Professional Documents

Culture Documents

ME314 HW4 Solution

ME314 HW4 Solution

Uploaded by

Bob BobOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ME314 HW4 Solution

ME314 HW4 Solution

Uploaded by

Bob BobCopyright:

Available Formats

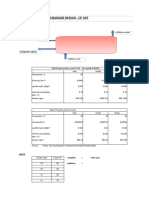

PROBLEM 3.

93

KNOWN: Wire diameters associated with a thermocouple junction, value of the convection heat

transfer coefficient.

FIND: Minimum wire lengths necessary to ensure the junction temperature is at the gas temperature.

SCHEMATIC:

Thermocouple junction

x1

L1

h = 700 W/m2 L Sting

T

L2

x2 D = 150 m

ASSUMPTIONS: (1) Steady-state, one-dimensional conditions, (2) Negligible radiation heat

transfer, (3) Constant properties, (4) Infinitely long fin behavior.

PROPERTIES: Table A-1, Copper ( T = 300 K): k = 401 W/m K; Constantan ( T = 300 K): k = 23

W/m K; Given, Chromel: k = 19 W/m K; Alumel: k = 29 W/m K.

ANALYSIS: To ensure the junction temperature is at the gas temperature (that is, the junction

temperature is not influenced by the sting temperature) we require the two wires to behave as infinitely

long fins. From Example 3.9, Comment 1, the requirement is,

1/ 2 1/ 2

k1 Ac k2 Ac

L1 2.65 ; L2 2.65

hP hP

where L = L1 + L2. With Ac = D2/4 = (150 10-6m)2/4 = 17.67 10-9m2 and P = D = 150

10-6 m = 471 10-6 m, we may calculate the following values of L1, L2, and L.

Material L1 (mm) L2 (mm)

(1) Copper 19.5 -

(2) Constantan - 4.70

L = L1 + L2 24.2 mm <

(1) Chromel 2.68 -

(2) Alumel - 3.30

L = L1 + L2 5.98 mm <

COMMENTS: Use of the chromel-alumel thermocouple junction leads to a substantial reduction in

the size of the measurement device, while simultaneously minimizing measurement error associated

with conduction along the wires to or from the sting.

PROBLEM 3.105

KNOWN: Thermal conductivity and diameter of a pin fin. Value of the heat transfer coefficient and

fin efficiency.

FIND: (a) Length of fin, (b) Fin effectiveness.

SCHEMATIC:

D= mm

f = 0.6

L

x

k

h = 220 W/m2•K

ASSUMPTIONS: (1) Steady-state, one-dimensional conditions, (2) Negligible radiation heat

transfer, (3) Constant properties, (4) Convection from fin tip.

PROPERTIES: Given, Aluminum Alloy: k = 160 W/m K.

ANALYSIS: For an active fin tip, the efficiency may be expressed in terms of the corrected fin

length as:

tanh(mLc )

f

mLc

where m hP / kAc 4h / kD 4 220W/m 2 K / 160W/m K 5 10 3 m 33.2m 1

tanh(33.2m-1 Lc )

Hence, f 0.6 which may be solved by trial-and-error (or by using IHT) to

33.2m 1 Lc

yield Lc = 0.0455 m = 45.5 mm. The fin length is therefore, L = Lc – D/4 = 0.0455 m – 0.005m/4 =

0.0443 m = 44.3 mm. <

The fin effectiveness is:

qf M tanh( mLc ) hPkAc ,b tanh( mLc ) 2

f tanh( mLc )

hAc,b b hAc,b b hAc ,b hD / k

2

2 3

tanh(33.2m 1

45.5 10 3 m) = 21.88 <

220W/m K 5 10 m

160W/m K

COMMENTS: The values of the fin effectiveness and fin efficiency are independent of the base or

fluid temperatures.

You might also like

- A Long, Circular Aluminium Rod Attached at One End ToDocument6 pagesA Long, Circular Aluminium Rod Attached at One End TocaptainhassNo ratings yet

- CH 11Document72 pagesCH 11cameronsidwell0% (2)

- Design Heat Exchanger Shell and Tube TheDocument8 pagesDesign Heat Exchanger Shell and Tube ThezatamaqeelNo ratings yet

- Layers of The Earth's Atmosphere Worksheet Includes Background Info, Student Worksheet, Answer Key PDFDocument13 pagesLayers of The Earth's Atmosphere Worksheet Includes Background Info, Student Worksheet, Answer Key PDFJasmine Joe100% (2)

- Internal Assessment Test I, Odd Semester (2018-2019) : Year/Sem: IV/VII Duration: 1 Hour Max. Marks: 50Document2 pagesInternal Assessment Test I, Odd Semester (2018-2019) : Year/Sem: IV/VII Duration: 1 Hour Max. Marks: 50Muthukrishnan biherNo ratings yet

- MUCLecture 2022 12253547Document4 pagesMUCLecture 2022 12253547beelin24No ratings yet

- Fins ExamplesDocument4 pagesFins ExamplesMalik Mustafa MohammedNo ratings yet

- Simplified Method of Heat Calculations of Oil-Air Heat ExchangersDocument9 pagesSimplified Method of Heat Calculations of Oil-Air Heat ExchangersAsad KhanNo ratings yet

- Temperature Distributions in Solids and in Laminar FlowDocument4 pagesTemperature Distributions in Solids and in Laminar FlowSambasiva Rao KaturiNo ratings yet

- Lec 8Document4 pagesLec 8Anonymous 2BJgxbxJ0% (1)

- Assignment - Solution 2Document12 pagesAssignment - Solution 2Saurabh ManralNo ratings yet

- Calc Reformer Skin Max Temp PDFDocument3 pagesCalc Reformer Skin Max Temp PDFirfanlarikhotmailcomNo ratings yet

- Unit IV and V Solved ProplemsDocument30 pagesUnit IV and V Solved ProplemsRajasekar KaruppusamyNo ratings yet

- Thermal Lab-2 Manual CompletedDocument69 pagesThermal Lab-2 Manual CompletedSiva RamanNo ratings yet

- Tutorial Questions 7 - 13Document3 pagesTutorial Questions 7 - 13Franklin GariNo ratings yet

- Cengel Fluid Mechanics 6 Edition PDFDocument7 pagesCengel Fluid Mechanics 6 Edition PDFVenkat MacharlaNo ratings yet

- Tutorial II SolutionsDocument6 pagesTutorial II SolutionsabhiNo ratings yet

- MATERIAL Mechanical DesignDocument13 pagesMATERIAL Mechanical DesignSchaieraNo ratings yet

- MATERIAL Mechanical DesignDocument11 pagesMATERIAL Mechanical DesignanisNo ratings yet

- Ch2 PDFDocument8 pagesCh2 PDFAlanNo ratings yet

- Thermal Conductvity Matal RodDocument7 pagesThermal Conductvity Matal RodTheOPGarriXNo ratings yet

- Bi 01 - 240425 - 083728Document10 pagesBi 01 - 240425 - 083728Wesley FroxenNo ratings yet

- Chapter 3, Solution 97CDocument6 pagesChapter 3, Solution 97CkarenNo ratings yet

- Heat Transfer Important QuestionsDocument52 pagesHeat Transfer Important QuestionsYeabsira WorkagegnehuNo ratings yet

- Heat Exchanger DesignDocument8 pagesHeat Exchanger Designkikokiko KarimNo ratings yet

- Tema 02Document5 pagesTema 02amas852No ratings yet

- HX qp1Document3 pagesHX qp1Delinda DimpleNo ratings yet

- Sheet 2Document6 pagesSheet 2Mohamed GhaniaNo ratings yet

- JPCS M5Or1B-06 V4-FinalDocument9 pagesJPCS M5Or1B-06 V4-FinalMohammed FouaidyNo ratings yet

- Expt. 7 Finned TubeDocument6 pagesExpt. 7 Finned TubePradeep DiwakarNo ratings yet

- Problems 1Document17 pagesProblems 1Hadia SAULATNo ratings yet

- PRQ 3232 Tercer Parcial II 2015Document2 pagesPRQ 3232 Tercer Parcial II 2015ingrid_brigithNo ratings yet

- NR 310803 Heat TransferDocument8 pagesNR 310803 Heat TransferSrinivasa Rao GNo ratings yet

- Answer Key CIA IIIDocument7 pagesAnswer Key CIA IIISUBRAMANI NANJANNo ratings yet

- Nov2020 Odl Test Mec551 Set BDocument5 pagesNov2020 Odl Test Mec551 Set BMUHAMMAD IKMAL MOHD ZAMRINo ratings yet

- NTU MethodDocument15 pagesNTU MethodVenkatesh KandalamNo ratings yet

- Mech302hw5s 2Document11 pagesMech302hw5s 2priyadarshini212007No ratings yet

- Module 5: Worked Out ProblemsDocument14 pagesModule 5: Worked Out ProblemscaptainhassNo ratings yet

- Thermal ConductivtyDocument3 pagesThermal ConductivtyYousef AqelNo ratings yet

- Engineering Academy: ESE Conventional Revision TEST - IDocument8 pagesEngineering Academy: ESE Conventional Revision TEST - Ividya chakitwarNo ratings yet

- HW ch05 2Document16 pagesHW ch05 2Ashna GautamNo ratings yet

- Heat Exchangers The Effectiveness Ntu Method CompressDocument15 pagesHeat Exchangers The Effectiveness Ntu Method CompressMichael HergetNo ratings yet

- تمرن فصل 7Document11 pagesتمرن فصل 7mohammadNo ratings yet

- Propiedades Del Carbon LiquidoDocument8 pagesPropiedades Del Carbon LiquidoDiegoFernado GuichonNo ratings yet

- Persamaan Konduksi & Kasus - Bag 1Document25 pagesPersamaan Konduksi & Kasus - Bag 1ArdanNo ratings yet

- Heat and Mass Transfer (Mce-303) Bachelor of Technology5 Sem End Semester ExaminationDocument4 pagesHeat and Mass Transfer (Mce-303) Bachelor of Technology5 Sem End Semester Examinationsumeetsharma27No ratings yet

- UCH402Document2 pagesUCH402AdityaNo ratings yet

- HMT Chapter 1Document118 pagesHMT Chapter 1Venugopal kulkarniNo ratings yet

- Chapter8-Assignment and SolutionDocument6 pagesChapter8-Assignment and SolutionDavid100% (1)

- LECTURE 02 Heat Transfer and Heat Exchangers Refrigeration and Air Conditioning HandoutDocument29 pagesLECTURE 02 Heat Transfer and Heat Exchangers Refrigeration and Air Conditioning HandoutCastelNo ratings yet

- T.Y.B.tech Mech Sem VDocument24 pagesT.Y.B.tech Mech Sem VChirag JainNo ratings yet

- sm3 023Document2 pagessm3 023Sadie HnatowNo ratings yet

- We M7 PDFDocument13 pagesWe M7 PDFMirza MesanovicNo ratings yet

- Aletas 240425 131005Document14 pagesAletas 240425 131005Wesley FroxenNo ratings yet

- Exercise 1 & 2Document10 pagesExercise 1 & 2mohammadNo ratings yet

- Heat TransferDocument21 pagesHeat TransferRahel Yemane Embaye TeweldeNo ratings yet

- N Comms 2630Document7 pagesN Comms 2630Alexandre HenriquesNo ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Rating: 4.5 out of 5 stars4.5/5 (5)

- Physical Electronics: Handbook of Vacuum PhysicsFrom EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- IIT JEE 2010 Chemistry AnalysisDocument3 pagesIIT JEE 2010 Chemistry Analysisfaizankhan260690No ratings yet

- NSP PresentationDocument28 pagesNSP PresentationAkhand SinghNo ratings yet

- FT PDFDocument1 pageFT PDFAbhishek Kumar SinghNo ratings yet

- SeminarDocument20 pagesSeminarMitesh KumarNo ratings yet

- Stefan's ContDocument8 pagesStefan's Contuyoi onaNo ratings yet

- Lab Report FTIRDocument8 pagesLab Report FTIRMohamad Saiful Mohd RaffiahNo ratings yet

- Module #1: P D H EDocument41 pagesModule #1: P D H Esebas_vNo ratings yet

- HW10 - Chap 17.5,17.7, Chap. 18.4-18Document21 pagesHW10 - Chap 17.5,17.7, Chap. 18.4-18Nastassja LopezNo ratings yet

- Chemistry Investiatory Project: To Identify The Functional Groups Present in An Organic CompoundDocument13 pagesChemistry Investiatory Project: To Identify The Functional Groups Present in An Organic CompoundMohesh .GNo ratings yet

- Formaldehyde Project Report by AbhishekDocument95 pagesFormaldehyde Project Report by AbhishekDaniel Márquez EspinozaNo ratings yet

- Thermodynamic CyclesDocument14 pagesThermodynamic CyclesBubai111No ratings yet

- Explain A Simple Vapour Compression Cycle Giving Clearly Its Flow Diagram?Document5 pagesExplain A Simple Vapour Compression Cycle Giving Clearly Its Flow Diagram?Ashok DaraNo ratings yet

- I.Abstract: R - (LN KT 2 LN KT 1) T1 T2Document4 pagesI.Abstract: R - (LN KT 2 LN KT 1) T1 T2Hoàng Thu HằngNo ratings yet

- Week 6 Grade 7 Intro Energy Forms and ChangesDocument35 pagesWeek 6 Grade 7 Intro Energy Forms and ChangesmkraemerNo ratings yet

- Lab Manual On Water and Waste Water Analysis by Santosh Kumar KharoleDocument58 pagesLab Manual On Water and Waste Water Analysis by Santosh Kumar KharoleSantosh Kumar75% (4)

- Take Home Quiz DestilasiDocument2 pagesTake Home Quiz DestilasiLutherJericoNo ratings yet

- Inorganic Chemistry Study Guide - Exam 1 - Chapters 1-3Document2 pagesInorganic Chemistry Study Guide - Exam 1 - Chapters 1-3Maddy AbdulNo ratings yet

- How Does Concentration Affect Rate of Reaction CourseworkDocument6 pagesHow Does Concentration Affect Rate of Reaction Courseworkdthtrtlfg100% (1)

- 2004-Kinetics of The Absorption of Carbon Dioxide Into Mixed Aqueous Solutions in AMP+PZDocument14 pages2004-Kinetics of The Absorption of Carbon Dioxide Into Mixed Aqueous Solutions in AMP+PZbaohongqian2020No ratings yet

- Homework ClassDocument11 pagesHomework ClassHossain100% (1)

- Second Law of Thermodynamics PDFDocument22 pagesSecond Law of Thermodynamics PDFফয়সাল আহমেদNo ratings yet

- Oxygen Generation.: by Vacuum Pressure Swing AdsorptionDocument5 pagesOxygen Generation.: by Vacuum Pressure Swing AdsorptionnyaungzinNo ratings yet

- 1 s2.0 S0378775306017538 MainDocument16 pages1 s2.0 S0378775306017538 MainpescaofritoNo ratings yet

- Ionic Equilibrium (Advanced) : (A) Solution of A Polyprotic Weak Acid: Der1: Let Us Take A Weak Diprotic Acid (HDocument20 pagesIonic Equilibrium (Advanced) : (A) Solution of A Polyprotic Weak Acid: Der1: Let Us Take A Weak Diprotic Acid (HJatin BhasinNo ratings yet

- Class 11 Chemistry Chapter 9 HydrogenDocument21 pagesClass 11 Chemistry Chapter 9 HydrogenAshik Meerankutty100% (1)

- 02 Chem X Icse Summary Chemical BondingDocument10 pages02 Chem X Icse Summary Chemical BondingShreyash ThamkeNo ratings yet

- CreepDocument13 pagesCreepKashif SattarNo ratings yet

- Blackbody RadiationDocument26 pagesBlackbody RadiationArjan LingayaNo ratings yet

- 2023 Usnco National Exam Part IDocument11 pages2023 Usnco National Exam Part IJason Allen TibonNo ratings yet