Professional Documents

Culture Documents

Safety: Wheel Loader General Specifications

Safety: Wheel Loader General Specifications

Uploaded by

UserCopyright:

Available Formats

You might also like

- 795B Master (v9)Document40 pages795B Master (v9)Rodrigo Bravo Rodrigo BravoNo ratings yet

- BS en 15380-5Document22 pagesBS en 15380-5rohita kumar dahNo ratings yet

- ZF - Bus Product Porfolio PDFDocument27 pagesZF - Bus Product Porfolio PDFFWEFWEFWNo ratings yet

- MT 3000 Mining Truck: 120 Ton (109 T) Payload CapacityDocument8 pagesMT 3000 Mining Truck: 120 Ton (109 T) Payload Capacitybayu enasoraNo ratings yet

- 3124-5.4 - P&H Planetary GearboxesDocument1 page3124-5.4 - P&H Planetary GearboxesJorge VillalobosNo ratings yet

- PH-Electric-Rope-Shovel-Components (Splited)Document3 pagesPH-Electric-Rope-Shovel-Components (Splited)Oscar JimenezNo ratings yet

- Caterpilla Performance 44®Document53 pagesCaterpilla Performance 44®Basago Minas Lo MejorNo ratings yet

- ERP22VL, 25VL, 30VL, 35VL (A976) Parts Manual: Yale Europe Materials Handling LimitedDocument480 pagesERP22VL, 25VL, 30VL, 35VL (A976) Parts Manual: Yale Europe Materials Handling LimitedЕвг100% (2)

- Voltas VVE BOPT 2T (AC)Document82 pagesVoltas VVE BOPT 2T (AC)Johnson James100% (2)

- Safety: Wheel Loader General SpecificationsDocument3 pagesSafety: Wheel Loader General SpecificationsWalter Cesar Loli MoralesNo ratings yet

- Electric Mining Shovel - DC Drive Product OverviewDocument5 pagesElectric Mining Shovel - DC Drive Product OverviewmohanNo ratings yet

- PC5500-6 Sales Brochure (2009) PDFDocument8 pagesPC5500-6 Sales Brochure (2009) PDFBenjamin Arnold CFNo ratings yet

- PC 8000-6 Backhoe DE PDFDocument8 pagesPC 8000-6 Backhoe DE PDFJon CarbonNo ratings yet

- CEBD013702 Shop ManualDocument1,035 pagesCEBD013702 Shop ManualBiswajit DasNo ratings yet

- L 2350 Specification SheetDocument3 pagesL 2350 Specification SheetCristianoNo ratings yet

- Pala O&KRH90CDocument7 pagesPala O&KRH90Cmchan1965100% (1)

- Terex RH200 - Brochure - M 135.0Document8 pagesTerex RH200 - Brochure - M 135.0Relining MineralsNo ratings yet

- Komatsu 930E-5SE Electric Drive Truck Spec SheetDocument4 pagesKomatsu 930E-5SE Electric Drive Truck Spec Sheetelectronico007No ratings yet

- Teh Spes IndonesiaDocument16 pagesTeh Spes IndonesiaJunius Rikarlis UmbaraNo ratings yet

- D11T Trans PDFDocument2 pagesD11T Trans PDFVictor Cardenas FernandezNo ratings yet

- Equipment & Dimensions: EH4500: Standard Equipment Optional Equipment Eh4500 Ac Wheel MotorDocument2 pagesEquipment & Dimensions: EH4500: Standard Equipment Optional Equipment Eh4500 Ac Wheel MotorAndi Wardiman AnwarNo ratings yet

- 830e Sales Brochure Aess565-01 (2001) PDFDocument4 pages830e Sales Brochure Aess565-01 (2001) PDFfernando chinchazoNo ratings yet

- 001 6060 RH340B Introduction CATDocument13 pages001 6060 RH340B Introduction CAThectorNo ratings yet

- 7495 Con Hydracrowd Pala Eléctrica de Cable CaterpillarDocument3 pages7495 Con Hydracrowd Pala Eléctrica de Cable CaterpillarEnzo Miguel Sarabia MontesNo ratings yet

- PC8000-6 A4 InternetDocument8 pagesPC8000-6 A4 InternetSACHIDHANANDHAM A100% (1)

- Formatos de Inspeccion Diario EX5600-6Document102 pagesFormatos de Inspeccion Diario EX5600-6Jair Ancelmo Villar PalominoNo ratings yet

- Hydraulic Mining Excavator: General Data: FeaturesDocument8 pagesHydraulic Mining Excavator: General Data: FeaturesIvan100% (1)

- Bolas PantografoDocument66 pagesBolas Pantografomaocaleirl100% (2)

- Exca enDocument12 pagesExca enFaruk AtalarNo ratings yet

- Pala O&KRH200Document8 pagesPala O&KRH200mchan1965100% (1)

- Palas Hidraulicas Sobre Orugas Cat 6060Document12 pagesPalas Hidraulicas Sobre Orugas Cat 6060thavo220% (1)

- Mine Air Systems No Idle System BrochureDocument2 pagesMine Air Systems No Idle System Brochureelia nugraha adiNo ratings yet

- Liebherr T262 GB NTBDocument8 pagesLiebherr T262 GB NTBJulioNo ratings yet

- Rotary Blasthole Drill Specifi Cations: 11.2 or 13.6 M (36.7 or 44.6 FT) Mast ConfigurationsDocument12 pagesRotary Blasthole Drill Specifi Cations: 11.2 or 13.6 M (36.7 or 44.6 FT) Mast ConfigurationsGARI100% (2)

- 797BDocument19 pages797Barfa ujiantoNo ratings yet

- Shipping Instructions For Ge787 and Ge788 Motorized Wheel: GEK-91671ADocument4 pagesShipping Instructions For Ge787 and Ge788 Motorized Wheel: GEK-91671Aait mimouneNo ratings yet

- RH 120 eDocument8 pagesRH 120 eIvanNo ratings yet

- XDR80TE充电型Document4 pagesXDR80TE充电型Wisan Nursamsi SidikNo ratings yet

- 797F CMD Field RetrofitDocument21 pages797F CMD Field Retrofitsergio conchaNo ratings yet

- D6T Guard ChangeDocument4 pagesD6T Guard ChangeRoger MendozaNo ratings yet

- 3120b BrochureDocument12 pages3120b Brochurealex100% (1)

- 12M PDFDocument8 pages12M PDFallan lariosaNo ratings yet

- 004 - CAT-6015 - Engine Pump DriveDocument26 pages004 - CAT-6015 - Engine Pump DriveGracia SediNo ratings yet

- rh90c BDocument8 pagesrh90c BDino AlajbegovicNo ratings yet

- Hydraulic Mining Excavator: Operating WeightDocument8 pagesHydraulic Mining Excavator: Operating Weighthenry sarmientoNo ratings yet

- SANY SET150S Off-Highway Mining TruckDocument3 pagesSANY SET150S Off-Highway Mining TruckAlex MazaNo ratings yet

- 5110B Prod Bulletin (TEJB7050)Document28 pages5110B Prod Bulletin (TEJB7050)suwarjitechnicNo ratings yet

- Manual de Operación y Mantenimiento 994 FDocument20 pagesManual de Operación y Mantenimiento 994 FSujeiry RodriguezNo ratings yet

- AA02193C STRG Pin Wear Checks and SizesDocument8 pagesAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteNo ratings yet

- Camion T282 PDFDocument4 pagesCamion T282 PDFgusta-sierraNo ratings yet

- 630e Sales Brochure Aess563-01 (2001) PDFDocument4 pages630e Sales Brochure Aess563-01 (2001) PDFfernando chinchazoNo ratings yet

- 365B L Your Working Advantage (AEDC0603-01)Document16 pages365B L Your Working Advantage (AEDC0603-01)suwarjitechnic100% (1)

- Structure and Function Hoist & SteeringDocument58 pagesStructure and Function Hoist & Steeringahmad nurNo ratings yet

- Hydraulic Shovel: Engine Bucket Operating SpecificationsDocument32 pagesHydraulic Shovel: Engine Bucket Operating SpecificationserallatuasanNo ratings yet

- SANY SKT105E Off-Highway Mining TruckDocument2 pagesSANY SKT105E Off-Highway Mining TruckAlex MazaNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerJackson PhinniNo ratings yet

- AA06051A Enlarge GDY Drain HolesDocument3 pagesAA06051A Enlarge GDY Drain HolesSebastiao DuarteNo ratings yet

- Generation2: CoverDocument4 pagesGeneration2: Coveralex_garcia_gutierrez100% (1)

- D8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pagesD8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDarío Ache EmeNo ratings yet

- Engine Gross Power: 510 KW (684 HP) Operating WeightDocument9 pagesEngine Gross Power: 510 KW (684 HP) Operating WeightNova kurniawan 34100% (1)

- EN-WX18HD - WX18 Hybrid DieselDocument3 pagesEN-WX18HD - WX18 Hybrid DieselNicolas Tapia CortesNo ratings yet

- EN-WX22HD - WX22 Hybrid DieselDocument3 pagesEN-WX22HD - WX22 Hybrid Diesellautaroi77No ratings yet

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- Battery ChargerDocument3 pagesBattery ChargerUserNo ratings yet

- Iph WK CatalogDocument13 pagesIph WK CatalogUserNo ratings yet

- Komatsu WL01-0720-V3 PreliminaryDocument12 pagesKomatsu WL01-0720-V3 PreliminaryUserNo ratings yet

- Towhaul Models 1 2Document1 pageTowhaul Models 1 2UserNo ratings yet

- Manitou MHT-X 10135 St3aDocument5 pagesManitou MHT-X 10135 St3aUserNo ratings yet

- Manitou MT-X 1440Document146 pagesManitou MT-X 1440UserNo ratings yet

- Manitou MHT-X 10130Document5 pagesManitou MHT-X 10130UserNo ratings yet

- Brazos PBPDocument26 pagesBrazos PBPparahu ariefNo ratings yet

- Hyster 279YDocument30 pagesHyster 279Ymilton apraezNo ratings yet

- Electrical System: Replacement, Checks, and Adjustments Trucks With Ev-100/200Zx or SR (Sem) and SP Motor ControllersDocument66 pagesElectrical System: Replacement, Checks, and Adjustments Trucks With Ev-100/200Zx or SR (Sem) and SP Motor ControllersInfoMecanicaTaller contacto100% (1)

- A Review On Different Aspects of Traction Motor Design For Railway ApplicationDocument10 pagesA Review On Different Aspects of Traction Motor Design For Railway ApplicationMt GolesNo ratings yet

- Materi SARANA - FreeportDocument79 pagesMateri SARANA - FreeportMuhammad Basir Biyantoro100% (1)

- Traction Drives PG 19Document43 pagesTraction Drives PG 19B DivyaNo ratings yet

- High Voltage EngineeringDocument54 pagesHigh Voltage EngineeringJakeNo ratings yet

- Question BankDocument32 pagesQuestion BankBhuvaneshNo ratings yet

- Ac Loco ManualDocument103 pagesAc Loco ManualDeepak Gehlot100% (1)

- Ee1451 LPDocument7 pagesEe1451 LPGokulakrishnanNo ratings yet

- Product Catalogue 2020/2021: Zero Emissions PowertrainsDocument21 pagesProduct Catalogue 2020/2021: Zero Emissions PowertrainsRaduNo ratings yet

- Curtis Controller 50288 - SESeries - RevF31Document9 pagesCurtis Controller 50288 - SESeries - RevF31ПетрNo ratings yet

- Boost 30.0 00 enDocument36 pagesBoost 30.0 00 en01911514616No ratings yet

- Training ReportDocument28 pagesTraining ReportPro OneNo ratings yet

- Module 11: Regenerative BrakingDocument19 pagesModule 11: Regenerative BrakingSuryadev Sinh SisodiyaNo ratings yet

- Z Source Inverter DesignDocument84 pagesZ Source Inverter Designakkarapakaananda100% (1)

- Wap7 Testing DetailedDocument31 pagesWap7 Testing DetailedKrishna Mohan Chauhan100% (1)

- High Speed Protection Scheme For Traction OHE of 25 KV AC Indian Railway SystemDocument8 pagesHigh Speed Protection Scheme For Traction OHE of 25 KV AC Indian Railway Systemrajesh kannanNo ratings yet

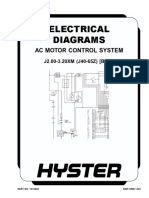

- Electrical Diagrams: Ac Motor Control SystemDocument34 pagesElectrical Diagrams: Ac Motor Control SystemIonut GrozaNo ratings yet

- 730e 81 PDFDocument16 pages730e 81 PDFNicole SmithNo ratings yet

- RRB CON ALP Trainees Descriptive QB 080820Document6 pagesRRB CON ALP Trainees Descriptive QB 080820swapna allaNo ratings yet

- ED - Notes Inroduction To Electric Drives-0Document8 pagesED - Notes Inroduction To Electric Drives-0Manideep ManiNo ratings yet

- Calculation of Traction Effort LocomotiveDocument5 pagesCalculation of Traction Effort Locomotiveriyyo2424No ratings yet

- Alt-B - Spec - WAP5 - Composite ConverterDocument42 pagesAlt-B - Spec - WAP5 - Composite ConverterjaiminNo ratings yet

- Electric Drive Truck: Gross Horsepower Nominal GVWDocument20 pagesElectric Drive Truck: Gross Horsepower Nominal GVWanzhen wangNo ratings yet

- Product Guide B 300 - 400Document58 pagesProduct Guide B 300 - 400Александр НиколаевNo ratings yet

Safety: Wheel Loader General Specifications

Safety: Wheel Loader General Specifications

Uploaded by

UserOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety: Wheel Loader General Specifications

Safety: Wheel Loader General Specifications

Uploaded by

UserCopyright:

Available Formats

WE1850-3

Wheel Loader

General Specifications

Safety

Reliability

Productivity

Operating capacities, weights and dimensions Working ranges

Standard lift High lift Engine 1491 kW 2000 hp

Bucket capacity** 32.88m 3

43 yd 3

30.58 m 3

40 yd 3 Kinetic Energy 1268 kW 1700 hp

Operating payload 58967 kg 130000 lb 54431 kg 120000 lb Storage System

Static tipping loads (KESS)***

Straight TBD TBD 147211 kg 324545 lb Payload

Full 40° turn TBD TBD 128996 kg 284388 lb Standard 58967 kg 130000 lb

Breakout force 1074833 N 241632 lb 935042 N 210206 lb High lift 54331 kg 120000 lb

Operating weight 268481 kg 592000 lb 269887 kg 595000 lb

Bucket capacity sized to material density

** Standard rock bucket based on a material density of 1780 kg/m3 (3000 lb/yd3)

Truck match 218 - 327 tonne 240 - 360 ton

*** Kinetic Energy Storage System Power available for acceleration

events and parasitic loads

General specifications General specifications

Power module Propulsion system

Diesel power options SR Hybrid Drive switched reluctance (SR) technology

Cummins diesel engine Tier 1, Tier 2 or Tier 4 propulsion system

Model QSK 60 • Digital microprocessor controlled traction drive

16 cylinders • SR Hybrid Drive advantages include:

- No commutator, brushes or rotor windings on SR motors or generator

Type 4-cycle turbocharged - SR KESS – Kinetic Energy Storage System

Rated power 1491 kW (2000 hp) @ 1800 rpm - Parts commonality - power conversion modules identical for motor

and generator

MTU Detroit diesel engine Tier 1, Tier 2 Tier 4

Travel speed

Model 16V series 4000 12V series 4000 Forward and reverse 0-19.31 km/h (0-12 mph)

16 cylinders 12 cylinders

Generator

Type 4-cycle turbocharged • G200 SR generator

Rated power 1491 kW (2000 hp) @ 1800 rpm • Switched reluctance (SR)

The independent power module mounting system, consisting of the engine Traction motors

coupled to the SR generator, is cradled within the rear frame by a three-point • B60 SR motor

isolation system. Planetary gearing

Radiator/oil cooler module Model 57

• Replaceable tube type, side-by-side split flow • In-line gear train mounted within the rim of the tire, transmitting power

• Thermostatically controlled, variable speed hydraulic motor-driven, from the traction motor through the tire/rim assembly.

radiator-mounted fan • A four-stage planetary drive unit in each position

• Total reduction 99:1

Exhaust system

Dual, low restriction mufflers with vertical, mid-hood discharge

Hydraulic system

Control system-LINCS II HPD drive box

• Pressurized, cooled, and filtered lubrication

LINCS II

• Ratio 1:1

Microprocessor based modular design Vehicle Control Unit (VCU) with

monitoring and diagnostics including integrated data logging and storage. Pumps (maximum flow rate at 1800 rpm)

Main Piston (5) 2336 L/min 617 gpm

LINCS II uses a dash mounted full color, touch screen display as the operator Steering Piston (2) 469 L/min 124 gpm

interface. Out-of-range conditions will cause an audible alarm along with a Fan Piston 170 L/min 45 gpm

message screen that is color coded to indicate severity. Accessory Piston 83 L/min 22 gpm Overall dimensions Air filtration

In addition, the touch-screen display provides repair technicians with Cooling system 83 L/min 22 gpm Standard lift High lift Primary

operational data and fault messages. Circulating pump Vane 409 L/min 108 gpm • Self cleaning KLENZ filtration system

A Tread 4.57 m 15 ft 0 in 4.57 m 15 ft 0 in

LINCS II load weigh Valves (flow per valve) • Replaceable Filter Media meets the MERV15 rating

Width outside 6.04 m 19 ft 10 in 6.04 m 19 ft 10 in • 5000 hour filter life achievable

Displays real-time load per pass, per truck and total loads Main Two (2) 1168 L/min 309 gpm B

tires • Filtered air for engine, drive system cooling and pressurized cab

• Memory capable of retaining months of production information Pump pressure 27580 kPa 4000 psi

Steering One (1) 469 L/min 124 gpm C1 Rock bucket 6.44 m 21 ft 0 in 6.44 m 21 ft 0 in

• Capable of interfacing with radio dispatch systems for Secondary

Pump pressure 27580 kPa 4000 psi without deflectors

real-time monitoring Dual safety filters for engine

C2 Rock bucket 6.71 m 22 ft 0 in 6.71 m 22 ft 0 in

Cylinders with deflectors Fluid capacities

Double-acting, single-stage (diameter and stroke), C3 Coal bucket 7.44 m 24 ft 5 in 7.44 m 24 ft 5 in

Steering and hoisting system (standard and high lift) Fuel 4542 L 1200 gal

Steering Hoist 381 mm x 2108 mm 15 in x 83 in Height bucket 12.62 m 41 ft 5 in 13.39 m 43 ft 11 in Hydraulic 1445 L 382 gal

D

Steering function is controlled by a single joystick. Constant engine rpm Bucket 318 mm x 1086 mm 12.5 in x 42.8 in fully raised SR converter cooling system 57 L 15 gal

assures full hydraulic steering response. Steering 200 mm x 762 mm 7.88 in x 30 in E Hinge – pin height 9.40 m 30 ft 10 in 9.91 m 32 ft 6 in Engine cooling system 490 L 130 gal

Crankcase (includes filters)

Articulation angle 40° F Dump clearance 6.48 m 21 ft 3 in 7.57 m 24 ft 10 in Detroit 250 L 66 gal

Turning radius Braking system G Reach at full lift 3.81 m 12 ft 6 in 3.43 m 11 ft 3 in Cummins 204 L 54 gal

Standard lift 17.06 m 55 ft 11 in Primary brake system Gearbox 27 L 7 gal

H Digging depth 0.10 m 0 ft 4 in 0.10 m 0 ft 4 in

High lift 16.10 m 52 ft 10 in Electric dynamic braking system is controlled from the accelerator pedal and Planetaries (each) 151 L 40 gal

can bring the loader to a full stop without application of mechanical brakes. I Ground clearance 0.69 m 2 ft 3 in 0.69 m 2 ft 3 in

Hoist and bucket control

J Wheelbase 7.47 m 24 ft 6 in 7.47 m 24 ft 6 in

Hoist and bucket control functions are incorporated into a single joystick Secondary brake system Structural

control. The proportional electro-hydraulic controlled hoist and bucket Air modulated traction motor speed disc brakes Overall length 19.12 m 62 ft 9 in 19.81 m 65 ft 0 in Frames are fabricated from high strength, low-alloy steel with excellent

K

system is independent of the steering system. • Single disc and caliper on each traction motor (4) carry position weld characteristics and extreme low temperature properties. The front

• Emergency fail safe brakes are spring applied in the event of air Overall length 19.84 m 65 ft 2 in 20.24 m 66 ft 5 in axle is an integral, fixed part of the front frame. The rear axle center

Standard/high lift cycle times: L

Hoist 12.6 Seconds* pressure loss bucket down oscillates 11 degrees.

Dump 2.9 Seconds* Parking brake system M Height over cab 6.73 m 22 ft 1 in 6.73 m 22 ft 1 in Unique forged ball and socket joints are utilized in multiple pivot locations

Float 5 Seconds* Spring applied, air release traction motor speed disc brakes

* All dimensions are based on standard tires and standard rock bucket with GET (lift arms, rear axle, frame articulation, hoist cylinders). These joints are

unless otherwise noted. superior in absorbing and distributing multi-directional stresses. Features

HPD gear box cooler module Power electronics cooler mode easily replaceable brass liners for long life and easy maintenance.

• Thermostatically controlled, variable speed 24V electric motor-driven, • Thermostatically controlled, variable speed 24V electric motor-driven, High strength castings are used in key areas of fabricated structures to

radiator mounted fan. radiator mounted fan. reduce stress and improve structural life.

* Estimated

2 3

General specifications

Tires/rims Optional features

Tires 58/85-57 L-4 • Auxiliary steering

Rims 47 x 57 with 6" flange • Beacon light kit

• Bucket GET options available

• Cold weather package- including:

Standard features - Battery heater

• 120V AC port - Engine heating system (oil and water)

• 360 camera system - Grease reservoir heater

- Hydraulic tank heater

• Accelerometer

• Exhaust discharge guard

• Access ladder lights

• Fire detection and suppression system (manual)

• Air conditioning / heater-defroster (filtered and pressurized)

• Fire suppression system (manual)

• Air dryer system

• Fluid sampling kit

• Air horn

• Lift arms - high lift

• Air tank bleed system

• Tires/rims

• Adjustable automatic lift height cut off

- Tires - 60/80R57

• Automatic bucket leveling control

- Rims - 47 x 57 with 5" flange

• Automatic electrical cabinet lights

• Automatic lubrication system • Windshield protection kit

• Back-up alarm, audible

• Battery disconnect switch

• Brake lights Buckets

• Central air regulator box

Standard, ISO-rated capacity:

• Central service with fast fuel

58967 kg / 130000 lb

• Data analysis and viewing software

• Data logging - downloadable production and maintenance logs High lift, ISO-rated capacity:

• Door interlock on electrical cabinet 54331 kg / 120000 lb

• Drawbar with tow points Rock and coal bucket configurations available

• Emergency stop buttons (cab and remote mounted) Buckets sized to material density

• Engine compartment lights

• Fire extinguisher, manual, 9.07 kg (20 lb)

• FOPS - falling object protection system Bucket hardware options

• Idle timer • Skid plates (replaceable)

• Inclinometer • Lip wear protection

• Interior lights • Wear liner kits

• Isolation monitor

For actual bucket configuration and sizing, consult your

• Joystick hoist and bucket control

local representative.

• Joystick steering control

• Jump start

• Ladder walkway (rear access w/retracting ladder)

• LED working lights (10 forward, 2 rear)

• LINCS II alarms

• LINCS II load weigh and monitoring

• Mirrors, rearview (parabolic)(2)

• Operator seat (11-way adjustable)

• Overspeed alarm

• Parking brake

• Retractable lap belt with shoulder harness

• Rock deflectors (bucket)

• ROPS - rollover protection structure

• Selectable throttle switch

• Starter disconnect switch

• Tinted safety glass throughout

• Training seat (with lap belt)

• Turn signals

• Twelve (12) volt power supply in cab

• Twelve (12) volt power port

• USB Ports (2)

• Walk around catwalk for cab

• Windshield washer reservoir (2.6 gal)

• Windshield wiper and washer (front and rear)

Product designs, specifications and/or data in this document are provided for informational purposes only and are not

warranties of any kind. Product designs and/or specifications may be changed at any time without notice. The only warranties

that apply to sales of products and services are Komatsu’s standard written warranties, which will be furnished upon request.

Komatsu and other trademarks and service marks used herein are the property of Komatsu Ltd., Komatsu America Corp.,

komatsu.com

Komatsu Mining Corp., or one of their affiliates, or the respective owners or licensees.

© 2021 Komatsu Mining Corp. All rights reserved.

EN-WE1850-3_SP01-0921-V1

You might also like

- 795B Master (v9)Document40 pages795B Master (v9)Rodrigo Bravo Rodrigo BravoNo ratings yet

- BS en 15380-5Document22 pagesBS en 15380-5rohita kumar dahNo ratings yet

- ZF - Bus Product Porfolio PDFDocument27 pagesZF - Bus Product Porfolio PDFFWEFWEFWNo ratings yet

- MT 3000 Mining Truck: 120 Ton (109 T) Payload CapacityDocument8 pagesMT 3000 Mining Truck: 120 Ton (109 T) Payload Capacitybayu enasoraNo ratings yet

- 3124-5.4 - P&H Planetary GearboxesDocument1 page3124-5.4 - P&H Planetary GearboxesJorge VillalobosNo ratings yet

- PH-Electric-Rope-Shovel-Components (Splited)Document3 pagesPH-Electric-Rope-Shovel-Components (Splited)Oscar JimenezNo ratings yet

- Caterpilla Performance 44®Document53 pagesCaterpilla Performance 44®Basago Minas Lo MejorNo ratings yet

- ERP22VL, 25VL, 30VL, 35VL (A976) Parts Manual: Yale Europe Materials Handling LimitedDocument480 pagesERP22VL, 25VL, 30VL, 35VL (A976) Parts Manual: Yale Europe Materials Handling LimitedЕвг100% (2)

- Voltas VVE BOPT 2T (AC)Document82 pagesVoltas VVE BOPT 2T (AC)Johnson James100% (2)

- Safety: Wheel Loader General SpecificationsDocument3 pagesSafety: Wheel Loader General SpecificationsWalter Cesar Loli MoralesNo ratings yet

- Electric Mining Shovel - DC Drive Product OverviewDocument5 pagesElectric Mining Shovel - DC Drive Product OverviewmohanNo ratings yet

- PC5500-6 Sales Brochure (2009) PDFDocument8 pagesPC5500-6 Sales Brochure (2009) PDFBenjamin Arnold CFNo ratings yet

- PC 8000-6 Backhoe DE PDFDocument8 pagesPC 8000-6 Backhoe DE PDFJon CarbonNo ratings yet

- CEBD013702 Shop ManualDocument1,035 pagesCEBD013702 Shop ManualBiswajit DasNo ratings yet

- L 2350 Specification SheetDocument3 pagesL 2350 Specification SheetCristianoNo ratings yet

- Pala O&KRH90CDocument7 pagesPala O&KRH90Cmchan1965100% (1)

- Terex RH200 - Brochure - M 135.0Document8 pagesTerex RH200 - Brochure - M 135.0Relining MineralsNo ratings yet

- Komatsu 930E-5SE Electric Drive Truck Spec SheetDocument4 pagesKomatsu 930E-5SE Electric Drive Truck Spec Sheetelectronico007No ratings yet

- Teh Spes IndonesiaDocument16 pagesTeh Spes IndonesiaJunius Rikarlis UmbaraNo ratings yet

- D11T Trans PDFDocument2 pagesD11T Trans PDFVictor Cardenas FernandezNo ratings yet

- Equipment & Dimensions: EH4500: Standard Equipment Optional Equipment Eh4500 Ac Wheel MotorDocument2 pagesEquipment & Dimensions: EH4500: Standard Equipment Optional Equipment Eh4500 Ac Wheel MotorAndi Wardiman AnwarNo ratings yet

- 830e Sales Brochure Aess565-01 (2001) PDFDocument4 pages830e Sales Brochure Aess565-01 (2001) PDFfernando chinchazoNo ratings yet

- 001 6060 RH340B Introduction CATDocument13 pages001 6060 RH340B Introduction CAThectorNo ratings yet

- 7495 Con Hydracrowd Pala Eléctrica de Cable CaterpillarDocument3 pages7495 Con Hydracrowd Pala Eléctrica de Cable CaterpillarEnzo Miguel Sarabia MontesNo ratings yet

- PC8000-6 A4 InternetDocument8 pagesPC8000-6 A4 InternetSACHIDHANANDHAM A100% (1)

- Formatos de Inspeccion Diario EX5600-6Document102 pagesFormatos de Inspeccion Diario EX5600-6Jair Ancelmo Villar PalominoNo ratings yet

- Hydraulic Mining Excavator: General Data: FeaturesDocument8 pagesHydraulic Mining Excavator: General Data: FeaturesIvan100% (1)

- Bolas PantografoDocument66 pagesBolas Pantografomaocaleirl100% (2)

- Exca enDocument12 pagesExca enFaruk AtalarNo ratings yet

- Pala O&KRH200Document8 pagesPala O&KRH200mchan1965100% (1)

- Palas Hidraulicas Sobre Orugas Cat 6060Document12 pagesPalas Hidraulicas Sobre Orugas Cat 6060thavo220% (1)

- Mine Air Systems No Idle System BrochureDocument2 pagesMine Air Systems No Idle System Brochureelia nugraha adiNo ratings yet

- Liebherr T262 GB NTBDocument8 pagesLiebherr T262 GB NTBJulioNo ratings yet

- Rotary Blasthole Drill Specifi Cations: 11.2 or 13.6 M (36.7 or 44.6 FT) Mast ConfigurationsDocument12 pagesRotary Blasthole Drill Specifi Cations: 11.2 or 13.6 M (36.7 or 44.6 FT) Mast ConfigurationsGARI100% (2)

- 797BDocument19 pages797Barfa ujiantoNo ratings yet

- Shipping Instructions For Ge787 and Ge788 Motorized Wheel: GEK-91671ADocument4 pagesShipping Instructions For Ge787 and Ge788 Motorized Wheel: GEK-91671Aait mimouneNo ratings yet

- RH 120 eDocument8 pagesRH 120 eIvanNo ratings yet

- XDR80TE充电型Document4 pagesXDR80TE充电型Wisan Nursamsi SidikNo ratings yet

- 797F CMD Field RetrofitDocument21 pages797F CMD Field Retrofitsergio conchaNo ratings yet

- D6T Guard ChangeDocument4 pagesD6T Guard ChangeRoger MendozaNo ratings yet

- 3120b BrochureDocument12 pages3120b Brochurealex100% (1)

- 12M PDFDocument8 pages12M PDFallan lariosaNo ratings yet

- 004 - CAT-6015 - Engine Pump DriveDocument26 pages004 - CAT-6015 - Engine Pump DriveGracia SediNo ratings yet

- rh90c BDocument8 pagesrh90c BDino AlajbegovicNo ratings yet

- Hydraulic Mining Excavator: Operating WeightDocument8 pagesHydraulic Mining Excavator: Operating Weighthenry sarmientoNo ratings yet

- SANY SET150S Off-Highway Mining TruckDocument3 pagesSANY SET150S Off-Highway Mining TruckAlex MazaNo ratings yet

- 5110B Prod Bulletin (TEJB7050)Document28 pages5110B Prod Bulletin (TEJB7050)suwarjitechnicNo ratings yet

- Manual de Operación y Mantenimiento 994 FDocument20 pagesManual de Operación y Mantenimiento 994 FSujeiry RodriguezNo ratings yet

- AA02193C STRG Pin Wear Checks and SizesDocument8 pagesAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteNo ratings yet

- Camion T282 PDFDocument4 pagesCamion T282 PDFgusta-sierraNo ratings yet

- 630e Sales Brochure Aess563-01 (2001) PDFDocument4 pages630e Sales Brochure Aess563-01 (2001) PDFfernando chinchazoNo ratings yet

- 365B L Your Working Advantage (AEDC0603-01)Document16 pages365B L Your Working Advantage (AEDC0603-01)suwarjitechnic100% (1)

- Structure and Function Hoist & SteeringDocument58 pagesStructure and Function Hoist & Steeringahmad nurNo ratings yet

- Hydraulic Shovel: Engine Bucket Operating SpecificationsDocument32 pagesHydraulic Shovel: Engine Bucket Operating SpecificationserallatuasanNo ratings yet

- SANY SKT105E Off-Highway Mining TruckDocument2 pagesSANY SKT105E Off-Highway Mining TruckAlex MazaNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerJackson PhinniNo ratings yet

- AA06051A Enlarge GDY Drain HolesDocument3 pagesAA06051A Enlarge GDY Drain HolesSebastiao DuarteNo ratings yet

- Generation2: CoverDocument4 pagesGeneration2: Coveralex_garcia_gutierrez100% (1)

- D8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pagesD8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDarío Ache EmeNo ratings yet

- Engine Gross Power: 510 KW (684 HP) Operating WeightDocument9 pagesEngine Gross Power: 510 KW (684 HP) Operating WeightNova kurniawan 34100% (1)

- EN-WX18HD - WX18 Hybrid DieselDocument3 pagesEN-WX18HD - WX18 Hybrid DieselNicolas Tapia CortesNo ratings yet

- EN-WX22HD - WX22 Hybrid DieselDocument3 pagesEN-WX22HD - WX22 Hybrid Diesellautaroi77No ratings yet

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- Battery ChargerDocument3 pagesBattery ChargerUserNo ratings yet

- Iph WK CatalogDocument13 pagesIph WK CatalogUserNo ratings yet

- Komatsu WL01-0720-V3 PreliminaryDocument12 pagesKomatsu WL01-0720-V3 PreliminaryUserNo ratings yet

- Towhaul Models 1 2Document1 pageTowhaul Models 1 2UserNo ratings yet

- Manitou MHT-X 10135 St3aDocument5 pagesManitou MHT-X 10135 St3aUserNo ratings yet

- Manitou MT-X 1440Document146 pagesManitou MT-X 1440UserNo ratings yet

- Manitou MHT-X 10130Document5 pagesManitou MHT-X 10130UserNo ratings yet

- Brazos PBPDocument26 pagesBrazos PBPparahu ariefNo ratings yet

- Hyster 279YDocument30 pagesHyster 279Ymilton apraezNo ratings yet

- Electrical System: Replacement, Checks, and Adjustments Trucks With Ev-100/200Zx or SR (Sem) and SP Motor ControllersDocument66 pagesElectrical System: Replacement, Checks, and Adjustments Trucks With Ev-100/200Zx or SR (Sem) and SP Motor ControllersInfoMecanicaTaller contacto100% (1)

- A Review On Different Aspects of Traction Motor Design For Railway ApplicationDocument10 pagesA Review On Different Aspects of Traction Motor Design For Railway ApplicationMt GolesNo ratings yet

- Materi SARANA - FreeportDocument79 pagesMateri SARANA - FreeportMuhammad Basir Biyantoro100% (1)

- Traction Drives PG 19Document43 pagesTraction Drives PG 19B DivyaNo ratings yet

- High Voltage EngineeringDocument54 pagesHigh Voltage EngineeringJakeNo ratings yet

- Question BankDocument32 pagesQuestion BankBhuvaneshNo ratings yet

- Ac Loco ManualDocument103 pagesAc Loco ManualDeepak Gehlot100% (1)

- Ee1451 LPDocument7 pagesEe1451 LPGokulakrishnanNo ratings yet

- Product Catalogue 2020/2021: Zero Emissions PowertrainsDocument21 pagesProduct Catalogue 2020/2021: Zero Emissions PowertrainsRaduNo ratings yet

- Curtis Controller 50288 - SESeries - RevF31Document9 pagesCurtis Controller 50288 - SESeries - RevF31ПетрNo ratings yet

- Boost 30.0 00 enDocument36 pagesBoost 30.0 00 en01911514616No ratings yet

- Training ReportDocument28 pagesTraining ReportPro OneNo ratings yet

- Module 11: Regenerative BrakingDocument19 pagesModule 11: Regenerative BrakingSuryadev Sinh SisodiyaNo ratings yet

- Z Source Inverter DesignDocument84 pagesZ Source Inverter Designakkarapakaananda100% (1)

- Wap7 Testing DetailedDocument31 pagesWap7 Testing DetailedKrishna Mohan Chauhan100% (1)

- High Speed Protection Scheme For Traction OHE of 25 KV AC Indian Railway SystemDocument8 pagesHigh Speed Protection Scheme For Traction OHE of 25 KV AC Indian Railway Systemrajesh kannanNo ratings yet

- Electrical Diagrams: Ac Motor Control SystemDocument34 pagesElectrical Diagrams: Ac Motor Control SystemIonut GrozaNo ratings yet

- 730e 81 PDFDocument16 pages730e 81 PDFNicole SmithNo ratings yet

- RRB CON ALP Trainees Descriptive QB 080820Document6 pagesRRB CON ALP Trainees Descriptive QB 080820swapna allaNo ratings yet

- ED - Notes Inroduction To Electric Drives-0Document8 pagesED - Notes Inroduction To Electric Drives-0Manideep ManiNo ratings yet

- Calculation of Traction Effort LocomotiveDocument5 pagesCalculation of Traction Effort Locomotiveriyyo2424No ratings yet

- Alt-B - Spec - WAP5 - Composite ConverterDocument42 pagesAlt-B - Spec - WAP5 - Composite ConverterjaiminNo ratings yet

- Electric Drive Truck: Gross Horsepower Nominal GVWDocument20 pagesElectric Drive Truck: Gross Horsepower Nominal GVWanzhen wangNo ratings yet

- Product Guide B 300 - 400Document58 pagesProduct Guide B 300 - 400Александр НиколаевNo ratings yet