Professional Documents

Culture Documents

Coating Parameters - Clear Formulations

Coating Parameters - Clear Formulations

Uploaded by

NguyễnMinhTiếnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coating Parameters - Clear Formulations

Coating Parameters - Clear Formulations

Uploaded by

NguyễnMinhTiếnCopyright:

Available Formats

Product Information

OPADRY® 200

Optimized Performance Coatings

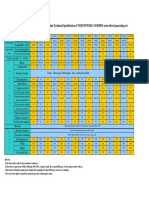

Coating Parameters – Clear Formulations

Opadry® 200 optimized performance coatings are dry blends containing a combination of excipients for the

aqueous film coating of pharmaceutical solid dosage forms. The coating parameters listed in the table below

are based on Colorcon data for Opadry 200 clear formulations. Individual product and machine functions

should be taken into account and conditions altered as required.

Conventional

Fully Perforated Side Vented Coating Pan

Pan

cm 38.1 60.96 122 152.4 40.64

Pan Diameter

in 15 24 48 60 16

Solution Preparation

Solvent Purified Water Purified Water Purified Water Purified Water Purified Water

Solids Content % w/w 7.5 7.5 7.5 7.5 7.5

Run Objectives

Theoretical

% w/w 1 1 1 1 1

Weight Gain

† † 1.5 - 3.0 12 - 15 120 - 160 320 - 350 3

Tablet Charge kg

Gun Configuration

Example Spray Schlick 931/7-1 Spraying Systems Schlick 931/7-1 Schlick 970/7-1

type Manesty

Gun S22 1/8 VAU S35 (ABC) S75

Number of

guns 1 1-2 3–4 5-6 1

Guns

Nozzle mm 1.2 1.2 1.2 1.2 1.2

Diameter in 0.05 0.05 0.05 0.05 0.05

Gun to Bed cm 10 17 25 25 15

Distance in 4 7 10 10 6

Gun to Gun cm N/A 10 15 15 N/A

Distance in N/A 4 6 6 N/A

Atomizing Air bar 1.4 1.7 2.5 2.5 1.4

Pressure psi 20 25 36 36 20

Pattern Air bar 1.4 1.7 2.5 2.5 1.4

Pressure psi 20 25 36 36 20

Process Parameters

Drying Air cu.m/hr 250 - 290 424 - 470 2300 - 3060 5440 - 6630 140

Volume cu.ft/min 147 - 175 250 - 275 1350 – 1800 3200 - 3900 80

Pan Speed* rpm* 18 14 8 6 20

Pre-warm °C 45 - 50 45 - 50 45 - 50 45 - 50 45 - 50

Tablet Bed °F 113 - 122 113 - 122 113 - 122 113 - 122 113 - 122

Inlet Air °C 60 65 65 65 65

Temperature °F 140 149 149 149 149

Tablet Bed °C 45 - 48 45 - 48 45 - 48 45 - 48 45 - 48

Temperature °F 113 - 118 113 - 118 113 - 118 113 - 118 113 - 118

Spray Rate g/min 12 - 20 35 - 50 250 - 350 480 - 680 12

Approximate

min 15 - 20 35 - 45 45 - 65 65 - 85 38

Coating Times

*Pan speed should be set so that even mixing of the bed occurs. This will be influenced by tablet size, shape, friability and baffle

type in the pan.

†

Tablet charge is dependent on tablet size and shape.

OPADRY® 200 -1-

The information contained herein, to the best of Colorcon, Inc.’s knowledge is true and accurate. Any recommendations or suggestions of

Colorcon, Inc. with regard to the products provided by Colorcon, Inc. are made without warranty, either implied or expressed, because of the

variations in methods, conditions and equipment which may be used in commercially processing the products, and no such warranties are

made for the suitability of the products for any applications that you may have disclosed. Colorcon, Inc. shall not be liable for loss of profit or

for incidental, special or consequential loss or damages.

© BPSI Holdings, 2010. The information contained in

Colorcon, Inc. makes no warranty, either expressed or implied, that the use of the products provided by Colorcon, Inc., will this document is proprietary to Colorcon, Inc. and

not infringe any trademark, trade name, copyright, patent or other rights held by any third person or entity when used in the customer’s may not be used or disseminated inappropriately.

application.

All trademarks, except where noted, are property

For more information, contact your Colorcon representative or call: of BPSI Holdings,LLC.

North America Europe/Middle East/Africa Asia Pacific Latin America

+1-215-699-7733 +44-(0)-1322-293000 +65-6438-0318 +54-11-5556-7700 pi_opadry_200_ coat_param_clear_v3_09_2011

You can InsertProductName

also visit our website at www.colorcon.com -2-

You might also like

- Grade7 ScienceDocument450 pagesGrade7 ScienceJannet Yang100% (4)

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Екатерина Калашникова100% (1)

- Sigma Fluid PDFDocument2 pagesSigma Fluid PDFHubertt Chacon AntonioNo ratings yet

- C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesC Check Value) OT Outside Tolerance (X Is Set)Best Auto TechNo ratings yet

- SatspecsDocument1 pageSatspecsRgonz79100% (1)

- Coating Parameters - Pigmented FormulationsDocument2 pagesCoating Parameters - Pigmented FormulationsNguyễnMinhTiếnNo ratings yet

- SIGMA Flange Fittings PDFDocument22 pagesSIGMA Flange Fittings PDFSopheareak ChhanNo ratings yet

- 1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveDocument4 pages1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveabrahamNo ratings yet

- VPC Chongqing CumminsDocument1 pageVPC Chongqing CumminspngchanhNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)OFFICE DANACNo ratings yet

- 101062-9290 TabelaDocument5 pages101062-9290 TabelaLIONN SOFTWARESNo ratings yet

- Specification 2. Specification: 2-1. Outdoor UnitsDocument2 pagesSpecification 2. Specification: 2-1. Outdoor UnitsAhmed NajjarNo ratings yet

- 101609-3272 TD PDFDocument3 pages101609-3272 TD PDFadhit_90No ratings yet

- OT Outside Tolerance (X Is Set)Document4 pagesOT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Pedro AbellanNo ratings yet

- OT Outside Tolerance (X Is Set)Document4 pagesOT Outside Tolerance (X Is Set)Agus WijayadiNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Agus WijayadiNo ratings yet

- 108622-4011 TDDocument7 pages108622-4011 TDririnmars22No ratings yet

- CB-8391 CBND Technical Data - Specifications PDFDocument43 pagesCB-8391 CBND Technical Data - Specifications PDFcoyuncoNo ratings yet

- Polystyrene Processing GuideDocument4 pagesPolystyrene Processing GuidemadogodNo ratings yet

- Cake Tin Sizes Sugar Temperatures Weight: 10 Inch 25.5cm 11 Inch 28cmDocument1 pageCake Tin Sizes Sugar Temperatures Weight: 10 Inch 25.5cm 11 Inch 28cmGarryNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Nikhil digheNo ratings yet

- Bronze Relief Valve DN10 DN15 DN20Document2 pagesBronze Relief Valve DN10 DN15 DN20billNo ratings yet

- Rule No. 1Document64 pagesRule No. 1Albert AliminNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)aimanNo ratings yet

- Lub SKIDSDocument2 pagesLub SKIDSgabrielNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- Check Valve 13701Document1 pageCheck Valve 13701sitaNo ratings yet

- PC Calibre Injection Molding SettingsDocument1 pagePC Calibre Injection Molding SettingsMitja GorseNo ratings yet

- "Simple" - Onoff Monobloc Air To WaterDocument1 page"Simple" - Onoff Monobloc Air To WaterAnonymous mE6MEje0No ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)СТО Дизель Улан-УдэNo ratings yet

- Super TacDocument2 pagesSuper TacVelina MilevaNo ratings yet

- VITA E VITA-VMK-Master Screen enDocument1 pageVITA E VITA-VMK-Master Screen enToma IoanaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Best Auto TechNo ratings yet

- 108622-2371 TDDocument4 pages108622-2371 TDririnmars22No ratings yet

- 9412Document3 pages9412Mihai-Eugen Popa100% (1)

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)OFFICE DANACNo ratings yet

- Huafengdongli 495 4100 Series OperationmanualDocument5 pagesHuafengdongli 495 4100 Series OperationmanualChanat MeonsiNo ratings yet

- Donaldson Hump Hoses, Reducers, Etc. - 055474 PDFDocument4 pagesDonaldson Hump Hoses, Reducers, Etc. - 055474 PDFkman548No ratings yet

- 2000 DataDocument1 page2000 DataAlexis PradoNo ratings yet

- Gmv5 - Ducted Hi Esp VRFDocument1 pageGmv5 - Ducted Hi Esp VRFAvk SanjeevanNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- Denison-Parker Premier SeriesDocument40 pagesDenison-Parker Premier SeriesDamNo ratings yet

- E-ABRASIC P 12 To P 220: For Coated Abrasives ProductsDocument2 pagesE-ABRASIC P 12 To P 220: For Coated Abrasives ProductsBas100% (1)

- Boiler Steam FlowDocument1 pageBoiler Steam FlowzalabiNo ratings yet

- Main CharacteristicsDocument1 pageMain CharacteristicsAlex OngNo ratings yet

- Dimensions and Ratings: Watertube BoilerDocument10 pagesDimensions and Ratings: Watertube Boilerfauzi endraNo ratings yet

- F615 F625 F629 ButterflyValves DS CraneFSDocument1 pageF615 F625 F629 ButterflyValves DS CraneFSmohamed ghareebNo ratings yet

- Farymann Technical Data Engines After 1981Document1 pageFarymann Technical Data Engines After 1981emreorakNo ratings yet

- Fiche Technique ODU 40KWDocument1 pageFiche Technique ODU 40KWHotel SétifNo ratings yet

- Victaulic Balancing Valves TA Series 786H/787H/788/789 and Series 78KHDocument16 pagesVictaulic Balancing Valves TA Series 786H/787H/788/789 and Series 78KHal hidayatNo ratings yet

- Interconnecting Piping For Hook Up New Wells at Guebiba ClusterDocument1 pageInterconnecting Piping For Hook Up New Wells at Guebiba ClusterCss SfaxienNo ratings yet

- Ceramco 3 Firing ChartDocument2 pagesCeramco 3 Firing ChartHarcha YounesNo ratings yet

- 071 Thermoplastic Diaphragm ValvesDocument5 pages071 Thermoplastic Diaphragm Valves정동현No ratings yet

- 4.82 KL PP FRP TanksDocument24 pages4.82 KL PP FRP TanksmaheshdgavaliNo ratings yet

- International Comparison Table For Test Sieves Table 1 - 125 MM - 1 MMDocument3 pagesInternational Comparison Table For Test Sieves Table 1 - 125 MM - 1 MMVasant HiremathNo ratings yet

- Technical Specification 18Document2 pagesTechnical Specification 18sarvan shivaNo ratings yet

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaDocument2 pages2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarNo ratings yet

- 2009manual ST-2TDocument12 pages2009manual ST-2TJean Michel BattailNo ratings yet

- Ceolus KG1000Document1 pageCeolus KG1000NguyễnMinhTiếnNo ratings yet

- Rug01-002482396 2018 0001 AcDocument5 pagesRug01-002482396 2018 0001 AcNguyễnMinhTiếnNo ratings yet

- Robaxin-750, 750 MG Film-Coated TabletsDocument4 pagesRobaxin-750, 750 MG Film-Coated TabletsNguyễnMinhTiếnNo ratings yet

- Coating Parameters - Pigmented FormulationsDocument2 pagesCoating Parameters - Pigmented FormulationsNguyễnMinhTiếnNo ratings yet

- OutlineDocument10 pagesOutlineLingyu LiuNo ratings yet

- Neighborhood and Connectivity of PixelsDocument25 pagesNeighborhood and Connectivity of Pixelswit12345No ratings yet

- Ideologies of GlobalizationDocument41 pagesIdeologies of GlobalizationDarlyn Joy Soliven50% (4)

- In Concrete ReportDocument1 pageIn Concrete ReportSophia AmbunanNo ratings yet

- Zhao - An Intertextual Approach To Translation at The Macro-LevelDocument9 pagesZhao - An Intertextual Approach To Translation at The Macro-LevelangielskiajNo ratings yet

- Drawer SlidesDocument48 pagesDrawer SlidesvadivelNo ratings yet

- A Beginners Guide On How Paper Tubes Cores Are ManufacturedDocument7 pagesA Beginners Guide On How Paper Tubes Cores Are ManufacturedAjaysinh JadejaNo ratings yet

- Quality in Practice - Building Trust Through Quality at GerbDocument6 pagesQuality in Practice - Building Trust Through Quality at Gerbsakshi1404No ratings yet

- AssessmentDocument10 pagesAssessmentUttara BNo ratings yet

- International ISO Standard 8501-2: Ctah, AptDocument13 pagesInternational ISO Standard 8501-2: Ctah, AptthaniNo ratings yet

- Speech in The Convention Study Sheet 12345678 Flashcards QuizletDocument1 pageSpeech in The Convention Study Sheet 12345678 Flashcards QuizletFahadNo ratings yet

- Preston and Stigs Stock Selecting ChecklistDocument3 pagesPreston and Stigs Stock Selecting ChecklistSaurabh TiwariNo ratings yet

- Mathematics 8-Marigold/ Sampaguita MULTIPLE CHOCE: Choose The Letter of The Correct Answer and Write It On The SpaceDocument4 pagesMathematics 8-Marigold/ Sampaguita MULTIPLE CHOCE: Choose The Letter of The Correct Answer and Write It On The SpaceIvy Jane MalacastaNo ratings yet

- Battery MSDSDocument3 pagesBattery MSDSAnkitNo ratings yet

- MetalurgiaDocument5 pagesMetalurgiaAndjelkaStankovicNo ratings yet

- The Impact of Inflation On Education: Dr. Jayeeta BhattacharjeeDocument12 pagesThe Impact of Inflation On Education: Dr. Jayeeta BhattacharjeeLiya Mae SantiagoNo ratings yet

- CBSE Class 6 Science Chapter 2 Components of Food Important Questions 2023-24Document3 pagesCBSE Class 6 Science Chapter 2 Components of Food Important Questions 2023-24Aiyana PraveshNo ratings yet

- Tickler Final PDFDocument29 pagesTickler Final PDFSerious LeoNo ratings yet

- Alexander 360 FeedbackDocument11 pagesAlexander 360 FeedbackHossain SumonNo ratings yet

- Speakout DVD Extra Intermediate Unit 10 PDFDocument1 pageSpeakout DVD Extra Intermediate Unit 10 PDFОксана МальцеваNo ratings yet

- Stellar Gold Event Guide 2021Document7 pagesStellar Gold Event Guide 2021CozmynNo ratings yet

- Frequently Asked Questions On Contractors Registration System (CRS) 13dec2021Document7 pagesFrequently Asked Questions On Contractors Registration System (CRS) 13dec2021Jianhua WuNo ratings yet

- Syllabus Debate PDFDocument5 pagesSyllabus Debate PDFJeicel Ann BarairoNo ratings yet

- What Is Bar Model, Sir?Document5 pagesWhat Is Bar Model, Sir?Denis TarorehNo ratings yet

- Motherboard Asus X99 DeluxeDocument10 pagesMotherboard Asus X99 DeluxeAlexandar ŠkaraNo ratings yet

- English-Speaking Countries CanadaDocument17 pagesEnglish-Speaking Countries CanadaTukan NakutNo ratings yet

- Session 1 - Advancement Technologies in Pyro-ProcessingDocument85 pagesSession 1 - Advancement Technologies in Pyro-Processingmahendra sen100% (1)

- DVD Stereo System SC-VKX60: Operating InstructionsDocument27 pagesDVD Stereo System SC-VKX60: Operating InstructionsSeb FacuNo ratings yet

- Channel Roles in A Dynamic Marketplace at Bec DomsDocument7 pagesChannel Roles in A Dynamic Marketplace at Bec DomsBabasab Patil (Karrisatte)No ratings yet