Professional Documents

Culture Documents

AAMA Standards Comparison - Organic Coatings On Fiber Reinforced

AAMA Standards Comparison - Organic Coatings On Fiber Reinforced

Uploaded by

ThanhHaCopyright:

Available Formats

You might also like

- Implant ProsthodonticsDocument5 pagesImplant ProsthodonticsAmar BhochhibhoyaNo ratings yet

- Carboline Carboguard 890 PDSDocument2 pagesCarboline Carboguard 890 PDSSamNo ratings yet

- 10.feeder Analysis & ModelingDocument117 pages10.feeder Analysis & ModelingNamiraNo ratings yet

- 2603 2604 2605 - Comparisons - 4 6 11 PDFDocument1 page2603 2604 2605 - Comparisons - 4 6 11 PDFuocmogiandi_a100% (1)

- Wet Adhesion of Latex Paints To A Gloss Alkyd Enamel SubstrateDocument4 pagesWet Adhesion of Latex Paints To A Gloss Alkyd Enamel Substrateasma hamzaNo ratings yet

- CP 2Document1 pageCP 2shameer bashaNo ratings yet

- Cinta EnterradaDocument4 pagesCinta EnterradaDaniel Garces DavilaNo ratings yet

- Hempaflor Decorate 600Document2 pagesHempaflor Decorate 600Riian Apriansyah100% (1)

- 1016 - AAMA Finish CriteriaDocument8 pages1016 - AAMA Finish Criteriaw leungNo ratings yet

- SXD-1818 DotDocument2 pagesSXD-1818 Dotasem1102345No ratings yet

- Standard QA PropertiesDocument4 pagesStandard QA PropertiesBagas CahyadiNo ratings yet

- Steel Shield 1100Document3 pagesSteel Shield 1100Moin AltafNo ratings yet

- Karnak Technical Bulletin No. 7 ASTM D1227 Designation Change Technical Notes 432337Document3 pagesKarnak Technical Bulletin No. 7 ASTM D1227 Designation Change Technical Notes 432337Malak HindiNo ratings yet

- Bradybondz (TM) B-423 Thermal Transfer Printable Glossy White Polyester Label StockDocument4 pagesBradybondz (TM) B-423 Thermal Transfer Printable Glossy White Polyester Label StockDeep SharmaNo ratings yet

- Interthane 990 Test Data PDFDocument2 pagesInterthane 990 Test Data PDFImam Situmeang100% (2)

- HereShield TDSDocument5 pagesHereShield TDSMahdi BagheriNo ratings yet

- Acrypoly Cast Acrylic - Data SheetDocument3 pagesAcrypoly Cast Acrylic - Data SheetAbhijit BhavsarNo ratings yet

- General Properties Viscosity Aging: PVC Paste Resin (Homopolymer)Document2 pagesGeneral Properties Viscosity Aging: PVC Paste Resin (Homopolymer)AminulIslamNo ratings yet

- E Cera Ceramic Porcelain Test Methods GlossaryDocument1 pageE Cera Ceramic Porcelain Test Methods GlossaryHasmukh KoringaNo ratings yet

- Intergard 251HS - Test DataDocument1 pageIntergard 251HS - Test DataImam Situmeang100% (1)

- Bopp TapeDocument2 pagesBopp TapeJayant Kumar Jha100% (1)

- Seal N Flex 1: Technical Data SheetDocument2 pagesSeal N Flex 1: Technical Data SheetNorman JohannisNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- General Properties Rheological Properties: PVC Paste Resin (Homopolymer)Document2 pagesGeneral Properties Rheological Properties: PVC Paste Resin (Homopolymer)AminulIslamNo ratings yet

- Product Data Sheet: Akzonobel Powder CoatingsDocument3 pagesProduct Data Sheet: Akzonobel Powder CoatingsFerhat ÖzcanNo ratings yet

- Amercoat 450HDocument2 pagesAmercoat 450HJairo ArroyoNo ratings yet

- Dekguard E2000: Constructive SolutionsDocument4 pagesDekguard E2000: Constructive SolutionsSyed HassaanNo ratings yet

- Ceramic Porcelain Test Methods GlossaryDocument1 pageCeramic Porcelain Test Methods GlossaryHsaam HsaamNo ratings yet

- FASARA Tech Data SheetDocument12 pagesFASARA Tech Data Sheetvlade naumovskiNo ratings yet

- Masterseal hlm5000r TdsDocument3 pagesMasterseal hlm5000r TdsHabib ArifnurNo ratings yet

- Proofex SMDocument4 pagesProofex SMSantosh SharmaNo ratings yet

- Dekguard E2000Document4 pagesDekguard E2000Muhammad UsmanNo ratings yet

- Masterseal HLM 5000 R: Liquid Cold-Applied Waterproofing Membrane SystemDocument2 pagesMasterseal HLM 5000 R: Liquid Cold-Applied Waterproofing Membrane SystemLemark R.No ratings yet

- Data Teknis Alcoflux KoreaDocument40 pagesData Teknis Alcoflux KoreaDebby saputraNo ratings yet

- Pds Zincanode 620 VocDocument2 pagesPds Zincanode 620 VocmuthukumarNo ratings yet

- Carboguard 890 GF PDSDocument2 pagesCarboguard 890 GF PDSfazeel mohammedNo ratings yet

- X-Seal PU25 +joint CordDocument52 pagesX-Seal PU25 +joint CordMohamed ElshabrawyNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Waterproofing & Damp Proofing Item DescriptionDocument2 pagesWaterproofing & Damp Proofing Item DescriptionKhin Sandi KoNo ratings yet

- X-Seal PU25Document2 pagesX-Seal PU25JoeNo ratings yet

- Fosroc Dekguard E2000: (Also Known As Nitocote FBC)Document4 pagesFosroc Dekguard E2000: (Also Known As Nitocote FBC)Tejinder KumarNo ratings yet

- X-Tech CrystalClear 3Document2 pagesX-Tech CrystalClear 3EGO AnimationNo ratings yet

- Dekguard E2000Document4 pagesDekguard E2000m.elsanee.cubicNo ratings yet

- Chapter 3 Roof EN 1corrDocument21 pagesChapter 3 Roof EN 1corrMPBGDNo ratings yet

- QL3009 Aq21Document4 pagesQL3009 Aq21Andrew LeeNo ratings yet

- Bitumastic 50: Selection & Specification DataDocument4 pagesBitumastic 50: Selection & Specification DataLuna LunaNo ratings yet

- ZA TDS Interpon D1025 GlossDocument2 pagesZA TDS Interpon D1025 Glossahmed hargaNo ratings yet

- Interthane 990: Long Term Recoatability With AestheticsDocument2 pagesInterthane 990: Long Term Recoatability With Aestheticssatheez3251No ratings yet

- Particle Board and MDFDocument26 pagesParticle Board and MDFjosefNo ratings yet

- 3M VHB Window Tape G45Document2 pages3M VHB Window Tape G45philipNo ratings yet

- Low Odor / Low VOC Acrylic Vinyl Copolymer Emulsion Putty Filler, Nr. 15035Document3 pagesLow Odor / Low VOC Acrylic Vinyl Copolymer Emulsion Putty Filler, Nr. 15035Mostafa Hussein AbdouNo ratings yet

- EU - TDS - Interpon D2525 STF TextureDocument3 pagesEU - TDS - Interpon D2525 STF TextureWilson ThomasNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- TDS Dekguard E2000 India3Document4 pagesTDS Dekguard E2000 India3Er Krishan YadavNo ratings yet

- Black Ced: Shri EkviraDocument10 pagesBlack Ced: Shri Ekviraaditya dixitNo ratings yet

- Dovetail Sherwin Williams PaintDocument2 pagesDovetail Sherwin Williams PaintDan SmithNo ratings yet

- 3M™ All Weather Thermoplastic: 1 DescriptionDocument6 pages3M™ All Weather Thermoplastic: 1 DescriptionAddin DinNo ratings yet

- Denso Glass Outerwrap TDSDocument3 pagesDenso Glass Outerwrap TDSIwan AgusNo ratings yet

- 3M™ Scotch-Weld™ Structural AdhesivesDocument10 pages3M™ Scotch-Weld™ Structural AdhesivesDan AyalaNo ratings yet

- 7-1883 TDS Grey Liquid EpoxyDocument2 pages7-1883 TDS Grey Liquid EpoxyPedro Santo Orsini RevengaNo ratings yet

- 2021 - 2022 Sharks Friendly Questions For GCIHS JHS Vrs DPS JHS IIDocument5 pages2021 - 2022 Sharks Friendly Questions For GCIHS JHS Vrs DPS JHS IIFelix AyornuNo ratings yet

- Natural Ice - CreamDocument13 pagesNatural Ice - CreamPalak MehtaNo ratings yet

- DGSM Cir WRT MMRDocument72 pagesDGSM Cir WRT MMRUttam SharmaNo ratings yet

- Space Closing Mechanics - DIFFERENT LOOPSDocument147 pagesSpace Closing Mechanics - DIFFERENT LOOPSdrarjunvedvyas100% (18)

- 1104A-44TG2 ElectropaK PN1784Document2 pages1104A-44TG2 ElectropaK PN1784NedhoNerimo TroyaNo ratings yet

- Climate Action Incentive Payment Notice 2022 06 25 09 46 45 07823 PDFDocument3 pagesClimate Action Incentive Payment Notice 2022 06 25 09 46 45 07823 PDFalex mac dougallNo ratings yet

- Battery ChargerDocument24 pagesBattery ChargerPhang Kumwing100% (1)

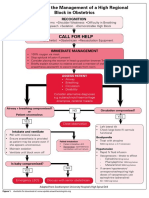

- Algorithm For The Management of A High Regional Block in ObstetricsDocument5 pagesAlgorithm For The Management of A High Regional Block in ObstetricsRaditya DidotNo ratings yet

- Confidence and Competence, Their Relationship and Impact On Workplace PerformanceDocument87 pagesConfidence and Competence, Their Relationship and Impact On Workplace PerformanceJules Savage-MilnerNo ratings yet

- Membrane Based SeparationDocument2 pagesMembrane Based SeparationRitika RawatNo ratings yet

- Pressure Conversion ChartDocument1 pagePressure Conversion Chartamarkore3486No ratings yet

- TPBNS19 (2) 1 - Xperan PRP Pada Nyeri OA Genu Review RD - v5.0Document13 pagesTPBNS19 (2) 1 - Xperan PRP Pada Nyeri OA Genu Review RD - v5.0sisil priscillaNo ratings yet

- Arctic WarmingDocument2 pagesArctic WarmingChâu Hồng AnhNo ratings yet

- Lecture 1 - Construction MaterialsDocument20 pagesLecture 1 - Construction MaterialspuskarNo ratings yet

- Roberts 2019Document8 pagesRoberts 2019MUHAMMAD ARDINo ratings yet

- Ipm Fruit Crops 23022015 PDFDocument92 pagesIpm Fruit Crops 23022015 PDFprudhvi_hyd100% (1)

- 09 em 002Document6 pages09 em 002Zelva ChileNo ratings yet

- RSO Service DirectoryDocument5 pagesRSO Service Directorydebbie_simNo ratings yet

- Case Ih Tractor 1070 Operators Manual 9 2822Document22 pagesCase Ih Tractor 1070 Operators Manual 9 2822zacharygonzalez130703jse100% (140)

- Chemistry InvestigatoryDocument15 pagesChemistry InvestigatoryTushar JaiswalNo ratings yet

- A&P Ch. 9 NotesDocument5 pagesA&P Ch. 9 Notesslefaveesu6orgNo ratings yet

- IS0125 F Fuel-ManagerDocument12 pagesIS0125 F Fuel-ManagerBilly12369No ratings yet

- Earth and Life Science: Quarter 2 - Module 9DDocument15 pagesEarth and Life Science: Quarter 2 - Module 9DJessaNo ratings yet

- This Set of Building Construction Multiple Choice QuestionsDocument5 pagesThis Set of Building Construction Multiple Choice QuestionspransuNo ratings yet

- Odd 3Document14 pagesOdd 3jeetguptaNo ratings yet

- 21 22 ĐỀ CƯƠNG ÔT 8 TUẦN HKI ANH 10 21 22Document12 pages21 22 ĐỀ CƯƠNG ÔT 8 TUẦN HKI ANH 10 21 22sangNo ratings yet

- File 274804260391Document22 pagesFile 274804260391Nemanja NikolicNo ratings yet

- What Is Risk ManagementDocument47 pagesWhat Is Risk ManagementSiddhardha Karanam100% (1)

AAMA Standards Comparison - Organic Coatings On Fiber Reinforced

AAMA Standards Comparison - Organic Coatings On Fiber Reinforced

Uploaded by

ThanhHaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AAMA Standards Comparison - Organic Coatings On Fiber Reinforced

AAMA Standards Comparison - Organic Coatings On Fiber Reinforced

Uploaded by

ThanhHaCopyright:

Available Formats

AAMA Standards Comparison - Organic Coatings on Fiber Reinforced

AAMA 623-10 AAMA 624-10 AAMA 625-10

Attribute (Basic Pigmented Coatings) (High Performance Coatings) (Superior Performance Coatings)

Minimum Initial Dry Film Thickness 20 microns (0.8 mil) 30 microns (1.2 mil); 25 microns (1.0 30 microns (1.2 mil); 25 microns (1.0

mil) topcoat if primer is used mil) topcoat if primer is used

Specular Gloss

Gloss values within + 5 units of manufacturer's specification

(per ASTM D523)

Outdoor Weathering Exposure Time 1 Year 5 years 10 years

(South Florida)

Alternate Accelarated Weathering (Exposure) NA 1450 MJ TURV (Arizona) (See 2900 MJ TURV (Arizona) (See

(EMMA w/ NTW) in lieu of Outdoor Weathering Section 6.13.1.1 of spec.) Section 6.13.1.1 of spec.)

in South Florida

Chalking Resistance 1 year: < 8 rating for colors and 5 years: < 8 rating for colors and 10 years: Chalk < 8 rating

(After Weather Exposure or EMMA) < 6 rating for whites per ASTM < 6 rating for whites per ASTM (per ASTM D4214)

D4214 D4214

Color Retention 1 year fade: delta E < 5 5 year fade: delta E < 5 10 year fade: delta E < 5

(After Exposure or EMMA)

Gloss Retention No Specification 5 years > 30% retention 10 years > 50% retention

(After Exposure or EMMA)

Erosion Resistance No Specification 5 years < 10% loss 10 years < 10% loss

(After Exposure or EMMA)

Direct Impact No film removal at initial test (not subject to weathering exposure)

Humidity Resistance (per ASTM D2247 or 1500 hr at 100OF & 100% humidity 3000 hr at 100OF & 100% humidity 4000 hr at 100OF & 100% humidity

D4585) - no visually apparent change and "few"

blisters < size 8 per ASTM D714)

Abrasion Resistance No Specification Volume of 40 L of sand or the Volume of 80 L of sand or the

(per ASTM D968) Abrasion Coefficient > 20 Abrasion Coefficient > 40

Chemical Resistance There shall be a minimum 90% gloss retention and a maximum color change of 5 ∆ E calculated in appearance

when examined by the unaided eye.accordance with ASTM D2244

Detergent Resistance There shall be a minimum 95% gloss retention and a maximum color change of 2 ∆ E calculated in appearance

when examined by the unaided eye.accordance with ASTM D2244

Window Cleaner Resistance No Specification There shall be a minimum 95% gloss retention and a maximum color

change of 2 ∆ E calculated in appearance when examined by the unaided

eye.accordance with ASTM D2244

Sealant Compatibility Sealant must meet AAMA 800 and have no effect on coating

Boiling Water Film Adhesion No Specification For thicknesses of 50 microns (2.0 mils) or less, no loss of adhesion after

20 minutes in 210°F - 212°F water

For thicknesses between 50 microns (2.0 mils) and 125 microns (5.0 mils),

no loss of adhesion after 20 minutes in 210°F - 212°F water

For coatings over 125 microns (5.0 mils), a minimum of five test pulls of six

valid test dollies shall exhibit substrate removal

Color Uniformity No Variation outside of limits established by range sample approval.

Dry Film Hardness No rupture when tested with "H" No rupture when tested with "F" hardness lead per ASTM D3363.

hardness lead per ASTM D3363.

Dry Film Adhesion For thicknesses of 50 microns (2.0 mils) or less, there shall be no removal of film under tape within or outside of

cross-hatched area or blistering anywhere on the test specimen.

For thicknesses between 50 microns (2.0 mils) and 125 microns (5.0 mils) and under, there shall be no removal

of film under tape within or outside of cross-hatched area or blistering anywhere on the test specimen.

For thicknesses over 125 microns (5.0 mils), any adhesive failure in the bond between the dolly and coating shall

not be in excessive of 50% of the dolly surface area. The bonded surface shall exhibit delamination of substrate

fiber, resin, fillers or a combination of component from the profile. Of the six pulls, a minimum of five shall exhibit

some evidence of substrate removal for passing the adhesion performance.

Wet Film Adhesion For thicknesses of 50 microns (2.0 mils) or less, there shall be no removal of film under tape within or outside of

cross-hatched area or blistering anywhere on the test specimen.

For thicknesses between 50 microns (2.0 mils) and 125 microns (5.0 mils) and under, there shall be no removal

of film under tape within or outside of cross-hatched area or blistering anywhere on the test specimen.

For coatings over 125 microns (5.0 mils), a minimum of five test pulls of six valid test dollies shall exhibit

substrate removal

Resistance to Cold Cracking 15 cycles of exposure to 100OF followed by exposure to -10OF, with no change in performance.

Oven Aging Verify hardness and adhesion after exposure to 140OF for 7 days and then 100% humidity for 4 days.

Reference Standards: Title

AAMA 623-10 Voluntary Specification, Performance Requirements and Test Procedures for Organic Coatings on Fiber Reinforced Thermoset Profiles

AAMA 624-10 Voluntary Specification, Performance Requirements and Test Procedures for High Performance Organic Coatings on Fiber Reinforced Thermoset Profiles

AAMA 625-10 Voluntary Specification, Performance Requirements and Test Procedures for Superior Performance Organic Coatings on Fiber Reinforced Thermoset Profiles

AAMA 800-10 Voluntary Specifications and Test Methods for Sealants

ASTM C207-06 Standard Specification for Hydrated Lime for Masonry Purposes

ASTM D523-08 Standard Test Method for Specular Gloss

ASTM D659-86 Standard Test Method for Evaluating Degree of Chalking of Exterior Paints

ASTM D714-02(2009) Standard Test Method for Evaluating Degree of Blistering of Paints

ASTM D968-05e1 Standard Test Methods for Abrasion Resistance of Organic Coatings by Falling Abrasive

ASTM D2244-09b Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates

ASTM D2247-10 Standard Practice for Testing Water Resistance of Coatings in 100% Relative Humidity

ASTM D2248-01a(2007) Standard Practice for Detergent Resistance of Organic Finishes

ASTM D3359-09e02 Standard Test Methods for Measuring Adhesion by Tape Test

ASTM D3363-05 Standard Test Method for Film Hardness by Pencil Test

ASTM D4138-07a Standard Test Methods for Measurement of Dry Film Thickness of Protective Coating Systems by Destructive, Cross-Sectioning Means

ASTM D4214-07 Standard Test Methods for Evaluating Degree of Chalking of Exterior Paint Films

ASTM D4541-09e1 Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers

ASTM D4585-07 Standard Practice for Testing the Water Resistance of Coatings Using Controlled Condensation

ASTM D5179-02(2008) Standard Test Method for Measuring Adhesion of Organic Coatings to Plastic Substrates by Direct Tensile Testing

ASTM D5796-02(2008) Standard Test Method for Measurement of Dry Film Thickness of Thin Film Coil-Coated Systems by Destructive Means Using a Boring Device

ASTM G90-10 Standard Practice for Performing Accelerated Outdoor Weathering of Nonmetallic Materials Using Concentrated Natural Sunlight

ASTM G179-04 Standard Specification for Metal Black Panel and White Panel Temperature Devices for Natural Weathering Tests

You might also like

- Implant ProsthodonticsDocument5 pagesImplant ProsthodonticsAmar BhochhibhoyaNo ratings yet

- Carboline Carboguard 890 PDSDocument2 pagesCarboline Carboguard 890 PDSSamNo ratings yet

- 10.feeder Analysis & ModelingDocument117 pages10.feeder Analysis & ModelingNamiraNo ratings yet

- 2603 2604 2605 - Comparisons - 4 6 11 PDFDocument1 page2603 2604 2605 - Comparisons - 4 6 11 PDFuocmogiandi_a100% (1)

- Wet Adhesion of Latex Paints To A Gloss Alkyd Enamel SubstrateDocument4 pagesWet Adhesion of Latex Paints To A Gloss Alkyd Enamel Substrateasma hamzaNo ratings yet

- CP 2Document1 pageCP 2shameer bashaNo ratings yet

- Cinta EnterradaDocument4 pagesCinta EnterradaDaniel Garces DavilaNo ratings yet

- Hempaflor Decorate 600Document2 pagesHempaflor Decorate 600Riian Apriansyah100% (1)

- 1016 - AAMA Finish CriteriaDocument8 pages1016 - AAMA Finish Criteriaw leungNo ratings yet

- SXD-1818 DotDocument2 pagesSXD-1818 Dotasem1102345No ratings yet

- Standard QA PropertiesDocument4 pagesStandard QA PropertiesBagas CahyadiNo ratings yet

- Steel Shield 1100Document3 pagesSteel Shield 1100Moin AltafNo ratings yet

- Karnak Technical Bulletin No. 7 ASTM D1227 Designation Change Technical Notes 432337Document3 pagesKarnak Technical Bulletin No. 7 ASTM D1227 Designation Change Technical Notes 432337Malak HindiNo ratings yet

- Bradybondz (TM) B-423 Thermal Transfer Printable Glossy White Polyester Label StockDocument4 pagesBradybondz (TM) B-423 Thermal Transfer Printable Glossy White Polyester Label StockDeep SharmaNo ratings yet

- Interthane 990 Test Data PDFDocument2 pagesInterthane 990 Test Data PDFImam Situmeang100% (2)

- HereShield TDSDocument5 pagesHereShield TDSMahdi BagheriNo ratings yet

- Acrypoly Cast Acrylic - Data SheetDocument3 pagesAcrypoly Cast Acrylic - Data SheetAbhijit BhavsarNo ratings yet

- General Properties Viscosity Aging: PVC Paste Resin (Homopolymer)Document2 pagesGeneral Properties Viscosity Aging: PVC Paste Resin (Homopolymer)AminulIslamNo ratings yet

- E Cera Ceramic Porcelain Test Methods GlossaryDocument1 pageE Cera Ceramic Porcelain Test Methods GlossaryHasmukh KoringaNo ratings yet

- Intergard 251HS - Test DataDocument1 pageIntergard 251HS - Test DataImam Situmeang100% (1)

- Bopp TapeDocument2 pagesBopp TapeJayant Kumar Jha100% (1)

- Seal N Flex 1: Technical Data SheetDocument2 pagesSeal N Flex 1: Technical Data SheetNorman JohannisNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- General Properties Rheological Properties: PVC Paste Resin (Homopolymer)Document2 pagesGeneral Properties Rheological Properties: PVC Paste Resin (Homopolymer)AminulIslamNo ratings yet

- Product Data Sheet: Akzonobel Powder CoatingsDocument3 pagesProduct Data Sheet: Akzonobel Powder CoatingsFerhat ÖzcanNo ratings yet

- Amercoat 450HDocument2 pagesAmercoat 450HJairo ArroyoNo ratings yet

- Dekguard E2000: Constructive SolutionsDocument4 pagesDekguard E2000: Constructive SolutionsSyed HassaanNo ratings yet

- Ceramic Porcelain Test Methods GlossaryDocument1 pageCeramic Porcelain Test Methods GlossaryHsaam HsaamNo ratings yet

- FASARA Tech Data SheetDocument12 pagesFASARA Tech Data Sheetvlade naumovskiNo ratings yet

- Masterseal hlm5000r TdsDocument3 pagesMasterseal hlm5000r TdsHabib ArifnurNo ratings yet

- Proofex SMDocument4 pagesProofex SMSantosh SharmaNo ratings yet

- Dekguard E2000Document4 pagesDekguard E2000Muhammad UsmanNo ratings yet

- Masterseal HLM 5000 R: Liquid Cold-Applied Waterproofing Membrane SystemDocument2 pagesMasterseal HLM 5000 R: Liquid Cold-Applied Waterproofing Membrane SystemLemark R.No ratings yet

- Data Teknis Alcoflux KoreaDocument40 pagesData Teknis Alcoflux KoreaDebby saputraNo ratings yet

- Pds Zincanode 620 VocDocument2 pagesPds Zincanode 620 VocmuthukumarNo ratings yet

- Carboguard 890 GF PDSDocument2 pagesCarboguard 890 GF PDSfazeel mohammedNo ratings yet

- X-Seal PU25 +joint CordDocument52 pagesX-Seal PU25 +joint CordMohamed ElshabrawyNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Waterproofing & Damp Proofing Item DescriptionDocument2 pagesWaterproofing & Damp Proofing Item DescriptionKhin Sandi KoNo ratings yet

- X-Seal PU25Document2 pagesX-Seal PU25JoeNo ratings yet

- Fosroc Dekguard E2000: (Also Known As Nitocote FBC)Document4 pagesFosroc Dekguard E2000: (Also Known As Nitocote FBC)Tejinder KumarNo ratings yet

- X-Tech CrystalClear 3Document2 pagesX-Tech CrystalClear 3EGO AnimationNo ratings yet

- Dekguard E2000Document4 pagesDekguard E2000m.elsanee.cubicNo ratings yet

- Chapter 3 Roof EN 1corrDocument21 pagesChapter 3 Roof EN 1corrMPBGDNo ratings yet

- QL3009 Aq21Document4 pagesQL3009 Aq21Andrew LeeNo ratings yet

- Bitumastic 50: Selection & Specification DataDocument4 pagesBitumastic 50: Selection & Specification DataLuna LunaNo ratings yet

- ZA TDS Interpon D1025 GlossDocument2 pagesZA TDS Interpon D1025 Glossahmed hargaNo ratings yet

- Interthane 990: Long Term Recoatability With AestheticsDocument2 pagesInterthane 990: Long Term Recoatability With Aestheticssatheez3251No ratings yet

- Particle Board and MDFDocument26 pagesParticle Board and MDFjosefNo ratings yet

- 3M VHB Window Tape G45Document2 pages3M VHB Window Tape G45philipNo ratings yet

- Low Odor / Low VOC Acrylic Vinyl Copolymer Emulsion Putty Filler, Nr. 15035Document3 pagesLow Odor / Low VOC Acrylic Vinyl Copolymer Emulsion Putty Filler, Nr. 15035Mostafa Hussein AbdouNo ratings yet

- EU - TDS - Interpon D2525 STF TextureDocument3 pagesEU - TDS - Interpon D2525 STF TextureWilson ThomasNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- TDS Dekguard E2000 India3Document4 pagesTDS Dekguard E2000 India3Er Krishan YadavNo ratings yet

- Black Ced: Shri EkviraDocument10 pagesBlack Ced: Shri Ekviraaditya dixitNo ratings yet

- Dovetail Sherwin Williams PaintDocument2 pagesDovetail Sherwin Williams PaintDan SmithNo ratings yet

- 3M™ All Weather Thermoplastic: 1 DescriptionDocument6 pages3M™ All Weather Thermoplastic: 1 DescriptionAddin DinNo ratings yet

- Denso Glass Outerwrap TDSDocument3 pagesDenso Glass Outerwrap TDSIwan AgusNo ratings yet

- 3M™ Scotch-Weld™ Structural AdhesivesDocument10 pages3M™ Scotch-Weld™ Structural AdhesivesDan AyalaNo ratings yet

- 7-1883 TDS Grey Liquid EpoxyDocument2 pages7-1883 TDS Grey Liquid EpoxyPedro Santo Orsini RevengaNo ratings yet

- 2021 - 2022 Sharks Friendly Questions For GCIHS JHS Vrs DPS JHS IIDocument5 pages2021 - 2022 Sharks Friendly Questions For GCIHS JHS Vrs DPS JHS IIFelix AyornuNo ratings yet

- Natural Ice - CreamDocument13 pagesNatural Ice - CreamPalak MehtaNo ratings yet

- DGSM Cir WRT MMRDocument72 pagesDGSM Cir WRT MMRUttam SharmaNo ratings yet

- Space Closing Mechanics - DIFFERENT LOOPSDocument147 pagesSpace Closing Mechanics - DIFFERENT LOOPSdrarjunvedvyas100% (18)

- 1104A-44TG2 ElectropaK PN1784Document2 pages1104A-44TG2 ElectropaK PN1784NedhoNerimo TroyaNo ratings yet

- Climate Action Incentive Payment Notice 2022 06 25 09 46 45 07823 PDFDocument3 pagesClimate Action Incentive Payment Notice 2022 06 25 09 46 45 07823 PDFalex mac dougallNo ratings yet

- Battery ChargerDocument24 pagesBattery ChargerPhang Kumwing100% (1)

- Algorithm For The Management of A High Regional Block in ObstetricsDocument5 pagesAlgorithm For The Management of A High Regional Block in ObstetricsRaditya DidotNo ratings yet

- Confidence and Competence, Their Relationship and Impact On Workplace PerformanceDocument87 pagesConfidence and Competence, Their Relationship and Impact On Workplace PerformanceJules Savage-MilnerNo ratings yet

- Membrane Based SeparationDocument2 pagesMembrane Based SeparationRitika RawatNo ratings yet

- Pressure Conversion ChartDocument1 pagePressure Conversion Chartamarkore3486No ratings yet

- TPBNS19 (2) 1 - Xperan PRP Pada Nyeri OA Genu Review RD - v5.0Document13 pagesTPBNS19 (2) 1 - Xperan PRP Pada Nyeri OA Genu Review RD - v5.0sisil priscillaNo ratings yet

- Arctic WarmingDocument2 pagesArctic WarmingChâu Hồng AnhNo ratings yet

- Lecture 1 - Construction MaterialsDocument20 pagesLecture 1 - Construction MaterialspuskarNo ratings yet

- Roberts 2019Document8 pagesRoberts 2019MUHAMMAD ARDINo ratings yet

- Ipm Fruit Crops 23022015 PDFDocument92 pagesIpm Fruit Crops 23022015 PDFprudhvi_hyd100% (1)

- 09 em 002Document6 pages09 em 002Zelva ChileNo ratings yet

- RSO Service DirectoryDocument5 pagesRSO Service Directorydebbie_simNo ratings yet

- Case Ih Tractor 1070 Operators Manual 9 2822Document22 pagesCase Ih Tractor 1070 Operators Manual 9 2822zacharygonzalez130703jse100% (140)

- Chemistry InvestigatoryDocument15 pagesChemistry InvestigatoryTushar JaiswalNo ratings yet

- A&P Ch. 9 NotesDocument5 pagesA&P Ch. 9 Notesslefaveesu6orgNo ratings yet

- IS0125 F Fuel-ManagerDocument12 pagesIS0125 F Fuel-ManagerBilly12369No ratings yet

- Earth and Life Science: Quarter 2 - Module 9DDocument15 pagesEarth and Life Science: Quarter 2 - Module 9DJessaNo ratings yet

- This Set of Building Construction Multiple Choice QuestionsDocument5 pagesThis Set of Building Construction Multiple Choice QuestionspransuNo ratings yet

- Odd 3Document14 pagesOdd 3jeetguptaNo ratings yet

- 21 22 ĐỀ CƯƠNG ÔT 8 TUẦN HKI ANH 10 21 22Document12 pages21 22 ĐỀ CƯƠNG ÔT 8 TUẦN HKI ANH 10 21 22sangNo ratings yet

- File 274804260391Document22 pagesFile 274804260391Nemanja NikolicNo ratings yet

- What Is Risk ManagementDocument47 pagesWhat Is Risk ManagementSiddhardha Karanam100% (1)