Professional Documents

Culture Documents

PT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - Sangatta

PT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - Sangatta

Uploaded by

ReksiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - Sangatta

PT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - Sangatta

Uploaded by

ReksiCopyright:

Available Formats

PT.

Tekenomiks Indonesia

Office : MEWS M8 Komplek PT KPC- SANGATTA - Kalimantan

Timur 75611 Indonesia

NORMAL

TECHNICAL ADVANCE FOR ECONOMIC GAIN

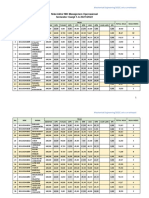

Wear Metal Report: 05357110

Client: PT.KALIMANTAN PRIMA PERSADA - SANGATTA

Attention:

Unit No. PM1025

ID No. SCANIA R580

Oil Name: PERTAMINA RORED HDA 85W-140

Compartment: DIFFERENTIAL FRONT S/N: -

Sample Date:

14/09/2021 14/10/2021 31/10/2021 09/11/2021 23/12/2021 12/01/2022

Received Date

30/09/2021 29/10/2021 20/11/2021 29/11/2021 31/12/2021 17/01/2022

Analysis Date:

30/09/2021 29/10/2021 20/11/2021 29/11/2021 31/12/2021 17/01/2022

Reported Date

01/10/2021 30/10/2021 20/11/2021 30/11/2021 02/01/2022 17/01/2022

Sample no:

05328131 05335647 05341699 05344836 05352957 05357110

SMU(hrs): 14707 15139 15275 15398 15768 16052

Oil Hrs: 1000 1000 2000 398 250 250

Oil Changed: Yes Yes Yes Yes Yes Yes

Component Hours - - - - - -

Wear Metal Rate 0.24 0.01 0.06 0.20 0.22 0.26

Wear Metals PPM PPM PPM PPM PPM PPM Caut High Comments on elevated results

lead 1.20 0.10 4.90 2.10 1.40 0.90 0 0 Oil viscosity Wear elements and

iron 230.20 8.00 80.30 47.50 40.70 62.60 250 500 Contamination within acceptable levels.

Continue with regular maintenance.(teo-

aluminium 0.10 0.10 0.50 1.50 0.90 0.10 0 0 sangattalab)

copper 5.10 0.10 23.40 23.80 6.10 0.30 30 50

chromium 1.60 0.10 1.40 1.10 1.40 0.10 6 10

tin 0.10 0.10 0.10 0.10 3.10 0.40 0 0

nickel 0.20 0.20 0.70 1.90 2.10 1.30 0 0

Contaminants

silicon 10.50 0.10 3.50 9.80 9.20 17.00 30 50

sodium 0.10 1.50 2.90 2.90 1.80 1.90 0 0

Oil Additives

magnesium 0.10 0.50 3.60 5.00 2.70 0.50

zinc 6.40 5.80 31.70 7.80 7.20 11.40 0 0

molybdenum 0.10 0.10 1.20 1.50 0.10 0.10 0 0

calcium 2.00 13.00 14.80 7.00 2.00 0.10 0 0

phosphorus 274.80 850.80 1004.80 881.40 527.50 222.40 0 0

boron 0.40 0.70 0.40 0.70 0.90 0.50 0 0

Infra Red

tbn 0 0 0 0 0 0 -0% -0%

tan 0 0 0 0 0 0 0 0

soot 0 0 0 0 0 0 0 0

glycol 0 0 0 0 0 0 0 0

water ppm 0 0 0 0 0 0 0 0

fuel dilution 0 0 0 0 0 0 0 0

oxidation 0 0 0 0 0 0 0 0

nitration 0 0 0 0 0 0 0 0

sulphation 0 0 0 0 0 0 0 0

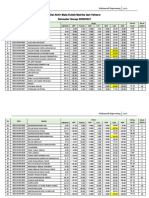

Physical Tests Particle Cleanliness Analysis

water (%) N/A N/A N/A N/A N/A N/A 0 0 ISO 4406 - 04 | -

f.debris (mg fe/l) 30 10 522 38 18 18 300 500 ISO 4406 - 06 | -

visc @ 100oc (mm2/s) N/A N/A N/A N/A N/A N/A +-10 0 ISO 4406 - 14 | -

visc @ 40oc (mm2/s) 365.9 379.9 364.9 374.3 349.0 353.1 +-10 +-30 Count 1ml | -

iso code (part/ml) -/-/- -/-/- -/-/- -/-/- -/-/- -/-/-

TECHENOMICS - Indonesia

TECHNICAL ADVANCE FOR ECONOMIC GAIN

Diagnosis on Elevated Results

Diagnosis 1. Sample No: 05357110

Oil viscosity Wear elements and Contamination within acceptable levels. Continue with regular maintenance.(teo-sangattalab)

Diagnosis 2. Sample No: 05352957

Oil viscosity and wear metal element acceptable limits. Continue with scheduled sampling. teo-sangatta lab

Diagnosis 3. Sample No: 05344836

Oil viscosity and wear metal element acceptable limits. Continue with scheduled sampling. yogi-sangatta lab

Diagnosis 4. Sample No: 05341699

Visually dark oil and PQ = 522 ppm. indicate from wear metal element. Please check oil level check condition oil check magnetic plug check oil leaks

and monitor next service. yogi_sangatta lab.

Diagnosis 5. Sample No: 05335647

Oil viscosity and wear metal element acceptable limits. Continue with scheduled sampling. yogi-sangatta lab

Diagnosis 6. Sample No: 05328131

Viscosity @ 40oC 113% above ISO standard. Please check oil level check condition oil check for oil leak check grade type oil used and monitor

viscosity trend. teo_sangatta lab.

You might also like

- Leaching of Nickel (Group B) 2Document16 pagesLeaching of Nickel (Group B) 2Thato MaamoeNo ratings yet

- Thermal Composites FINALDocument27 pagesThermal Composites FINALTristan Joshua AlbaNo ratings yet

- P&D AlcoholsDocument5 pagesP&D AlcoholsBrandon RamkissoonNo ratings yet

- Hex 1201 FD LH 16112018Document2 pagesHex 1201 FD LH 16112018Tino FebriantoNo ratings yet

- 06 Daily ETP Report Sep-22Document1 page06 Daily ETP Report Sep-22sky textiles300No ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Titrasi Asam Dan BasaDocument12 pagesTitrasi Asam Dan Basadiana kholidaNo ratings yet

- Metrado FINAL Inst Eléct UGEL Sn MarcosDocument10 pagesMetrado FINAL Inst Eléct UGEL Sn MarcosNARCNo ratings yet

- Stainless Steel ChemicalDocument1 pageStainless Steel ChemicaljnmanivannanmechNo ratings yet

- Kualitas Air Blok A Siklus V 2021Document96 pagesKualitas Air Blok A Siklus V 2021Arico RiyomaNo ratings yet

- National Highways Authority of India: Oven Calibration ReportDocument2 pagesNational Highways Authority of India: Oven Calibration ReportDeepakNo ratings yet

- Sample Number Sample Time Elapsed Time Sodium Hydroxide Concentaion (Mol/dm ) Ethyl Acetate Concentraio N (Mol/dm )Document5 pagesSample Number Sample Time Elapsed Time Sodium Hydroxide Concentaion (Mol/dm ) Ethyl Acetate Concentraio N (Mol/dm )Kelly Sheine SisonNo ratings yet

- Sample Number Sample Time Elapsed Time Sodium Hydroxide Concentaion (Mol/dm ) Ethyl Acetate Concentraio N (Mol/dm )Document5 pagesSample Number Sample Time Elapsed Time Sodium Hydroxide Concentaion (Mol/dm ) Ethyl Acetate Concentraio N (Mol/dm )Kelly Sheine SisonNo ratings yet

- Tds Bcmi Lmr7000Document2 pagesTds Bcmi Lmr7000Mamoon ShahidNo ratings yet

- Micro Alloyed Steels Voestalpine EN 30102020Document4 pagesMicro Alloyed Steels Voestalpine EN 30102020pierocarnelociNo ratings yet

- Planilla de Hierros Sala Profesores MC Tipo No. Dimensiones A B C D (M) Cadena de Amarre Ø (MM)Document2 pagesPlanilla de Hierros Sala Profesores MC Tipo No. Dimensiones A B C D (M) Cadena de Amarre Ø (MM)Lenny Viteri EnriquezNo ratings yet

- Worksheet in RC Retaining WallDocument1 pageWorksheet in RC Retaining WallteweldeNo ratings yet

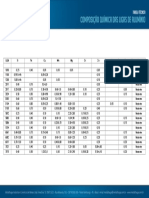

- 1 Composicao Quimica Das Ligas de AluminioDocument1 page1 Composicao Quimica Das Ligas de AluminioNorberto A. GhiggiNo ratings yet

- Lam 1 Data PrimerDocument4 pagesLam 1 Data PrimerUrshalina MasiaraNo ratings yet

- Sympatec - Typical Sample Report PDFDocument1 pageSympatec - Typical Sample Report PDFhamedNo ratings yet

- 16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFDocument5 pages16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFmaga2000No ratings yet

- Chemical Compo - TupiplDocument2 pagesChemical Compo - TupiplMadhubalan AlagarNo ratings yet

- EDAPLAN METOLAT GF For Inorg Pigments 2017Document18 pagesEDAPLAN METOLAT GF For Inorg Pigments 2017manuel h.ddc.No ratings yet

- All Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconDocument3 pagesAll Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconkartikNo ratings yet

- Ligas de Aco DZ UltraDocument2 pagesLigas de Aco DZ Ultraaldofernandes100% (1)

- Grade Data Sheet V 3 PDFDocument7 pagesGrade Data Sheet V 3 PDFpcman147No ratings yet

- Planilla de Refuerzos: Mc. F TipoDocument4 pagesPlanilla de Refuerzos: Mc. F TipofabioNo ratings yet

- TDS BCMI-LMR 7001Document2 pagesTDS BCMI-LMR 7001Mamoon ShahidNo ratings yet

- Entrada Excel PDFDocument2 pagesEntrada Excel PDFKM DegraciaNo ratings yet

- Micro-Alloyed Steels: High-Strength Steels With Yield Strengths Up To 550 MpaDocument4 pagesMicro-Alloyed Steels: High-Strength Steels With Yield Strengths Up To 550 MpacurtisvaleroNo ratings yet

- 001 AggregateDocument4 pages001 Aggregatevanessa ImlerNo ratings yet

- JSW Salem - 22-5-18Document1 pageJSW Salem - 22-5-18HavanNo ratings yet

- Chemical Compositions of Stainless SteelsDocument2 pagesChemical Compositions of Stainless Steelsmohamed faragNo ratings yet

- StreamDocument4 pagesStreamNARAYAN DESAINo ratings yet

- Acos Ferramenta Ligados Astm A 681Document2 pagesAcos Ferramenta Ligados Astm A 681Wenderson SouzaNo ratings yet

- Med. Transp. Willian T3 - Julio.23Document9 pagesMed. Transp. Willian T3 - Julio.23Pedro Niño de GuzmánNo ratings yet

- Table 1 Chemical RequirementsDocument2 pagesTable 1 Chemical RequirementsmoodydoodyNo ratings yet

- Garnet Technical Data Sheet: Distribution Can Be Expected To Be Within The Above Value. For: Salgo MineralsDocument1 pageGarnet Technical Data Sheet: Distribution Can Be Expected To Be Within The Above Value. For: Salgo MineralsskNo ratings yet

- Impri Mi RRRRR RRRRRRRDocument11 pagesImpri Mi RRRRR RRRRRRRCristhian MontesNo ratings yet

- Chemical Composition of Nickel AlloysDocument1 pageChemical Composition of Nickel AlloyscandraNo ratings yet

- Copper Nickel Pipe Din86089 Eemua145Document1 pageCopper Nickel Pipe Din86089 Eemua145Araby GamalNo ratings yet

- Ic 269Document5 pagesIc 269Poonam SahniNo ratings yet

- Plates Steel MetalDocument12 pagesPlates Steel MetalAnonymous aWpx7nENo ratings yet

- Inóx 420ni Peso: Teor Encontrado Carb. Silício Cromo Ni MN MoDocument1 pageInóx 420ni Peso: Teor Encontrado Carb. Silício Cromo Ni MN MoAnonymous hj68hZmoNo ratings yet

- TALLER No 1 MRP GRUPO 6Document32 pagesTALLER No 1 MRP GRUPO 6Natalia PedrozaNo ratings yet

- Phosphate RockDocument3 pagesPhosphate RockManoj Kumar AcharyNo ratings yet

- Cycloidal Follower Displacement: Theta (Deg)Document24 pagesCycloidal Follower Displacement: Theta (Deg)navdinNo ratings yet

- Technical Data Sheet - ASTM A312 TP316Document2 pagesTechnical Data Sheet - ASTM A312 TP316Sri GangaNo ratings yet

- 6013323b064c2121a02f8167 - ASME A-Number Reference ChartDocument1 page6013323b064c2121a02f8167 - ASME A-Number Reference ChartBruno SantosNo ratings yet

- 0.3 0.15 2.0 Progressivo: Aliquota Marginale Aliquota Media Elasticità Dell'imposta Al Reddito Regime Di ImposizioneDocument18 pages0.3 0.15 2.0 Progressivo: Aliquota Marginale Aliquota Media Elasticità Dell'imposta Al Reddito Regime Di ImposizionemNo ratings yet

- API SPEC 5CT 10TH 2018 Table C4Document1 pageAPI SPEC 5CT 10TH 2018 Table C4Johanes GigihNo ratings yet

- Steel Specification PDFDocument8 pagesSteel Specification PDFPeter AntonyNo ratings yet

- En 10025-2-2004 BS HotRolledProductDocument7 pagesEn 10025-2-2004 BS HotRolledProductChrill DsilvaNo ratings yet

- Materi 5 Selectivitas BioleachingDocument8 pagesMateri 5 Selectivitas BioleachingemiaNo ratings yet

- N 1-Where An Ellipsis (... ) Appears in This Table, There Is No Requirement and The Element Need Neither Be Analyzed For or ReportedDocument1 pageN 1-Where An Ellipsis (... ) Appears in This Table, There Is No Requirement and The Element Need Neither Be Analyzed For or ReportedrajeshNo ratings yet

- 742 PDFDocument1 page742 PDFrajeshNo ratings yet

- Sr. Descrption m3: M/s. Rawail Builders Construction of Bridge Near Burma Town, Lehtrar Road, IslamabadDocument3 pagesSr. Descrption m3: M/s. Rawail Builders Construction of Bridge Near Burma Town, Lehtrar Road, IslamabadKASHIF MUGHALNo ratings yet

- VLE Using UNIFAC in ExcelDocument55 pagesVLE Using UNIFAC in Exceljdgh1986No ratings yet

- 01-Concrete Mix + MED CertDocument21 pages01-Concrete Mix + MED CertAnwar SadathNo ratings yet

- Dimenzije I Tezine LimovaDocument2 pagesDimenzije I Tezine LimovaSinisa SimbaNo ratings yet

- Alüminyum AlaşımlarıDocument11 pagesAlüminyum AlaşımlarıMahmut IspirNo ratings yet

- Nilai Akhir MK Manajemen OperasionalDocument3 pagesNilai Akhir MK Manajemen OperasionalReksiNo ratings yet

- Nilai Akhir Mata Kuliah Mekanika Getaran Dan KebisinganDocument2 pagesNilai Akhir Mata Kuliah Mekanika Getaran Dan KebisinganReksiNo ratings yet

- Nilai Akhir Mata Kuliah Matriks Dan VektorsDocument4 pagesNilai Akhir Mata Kuliah Matriks Dan VektorsReksiNo ratings yet

- Nilai Akhir Praktikum FisikaDocument3 pagesNilai Akhir Praktikum FisikaReksiNo ratings yet

- Name: Yanda Savira Alvianty NIM: 1804904901 Class: Nursing 3A Semester 6. Dialy ActivityDocument1 pageName: Yanda Savira Alvianty NIM: 1804904901 Class: Nursing 3A Semester 6. Dialy ActivityReksiNo ratings yet

- Anne A Ling and Normalizing of SteelDocument5 pagesAnne A Ling and Normalizing of SteelTareef HashNo ratings yet

- (E-104) Air Cooled Heat Exchangers - Rev1 PDFDocument13 pages(E-104) Air Cooled Heat Exchangers - Rev1 PDFmihir_jha2No ratings yet

- Y7 Simple Chemical ReactionsDocument6 pagesY7 Simple Chemical ReactionstronicgirlNo ratings yet

- MagnetsDocument18 pagesMagnetsKhaira Racel Jay PucotNo ratings yet

- BRH Eplug Rotaryshaftvalves GeDocument28 pagesBRH Eplug Rotaryshaftvalves GeJosh FryNo ratings yet

- NALCOOL 2000 - Automobile Coolant Corrosion InhibitorDocument2 pagesNALCOOL 2000 - Automobile Coolant Corrosion InhibitorChemEqualNo ratings yet

- 0620 s11 QP 31Document12 pages0620 s11 QP 31Kelso ZwariyaNo ratings yet

- Porta Cabin Tech SpecDocument6 pagesPorta Cabin Tech SpecFARES BEN MESSAOUDNo ratings yet

- Web Page Blocked: Home Matter IndexDocument5 pagesWeb Page Blocked: Home Matter Index4arunpandeyNo ratings yet

- Atomic Structure & The Periodic Table (Multiple Choice) QP PDFDocument23 pagesAtomic Structure & The Periodic Table (Multiple Choice) QP PDFJaycel Marie0% (1)

- Bonding QDocument19 pagesBonding QhamedNo ratings yet

- Thermodynamic Re-Optimization of The Cu-Mg-Sn System at The Cu-Mg SideDocument10 pagesThermodynamic Re-Optimization of The Cu-Mg-Sn System at The Cu-Mg SideJaime MoralesNo ratings yet

- Class10 Chapter - 2 Acids, Bases and Salts (Notes)Document9 pagesClass10 Chapter - 2 Acids, Bases and Salts (Notes)SNo ratings yet

- WX100 Finish Specification 1. Scope: Worldwide Fastener StandardDocument18 pagesWX100 Finish Specification 1. Scope: Worldwide Fastener StandardGustavo FelipeNo ratings yet

- Genersys 1850Document2 pagesGenersys 1850Villalobos EduardoNo ratings yet

- A Brief Summary On Submerged Arc Welding Process and SAW Wires.20140121.222422Document2 pagesA Brief Summary On Submerged Arc Welding Process and SAW Wires.20140121.222422quiltport77No ratings yet

- Acids and Bases Weebly FileDocument5 pagesAcids and Bases Weebly Fileapi-240469044No ratings yet

- Galvanising and Current TrendsDocument32 pagesGalvanising and Current TrendsMritunjayNo ratings yet

- Metallic BiomaterialsDocument26 pagesMetallic BiomaterialspufarinaaNo ratings yet

- Evaluation of Red Mud Reinforced Al-2024 MMC Fabricated Using Stir Casting TechniqueDocument5 pagesEvaluation of Red Mud Reinforced Al-2024 MMC Fabricated Using Stir Casting Techniqueamiter84No ratings yet

- Hardenable Boron SteelDocument8 pagesHardenable Boron Steelkuhn403825No ratings yet

- 11 Staff Living Quarter Shoshima Rest Camp WOPDocument22 pages11 Staff Living Quarter Shoshima Rest Camp WOPAbreham WorkuNo ratings yet

- Astm B 150Document6 pagesAstm B 150arifin rizalNo ratings yet

- Ulangkaji Akhir Menjelang SPM AnswerDocument36 pagesUlangkaji Akhir Menjelang SPM AnswerHee Ting Wong100% (1)

- Unit 4 Answers FinalDocument14 pagesUnit 4 Answers FinalAditya BishtNo ratings yet

- Practical Exercise 02Document17 pagesPractical Exercise 02FeRro ReniNo ratings yet

- Centrifugal Pump (Various Air Handling Methods)Document31 pagesCentrifugal Pump (Various Air Handling Methods)karthick_mariner92No ratings yet