Professional Documents

Culture Documents

CBLM Controlling Weeds

CBLM Controlling Weeds

Uploaded by

marlene a. dinlayanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CBLM Controlling Weeds

CBLM Controlling Weeds

Uploaded by

marlene a. dinlayanCopyright:

Available Formats

Sector: AGRICULTURE AND FISHERY

Qualification: AGRICULTURAL CROPS PRODUCTION NC III

Unit of Competency: CONTROL WEEDS

Module Title: CONTROLLING WEEDS

Technical Education and Skills Development Authority

Kinoguitan National Agricultural School

Buko, Kinoguitan, Misamis Oriental

How to use this Competency- Based Learning Material

Welcome to the learner’s guide for the module: CONTROLLING WEEDS. This

learning material contains activities for you to complete.

The unit of competency “CONTROL WEEDS” contains the knowledge, skills and

attitudes required for AGRICULTURAL CROPS PRODUCTION NC III as CORE

Unit of Competency.

You are required to go through a series of learning activities in order to complete

each learning outcomes of the module. In each learning outcome there do

Instruction Sheets to help you better understand the required activities. Follow

these activities on your own and answer the self-check at the end of each

learning outcome. You may remove a blank answer sheet at the end of each

module (or get from your facilitator/trainer) to write your answers for each self-

check. If you have questions, don’t hesitate to ask your facilitator for assistance.

Instruction sheets:

Information Sheet – This will provide you with information (Concepts,

principles and other relevant information) needed in performing certain

activities.

Job Sheet – This is designed to guide you how to do job that will contribute to

the attainment of the learning outcome.

Assignment Sheet – The assignment sheet is a guide used to enhance (follow

up) what you have learned in the information sheet, operation sheet or job

sheet.

Worksheet– are the different forms that you need to fill up in certain activities

that you performed Recognition of Prior Learning (RPL)

You may already have some or most of the knowledge and skills covered in

this learner’s guide because you have:

Been working for some time

Already completed training in this area

If you can demonstrate to your trainer that you are competent in a

particular outcome, you don’t have to do the same training again.

Talk to your trainer about having them formally recognized. If you have a

qualification or certificate of competence from previous training, show it to your

trainer. If the skills you acquired are still current and relevant to the unit/s of

competency they may become part of the evidence you can present for RPL. If

you are not sure about the accuracy of your skills discuss this with your trainer.

After completing this module ask your trainer to assess your competency.

Result of your assessment will be recorded in your competency profile. All the

learning activities are designed for you to complete at your own pace.

Inside this learner’s guide you will find the activities for you to complete

and at the back are the relevant information sheets for each learning outcome.

Each learning outcome may have more than one learning activities.

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 2 of 29

Marlene A. Dinlayan Revision # 0

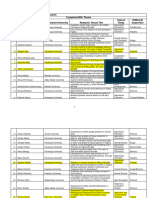

AGRICULTURAL CROPS PRODUCTION NC III

List of Competencies

No. Unit of Competency Module Title Code

Prepare land for AGR611310

Preparing land for agricultural

1. agricultural crop crop production

production

Implement post-harvest Implementing post-harvest AGR611311

2.

program program

Implement plant Implementing plant nutrition AGR611312

3.

nutrition program program

4. Control weeds Controlling weeds AGR611313

Prepare and apply Preparing and applying AGR611314

5.

chemicals chemicals

Establish agronomic AGR611320

6. Establishing agronomic crops

crops

Undertake agronomic AGR611321

Undertaking agronomic crop

7. crop maintenance maintenance activities

activities

Undertake agronomic AGR611322

Undertaking agronomic crop

8. crop harvesting harvesting activities

activities

Save, prepare and store Saving, preparing and storing AGR611323

9.

agricultural seed agricultural seed

Implement vertebrate Implementing vertebrate pest AGR611324

10.

pest control program control program

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 3 of 29

Marlene A. Dinlayan Revision # 0

TABLE OF CONTENTS

Page

How to Use This CBLM .................................................................................. 2

TM 1 List of Competencies ............................................................................ 3

Module Content .............................................................................................. 5

Learning Outcomes Summary (LO2) Plan the

implementation of control measures ............................................................ 7

Learning Experiences .................................................................................... 8

Information Sheet 4.2-1 Chemical, biological and cultural

control methods and treatments for weeds .................................................. 9-11

Self- Check 4.2-1 .................................................................................... 12

Answer Key 4.2-1 .................................................................................... 13

Task Sheet 4.2-1 apply round-up ready (systemic

herbicide) ................................................................................................ 14

Performance Criteria Checklist 4.2-1 ...................................................... 15

Information Sheet 4.2-2 Range and use of tools, equipment

and implements for weed control ............................................................... 16-18

Self- Check 4.2-2 .................................................................................... 19

Answer Key 4.2-2 .................................................................................... 20

Information Sheet 4.2-3 Selection, use and maintenance of

PPE .......................................................................................................... 21-22

Self- Check 4.2-3 .................................................................................... 23

Answer Key 4.2-3 .................................................................................... 24

Information Sheet 4.2-4 OHS issues and environmental

legislative requirements ........................................................................... 25-26

Self- Check 4.2-4 .................................................................................... 27

Answer Key 4.2-4 .................................................................................... 28

Bibliography/ References ............................................................................ 29

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 4 of 29

Marlene A. Dinlayan Revision # 0

UNIT OF COMPETENCY : CONTROL WEEDS

CODE : AGR611313

MODULE TITLE : CONTROLLING WEEDS

MODULE DESCRIPTOR : This unit covers the skills, knowledge and attitudes

required to control weeds, taking into consideration integrated pest management

options. Implementation is likely to be under limited supervision from others

with checking only related to overall progress. Responsibility for and limited

organization of the work of others may be involved. Implementation requires the

application of knowledge in areas such as weed recognition, biology and control,

and the lifecycles of weed predators and hosts.

NOMINAL DURATION : 44 hours

Summary of Learning Outcomes:

1. Assess weed infestation

2. Plan the implementation of control measures

3. Implement control measures

4. Monitor control methods

Assessment Criteria:

1. Scope, density and size of the infestation is assessed.

2. Weeds and beneficial organisms are identified and reported or

recorded in field notes.

3. Levels of weed infestations tolerated by the client, market or

environment are identified from the integrated pest management

(IPM) strategy.

4. Infestation levels, above which plant health or growth objectives are

compromised, are identified.

5. Professional advice is obtained as required according to enterprise

guidelines.

6. Control measures suitable for the infestation are selected from IPM

strategy.

7. Tools, equipment and implements are selected for each work

activity according to enterprise work procedures.

8. OHS hazards are identified, risks assessed, controls implemented

and reported to the supervisor.

9. Suitable safety equipment and personal protective equipment (PPE)

are selected, used, maintained and stored.

10. Control measures selected need to be in full consideration of

environmental implications.

11. Control of harmful weeds with the use of cover crops.

12. Enterprise work team, contractors and IPM product suppliers are

coordinated in a sequential, timely and effective manner in

consultation with the supervisor.

13. Control measures are implemented according to the IPM principles

(e.g. water management for rice).

14. Implementation of IPM activities is undertaken according to OHS

requirements.

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 5 of 29

Marlene A. Dinlayan Revision # 0

15. A clean and safe work area is maintained throughout and on

completion of each work activity.

16. Land is prepared to ensure weed elimination.

17. Records are maintained as required by legislation and enterprise

guidelines.

18. Control methods are monitored to identify side effects to other

plants, animals or external environment.

19. Effectiveness of control methods are assessed in reference to

specified industry and enterprise standards.

20. Adjustments to IPM control methods are implemented where

necessary to meet enterprise specifications.

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 6 of 29

Marlene A. Dinlayan Revision # 0

LEARNING OUTCOME SUMMARY

Learning Outcome 2

Plan the implementation of control measures

Contents:

1. Chemical, biological, cultural and mechanical control methods and

treatments for weeds

2. Range and use of tools, equipment and implements for weed control

3. Selection, use and maintenance of PPE

4. OHS issues and environmental legislative requirements in weed control

Assessment Criteria

1. Control measures suitable for the infestation are selected from IPM strategy.

2. Tools, equipment and implements are selected for each work activity according

to enterprise work procedures.

3. OHS hazards are identified, risks assessed, controls implemented and

reported to the supervisor.

4. Suitable safety equipment and personal protective equipment (PPE) are

selected, used, maintained and stored.

5. Control measures selected need to be in full consideration of environmental

implications

6. Control of harmful weeds with the use of cover crops

Condition:

The students/trainees must be provided with the following:

o CBLM o Rubber boots for lowland

o DLP environment

o Computer o Goggles

o Instructional videos o Mask/ Respirator

o Field with weeds o Cotton Gloves ( for manual

o Sprayer method)

o Round-up ready o Rubber Gloves (for chemical

o Water method)

o PPE o Buli hat

o Sweat shirt/ Protective coat

Assessment Methods:

1. Written Examination

2. Oral Questioning

3. Demonstration

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 7 of 29

Marlene A. Dinlayan Revision # 0

LEARNING EXPERIENCES

Learning Outcome 2

Plan the implementation of control measures

Learning Activities Special Instruction

Read Information Sheet 4.2-1 Chemical,

biological, cultural and mechanical

control methods and treatments for

weeds Read and understand the information

sheet and check yourself by answering

Answer Self- Check 4.2-1 the self-check. You must answer all

correctly before proceeding to the next

Compare your self-check answers to

activity.

answer key 4.2-1

View video presentation on how to Evaluate your own work for every job

control weeds using systemic herbicides sheet using the performance criteria

checklist.

Perform Task Sheet 4.2-1 apply round-

up ready (systemic herbicide) When you are ready, present your work

to your trainer for final evaluation and

Compare your performance against recording.

Performance Criteria Checklist 4.2-1

Read Information Sheet 4.2-2 Range After doing all activities of this Learning

and use of tools, equipment and Outcome, you are ready to proceed to

implements for weed control the next Learning Outcome which is

Implement control measures.

Answer Self Check 4.2-2

Compare your Self-Check answers to

Answer Keys 4.2-2

Read Information Sheet 4.2-3 Selection,

use and maintenance of PPE

Answer Self Check 4.2-3

Compare your Self-Check answers to

Answer Keys 4.2-3

Read Information Sheet 4.2-4 OHS

issues and environmental legislative

requirements

Answer Self- Check No. 4.2-4

Compare your answer to Answer Key

No 4.2-4

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 8 of 29

Marlene A. Dinlayan Revision # 0

Information Sheet 4.2-1

Chemical, biological, cultural and mechanical control methods and

treatments for weeds

Weed control, a botanical component of pest control, stops weeds from reaching

a mature stage of growth when they could be harmful to domesticated plants.

Methods and treatments should be considered:

What type of method is being prepared?

What are the differences of the weed control

methods and treatments?

Is a chemical method favourable

to all types of weeds?

Are biological and cultural a practical and

economically affordable weed control?

After reading this information sheet, the trainee is expected to

1. Identify the control methods and treatments

2. Prepare one control methods

3. Importance of weeds control methods and treatments

4. Identify control measures needed in full consideration of environmental

implications

Weed control, a botanical component of pest control, stops weeds from reaching

a mature stage of growth when they could be harmful to domesticated plants.

Methods and treatments of Weed control

1.Chemical control- Chemicals that are used to kill plants or weeds are called

herbicides.

Soil application

Soil surface application: Herbicides are usually applied to soil surface to form a

uniform herbicide layer. The applied herbicides, due to their low solubility may

penetrate only few centimeters into the soil. Weeds germinating in the top layers

are killed due to incidental absorption of herbicides.

eg. triazines, ureas and anilide

Soil incorporation: Some herbicides are applied to soil surface and incorporated

into the soil either by tillage or irrigation for their effectiveness.

eg. volatile herbicides viz., aniline and carbamate

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 9 of 29

Marlene A. Dinlayan Revision # 0

Sub-surface application: Perennial weeds like Cyperus rotundus and Cynodon

dactylon are controlled by injecting herbicides to the lower layers of the soil at

several points.

Band application: Herbicides are applied as narrow bands over or along the crop

row. The weeds in between the crop rows can be controlled by intercultivation or

band application of herbicide. This method is useful where labour is expensive

and intercultivation is possible.

eg. Weeds in maize can be controlled effectively by spraying atrazine on seed row

at the time of sowing.

Foliar application

Blanket application: Application of herbicide over the entire leaf area. Selective

herbicides are applied by this method.

Directed Application: Herbicide are applied directly to weeds between crop

rows, avoiding the crop foliage. Care is taken to avoid spray fluid falling on the

crop.

eg. Late weeds in cotton can be controlled by spraying non selective herbicide by

directed spray.

Spot application: Herbicides are applied or poured on small patches of weeds,

leaving the relatively wee free patches untreated. It minimizes the herbicide

usage per unit area.

Benefits of chemical method:

1. Herbicides can be applied for weed control in crop rows and where

cultivation is impossible.

2. Pre-emergence herbicides provide early season weed control.

3. Cultivation & manual methods of weed control may injure the root

system.

4. Herbicides reduce the need for pre-planting tillage. They are extremely

useful in minimal\zero tillage.

5. Herbicides can control many perennial weed which cannot be controlled

by other methods. Eg: Cyperus sp.,

2.Biological control- is broadly defined as

the use of an agent, a complex of agents, or

biological processes to bring about weed

suppression. All forms of macrobial and

microbial organisms are considered as

biological control agents. Examples of

biological control agents include, but are not

limited to: arthropods (insects and mites),

plant pathogens (fungi, bacteria, viruses, and

nematodes), fish, birds, and other animals.

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 10 of 29

Marlene A. Dinlayan Revision # 0

Biological control has been used successfully as a practical and economically

affordable weed control method in many situations.

Biological control agents and methods are developed as weed control options to

maintain sustainability in agriculture and for the protection of natural

resources. Biological weed control should be a component of integrated weed

management systems consisting of multiple biological control organisms and

judicious use of chemical, cultural, and physical methods.

3.Cultural Control- refers to any

technique that involves maintaining field

conditions such that weeds are less

likely to become established and/or

increase in number. Examples of

cultural weed control would be crop

rotation, avoiding overgrazing of pastures

or rangeland, using well-adapted

competitive forage species, and

maintaining good soil fertility.

4.Mechanical Control- refers to any technique that involves the use of farm

equipment to control weeds. The two mechanical control techniques most often

used are harrowing, tillage and mowing.

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 11 of 29

Marlene A. Dinlayan Revision # 0

Self- Check 4.2-1

Multiple Choices: kindly write the letter of your choice on the answer sheets provided

to by your trainer. Check your own answer on the Answer Key provide herewith. You

have to get the perfect score before you will be allowed to proceed to the next task.

Be honest in answering the Self-Check.

1. A botanical component of pest control, stops weeds from reaching a mature stage

of growth.

a. Mechanical control c. Weed control

b. Weeds d. crop rotation

2. A practical and economically affordable weed control method in many situations.

a. Soil fertility c. chemical control

b. Biological control d. mechanical control

3. Methods of application of chemical weed control.

a. Foliar and soil application c. tillage and mowing application

b. Crop rotation d. macrobial and microbial organisms

4. Technique that involves the use of farm equipment to control weeds.

a. Cultural c. chemical

b. mechanical d. biological

5. A technique that involves maintaining field conditions such that weeds are less

likely to become established and/or increase in number.

a. cultural c. crop rotation

b. biological d. good soil fertility

6. Mechanical control techniques most often used.

a. tillage and mowing c. crop rotation

b. cropping d. equipment’s

7. Chemicals that are used to kill plants or weeds are called ________.

a. insecticides c. rodenticides

b. pesticides d. herbicides

8. Is broadly defined as the use of an agent, a complex of agents, or biological

processes to bring about weed suppression.

a. cultural c. chemical

b. mechanical d. biological

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 12 of 29

Marlene A. Dinlayan Revision # 0

Answer Key 4.2-1

1. c

2. b

3. a

4. b

5. a

6. a

7. d

8. d

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 13 of 29

Marlene A. Dinlayan Revision # 0

TASK SHEET 4.2-1

Title: Apply round-up ready (systemic herbicide)

Performance Objective:

Given all the information, materials, tools and resources you are required to

perform foliar application of weed control within 15 minutes while observing

OSHP and industry standards.

Supplies/Materials :

PPE

Atomizer/sprayer

Roundup ready

Water

Field with weeds

Equipment : Not Applicable

Steps/Procedure:

1. Wear your personal protective equipment (PPE)

2. Read the manual/guidelines of the chemical products.

3. Follow steps given.

4. Spray it in field.

Assessment Method:

Demonstration and oral questioning

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 14 of 29

Marlene A. Dinlayan Revision # 0

Performance Criteria Checklist 4.2-1

Name of the Trainee: ________________________ Date: ______________

During the demonstration, did the trainee.. Yes No

1. Wear the personal protective equipment (PPE).

2. Read the manual/guidelines of chemical products.

3. Followed the steps/guidelines.

4. Sprayed it in the field.

The trainee was Competent Not Yet Competent

Trainees Signature: _________________

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 15 of 29

Marlene A. Dinlayan Revision # 0

Information Sheet 4.2-2

Range and use of tools, equipment and implements for weed control

Introduction:

Weeding is probably one of the most

disliked gardening/cultivation tasks;

usually because it’s hard work and the job

never seems to be finished (remove one

weed and two more will spring up in its

place!).

So what's the best way to remove weeds

from your farm and garden?

There’s no simple answer; the best method and/or tool depends on a number of

factors –

you (for example, your hand strength and dexterity, ability to kneel and

reach, how much time and patience you have, your capacity in financial,

your numbers of man power )

the type and number of weeds (such as weeds with long taproots, large

rootballs, runners or stolons, size, woody versus soft, annual versus

perennial)

conditions (soil type and moisture level, where the weeds are e.g., garden

bed, between patio pavers, climbing up a tree), and

preferences (for example, organic vs mechanical vs chemical).

At the end of the Information Sheet, the trainees are expected to:

1. Classify the tools and equipment for weed control ;

2. Identify it’s uses;

3. Perform how to use the tools and equipment.

Standard horticultural tools such as gardening implements, mechanised and

manually operated spray applicators and cultivators, tractors and trailed

equipment may be required. Monitoring equipment for the implementation of an

IPM program may include insect traps, soil, fertiliser and plant tissue test kits

and sampling equipment.

List of tools, equipment and implements for weed control:

Your Hands- by hand Pulling it is the easiest and most convenient weeder.

Hoes and Hand Hoes- for pulling a large clump of tiny weeds or deep tap

rooted weeds is a job for either a hoe or a hand hoe.

1. Draw Hoe - the familiar flat-bladed hoe works best when pulled. With a

sharp blade, you can make quick work of the long rows between

vegetable crops.

2. Warren Hoe - has a pointed, heart-shaped blade that is usually used

for creating furrows but also works well for small weeds and weeding

between rows.

3. Scuffle, Stirrup or Dutch Hoe - Cuts weeds at the surface in a

push/pull motion. Easy to use and nice for covering a larger area.

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 16 of 29

Marlene A. Dinlayan Revision # 0

Draw hoe Warren Hoe

Dutch-style scuffle hoe stirrup hoe

Weeder- It’s designed to help remove

weeds with a tap root, with the tines

penetrating the soil to easily pull the

weed out. Some prefer standup

weeders (like this one). You push the

spikes into the ground, press down on

the lever with your foot, and it grabs

the weed and its roots (dandeliona).

“Bolos”/”guna”- a tool use for digging out roots and weeding.

Herbicides- also commonly known as weedkillers are

chemical substances used to control unwanted

plants.

1. Chemical - Sometimes the only option is to kill

the existing vegetation. Products, like RoundUp

and Weed-B-Gone, are systemic, meaning they

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 17 of 29

Marlene A. Dinlayan Revision # 0

pass through the plants vascular system and get down into the roots,

to kill the whole plant.

2. Less Toxic - The newer acetic acid-based herbicides work by burning

the leaves of the plants. They tend to take more applications to fully

kill the plants since they are not systemic and the roots may survive

the first couple of burns.

Operated sprayer/knapsack sprayer- used for effective use of pesticides

and herbicides is important for good yields in any crop, and could save

you money and/or increase yields.

Soil Cultivators- practical machines for successful weed management.

Soil cultivators are popular farming equipment used for mechanical weed

control. There are various types of soil cultivators available on the market.

Some of them are more appropriate for pre-emergence weeding, while

other types enable the post-emergence cultivation. Dependent upon the

most appropriate way in which the weeds must be managed.

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 18 of 29

Marlene A. Dinlayan Revision # 0

Self- Check 4.2-2

Multiple Choices: kindly write the letter of your choice on the answer sheets provided

to by your trainer. Check your own answer on the Answer Key provide herewith. You

have to get the perfect score before you will be allowed to proceed to the next task.

Be honest in answering the Self-Check.

1. It is for pulling a large clump of tiny weeds or deep tap rooted weeds.

c. Shears c. hoes

d. Garden rake d. shovel

2. Has a pointed, heart-shaped blade that is usually used for creating furrows

but also works well for small weeds and weeding between rows..

a. Warren hoe c. draw

b. Dutch Hoe d. mechanical control

3. Also commonly known as weedkillers are chemical substances used to control

unwanted plants..

a. Foliar and soil application c. pesticides

b. Operated sprayer d. herbicides

4. The familiar flat-bladed hoe works best when pulled. With a sharp blade, you

can make quick work of the long rows between vegetable crops..

a. Warren hoe c. draw hoe

b. Dutch hoe d. scuffle hoe

5. Practical machines for successful weed management.

a. Mechanical control c. lawn mower

b. Soil cultivator d. tillage

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 19 of 29

Marlene A. Dinlayan Revision # 0

Answer Key 4.2-3

1. C

2. A

3. D

4. C

5. B

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 20 of 29

Marlene A. Dinlayan Revision # 0

Information Sheet 4.2-3

Selection, use and maintenance of PPE

Introduction

The selection of PPE takes account of risk to

health based on the knowledge of the hazard

and exposure assessment. Consideration is the

required as to the degree of protection needed

and the job tasks must be analysed to

determine if there are any constraints on

selection of tools/equipment.

At the end of the Information Sheet, the

trainees are expected to:

1. Identify the considerations in selecting

of PPE;

2. Identify the appropriate uses and maintenance;

3. Execute in selecting PPE in controlling weeds in lowland environment.

4.

It is also wise to involve those who will wear the PPE in its selection. Equipment

must be correctly fitted and adjusted for maximum comfort.

Criteria for selection include the following consideration:

Nature of hazard-gases, vapor or liquid

Severity of exposure

Frequency and distribution of exposure-how often and for how long

Parts of body exposed and manner of exposure

Nature of work engaged in when exposed to the hazards

Environmental condition, and

Degree of protection which a particular PPE can provide

Eye and face protection - To provide protection during exposure to hazards like

flying particles, insects, liquid chemicals, caustic liquids, sun/ light radiation.

Hearing protection - To provide protection during exposure to high pitch and

loud noise levels.

Respiratory protection - To provide protection from inhalation hazards such as

vapors, mists, particulates, pesticides, and gases.

Hand protection - To provide protection during exposure to potential hazards

such as sharp objects, abrasive surfaces, temperature extremes, and chemical

contact.

Head protection - To provide protection to potential hazards such as falling

objects, striking against low-hanging objects, electrical hazards, or chemical

application.

Foot protection - To provide protection for situations with the potential of

injuries, chemical or liquid exposures, piercing objects.

Clothing protection - To provide protection from potential hazards such as

entanglement, skin cancer, bodily injury, and pesticide contamination.

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 21 of 29

Marlene A. Dinlayan Revision # 0

Head-to-Toe PPE maintenance:

Heads up on hard hat care

Clean hard hats regularly with warm water and soap, and allow to air dry.

Store head protection out of the sun, away from extreme temperatures,

and in a safe place (like a locker) where it can't get knocked around and

damaged.

Check the headband to make sure that it isn't stretched or worn and that

the hat fits comfortably on the head.

Replace a hard hat if it is cracked, dented, or has taken a heavy blow.

Keep an eye on safety eyewear

Clean safety glasses and goggles regularly with mild soap and water.

Wash lenses with water before wiping to prevent scratching. (If employees

don't have access to clean water, tell them to blow dust and grit from

lenses before wiping.)

Store eye protection preferably in a clean dust-proof case or in a safe place

such as the top shelf of a locker where it won't get scratched or otherwise

damaged.

Replace safety glasses if frames are bent, and replace goggles if headbands

are loose, twisted, knotted, or worn. Replace any kind of eye protection if

lenses are scratched or pitted and impair vision.

Now hear this! Take good care of hearing protection!

Wipe earmuffs with a damp cloth after each use, store them in a safe

place, and replace cushions when they lose their resilience.

Wash reusable earplugs every day, store them in a clean case, and replace

if plugs are hard or discolored.

Wipe canal caps (headband plugs) with a damp cloth after each use, store

them in a safe place so the headband won't get bent or twisted, and

replace if the band is damaged and no longer fits comfortably.

Breathe easy with well-maintained respirators.

Clean and disinfect them according to manufacturer's instructions.

Check for holes, cracks, deterioration, and any other problems that could

interfere with the effectiveness of protection.

Store in a safe location, protected from dust, light, heat, cold, moisture,

and chemicals.

Place the respirator so that rubber and plastic parts are in a normal

position and hold their shape.

Lend a hand to keep gloves in good shape.

Keep gloves clean and dry.

Have a backup pair in case gloves get wet (or must be washed) and need

to dry.

Check for holes, cracks, and other damage before each use.

Replace worn or damaged gloves right away.

Put your best foot forward for foot protection.

Wipe wet or soiled shoes with a clean cloth or paper towel.

Air out work shoes after work, and check regularly for signs of damage or

wear.

Have worn or damaged shoes repaired, or replace them.

Change socks during the lunch break to keep feet and shoes dry if feet

sweat a lot.

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 22 of 29

Marlene A. Dinlayan Revision # 0

Self- Check 4.2-3

Essay: Discuss briefly, the consideration in criteria for selection of PPE and its

uses.(10 points)

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 23 of 29

Marlene A. Dinlayan Revision # 0

Answer Key 4.2-3

Criteria for selection include the following consideration:

Nature of hazard-gases, vapor or liquid

Severity of exposure

Frequency and distribution of exposure-how often and for how long

Parts of body exposed and manner of exposure

Nature of work engaged in when exposed to the hazards

Environmental condition, and

Degree of protection which a particular PPE can provide

Eye and face protection - To provide protection during exposure to hazards like

flying particles, insects, liquid chemicals, caustic liquids, sun/ light radiation.

Hearing protection - To provide protection during exposure to high pitch and

loud noise levels.

Respiratory protection - To provide protection from inhalation hazards such as

vapors, mists, particulates, pesticides, and gases.

Hand protection - To provide protection during exposure to potential hazards

such as sharp objects, abrasive surfaces, temperature extremes, and chemical

contact.

Head protection - To provide protection to potential hazards such as falling

objects, striking against low-hanging objects, electrical hazards, or chemical

application.

Foot protection - To provide protection for situations with the potential of

injuries, chemical or liquid exposures, piercing objects.

Clothing protection - To provide protection from potential hazards such as

entanglement, skin cancer, bodily injury, and pesticide contamination.

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 24 of 29

Marlene A. Dinlayan Revision # 0

Information Sheet 4.2-4

OHS issues and environmental legislative requirements

Introduction

OHS requirements may include identifying hazards, assessing risks and

implementing controls, cleaning, maintaining and storing tools, equipment and

machinery, appropriate use, maintenance and storage of PPE including sun

protection, safe operation of tools, equipment and machinery, safe handling, use

and storage of chemicals, organically based materials and hazardous

substances, correct manual handling, basic first aid, safety procedures for

protection of others, personal hygiene, and reporting problems to supervisors.

At the end of this Information Sheet, the trainees are expected to:

1. Identify the broad areas of hazards

2. Recognize workplace hazards

3. Classify the prevention of hazards and risk

The Occupational Health and Safety Regulation 2001 define a hazard as

‘anything (including work practices or procedures) that has the potential to harm

the health or safety of a person:

Hazards can be grouped into five broad areas:

o physical eg. noise, radiation, light, vibration

o chemical eg. poisons, dusts

o biological eg. viruses, plants, parasites

o mechanical/electrical eg. slips, trips and falls, tools, electrical

equipment

o psychological eg. fatigue, violence, bullying.

Hazards can arise from:

o the work environment

o the use of machinery and substances

o poor work design

o inappropriate systems and procedures

Examples of workplace hazards include:

o manual handling e.g pushing, pulling,

carrying, lifting

o work environment e.g. floor surfaces, noise,

temperature

o machinery

o heat e.g. burns and scalds

o electricity e.g. electrocution

o harassment e.g. bullying and/or violence

o hazardous substances e.g. chemicals, fumes

o biological waste

o skin penetrating injuries e.g. knife or syringe injuries

o noise

o confined space

Recognising the hazards in a workplace and taking steps to eliminate or control

the hazard ensures the safety and well-being of all employees. It is easier and

more effective to eliminate or control the hazard before serious injuries result.

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 25 of 29

Marlene A. Dinlayan Revision # 0

The Occupational Health and Safety Regulation 2001 states that an employer

must eliminate any reasonably foreseeable risk to the health and safety of

employees and others in the workplace and if this is not practicable must control

the risk.

Hazards can be dealt/prevent with by:

o eliminating the hazard

o changing the equipment or materials

o changing work methods

o using personal protection equipment (PPE) (as a

last resort)

There are a number of ways hazards can be identified in the workplace. These

include:

o workplace inspections

o consultation between employees and employers

o monitoring injury and illness records

o health and environment monitoring

o recording complaints

o observation

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 26 of 29

Marlene A. Dinlayan Revision # 0

Self- Check 4.2-4

Enumeration: Fill in the table below with atleast 5 examples of hazards in the

work place.

Hazards

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 27 of 29

Marlene A. Dinlayan Revision # 0

Answer Key 4.2-4

Enumeration: List examples of hazards in workplace.

o manual handling e.g pushing, pulling, carrying, lifting

o work environment e.g. floor surfaces, noise, temperature

o machinery

o heat e.g. burns and scalds

o electricity e.g. electrocution

o harassment e.g. bullying and/or violence

o hazardous substances e.g. chemicals, fumes

o biological waste

o skin penetrating injuries e.g. knife or syringe injuries

o noise

o confined space

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 28 of 29

Marlene A. Dinlayan Revision # 0

Bibliography

Anderson, Wood Powell (1977). Weed Science Principles. Methods of weed control pp.

63-91. West Publishing Company

National Forage and Grassland Curriculum (2008). Oregon State University.

http://forages.oregonstate.edu

Kate Blood, Environmental Weeds-A Field Guide for SE Australia 2001, CRC for Weed

Management Systems.

F.J. Richardson, 2011, R.G. Richardson and R.C.H Shepherd, Weeds of the south-east –

An identification guide for Australia.

Rahkonen, J., P. Vanhala, 1991. Response of a mixed weed stand. Department of

Agricultural Engineering, University of Helsinki, Finland, 167-169

Angel Trifonov, PhD , Machines and implements for non-chemical weed control in organic

vegetable growing.

Personal Protective Equipment Guide; Shell Safety Committee; June 1989

Personal protective equipment at Work-Guidance on Regulations: HSE Document

Code of Practise for Selection, Use and Maintenance of Respiratory Protective Devices;

Singapore Standard CP 74-1998

Ines Marjanovic,Agronomist, Life-Saving Farm Machinery for Weed Removal: Soil

Cultivators

Document No.

Date Developed:

December 2021 Issued by:

Agricultural Crops Production

NC III Developed by: Page 29 of 29

Marlene A. Dinlayan Revision # 0

You might also like

- Indian Economic Development Subhash DeyDocument136 pagesIndian Economic Development Subhash Deymansi singh65% (52)

- CBLM Organic VegetablesDocument27 pagesCBLM Organic VegetablesLinet Robles-Perlas100% (4)

- NCFRS-GIS Enrollment Form FINAL v2Document2 pagesNCFRS-GIS Enrollment Form FINAL v2KennethSerpido90% (51)

- Competency Based Learning Material: S: A F Q: O A P Ncii U C: P O V M T: P O VDocument36 pagesCompetency Based Learning Material: S: A F Q: O A P Ncii U C: P O V M T: P O VErethro Cytes80% (5)

- Session - Plan - Produce Organic Concoctions and ExtractsDocument3 pagesSession - Plan - Produce Organic Concoctions and ExtractsGuada Lupe100% (3)

- ACP NCIII - JAF - COC4 Portfolio For RevisedDocument135 pagesACP NCIII - JAF - COC4 Portfolio For RevisedJohn Fabia100% (1)

- Apply Safety Measures in Farm OperationDocument88 pagesApply Safety Measures in Farm OperationErethro Cytes100% (3)

- UC6-Establishing Agronomic CropsDocument133 pagesUC6-Establishing Agronomic CropsMa Luisa Ancog AngsincoNo ratings yet

- UC2-Core-Plant CropsDocument99 pagesUC2-Core-Plant CropsMa Luisa Ancog Angsinco100% (1)

- CBLM Implementing Plant Nutrition ProgramDocument64 pagesCBLM Implementing Plant Nutrition Programmarlene a. dinlayanNo ratings yet

- P4 English End of Term I Joint ExaminationDocument14 pagesP4 English End of Term I Joint ExaminationStuart Cyprian100% (2)

- TLE 7-8 Animal Production Q1 - M3 For PrintingDocument24 pagesTLE 7-8 Animal Production Q1 - M3 For PrintingMari PagxNo ratings yet

- Nutrient Use Efficiency in PlantsDocument287 pagesNutrient Use Efficiency in PlantsVani Vin Go100% (1)

- 001 CBLM CORE FinalDocument75 pages001 CBLM CORE FinalSi Kevin100% (1)

- CBLM CORE FinalDocument27 pagesCBLM CORE FinalMichelleAdanteMorong100% (1)

- CBLM HorticultureDocument67 pagesCBLM HorticultureJomar Ababa Denila50% (2)

- CBC Acp NciiDocument32 pagesCBC Acp NciiJudy Mae Lawas100% (2)

- Carry-Out Harvest and Postharvest OperationsDocument40 pagesCarry-Out Harvest and Postharvest OperationsAmeer Jaffar A. Laban75% (4)

- 1 Plan Training Session OliDocument45 pages1 Plan Training Session OliGerald Campanilla100% (2)

- CBC 1 Agricultural Crops Production NC IDocument55 pagesCBC 1 Agricultural Crops Production NC IDiana Daina100% (2)

- Competency-Based Learning Material: SectorDocument52 pagesCompetency-Based Learning Material: SectorMARICEL LOPEZ100% (2)

- UC7 - Undertake Agronomic Crops HarvestingDocument51 pagesUC7 - Undertake Agronomic Crops HarvestingRayge HarbskyNo ratings yet

- UC3-Core-Caring-and-maintaining-crops WORDDocument126 pagesUC3-Core-Caring-and-maintaining-crops WORDEdith BasubasNo ratings yet

- Prepare Land For Agricultural Crops ProductionDocument32 pagesPrepare Land For Agricultural Crops ProductionRollyn A. Amante - BazarNo ratings yet

- EDITED FINAL CBLM Plant CropsDocument71 pagesEDITED FINAL CBLM Plant CropsEdith Basubas100% (1)

- CBLM (Prepare Land)Document144 pagesCBLM (Prepare Land)joylyn franNo ratings yet

- CBML Agriculture - 6Document107 pagesCBML Agriculture - 6Neil Andrew TalaroNo ratings yet

- CBLM Oap FileDocument47 pagesCBLM Oap FileHILLARY YOLANDANo ratings yet

- W CBLM-new Care and Maintain CropsDocument106 pagesW CBLM-new Care and Maintain Cropsanna luna llubitNo ratings yet

- Abarientos - PTS 8 CBLMDocument41 pagesAbarientos - PTS 8 CBLMLoren Ann Ituriaga AbarientosNo ratings yet

- CBLM 1 PDFDocument111 pagesCBLM 1 PDFRyan Joseph Cuasay100% (2)

- Perform Nursery Production Agri NCIIDocument26 pagesPerform Nursery Production Agri NCIIjazzy mallari100% (2)

- Raymond CBLMDocument35 pagesRaymond CBLManna luna llubit100% (2)

- How To Use This Competency - Based Learning MaterialsDocument16 pagesHow To Use This Competency - Based Learning MaterialsMashelet Villezas ValleNo ratings yet

- UC3-Core-Caring and Maintaining CropsDocument115 pagesUC3-Core-Caring and Maintaining CropsLoreto Ocong100% (1)

- Oap Conco CBLMDocument51 pagesOap Conco CBLMKenn Marvin Salcedo II100% (1)

- UC4-Core-Carrying-out-harvest-and-postharvest-operations WORDDocument84 pagesUC4-Core-Carrying-out-harvest-and-postharvest-operations WORDEdith BasubasNo ratings yet

- CBLM On OAPDocument54 pagesCBLM On OAPdarwin bonagua100% (2)

- Organic VegetablesDocument119 pagesOrganic VegetablesDiana Daina100% (3)

- Evidence Plan UC1 ACP NC2Document3 pagesEvidence Plan UC1 ACP NC2Danny R. Salvador100% (2)

- Acp NciiDocument52 pagesAcp NciiRatsaduh Baluyut100% (6)

- TR - Agricultural Crops Production NC IIDocument75 pagesTR - Agricultural Crops Production NC IIAldrin Taghap0% (1)

- SESSION PLAN For ACP NC IIDocument88 pagesSESSION PLAN For ACP NC IIYamaguchi Kumiko75% (4)

- Competency - Based Learning Materials For Organic Agriculture Production NC IiDocument48 pagesCompetency - Based Learning Materials For Organic Agriculture Production NC Iiaaronjules50% (2)

- Oap Module 1Document145 pagesOap Module 1ressa1608100% (1)

- CBLM Oap Ncii PDFDocument128 pagesCBLM Oap Ncii PDFFJ Villegas89% (36)

- OrganicAgriSESSION PLANDocument12 pagesOrganicAgriSESSION PLANMark Stephen Perillo80% (5)

- Acp NC Ii HandoutsDocument60 pagesAcp NC Ii HandoutsJilai DegraciaNo ratings yet

- Horti - CBLM and Assessment ToolDocument29 pagesHorti - CBLM and Assessment ToolArnulfo VargasNo ratings yet

- CBLM Oap 3Document36 pagesCBLM Oap 3Constantino Elonah Jean100% (2)

- Training Plan Oap FinalDocument20 pagesTraining Plan Oap FinalMaiko Gil Hiwatig100% (2)

- Progress Chart Agricrops NC IIDocument4 pagesProgress Chart Agricrops NC IIDj-Ram Vicente Vida80% (5)

- Institutional Assessment ToolDocument20 pagesInstitutional Assessment ToolBergo Agustin100% (2)

- Plant CropsDocument40 pagesPlant CropsAmeer Jaffar A. LabanNo ratings yet

- Workshop Inspection Checklist TUESDAYDocument1 pageWorkshop Inspection Checklist TUESDAYTuesday EscabarteNo ratings yet

- UC4-Core-Carrying-out Harvest and Postharvest OperationsDocument77 pagesUC4-Core-Carrying-out Harvest and Postharvest OperationsLoreto OcongNo ratings yet

- Evidence Plan: Demonstration With Oral Questioning Written TestDocument13 pagesEvidence Plan: Demonstration With Oral Questioning Written TestvayaNo ratings yet

- CBLM FloresDocument42 pagesCBLM FloresJinky Aydalla100% (2)

- Session Plan - Produce Organic VegetableDocument14 pagesSession Plan - Produce Organic VegetableMerly Salvador100% (1)

- CBC Organic. NewDocument74 pagesCBC Organic. NewDiana Daina100% (1)

- JUAREZ FLS 1-Training Activity MatrixDocument5 pagesJUAREZ FLS 1-Training Activity MatrixClaireSobredilla-Juarez100% (1)

- OkayDocument66 pagesOkaydatorkateclarisseNo ratings yet

- Antonio PTS 8 CBLM Cultivate SoilDocument33 pagesAntonio PTS 8 CBLM Cultivate SoilGaivereal TagabeNo ratings yet

- CBLM TemplateDocument46 pagesCBLM TemplateSherwin CorpuzNo ratings yet

- Competency Based Learning MaterialsDocument72 pagesCompetency Based Learning MaterialsLynde MaputolNo ratings yet

- Chandan Kumar Dash ResumeDocument3 pagesChandan Kumar Dash ResumeChandan kumar DashNo ratings yet

- Studies On Biology, Seed Dispersal and Host Interaction of Dendrophthoe Falcata (L.F.)Document7 pagesStudies On Biology, Seed Dispersal and Host Interaction of Dendrophthoe Falcata (L.F.)Sittie Janna DidaagunNo ratings yet

- NSSCO - Agricultural Science Paper 1 6115-1 - First Proof 14.04.2022Document20 pagesNSSCO - Agricultural Science Paper 1 6115-1 - First Proof 14.04.2022sheehamajohannes32No ratings yet

- Sip CRMDocument82 pagesSip CRMAgney KudekarNo ratings yet

- Viewpoint Level1 High Intermediate Answer Key Units1to12 Video Activity WorksheetsDocument6 pagesViewpoint Level1 High Intermediate Answer Key Units1to12 Video Activity WorksheetsmagdamemerencianoNo ratings yet

- Sustainability - Sabah Takes The Lead in Palm Oil CertificationDocument13 pagesSustainability - Sabah Takes The Lead in Palm Oil CertificationmdonysiusNo ratings yet

- Syntropic FarmingDocument9 pagesSyntropic FarmingMou DASNo ratings yet

- How My Brother Leon Brought Home A WifeDocument9 pagesHow My Brother Leon Brought Home A WifeEdeson Xyviel A. Beredo69% (16)

- Cost and Returns in The Pearl (Moti) Farming: Project ReportDocument10 pagesCost and Returns in The Pearl (Moti) Farming: Project ReportSanjuNo ratings yet

- Local Law BookDocument59 pagesLocal Law BookTouseef HamidNo ratings yet

- 12th Practical ManualDocument7 pages12th Practical ManualShree PinnintiNo ratings yet

- Preparation of Single Enterprise Farm PlanDocument3 pagesPreparation of Single Enterprise Farm PlanAvinash kafleNo ratings yet

- Consumer Awareness and Satisfaction Towards Organic Products in Palakkad District-KeralaDocument9 pagesConsumer Awareness and Satisfaction Towards Organic Products in Palakkad District-KeralaEditor IJTSRDNo ratings yet

- Annex 3Document9 pagesAnnex 3Tesfahun GetachewNo ratings yet

- Tribes Castes of Ce 03 RussDocument674 pagesTribes Castes of Ce 03 RussBranko NikolicNo ratings yet

- NUPI SIPRI Fact Sheet Sudan May 2022Document4 pagesNUPI SIPRI Fact Sheet Sudan May 2022Sara ElkhalifaNo ratings yet

- WEEK 4bDocument3 pagesWEEK 4bjanice alquizarNo ratings yet

- Submitted by Jagadeesh Kumar 1602-14-744-005Document17 pagesSubmitted by Jagadeesh Kumar 1602-14-744-005Shinde vishalNo ratings yet

- GreenOnions PDFDocument5 pagesGreenOnions PDFdellcayugaNo ratings yet

- National Bank For Agriculture and Rural Development (NABARD)Document58 pagesNational Bank For Agriculture and Rural Development (NABARD)kavita choudharyNo ratings yet

- Identification and Quantification of DriDocument55 pagesIdentification and Quantification of DriYvan Kwidja DjamiNo ratings yet

- Garlic As A PesticideDocument3 pagesGarlic As A PesticideCHARLES PUTISNo ratings yet

- Suivi de La Regeneration Naturelle Du CeDocument18 pagesSuivi de La Regeneration Naturelle Du CeHakim ANo ratings yet

- The Effects of Pesticides On Humans and The EnvironmentDocument6 pagesThe Effects of Pesticides On Humans and The EnvironmentIJAERS JOURNALNo ratings yet

- Nazareth Village Farm - Final ReportDocument61 pagesNazareth Village Farm - Final ReportVern PetermanNo ratings yet