Professional Documents

Culture Documents

Timken Crossed Roller Precision Bearing Sell Sheet - 5494

Timken Crossed Roller Precision Bearing Sell Sheet - 5494

Uploaded by

kiranmittisilaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Timken Crossed Roller Precision Bearing Sell Sheet - 5494

Timken Crossed Roller Precision Bearing Sell Sheet - 5494

Uploaded by

kiranmittisilaCopyright:

Available Formats

Crossed

Roller Precision

Bearings

Designed to offer the highest levels

of rotation accuracy and rigidity while

conserving space and saving material costs.

Applications This bearing features two sets of

races and rollers brought together

Precision rotary and indexing at right angles – with alternate rollers

tables for machine tools facing opposite directions.

To save space and require less

Vertical and horizontal boring mills

housing material, the bearing’s cross

Vertical grinding machines section height barely exceeds that of

Rotary surface grinding machines a single-row bearing. Its steep-angle,

tapered geometry results in a total

Large gear hobbing machines

effective bearing spread many

Turrets – gun and radar times greater than the width

grinding machines. It also is uniquely

Large telescopes (radio and optical) of the bearing itself.

suited to many other pivot and pedestal

Swiveling cameras Able to withstand high overturning applications where space is limited and

moments, the crossed roller bearing is the lowest possible center of gravity of

Steering pivots and castors

ideal for the table bearing of machine a rotating mass is required.

Pivots where height is restricted tools, including vertical boring and

Microscope tables

Crane center pivots

Features Benefits

• Less housing material

Swiveling bogies • Two rows of rollers in the space of one

• Machining requirements reduced

• Cross section occupies little space

• Reduced cost

Welding manipulators • Maximum accuracy of rotation

• Roller configuration gives wide effective spread

• High stability

Large tanker mooring buoys • Line contact on roller and raceway

• Greater tilting stiffness

• Longer expected bearing life

Rotary assembly jigs • Adjustable design for optimum preload • Maximum rigidity

• Minimum runout

Industrial robots

• Relubrication ability – lubricant, fed between the

• Allows lubricants and contaminants to be purged

single races, may pass out at each side of the bearing

• Low inertia

• Nylon separators

• Low running torque

• Provides tough, shock-resistant core and hard,

• Case-hardened steel

wear-resistant surfaces

Schematic showing the principle of the

crossed roller bearing, where two sets

Effective spread

of rollers are at right angles to each

other (alternate rollers facing opposite

directions) within a section height ‘T’. T

Total effective bearing spread and,

hence, stability of the bearing is much

Type TXRDO greater than the actual section height ‘T’.

Dimensions and Ratings

04-14: 29 Order No. 5494 | Timken is a registered trademark of The Timken Company. | © 2014 The Timken Company | Printed in U.S.A.

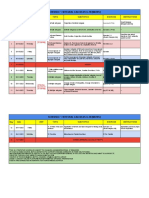

Crossed Roller Bearing Type TXRDO(1)

(Double Outer Race – Two Inner Races)

Metric Precision Levels S, P

D d T R Load Ratings (2) Part

K (4) Preload (5)

O.D. Bore Width Radius Radial (3) Axial Number

mm mm mm mm kN kN mm

in. in. in. in. lbs. lbs. in.

400.000 300.000 37.000 1.5 63.0 80.1 0.45 0.025 to 0.040 JXR637050

15.748 11.8110 1.4567 0.06 14200 18000 0.001 to 0.0015

425.000 310.000 45.000 2.5 82.2 102.0 0.46 0.025 to 0.040 JXR652050

16.7323 12.2047 1.7717 0.10 18500 22900 0.001 to 0.0015

495.000 370.000 50.000 3.0 93.6 119.0 0.45 0.040 to 0.050 JXR699050

19.4882 14.5669 1.9685 0.12 21000 26800 0.0015 to 0.002

Inch Precision Levels 3, 0

Type TXRDO

D d T R Load Ratings (2) Part

K (4) Preload (5)

O.D. Bore Width Radius Radial (3) Axial Number

The bearing’s most common mm mm mm mm kN kN mm

in. in. in. in. lbs. lbs. in.

®

configuration is type TXRDO,

279.400 203.200 31.750 1.5 51.2 61.4 0.48 0.025 to 0.040 XR496051

featuring a double outer race and 11.0000 8.0000 1.2500 0.06 11500 13800 0.001 to 0.0015

two inner rings, with rollers spaced 457.200 330.200 63.500 3.3 100.0 123.0 0.47 0.040 to 0.050 XR678052

by nylon separators. Other 18.0000 13.0000 2.5000 0.13 22500 27600 0.0015 to 0.002

configurations to fit specific 609.600 457.200 63.500 3.3 141.0 178.0 0.45 0.040 to 0.050 XR766051

24.0000 18.0000 2.5000 0.13 31600 40100 0.0015 to 0.002

application needs are available.

760.000 580.000 80.000 6.4 215.0 234.0 0.46 0.075 to 0.100 XR820060

We will be happy to suggest a 29.9213 22.8346 3.1500 0.25 48400 52500 0.003 to 0.004

configuration for your environment 914.400 685.800 79.375 3.3 270.0 343.0 0.45 0.075 to 0.100 XR855053

and application. 36.0000 27.0000 3.1250 0.13 60700 77200 0.003 to 0.004

1117.600 901.700 82.550 3.3 300.0 395.0 0.44 0.100 to 0.150 XR882055

Timken crossed roller bearings are 44.0000 35.5000 3.2500 0.13 67400 88900 0.004 to 0.006

available in bore sizes ranging from 1327.150 1028.700 114.300 3.3 405.0 534.0 0.44 0.125 to 0.180 XR889058

203.2 mm to 1549.4 mm (8 in. to 61 52.2500 40.5000 4.5000 0.13 91000 120000 0.005 to 0.007

in.), with radial and axial runouts as 1828.800 1549.400 101.600 3.3 516.0 698.0 0.43 0.150 to 0.200 XR897051

72.0000 61.0000 4.0000 0.13 116000 157000 0.006 to 0.008

low as 5.08 μm (0.0002 in.); other

design configurations are available. (1)

ot all types and sizes are listed. Other design

N D

configurations are available. Contact your Timken d

representative for further information. R R

(2)

L oad calculations based on 500 RPM for 3000 hours.

(3)

Two-row radial load rating shown.

LET US HELP

For more information, please

(4)

K-factor is a ratio of radial load rating to axial load

rating – see Engineering Section of Machine Tool

Catalog for usage.

T

(5)

P reload set by adjustments to top inner ring clamping

consult an authorized Timken spacer plate. Value ranges listed apply to typical

lower speed applications. Other preload values may R R

distributor or sales representative, be appropriate, and are available on request. Contact

or visit www.timken.com. your Timken representative.

The Timken team applies their know-how to improve the reliability and performance of machinery in diverse www.timken.com

markets worldwide. The company designs, makes and markets high-performance mechanical components,

including bearings, gears, chain and related mechanical power transmission products and services.

Stronger. Commitment. Stronger. Value. Stronger. Worldwide. Stronger. By Design.

You might also like

- Periodic Table Practice TestDocument4 pagesPeriodic Table Practice TestKattia MartinezNo ratings yet

- Force Diagrams & Statics: Free Particle Model Worksheet 4Document7 pagesForce Diagrams & Statics: Free Particle Model Worksheet 4api-292718088No ratings yet

- Course Drive Train Works Wears Heavy Equipment Caterpillar PDFDocument114 pagesCourse Drive Train Works Wears Heavy Equipment Caterpillar PDFBruno Cecatto93% (29)

- Engineering Design (Marine Engineering)Document7 pagesEngineering Design (Marine Engineering)Abdul MalikNo ratings yet

- Heavy Duty Ball Screw Linear ActuatorsDocument12 pagesHeavy Duty Ball Screw Linear ActuatorsFernando NinoNo ratings yet

- RBC DTJDocument2 pagesRBC DTJVendro MunajadNo ratings yet

- BearingsDocument48 pagesBearingsInaam Ur RehmanNo ratings yet

- Scheerer Gearbox 4-MinDocument4 pagesScheerer Gearbox 4-MinChristian OvalleNo ratings yet

- 5) Bearing Fundamentals PDFDocument123 pages5) Bearing Fundamentals PDFRizal Gunawan100% (1)

- Aerzen Airgas GM 150 SDocument4 pagesAerzen Airgas GM 150 SMMauricio GaticaNo ratings yet

- Edrive Eliminator HD BrochureDocument12 pagesEdrive Eliminator HD BrochureminakirolosNo ratings yet

- RB Flexible Coupling: The Standard Range ComprisesDocument12 pagesRB Flexible Coupling: The Standard Range ComprisesMoamenNo ratings yet

- NBC Cement BrochureDocument23 pagesNBC Cement BrochureAnkit SharmaNo ratings yet

- CATALOGO-Bombas WarrenDocument4 pagesCATALOGO-Bombas Warrenjlrllfn81No ratings yet

- Jaw Crusher ThyssenkruppDocument12 pagesJaw Crusher ThyssenkrupplucasmaltaNo ratings yet

- IndexerDocument40 pagesIndexerAnonymous 9q5GEfm8INo ratings yet

- Cobra Solid Lubricants BrochureDocument4 pagesCobra Solid Lubricants Brochureernesto anwart ruiz laraNo ratings yet

- Why SKF - CARB Toroidal Roller Bearings - 06550 - 2 EN PDFDocument2 pagesWhy SKF - CARB Toroidal Roller Bearings - 06550 - 2 EN PDFBanksyNo ratings yet

- Chaubey-Jain2017 Article InvestigationsOnMicrogeometryODocument15 pagesChaubey-Jain2017 Article InvestigationsOnMicrogeometryOranim najibNo ratings yet

- HT Bulletin 711Document10 pagesHT Bulletin 711saulomonNo ratings yet

- Flexiroc T35: Surface Drill Rig For Quarrying and ConstructionDocument5 pagesFlexiroc T35: Surface Drill Rig For Quarrying and ConstructionNanhoua YeoNo ratings yet

- Prochem Bulletin 720 WEB 6 PDFDocument10 pagesProchem Bulletin 720 WEB 6 PDFmember1000No ratings yet

- SV Series CatalogoDocument8 pagesSV Series CatalogoEuler Vilca CarhuanchoNo ratings yet

- 16 SB115CDocument1 page16 SB115CAdnane BensmaineNo ratings yet

- Renk MaagDocument12 pagesRenk MaagDhananjay B KNo ratings yet

- Mobley 2001Document8 pagesMobley 2001Harikumar ANo ratings yet

- Everything You Need To Keep On RollingDocument8 pagesEverything You Need To Keep On RollingAlexander GoezNo ratings yet

- ERIEZ Limpiador Magnético de RefrigeranteDocument12 pagesERIEZ Limpiador Magnético de RefrigeranteangelsiddhartaNo ratings yet

- Lj-Ts Series Horizontal ScreensDocument8 pagesLj-Ts Series Horizontal ScreensLuis Vallecillo100% (1)

- Series Q Ball Bearing, Swivel Castors SGD With Plate Fitting - 2400925Document2 pagesSeries Q Ball Bearing, Swivel Castors SGD With Plate Fitting - 2400925duc minhNo ratings yet

- 1238 Jaw Crusher PDFDocument12 pages1238 Jaw Crusher PDFRasoolKhadibiNo ratings yet

- Kinshofer Rotator Line Product FeaturesDocument5 pagesKinshofer Rotator Line Product FeaturesHOryshorNo ratings yet

- Wire Race Bearings As Roller Bearings: Light Bearings For InnovationDocument8 pagesWire Race Bearings As Roller Bearings: Light Bearings For Innovationkizzie1No ratings yet

- 13-Double-Row Spherical Roller Bearing PDFDocument43 pages13-Double-Row Spherical Roller Bearing PDFAmanNo ratings yet

- ENG-MKT41 - Roller Cone Drill Bit Brochure - Distribution FileDocument8 pagesENG-MKT41 - Roller Cone Drill Bit Brochure - Distribution FileMarianNo ratings yet

- Zero-Max CD Couplings A4Document20 pagesZero-Max CD Couplings A4ataraxia57No ratings yet

- RKB - ROVSX - For - Vibrating - Machinery - WebDocument17 pagesRKB - ROVSX - For - Vibrating - Machinery - WebCristian OrtizNo ratings yet

- RENK MAAG Turbo GearboxesDocument12 pagesRENK MAAG Turbo Gearboxeshumayun121100% (1)

- REV0 - VER0 - Catálogo Bomba LCC-MDocument8 pagesREV0 - VER0 - Catálogo Bomba LCC-MalanfbventuraNo ratings yet

- Kymera XTreme Hybrid Drill BitDocument2 pagesKymera XTreme Hybrid Drill BitclaudiaNo ratings yet

- SDB 206 2 Small Diameter Beveler DatasheetDocument2 pagesSDB 206 2 Small Diameter Beveler DatasheetTulioLopezJNo ratings yet

- Rotary Deck Bushing: Balls Make The Difference... Increased Drilling Production Proves ItDocument2 pagesRotary Deck Bushing: Balls Make The Difference... Increased Drilling Production Proves ItFedericoButronNo ratings yet

- SKF Spherical Roller Bearings For Wind Turbine Main ShaftsDocument5 pagesSKF Spherical Roller Bearings For Wind Turbine Main ShaftsDaniel FuhrNo ratings yet

- Drive Train Parts QualityDocument67 pagesDrive Train Parts QualityAnonymous Dq7m7Hq7ar100% (4)

- 6 3 p0016 0044 Rotary - en PDFDocument29 pages6 3 p0016 0044 Rotary - en PDFmok waneNo ratings yet

- FR Series: Specification SheetDocument3 pagesFR Series: Specification SheetandrymartNo ratings yet

- Cyclo6000-001 BROCHUREDocument4 pagesCyclo6000-001 BROCHUREestebanNo ratings yet

- 0511 Grob PDFDocument7 pages0511 Grob PDFJ VeluNo ratings yet

- Gear& Gear Trains PDFDocument55 pagesGear& Gear Trains PDFSumit SumanNo ratings yet

- Session12 PDFDocument8 pagesSession12 PDFStar SealNo ratings yet

- FlexiRoc T35 EpirocDocument5 pagesFlexiRoc T35 EpirocDaniel Páez100% (2)

- Ball Bearing Design Classes 2021Document75 pagesBall Bearing Design Classes 2021Apurba barmanNo ratings yet

- Crossed Roller BearingsDocument4 pagesCrossed Roller BearingsAvijitSinharoyNo ratings yet

- 014 - 030 Single Reduction Worm IntroductionDocument17 pages014 - 030 Single Reduction Worm IntroductionAlejandro MartinezNo ratings yet

- Myonic Spindle Presentation - 2019 (Public)Document7 pagesMyonic Spindle Presentation - 2019 (Public)hvurur99No ratings yet

- Reversible Impactors: When Versatility, Reliability, and Long Service Life Matter!Document2 pagesReversible Impactors: When Versatility, Reliability, and Long Service Life Matter!Dwi ApNo ratings yet

- Planetary Roller Screws: Linear Solutions Made EasyDocument8 pagesPlanetary Roller Screws: Linear Solutions Made Easyshiva dNo ratings yet

- Vertical and Horizontal Turning/Grinding CentersDocument18 pagesVertical and Horizontal Turning/Grinding CentersArchi DamosNo ratings yet

- Trajan 20 MST1Document1 pageTrajan 20 MST1Bonnelly Peralta AlmanzarNo ratings yet

- Thyssenkrupp - Jaw Crusher PDFDocument7 pagesThyssenkrupp - Jaw Crusher PDFFernando MilmanNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- 10 Best Questions To Ask in An Interview 2021Document12 pages10 Best Questions To Ask in An Interview 2021kiranmittisilaNo ratings yet

- The SKF Model For Calculating The Frictional Moment: Diagram 1 Shows How Friction Changes, As ADocument15 pagesThe SKF Model For Calculating The Frictional Moment: Diagram 1 Shows How Friction Changes, As AkiranmittisilaNo ratings yet

- Lubricant Evaluation For Bearing Operation in Rotating Electric MachinesDocument9 pagesLubricant Evaluation For Bearing Operation in Rotating Electric MachineskiranmittisilaNo ratings yet

- IJTC2008-71305: Hydraulic Fluid Viscosity Selection For Improved Fuel EconomyDocument3 pagesIJTC2008-71305: Hydraulic Fluid Viscosity Selection For Improved Fuel EconomykiranmittisilaNo ratings yet

- Insight Services 1Document50 pagesInsight Services 1kiranmittisilaNo ratings yet

- Validation of Combined Analytical Methods To Predict Slip in Cylindrical Rollwe BearingsDocument34 pagesValidation of Combined Analytical Methods To Predict Slip in Cylindrical Rollwe BearingskiranmittisilaNo ratings yet

- An Analytical Model of Rolling Bearing System For Outer Race Fault PredictionDocument4 pagesAn Analytical Model of Rolling Bearing System For Outer Race Fault PredictionkiranmittisilaNo ratings yet

- Cylindrical Roller Bearings Robust SeriesDocument1 pageCylindrical Roller Bearings Robust SerieskiranmittisilaNo ratings yet

- Investigation of Roller Sliding in Wind Turbine Gearbox High-Speed-Shaft BearingsDocument28 pagesInvestigation of Roller Sliding in Wind Turbine Gearbox High-Speed-Shaft BearingskiranmittisilaNo ratings yet

- Cylindrical Roller Bearings Crane SheavesDocument1 pageCylindrical Roller Bearings Crane SheaveskiranmittisilaNo ratings yet

- Cylindrical Roller Bearings Ew SeriesDocument1 pageCylindrical Roller Bearings Ew SerieskiranmittisilaNo ratings yet

- Research On Crowning Profile To Obtain Maximum Load Carrying Capacity For Roller BearingsDocument6 pagesResearch On Crowning Profile To Obtain Maximum Load Carrying Capacity For Roller BearingskiranmittisilaNo ratings yet

- Paratie Plus - IntroDocument38 pagesParatie Plus - IntroManuel MoyaNo ratings yet

- EM Fields Lecture SlidesDocument89 pagesEM Fields Lecture SlidesDominic LadesmaNo ratings yet

- Manual de Instalacion Sonda de PH Redox EmecDocument10 pagesManual de Instalacion Sonda de PH Redox EmecRobinson JimenezNo ratings yet

- Homework #3Document3 pagesHomework #3Deniz GüneşNo ratings yet

- Dynacoll 7381: Chemical CompositionDocument2 pagesDynacoll 7381: Chemical CompositionWSERNo ratings yet

- Out of Plane Vibration Mitigation of Wind Turbine Rotor Blades Using Nonlinear Energy SinkDocument15 pagesOut of Plane Vibration Mitigation of Wind Turbine Rotor Blades Using Nonlinear Energy SinkMarcus Girão de MoraisNo ratings yet

- Barandes On Magnetic Forces and WorkDocument7 pagesBarandes On Magnetic Forces and Workdavid zilbermanNo ratings yet

- Trigonometry: 1. 11. The ExpressionDocument8 pagesTrigonometry: 1. 11. The ExpressionRakesh KumarNo ratings yet

- Kraft PaperDocument2 pagesKraft PaperEko SusantoNo ratings yet

- Playlist and Session Links - CA-F Maths - Pranav PopatDocument8 pagesPlaylist and Session Links - CA-F Maths - Pranav Popatshreya shettyNo ratings yet

- Integral Cal Schedule G-20Document2 pagesIntegral Cal Schedule G-20Sourav SharmaNo ratings yet

- Pearson Edexcel Exam Timetable June 2021 Bangladesh FinalDocument5 pagesPearson Edexcel Exam Timetable June 2021 Bangladesh FinalAsma YasinNo ratings yet

- Probability Virtual Review (November 2020)Document3 pagesProbability Virtual Review (November 2020)jlNo ratings yet

- Development of Indigenous Cobalt Based Industrial Gamma Radiography Exposure Device (COCAM-120)Document1 pageDevelopment of Indigenous Cobalt Based Industrial Gamma Radiography Exposure Device (COCAM-120)Mukhar SharmaNo ratings yet

- MZ3111Document27 pagesMZ3111writersleedNo ratings yet

- Construction and WindingDocument19 pagesConstruction and WindingBT21EE017 Gulshan RajNo ratings yet

- Incoming SR Cbse Super Chaina Set-B Iit Schedule - 03-03-2023Document141 pagesIncoming SR Cbse Super Chaina Set-B Iit Schedule - 03-03-2023Satvik PadiyalaNo ratings yet

- Goodman - Service Instructions RT6100004r13 May 2009Document69 pagesGoodman - Service Instructions RT6100004r13 May 20094iscribd100% (1)

- Review:: What Is M ? What Is M ? What Is M ?Document50 pagesReview:: What Is M ? What Is M ? What Is M ?Jinky OstanNo ratings yet

- Lec 2 Theories of Failure (Dr. M.M.abdelkader)Document13 pagesLec 2 Theories of Failure (Dr. M.M.abdelkader)Ahmed AlyNo ratings yet

- The Electronic Structures of Homonuclear Diatomic MoleculesDocument12 pagesThe Electronic Structures of Homonuclear Diatomic MoleculesCameliatus SyarifahNo ratings yet

- Lecture Pt. 3Document39 pagesLecture Pt. 3zy- SBGNo ratings yet

- ACI-349.2R-97 Embedment Design Examples PDFDocument26 pagesACI-349.2R-97 Embedment Design Examples PDFAnonymous IwqK1NlNo ratings yet

- Valean Ci More Almost Impossible Integrals Sums and Series ADocument847 pagesValean Ci More Almost Impossible Integrals Sums and Series AStrahinja DonicNo ratings yet

- M-3 MCQ Mock Test - 1: Ws Ica Manoj Chaudhari'S A World of Maths Maths. AcademyDocument7 pagesM-3 MCQ Mock Test - 1: Ws Ica Manoj Chaudhari'S A World of Maths Maths. AcademySameer BhuvajiNo ratings yet

- Performance Climate Changer Product ReportDocument16 pagesPerformance Climate Changer Product ReportRicardo GutierrezNo ratings yet

- Rate Ratio ProportionDocument31 pagesRate Ratio ProportionPabora KennethNo ratings yet

- Soil Details-1Document29 pagesSoil Details-1jibeesh cmNo ratings yet