sirene function properly

flammable gas and toxic gas No. 13 / 2015 Risk Reduction - Process N/A Risk Reduction - Process change N/A

coming out from flare will not change

burn out and potential exposure Risk Reduction - - PTW, JSA, Daily TBM Risk Reduction - Administrative N/A

to surrounding Administrative - Emergency procedure

- Strict access control inside flare's heat radiant

- Regular short break

Specific PPE - Fire retardant coverall Specific PPE N/A

- Full face mask with toxic gas cartridge

A OS 2 - Upset process condition at Hot Surface (injury) 1 Safety (SA) OPS-SA-1.1.2.1 Y 1. Manpower Minister Regulation 5 / 4 3 12 M-H N Elimination N/A 3 1 3 L Elimination N/A SM/CM

existing plant will increase 2018 Isolation N/A Isolation N/A

flame and heat radius 2. Health Minister Regulation 70 / Risk Reduction - N/A Risk Reduction - Substitution N/A

- Flare pilot suddenly off, all 2016 Substitution

flammable gas and toxic gas 3. Health Minister Regulation 48 / Risk Reduction - - Fire water Risk Reduction - Engineering N/A

coming out from flare will not 2016 Engineering - Drinking water supply

burn out and potential exposure 4. Local Regulation of Balikpapan - Existing FGS and Sirene function properly

to surrounding No. 13 / 2015 Risk Reduction - Process N/A Risk Reduction - Process change N/A

change

Risk Reduction - - PTW, JSA, Daily TBM Risk Reduction - Administrative N/A

Administrative - Emergency procedure

- Strict access control inside flare's heat radiant

- Regular short break

Specific PPE - Fire retardant coverall Specific PPE N/A

- Full face mask with toxic gas cartridge

E Area risk 2 Explosion hazard PS 1 Inadequate purging of flare Property damage 1 Safety (SA) OPS-SA-1.2.1.1 N 5 3 15 H Y Elimination N/A 3 1 3 L Elimination N/A SM/CM

assessment/surveys before startup Isolation N/A Isolation N/A

Risk Reduction - N/A Risk Reduction - Substitution N/A

Substitution

Risk Reduction - - Fire water Risk Reduction - Engineering N/A

Engineering - Existing FGS and Sirene function properly

- During shutdown of flare, flare shall be preserve with N2 to prevent O2

ingression

- Adequate purging with N2

Risk Reduction - Process N/A Risk Reduction - Process change N/A

change

- 26071-100-GPP-GHX-00002 (Project Emergency Handling Procedure)

- PSSR (Pre-startup Safety Review)

Risk Reduction - - Emergency procedure

Administrative - Follow flare startup procedure

- Trained plant operator

Specific PPE - Fire retardant coverall Specific PPE N/A

E Area risk 3 Chemical hazards E 1 Fluids leakage at offshore Sea water pollution 1 Environment (EN) OPS-EN-1.3.1.1 N 5 3 15 H Y Elimination N/A 3 1 3 L Elimination N/A SM/CM

assessment/surveys (hydrocarbon release) during flare offshore startup Isolation N/A Isolation N/A

such as hydrocarbon Risk Reduction - N/A Risk Reduction - Substitution N/A

Substitution

Risk Reduction - - Fire water Risk Reduction - Engineering N/A

Engineering - Provide spill kit and absorbant

Risk Reduction - Process N/A Risk Reduction - Process change N/A

change

- 26071-100-GPP-GHX-00002 (Project Emergency Handling Procedure) Risk Reduction - Administrative N/A

- PSSR (Pre-startup Safety Review)

- Emergency procedure for LOPC at sea water

- Follow flare startup procedure

Risk Reduction -

- Trained plant operator

Administrative

- Proper line check and line up

- Joint flange management

- Good communication with Pertamina RU-V emergency response team

Specific PPE N/A Specific PPE N/A

E Area risk E Company reputation 2 Reputation (RE) OPS-RE-1.3.1.2 N 5 3 15 H Y Elimination N/A 3 1 3 L Elimination N/A SM/CM

assessment/surveys Isolation N/A Isolation N/A

Risk Reduction - N/A Risk Reduction - Substitution N/A

Substitution

Risk Reduction - N/A Risk Reduction - Engineering N/A

Engineering

Risk Reduction - Process N/A Risk Reduction - Process change N/A

change

- 26071-100-GPP-GHX-00002 (Project Emergency Handling Procedure)

- Good communication with Pertamina RU-V emergency response team

Risk Reduction -

- Establish comdev programs to have good coomunication with NGO

Administrative

- Establish good communication with media

Specific PPE N/A Specific PPE N/A

A Engineering change analysis E 2 Failed to burn out all of - Air pollution 1 Environment (EN) OPS-EN-1.3.2.1 N 4 3 12 M-H N Elimination N/A 3 1 3 L Elimination N/A SM/CM

hydrocarbon released to flare - water pollution Isolation N/A Isolation N/A

due to engineering changes on Risk Reduction - N/A Risk Reduction - Substitution N/A

hydrocarbon flow to flare Substitution

Risk Reduction - To consider required flare capacity during FEED & design stages Risk Reduction - Engineering N/A

Engineering

Risk Reduction - Process N/A Risk Reduction - Process change N/A

change

Risk Reduction - HAZOP study Risk Reduction - Administrative N/A

Administrative

Specific PPE N/A Specific PPE N/A

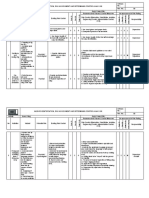

2 Purging N Work process reviews/task- 1 Nitrogen OS 1 - Exposed with nitrogen during - Injury 1 Safety (SA) OPS-SA-2.1.1.1 Y Manpower Minister Regulation No. 3 3 9 M N Elimination N/A 3 1 3 L Elimination N/A SM/CM

based risk assessment purging or drying - Cold burn 37 / 2016 Isolation N/A Isolation N/A

114_Commissioning/Operations (OPS)

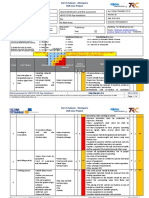

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Risk Identification Legal Inherent Risk Residual Risk

Operation Potency of Major

Source of Hazard Accident Hazard Additional Control

No Process / Activities Condition No. Regulation Hierarcy of Control Existing Control Hierarcy of Control PIC

Introduced Hazard Category HS E Tot Tot Planned

(N/A/E) S P R S P R

Hazard/Aspect Detail Risk Explanation Consequency Consequency Category Hazard Code Score Score

H OS E PS S Y/N Y/N Y/N

- Expose with liquid nitrogen Risk Reduction - N/A Risk Reduction - Substitution N/A

(cyrogenic) Substitution

Risk Reduction - - Discharge point shall be at open space Risk Reduction - Engineering N/A

Engineering - To provide enough water source for emergency purpose in case required to

melt down pipe or body part freeze with liquid nitrogen

Risk Reduction - Process N/A Risk Reduction - Process change N/A

change

Risk Reduction - - Discharge point shall be barricaded and installed with warning sign Risk Reduction - Administrative N/A

Administrative

Specific PPE Specific PPE : a full faceshield over safety glasses Specific PPE N/A

cryogenically rated, loose-fitting gloves

3 Plant Startup N Work process reviews/task- 1 Fire/Explosion PS 1 Fire / Explosion due to: Fatality 1 Safety (SA) OPS-SA-3.1.1.1 Y Manpower Minister Regulation No. 1 4 4 16 H Y Elimination - Strict control of ignition sources at process area or hazardous area 3 1 3 L Elimination N/A SM/CM

based risk assessment - Improper startup sequence / 198 - Maintain good housekeeping, keep away flammable and combustible material

- Inadequate purging

- Process disturbance by other Isolation N/A Isolation N/A

activities Risk Reduction - Enforcement of inherently safe devices and/or explosion proof Risk Reduction - Substitution N/A

Substitution equipment/material at process area (hazardous area)

Risk Reduction - - To ensure fire and gas detection system and fire fighting system working Risk Reduction - Engineering N/A

Engineering properly

- Fire alarm & Emergency sirene working properly

- Adequate purging and oxygen content checking before startup

Risk Reduction - Process N/A Risk Reduction - Process change N/A

change

Risk Reduction - - 26071-100-GPP-GHX-00002 (Project Emergency Handling Procedure) Risk Reduction - Administrative N/A

Administrative - SOP for startup each individual unit and process area

- Follow strictly the startup sequence

- PSSR (Pre-startup Safety Review)

- Establish good communication system and emergency response plan

- To carry out system leak test prior to start the system/unit; run the equipment

or machinery with flammable fluids

- Strict access control

- Trained & experience person to operate utilities and process plant shall be

provided

- Supervision by licensor supervisor

Specific PPE - Fire retardant coverall Specific PPE N/A

- Ear plug/ear muff

N Work process reviews/task- PS 2 Public isssue Company reputation 1 Reputation (RE) OPS-RE-3.1.2.1 N 4 3 12 M-H N Elimination N/A 3 1 3 L Elimination N/A SM/CM

based risk assessment Isolation N/A Isolation N/A

Risk Reduction - N/A Risk Reduction - Substitution N/A

Substitution

Risk Reduction - N/A Risk Reduction - Engineering N/A

Engineering

Risk Reduction - Process N/A Risk Reduction - Process change N/A

change

Risk Reduction - - Pers Release as soon as pollution incident happen Risk Reduction - Administrative N/A

Administrative

Specific PPE N/A Specific PPE N/A

A Engineering change analysis OS PS 3 Fire & explosion because Fatality 1 Safety (SA) OPS-SA-3.1.3.1 N 4 3 12 M-H N Elimination N/A 3 1 3 L Elimination N/A SM/CM

insufficient purging before Isolation N/A Isolation N/A

startup due to not enough Risk Reduction - N/A Risk Reduction - Substitution N/A

nitrogen production & capacity Substitution

from the nitrogen plant Risk Reduction - - To consider nitrogen consumption during FEED & design stages Risk Reduction - Engineering N/A

Engineering - To consider provide nitrogen's feeding facilities when required to buy nitrogen

from outside

Risk Reduction - Process N/A Risk Reduction - Process change N/A

change

Risk Reduction - HAZOP study Risk Reduction - Administrative N/A

Administrative

Specific PPE N/A Specific PPE N/A

A Area risk H 4 People exposed with dense Health impact 1 Health (H) OPS-H-3.1.4.1 N 4 3 12 M-H N Elimination N/A 3 1 3 L Elimination N/A SM/CM

assessment/surveys black smoke and toxic fumes Isolation N/A Isolation N/A

which are generated from fire Risk Reduction - N/A Risk Reduction - Substitution N/A

reaction Substitution

Risk Reduction - - Provide dedicated assembly point Risk Reduction - Engineering N/A

Engineering - provide windsock to get the information about wind direction

- Readiness of foam and water to distinguish fire

Risk Reduction - Process N/A Risk Reduction - Process change N/A

change

Risk Reduction - - Have a good communication woth fire station RU-V Risk Reduction - Administrative N/A

Administrative

Specific PPE N/A Specific PPE N/A

A Area risk E 5 - dense black smoke as - Air pollution 1 Environment (EN) OPS-EN-3.1.5.1 N 5 2 10 M-H N Elimination N/A 3 1 3 L Elimination N/A SM/CM

assessment/surveys pollutant to the air - water pollution Isolation N/A Isolation N/A

- unburned hydrocarbon - soil pollution Risk Reduction - N/A Risk Reduction - Substitution N/A

exposed to the soil and water Substitution

Risk Reduction - Readiness of fire water system such as hydrant, fire truck, fire monitor, fire Risk Reduction - Engineering N/A

Engineering water pump, etc

Risk Reduction - Process N/A Risk Reduction - Process change N/A

change

Risk Reduction - - Establish good coordination with Pertamina RU-V emergency response team Risk Reduction - Administrative N/A

Administrative - establish good coordination with local government emergency response team

- develop response strategy to prevent the spread of dense smoke and

hydrocarbon (in-situ/local containment)

- trained ERT team to response with hydrocarbon fire and spillage

Specific PPE N/A Specific PPE N/A

115_Commissioning/Operations (OPS)

You might also like

- RAISE Plus WEEKLY PLAN FOR BLENDED LEARNING TleDocument3 pagesRAISE Plus WEEKLY PLAN FOR BLENDED LEARNING TleRomeo jr RamirezNo ratings yet

- Benzene: 1. Purpose 2. ScopeDocument8 pagesBenzene: 1. Purpose 2. ScopeKandhasamy888No ratings yet

- 7105 JHRA 008 12 Pneumatic Testing ActivitiesDocument7 pages7105 JHRA 008 12 Pneumatic Testing Activitiesarnel sungkip100% (1)

- Generic Hirac - Risk Assessment Level 1Document3 pagesGeneric Hirac - Risk Assessment Level 1Anonymous dFaBw2O7KM100% (1)

- IG1 Element 1Document48 pagesIG1 Element 1harikrishna100% (1)

- HIRAC (Potential of Major Accident Hazard (MAH) )Document8 pagesHIRAC (Potential of Major Accident Hazard (MAH) )hendraNo ratings yet

- Hazard Identification Risk Assesment & Control (Hirac)Document8 pagesHazard Identification Risk Assesment & Control (Hirac)hendraNo ratings yet

- Hse Manual: Document Status PageDocument23 pagesHse Manual: Document Status PagePerwez21No ratings yet

- Risk Assessment Piling WorksDocument10 pagesRisk Assessment Piling Workspa20060No ratings yet

- PRO-HSE 001 HSE Objective and Management System Rev.0ADocument6 pagesPRO-HSE 001 HSE Objective and Management System Rev.0ADesfrial DialNo ratings yet

- ANTON - HSE Management Plan - 2022Document72 pagesANTON - HSE Management Plan - 2022Geyko RuslanNo ratings yet

- Toolbox Talk - Permit To WorkDocument1 pageToolbox Talk - Permit To WorkrajNo ratings yet

- Lock Out Tag Out Program Log BookDocument1 pageLock Out Tag Out Program Log BookwaytobhushanNo ratings yet

- AzSPU Chemical and Hazardous Materials Management ProcedureDocument24 pagesAzSPU Chemical and Hazardous Materials Management ProcedureAmir M. ShaikhNo ratings yet

- Safety Training PassportDocument2 pagesSafety Training PassportAbhaySngh100% (1)

- WHS PPE Minimum Requirement Matrix v2Document1 pageWHS PPE Minimum Requirement Matrix v2DOUHANo ratings yet

- HIRA Temporary Electrical SuppliesDocument3 pagesHIRA Temporary Electrical SuppliesChandresh SinghNo ratings yet

- HIRA ChemicalDocument1 pageHIRA Chemicalramesh rmNo ratings yet

- Hirarc 2023Document2 pagesHirarc 2023Ariff ZakariaNo ratings yet

- Risk Assessment For Blinding Concrete - 01Document6 pagesRisk Assessment For Blinding Concrete - 01Bulent Ak100% (1)

- HSE-RA-031 Back Filling of - Excavation - Rev 0Document9 pagesHSE-RA-031 Back Filling of - Excavation - Rev 0عمروNo ratings yet

- Job Description - Baûng Moâ Taû Coâng VieäcDocument8 pagesJob Description - Baûng Moâ Taû Coâng VieäcquycoctuNo ratings yet

- Health and Safety Monthly Performance Summary Report: ReactiveDocument2 pagesHealth and Safety Monthly Performance Summary Report: ReactivegkNo ratings yet

- PDO Hse AuditDocument21 pagesPDO Hse Auditnagul kmtcNo ratings yet

- COSHH DrakerDocument2 pagesCOSHH DrakerzaimNo ratings yet

- Accident and Incident Report ProcedureDocument23 pagesAccident and Incident Report ProcedureWakarusa Co100% (1)

- CP - 109 - Safe Work Obsevation ProcessDocument8 pagesCP - 109 - Safe Work Obsevation ProcessYusufNo ratings yet

- STOP WORK AUTHORITY POLICY in Saudi ArabiaDocument1 pageSTOP WORK AUTHORITY POLICY in Saudi ArabiaaymenmoatazNo ratings yet

- PR 15 Hira Procedure Bim& Tim r1Document17 pagesPR 15 Hira Procedure Bim& Tim r1Purna Chandra BaruaNo ratings yet

- JHA Vessel EntryDocument2 pagesJHA Vessel EntryRiyadh SalehNo ratings yet

- Job Hazard Analysis For Decanting of Propane From Truck To TankDocument17 pagesJob Hazard Analysis For Decanting of Propane From Truck To TankAdebiyi Ismail RaitoNo ratings yet

- Risk Assessment - 002 PDFDocument5 pagesRisk Assessment - 002 PDF채종언No ratings yet

- HSE ManualDocument22 pagesHSE ManualvladNo ratings yet

- Hazard Identification, Risk Assessment and Determining Control AnalysisDocument6 pagesHazard Identification, Risk Assessment and Determining Control AnalysisKhaty JahNo ratings yet

- Hsi Investigation ProcedureDocument46 pagesHsi Investigation ProceduremohamedNo ratings yet

- 17 Subcon RequirementsDocument38 pages17 Subcon RequirementsMohammed MinhajNo ratings yet

- National Safety Week Program AgendaDocument3 pagesNational Safety Week Program AgendaDJadee Anuppur AmlaiNo ratings yet

- Project Hira-Razor Pay-EIPL-RPDocument12 pagesProject Hira-Razor Pay-EIPL-RPKamesh A100% (1)

- Manual For SIEP-led HSE AuditingDocument60 pagesManual For SIEP-led HSE AuditingClive NicliNo ratings yet

- ISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4Document1 pageISK Valuation Atrix: Exposure Factor Level 1 Level 2 Level 3 Level 4dnmuleNo ratings yet

- PAINTING Risk AssessmentDocument5 pagesPAINTING Risk AssessmentrajNo ratings yet

- Hydrotest Procedure For Unloading and Condensate Tanks: Shirvan Gas Turbine Power PlantDocument11 pagesHydrotest Procedure For Unloading and Condensate Tanks: Shirvan Gas Turbine Power PlantepbamdadNo ratings yet

- RA For Air BlowingDocument8 pagesRA For Air BlowingMD AZHER ULLAH BAIG100% (1)

- Environmental Incident Reporting FormDocument1 pageEnvironmental Incident Reporting FormKathleen PaladanNo ratings yet

- Hazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisDocument7 pagesHazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisZeroRecoNo ratings yet

- Site Safety Procedure-RV1Document21 pagesSite Safety Procedure-RV1raeiszNo ratings yet

- Chemical Register Chec MacfeamDocument2 pagesChemical Register Chec MacfeamBekmengNo ratings yet

- Plant Isolation, Safety Tag and Lockout ProceduresDocument8 pagesPlant Isolation, Safety Tag and Lockout ProceduresiuiuiooiuNo ratings yet

- PCSB HSE Policy - Aug 2021Document1 pagePCSB HSE Policy - Aug 2021Thep SeafarerNo ratings yet

- Transportation pROCEDUREDocument44 pagesTransportation pROCEDUREBayu AkbarNo ratings yet

- Driving and Journey Management ProcedureDocument6 pagesDriving and Journey Management ProcedureRonny FitriadiNo ratings yet

- Daily HSE ReportDocument5 pagesDaily HSE ReportSayeed MalikNo ratings yet

- Hot Work ProcedureDocument36 pagesHot Work ProcedureShams JogNo ratings yet

- Ocm1 Confined SpaceDocument2 pagesOcm1 Confined SpacerapidsicuminteNo ratings yet

- HIRADC COSHH Antifreeze or CoolantDocument3 pagesHIRADC COSHH Antifreeze or CoolantwisnukerNo ratings yet

- 08PR301C - Storage and Handling of Gas CylindersDocument7 pages08PR301C - Storage and Handling of Gas Cylinderskenoly123No ratings yet

- Rec. PPEsDocument2 pagesRec. PPEsManoj Kumar100% (2)

- Pre Job Work Hazard Assessment FormDocument1 pagePre Job Work Hazard Assessment Formjust a random fnaf kidNo ratings yet

- DSM-FRM-0001-27-0, HDPE PE-100 Pipe InstallationDocument4 pagesDSM-FRM-0001-27-0, HDPE PE-100 Pipe Installationkadir tanzaniaNo ratings yet

- 6 - Store InspectionDocument4 pages6 - Store InspectionabdulrehmanNo ratings yet

- HIRAC (Precommissioning)Document13 pagesHIRAC (Precommissioning)hugocupuNo ratings yet

- Hirac (Civil)Document26 pagesHirac (Civil)hugocupuNo ratings yet

- Atlas Copco Roto - Z SdsDocument14 pagesAtlas Copco Roto - Z SdsHector Martin BarajasNo ratings yet

- SDS HallStar Monoplex DOS 3143 2020-09Document6 pagesSDS HallStar Monoplex DOS 3143 2020-09Anonymous HI6BetNo ratings yet

- Safety Data Sheet: Rubia Fleet HD 200 Sae 10WDocument11 pagesSafety Data Sheet: Rubia Fleet HD 200 Sae 10WRamida Elisa Kristiani SimanjuntakNo ratings yet

- MSDS PolyacrylamideDocument6 pagesMSDS PolyacrylamideMuhammad Alief IjlalNo ratings yet

- Ergonomics and Telework A Systematic ReviewDocument12 pagesErgonomics and Telework A Systematic ReviewCaroHerreraNo ratings yet

- What Is SiRAC (ENG) FinalDocument2 pagesWhat Is SiRAC (ENG) FinalSiti NorshahiraNo ratings yet

- Safety Data Sheet: 1 Identification of The SubstanceDocument6 pagesSafety Data Sheet: 1 Identification of The SubstancePedro Jesús Navarrete SegadoNo ratings yet

- MSDS Bio Pellets V1Document8 pagesMSDS Bio Pellets V1SARCA MADALINANo ratings yet

- Starbucks' HR Practices Ensure Its Brew IsDocument17 pagesStarbucks' HR Practices Ensure Its Brew IsMugheera AhmedNo ratings yet

- Fispq Lubribond-220 - SDSDocument9 pagesFispq Lubribond-220 - SDSbruno.donizeteNo ratings yet

- OVERTIME APPROVAL FORM 1 Feb19Document1 pageOVERTIME APPROVAL FORM 1 Feb19Faihatul AkmaNo ratings yet

- 20 Workplace Safety Rules and Tips To Know: SafetyinfoDocument5 pages20 Workplace Safety Rules and Tips To Know: Safetyinfogoyalvikas86No ratings yet

- Learning Outcome 3 Control Hazards and Risks: Contents: - Safety RegulationDocument2 pagesLearning Outcome 3 Control Hazards and Risks: Contents: - Safety RegulationNovelyn RabinoNo ratings yet

- Novus SDSDocument7 pagesNovus SDSPetra SasaranNo ratings yet

- OB Unit-4 BDocument24 pagesOB Unit-4 BNadeemNo ratings yet

- Defining Performance Standards in Job DescriptionsDocument3 pagesDefining Performance Standards in Job DescriptionsGiovylyn Silot ZabalaNo ratings yet

- Safe Change Management Checklist: Review Date: Location: Description: Section A: Proposed Change CommentsDocument5 pagesSafe Change Management Checklist: Review Date: Location: Description: Section A: Proposed Change CommentsAnne EvansNo ratings yet

- 01 WI HSE 001 - Risk Assessment FormDocument2 pages01 WI HSE 001 - Risk Assessment FormMisbah Ul Haq LabeedNo ratings yet

- S2-F25-Emergency Test in Case of Chemical SpillDocument2 pagesS2-F25-Emergency Test in Case of Chemical SpillJHUPEL ABARIALNo ratings yet

- 4.12 Health and SafetyDocument17 pages4.12 Health and SafetySARAHNo ratings yet

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument7 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- Assignment of SQLDocument5 pagesAssignment of SQLRaghvendra Pal100% (1)

- Class Notes Element 7Document9 pagesClass Notes Element 7danish asrarNo ratings yet

- Types of Hazard in The WorkplaceDocument29 pagesTypes of Hazard in The Workplacemonaliza gumbayNo ratings yet

- TOPIC 1 - Meeting Competitive Challenges Through HR PracticesDocument21 pagesTOPIC 1 - Meeting Competitive Challenges Through HR PracticesMuhammad Aqil HaziqNo ratings yet

- JOB Hazard Analysis C: ArpenterDocument2 pagesJOB Hazard Analysis C: ArpenterUMUTNo ratings yet

- 2coms Consulting PVT LTD - Google SearchDocument1 page2coms Consulting PVT LTD - Google SearchmocharlaphoneNo ratings yet

- AF Demi-Diamond Fruit Fly Trap MSDS (ENG) 02-2022Document5 pagesAF Demi-Diamond Fruit Fly Trap MSDS (ENG) 02-2022Alice LfNo ratings yet