Professional Documents

Culture Documents

Features: 1Mb Serial SPI MRAM

Features: 1Mb Serial SPI MRAM

Uploaded by

supOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Features: 1Mb Serial SPI MRAM

Features: 1Mb Serial SPI MRAM

Uploaded by

supCopyright:

Available Formats

MR25H10

FEATURES 1Mb Serial SPI MRAM

• No write delays

• Unlimited write endurance

• Data retention greater than 20 years

• Automatic data protection on power loss

• Block write protection

• Fast, simple SPI interface with up to 40 MHz clock rate

• 2.7 to 3.6 Volt power supply range

DFN

• Low current sleep mode

• Industrial temperatures

• Available in 8-pin DFN or 8-pin DFN Small Flag RoHS-compliant

packages

• Direct replacement for serial EEPROM, Flash, FeRAM

• AEC-Q100 Grade 1 Option Small Flag DFN

INTRODUCTION

The MR25H10 is a 1,048,576-bit magnetoresistive random access memory

(MRAM) device organized as 131,072 words of 8 bits. The MR25H10 offers serial RoHS

EEPROM and serial Flash compatible read/write timing with no write delays and

unlimited read/write endurance.

Unlike other serial memories, both reads and writes can occur randomly in memory with no delay between

writes. The MR25H10 is the ideal memory solution for applications that must store and retrieve data and

programs quickly using a small number of I/O pins.

The MR25H10 is available in either a 5 mm x 6 mm 8-pin DFN package or a 5 mm x 6 mm 8-pin DFN Small

Flag package. Both are compatible with serial EEPROM, Flash, and FeRAM products.

The MR25H10 provides highly reliable data storage over a wide range of temperatures. The product is

offered with Industrial (-40° to +85 °C) and AEC-Q100 Grade 1 (-40°C to +125 °C) operating temperature

range options.

CONTENTS

1. DEVICE PIN ASSIGNMENT......................................................................... 2

2. SPI COMMUNICATIONS PROTOCOL...................................................... 4

3. ELECTRICAL SPECIFICATIONS................................................................. 10

4. TIMING SPECIFICATIONS.......................................................................... 12

5. ORDERING INFORMATION....................................................................... 12

6. MECHANICAL DRAWING.......................................................................... 13

7. REVISION HISTORY...................................................................................... 15

How to Reach Us.......................................................................................... 15

Copyright © Everspin Technologies 2018 1 MR25H10 Rev. 9.5 3/2018

MR25H10

1. DEVICE PIN ASSIGNMENT

Overview

The MR25H10 is a serial MRAM with memory array logically organized as 128Kx8 using the four pin in-

terface of chip select (CS), serial input (SI), serial output (SO) and serial clock (SCK) of the serial peripheral

interface (SPI) bus. Serial MRAM implements a subset of commands common to today’s SPI EEPROM and

Flash components allowing MRAM to replace these components in the same socket and interoperate on

a shared SPI bus. Serial MRAM offers superior write speed, unlimited endurance, low standby & operating

power, and more reliable data retention compared to available serial memory alternatives.

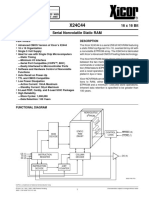

Figure 1.1 Block Diagram

WP Instruction Decode

CS Clock Generator

HOLD Control Logic

SCK Write Protect

128KB

MRAM ARRAY

Instruction Register

Address Register 17 8

Counter

SO

SI Data I/O Register

Nonvolatile Status

Register

System Configuration

Single or multiple devices can be connected to the bus as shown in Figure 1.2. Pins SCK, SO and SI are

common among devices. Each device requires CS and HOLD pins to be driven separately.

Figure 1.2 System Configuration

SCK

MOSI

MISO

SO SI SCK SO SI SCK

SPI EVERSPIN SPI MRAM 1 EVERSPIN SPI MRAM 2

Micro Controller

CS HOLD CS HOLD

CS1

HOLD 1

CS2

HOLD 2

MOSI = Master Out Slave In

MISO = Master In Slave Out

Copyright © Everspin Technologies 2018 2 MR25H10 Rev. 9.5 3/2018

MR25H10

DEVICE PIN ASSIGNMENT

Figure 1.3 Pin Diagrams (Top View)

CS 1 8 VDD

SO 2 7 HOLD

WP 3 6 SCK

VSS 4 5 SI

8-Pin DFN or 8-Pin DFN Small Flag Package

Table 1.1 Pin Functions

Signal Name Pin I/O Function Description

An active low chip select for the serial MRAM. When chip select is high, the

memory is powered down to minimize standby power, inputs are ignored

CS 1 Input Chip Select

and the serial output pin is Hi-Z. Multiple serial memories can share a com-

mon set of data pins by using a unique chip select for each memory.

The data output pin is driven during a read operation and remains Hi-Z at

SO 2 Output Serial Output all other times. SO is Hi-Z when HOLD is low. Data transitions on the data

output occur on the falling edge of SCK.

A low on the write protect input prevents write operations to the Status

WP 3 Input Hold

Register.

VSS 4 Supply Ground Power supply ground pin.

All data is input to the device through this pin. This pin is sampled on the

SI 5 Input Serial Input rising edge of SCK and ignored at other times. SI can be tied to SO to create

a single bidirectional data bus if desired.

Synchronizes the operation of the MRAM. The clock can operate up to 40

MHz to shift commands, address, and data into the memory. Inputs are

captured on the rising edge of clock. Data outputs from the MRAM occur

SCK 6 Input Serial Clock on the falling edge of clock. The serial MRAM supports both SPI Mode 0

(CPOL=0, CPHA=0) and Mode 3 (CPOL=1, CPHA=1). In Mode 0, the clock is

normally low. In Mode 3, the clock is normally high. Memory operation is

static so the clock can be stopped at any time.

A low on the Hold pin interrupts a memory operation for another task.

When HOLD is low, the current operation is suspended. The device will

HOLD 7 Input Hold

ignore transitions on the CS and SCK when HOLD is low. All transitions of

HOLD must occur while CS is low.

VDD 8 Supply Power Supply Power supply voltage from +2.7 to +3.6 volts.

Copyright © Everspin Technologies 2018 3 MR25H10 Rev. 9.5 3/2018

MR25H10

2. SPI COMMUNICATIONS PROTOCOL

MR25H10 can be operated in either SPI Mode 0 (CPOL=0, CPHA =0) or SPI Mode 3 (CPOL=1, CPHA=1). For

both modes, inputs are captured on the rising edge of the clock and data outputs occur on the falling

edge of the clock. When not conveying data, SCK remains low for Mode 0; while in Mode 3, SCK is high. The

memory determines the mode of operation (Mode 0 or Mode 3) based upon the state of the SCK when CS

falls.

All memory transactions start when CS is brought low to the memory. The first byte is a command code. De-

pending upon the command, subsequent bytes of address are input. Data is either input or output. There

is only one command performed per CS active period. CS must go inactive before another command can

be accepted. To ensure proper part operation according to specifications, it is necessary to terminate each

access by raising CS at the end of a byte (a multiple of 8 clock cycles from CS dropping) to avoid partial or

aborted accesses.

Table 2.1 Command Codes

Instruction Description Binary Code Hex Code Address Bytes Data Bytes

WREN Write Enable 0000 0110 06h 0 0

WRDI Write Disable 0000 0100 04h 0 0

RDSR Read Status Register 0000 0101 05h 0 1

WRSR Write Status Register 0000 0001 01h 0 1

READ Read Data Bytes 0000 0011 03h 3 1 to ∞

WRITE Write Data Bytes 0000 0010 02h 3 1 to ∞

SLEEP Enter Sleep Mode 1011 1001 B9h 0 0

WAKE Exit Sleep Mode 1010 1011 ABh 0 0

Status Register and Block Write Protection

The status register consists of the 8 bits listed in table 2.2. Status register bits BP0 and BP1 define the mem-

ory block arrays that are protected as described in table 2.3. The Status Register Write Disable bit (SRWD)

is used in conjunction with bit 1 (WEL) and the Write Protection pin (WP) as shown in table 2.4 to enable

writes to status register bits. The fast writing speed of MR25H10 does not require write status bits. The

state of bits 6,5,4, and 0 can be user modified and do not affect memory operation. All bits in the status

register are pre-set from the factory to the “0” state.

Table 2.2 Status Register Bit Assignments

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

SRWD Don’t Care Don’t Care Don’t Care BP1 BP0 WEL Don’t Care

Copyright © Everspin Technologies 2018 4 MR25H10 Rev. 9.5 3/2018

MR25H10

SPI COMMUNICATIONS PROTOCOL

Table 2.3 Block Memory Write Protection

Status Register Memory Contents

BP1 BP0 Protected Area Unprotected Area

0 0 None All Memory

0 1 Upper Quarter Lower Three-Quarters

1 0 Upper Half Lower Half

1 1 All None

Table 2.4 Memory Protection Modes

Status

WEL SRWD WP Protected Blocks Unprotected Blocks

Register

0 X X Protected Protected Protected

1 0 X Protected Writable Writable

1 1 Low Protected Writable Protected

1 1 High Protected Writable Writable

When WEL is reset to 0, writes to all blocks and the status register are protected. When WEL is set to 1,

BP0 and BP1 determine which memory blocks are protected. While SRWD is reset to 0 and WEL is set to 1,

status register bits BP0 and BP1 can be modified. Once SRWD is set to 1, WP must be high to modify SRWD,

BP0 and BP1.

Read Status Register (RDSR)

The Read Status Register (RDSR) command allows the Status Register to be read. The Status Register can

be read at any time to check the status of write enable latch bit, status register write protect bit, and block

write protect bits. For MR25H10, the write in progress bit (bit 0) is not written by the memory because

there is no write delay. The RDSR command is entered by driving CS low, sending the command code, and

then driving CS high.

Figure 2.1 RDSR

CS

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 Mode 3

SCK Mode 0

SI 0 0 0 0 0 1 0 1

MSB

Status Register Out

SO High Impedance

7 6 5 4 3 2 1 0

High Z

MSB

Copyright © Everspin Technologies 2018 5 MR25H10 Rev. 9.5 3/2018

MR25H10

SPI COMMUNICATIONS PROTOCOL

Write Enable (WREN)

The Write Enable (WREN) command sets the Write Enable Latch (WEL) bit in the status register to 1. The

WEL bit must be set prior to writing in the status register or the memory. The WREN command is entered

by driving CS low, sending the command code, and then driving CS high.

Figure 2.2 WREN

CS

Mode 3 0 1 2 3 4 5 6 7 Mode 3

SCK Mode 0 Mode 0

Instruction (06h)

SI 0 0 0 0 0 1 1 0

High Impedance

SO

Write Disable (WRDI)

The Write Disable (WRDI) command resets the WEL bit in the status register to 0. This prevents writes to

status register or memory. The WRDI command is entered by driving CS low, sending the command code,

and then driving CS high.

The WEL bit is reset to 0 on power-up or completion of WRDI.

Figure 2.3 WRDI

CS

Mode 3 0 1 2 3 4 5 6 7 Mode 3

SCK Mode 0 Mode 0

Instruction (04h)

SI 0 0 0 0 0 1 0 0

High Impedance

SO

Write Status Register (WRSR)

The Write Status Register (WRSR) command allows new values to be written to the Status Register. The

WRSR command is not executed unless the Write Enable Latch (WEL) has been set to 1 by executing a

WREN command while pin WP and bit SRWD correspond to values that make the status register writable

as seen in table 2.4. Status Register bits are non-volatile with the exception of the WEL which is reset to 0

upon power cycling.

Copyright © Everspin Technologies 2018 6 MR25H10 Rev. 9.5 3/2018

MR25H10

SPI COMMUNICATIONS PROTOCOL

The WRSR command is entered by driving CS low, sending the command code and status register write

data byte, and then driving CS high.The WRSR command is entered by driving CS low, sending the com-

mand code and status register write data byte, and then driving CS high.

Figure 2.4 WRSR

CS

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Mode 3

SCK Mode 0

Instruction (01h) Status Register In

SI 0 0 0 0 0 0 0 1 7 6 5 4 3 2 1 0

MSB

High Impedance

SO

Read Data Bytes (READ)

The Read Data Bytes (READ) command allows data bytes to be read starting at an address specified by the

24-bit address. Only address bits 0-16 are decoded by the memory. The data bytes are read out sequen-

tially from memory until the read operation is terminated by bringing CS high The entire memory can be

read in a single command. The address counter will roll over to 0000h when the address reaches the top of

memory.

The READ command is entered by driving CS low and sending the command code. The memory drives the

read data bytes on the SO pin. Reads continue as long as the memory is clocked. The command is termi-

nated by bring CS high.

Figure 2.5 READ

CS

0 1 2 3 4 5 6 7 8 9 10 28 29 30 31 32 33 34 35 36 37 38 39

SCK

Instruction (03h) 24-Bit Address

SI 0 0 0 0 0 0 1 1 X X X 3 2 1 0

MSB

Data Out 1 Data Out 2

High Impedance

SO 7 6 5 4 3 2 1 0 7

MSB

Copyright © Everspin Technologies 2018 7 MR25H10 Rev. 9.5 3/2018

MR25H10

SPI COMMUNICATIONS PROTOCOL

Write Data Bytes (WRITE)

The Write Data Bytes (WRITE) command allows data bytes to be written starting at an address specified by

the 24-bit address. Only address bits 0-16 are decoded by the memory. The data bytes are written sequen-

tially in memory until the write operation is terminated by bringing CS high. The entire memory can be

written in a single command. The address counter will roll over to 0000h when the address reaches the top

of memory.

Unlike EEPROM or Flash Memory, MRAM can write data bytes continuously at its maximum rated clock

speed without write delays or data polling. Back to back WRITE commands to any random location in mem-

ory can be executed without write delay. MRAM is a random access memory rather than a page, sector, or

block organized memory so it is ideal for both program and data storage.

The WRITE command is entered by driving CS low, sending the command code, and then sequential write

data bytes. Writes continue as long as the memory is clocked. The command is terminated by bringing CS

high.

Figure 2.6 WRITE

CS

0 1 2 3 4 5 6 7 8 9 10 28 29 30 31 32 33 34 35 36 37 38 39

SCK

Instruction (02h) 24-Bit Address

SI 0 0 0 0 0 0 1 0 X X X 3 2 1 0 7 6 5 4 3 2 1 0

MSB MSB

High Impedance

SO

CS

40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 Mode 3

SCK Mode 0

Data Byte 2 Data Byte 3 Data Byte N

SI 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

MSB MSB

High Impedance

SO

Copyright © Everspin Technologies 2018 8 MR25H10 Rev. 9.5 3/2018

MR25H10

SPI COMMUNICATIONS PROTOCOL

Enter Sleep Mode (SLEEP)

The Enter Sleep Mode (SLEEP) command turns off all MRAM power regulators in order to reduce the overall

chip standby power to 3 μA typical. The SLEEP command is entered by driving CS low, sending the com-

mand code, and then driving CS high. The standby current is achieved after time, tDP.

Figure 2.7 SLEEP

CS

t DP

0 1 2 3 4 5 6 7 Mode 3

SCK Mode 0

Instruction (B9h)

SI 1 0 1 1 1 0 0 1

Active Current Standby Current Sleep Mode Current

SO

Exit Sleep Mode (WAKE)

The Exit Sleep Mode (WAKE) command turns on internal MRAM power regulators to allow normal operation.

The WAKE command is entered by driving CS low, sending the command code, and then driving CS high.

The memory returns to standby mode after tRDP. The CS pin must remain high until the tRDP period is over.

Figure 2.8 WAKE

CS

t RDP

0 1 2 3 4 5 6 7 Mode 3

SCK Mode 0

Instruction (ABh)

SI 1 0 1 0 1 0 1 1

Sleep Mode Current Standby Current

SO

Copyright © Everspin Technologies 2018 9 MR25H10 Rev. 9.5 3/2018

MR25H10

3. ELECTRICAL SPECIFICATIONS

Absolute Maximum Ratings

This device contains circuitry to protect the inputs against damage caused by high static voltages or

electric fields; however, it is advised that normal precautions be taken to avoid application of any voltage

greater than maximum rated voltages to these high-impedance (Hi-Z) circuits.

The device also contains protection against external magnetic fields. Precautions should be taken to avoid

application of any magnetic field more intense than the field intensity specified in the maximum ratings.

Table 3.1 Absolute Maximum Ratings1

Symbol Parameter Conditions Limit Unit

VDD Supply voltage2 -0.5 to 4.0 V

VIN Voltage on any pin2 -0.5 to VDD + 0.5 V

IOUT Output current per pin ±20 mA

PD Package power dissipation 3 0.600 W

Industrial -45 to 95 °C

TBIAS Temperature under bias

AEC-Q100 Grade 1 -45 to 130 °C

Tstg Storage Temperature -55 to 150 °C

TLead Lead temperature 3 minutes max 260 °C

Hmax_write Maximum magnetic field exposure Write

12,000 A/m

Hmax_read Maximum magnetic field exposure Read or Standby

1

Permanent device damage may occur if absolute maximum ratings are exceeded. Functional operation

should be restricted to recommended operating conditions. Exposure to excessive voltages or magnetic

fields could affect device reliability.

2

All voltages are referenced to VSS. The DC value of VIN must not exceed actual applied VDD by more than

0.5V. The AC value of VIN must not exceed applied VDD by more than 2V for 10ns with IIN limited to less than

20mA.

Power dissipation capability depends on package characteristics and use environment.

3

Copyright © Everspin Technologies 2018 10 MR25H10 Rev. 9.5 3/2018

MR25H10

ELECTRICAL SPECIFICATIONS

Table 3.2 Operating Conditions

Symbol Parameter Grade Min Max Unit

Industrial 2.7 3.6 V

VDD Power supply voltage

AEC-Q100 Grade1 3.0 3.6 V

VIH Input high voltage All 2.2 VDD + 0.3 V

VIL Input low voltage All -0.5 0.8 V

Industrial -40 85 °C

TA Temperature under bias

AEC-Q100 Grade1 1 -40 125 °C

1

AEC-Q100 Grade 1 temperature profile assumes 10 percent duty cycle at maximum temperature (2 years

out of 20-year life.)

Table 3.3 DC Characteristics

Symbol Parameter Conditions Min Typical Max Unit

ILI Input leakage current - - ±1 μA

ILO Output leakage current - - ±1 μA

IOL = +4 mA - - 0.4 V

VOL Output low voltage

IOL = +100 μA - - VSS + 0.2v V

(IOH = -4 mA) 2.4 - - V

VOH Output high voltage

(IOH = -100 μA) VDD - 0.2 - - V

Table 3.4 Power Supply Characteristics

Symbol Parameter Conditions Typical Max Unit

1 MHz 2.5 3 mA

IDDR Active Read Current

40 MHz 6 10 mA

1 MHz 8 13 mA

IDDW Active Write Current

40 MHz 23 27 mA

ISB Standby Current CS high and SPI bus inactive 90 115 μA

Izz Standby Sleep Mode Current CS high and SPI bus inactive 7 30 μA

Copyright © Everspin Technologies 2018 11 MR25H10 Rev. 9.5 3/2018

MR25H10

4. TIMING SPECIFICATIONS

Table 4.1 Capacitance1

Symbol Parameter Typical Max Unit

CIn Control input capacitance - 6 pF

CI/O Input/Output capacitance - 8 pF

1

ƒ = 1.0 MHz, dV = 3.0 V, TA = 25 °C, periodically sampled rather than 100% tested.

Table 4.2 AC Measurement Conditions

Parameter Value Unit

Logic input timing measurement reference level 1.5 V

Logic output timing measurement reference level 1.5 V

Logic input pulse levels 0 or 3.0 V

Input rise/fall time 2 ns

Output load for low and high impedance parameters See Figure 4.1

Output load for all other timing parameters See Figure 4.2

Figure 4.1 Output Load for Impedance Parameter Measurements

ZD= 50 Ω

Output

RL = 50 Ω

VL = 1.5 V

Figure 4.2 Output Load for all Other Parameter Measurements

3.3 V

590 Ω

Output

435 Ω 30 pF

Copyright © Everspin Technologies 2018 12 MR25H10 Rev. 9.5 3/2018

MR25H10

TIMING SPECIFICATIONS

Power-Up Timing

The MR25H10 is not accessible for a start-up time, tPU= 400 μs after power up. Users must wait this time

from the time when VDD (min) is reached until the first CS low to allow internal voltage references to become

stable. The CS signal should be pulled up to VDD so that the signal tracks the power supply during power-up

sequence.

Table 4.3 Power-Up

Symbol Parameter Min Typical Max Unit

VWI Write Inhibit Voltage 2.2 - 2.7 V

tPU Startup Time 400 - - μs

Figure 4.3 Power-Up Timing

VDD

VDD(max)

Chip Selection not allowed

VDD(min)

Reset state t PU Normal Operation

of the

device

VWI

Time

Copyright © Everspin Technologies 2018 13 MR25H10 Rev. 9.5 3/2018

MR25H10

TIMING SPECIFICATIONS

Synchronous Data Timing Table 4.4 AC Timing Parameters1

Symbol Parameter Conditions Min Max Unit

fSCK SCK Clock Frequency 0 40 MHz

tRI Input Rise Time - 50 ns

tRF Input Fall Time - 50 ns

tWH SCK High Time 11 - ns

tWL SCK Low Time 11 - ns

Synchronous Data Timing (See figure 4.4)

tCS CS High Time 40 - ns

tCSS CS Setup Time 10 - ns

tCSH CS Hold Time 10 - ns

tSU Data In Setup Time 5 - ns

tH Data In Hold Time 5 - ns

VDD = 2.7 to

Output Valid Industrial Grade 0 10 ns

3.6v.

VDD = 3.0 to

tV Output Valid Industrial Grade 0 9 ns

3.6v.

VDD = 3.0 to

Output Valid AEC-Q100 Grade 1 0 10 ns

3.6v.

tHO Output Hold Time 0 - ns

HOLD Timing (See figure 4.5)

tHD HOLD Setup Time 10 - ns

tCD HOLD Hold Time 10 - ns

tLZ HOLD to Output Low Impedance - 20 ns

tHZ HOLD to Output High Impedance - 20 ns

Other Timing Specifications

tWPS WP Setup To CS Low 5 - ns

tWPH WP Hold From CS High 5 - ns

tDP Sleep Mode Entry Time 3 - μs

tRDP Sleep Mode Exit Time 400 - μs

tDIS Output Disable Time 12 - ns

1

Over the Operating Temperature Range and CL= 30 pF

Copyright © Everspin Technologies 2018 14 MR25H10 Rev. 9.5 3/2018

MR25H10

Figure 4.4 Synchronous Data Timing

Figure 4.5 HOLD Timing

CS

tCD

tCD

SCK

tHD

tHD

HOLD

tHZ tLZ

SO

Copyright © Everspin Technologies 2018 15 MR25H10 Rev. 9.5 3/2018

MR25H10

5. ORDERING INFORMATION

Figure 5.1 Part Numbering System

MR 25H 10 C DC

Package Options

DC 8 Pin DFN on Tray

DCR 8 Pin DFN on Tape and Reel

DF 8 pin DFN Small Flag on Tray

DFR 8 pin DFN Small Flag on Tape and Reel

Temperature Range

C -40 to +85 °C ambient (Industrial)

M -40 to +125 °C ambient (AEC-Q100 Grade 1)

Memory Density

10 1 Mb

Interface

25H High Speed Serial SPI Family

Product Type

MR Magnetoresistive RAM

Table 5.1 Available Parts

Temperature

Grade Package Shipping Container Order Part Number

Range

1

Tray MR25H10CDC 1

8-DFN

Industrial -40 to +85 C

Tape and Reel MR25H10CDCR 1

Tray MR25H10CDF

Small Flag 8-DFN

Tape and Reel MR25H10CDFR

1

Tray MR25H10MDC 1

8-DFN

AEC-Q100 Grade 1 -40 to +125 C

Tape and Reel MR25H10MDCR 1

Tray MR25H10MDF

Small Flag 8-DFN

Tape and Reel MR25H10MDFR

Note:

1. The DC pckage option (8-DFN) is not recommended for new designs. Please select the DF (small flag

8-DFN) option for new designs.

Copyright © Everspin Technologies 2018 16 MR25H10 Rev. 9.5 3/2018

MR25H10

6. MECHANICAL DRAWINGS

Figure 6.1 DFN Package

Dimension A B C D E F G H I J K L M N

Max. 5.10 6.10 1.00 1.27 0.45 0.05 0.35 0.70 4.20 4.20 0.261 0.05

C0.35 R0.20

Min. 4.90 5.90 0.90 BSC 0.35 0.00 Ref. 0.50 4.00 4.00 0.195 0.00

NOTE:

1. All dimensions are in mm. Angles in degrees.

2. Coplanarity applies to the exposed pad as well as the terminals. Coplanarity shall be

within 0.08 mm.

3. Warpage shall not exceed 0.10 mm.

4. Refer to JEDEC MO-229

Copyright © Everspin Technologies 2018 17 MR25H10 Rev. 9.5 3/2018

MR25H10

6. MECHANICAL DRAWINGS

Figure 6.2 Small Flag DFN Package

Exposed metal Pad. Do not con-

nect anything except VSS

A

2X 0.10 C

5 8

2X 0.10 C

J

B

I

G L

M H

Pin 1 Index 4 1

C Detail A F

K N

D E

Detail A

Dimension A B C D E F G H I J K L M N

Max 5.10 6.10 0.90 1.27 0.45 0.05 1.60 0.70 2.10 2.10 .210 0.05

C0.45 R0.20

Min 4.90 5.90 0.80 BSC 0.35 0.00 1.20 0.50 1.90 1.90 .196 0.00

NOTE:

1. All dimensions are in mm. Angles in degrees.

2. Coplanarity applies to the exposed pad as well as the terminals. Coplanarity shall be

within 0.08 mm.

3. Warpage shall not exceed 0.10 mm.

4. Refer to JEDEC MO-229

Copyright © Everspin Technologies 2018 18 MR25H10 Rev. 9.5 3/2018

MR25H10

7. REVISION HISTORY

Revision Date Description of Change

0 Sep 12, 2008 Initial Advance Information Release

Change ac load resistance, tPU to 400 us, tRDP to 400 us, Change # of Address Bytes in Table

1 Jul 10, 2009

2 to 3, New Package Drawing, Make Preliminary

2 Jul 16, 2009 Increase Absolute Max Magnetic Field during write, read, and standby to 12,000 A/m

3 Jan 5, 2010 Described block protect in detail with power sequencing.

4 Feb 5, 2010 Added section system configuration.

5 May 17, 2010 Removed commercial specifications. All parts meet industrial specifications.

Corrected various typos. Clarified block and status register protection description. Revised

6 Sep 14, 2011 Table 3.4 Power Supply specifications. Added AEC-Q100 Grade 1 ordering option. Revised

Table 3.1, Table 3.2, Table 4.4 revised and Note 2 deleted, revised Figure 5.1 and Table 5.1.

Corrected VOL in Table 3.3 to read VOL Max = VSS + 0.2v. Operating Conditions Power Supply

Voltage for AEC-Q100 Grade1revised to 3.0-3.6v. Table 4.4: Output Valid tV specifications

revised to include VDD ranges for Industrial and AEC-Q100 Grade 1 options. Corrected SI

November 18, waveform in Figure 2.8. Output Valid, tv for AEC-Q100 Grade revised from 9ns max to 10ns

7

2011 max in Table 4.4. New Small Flag DFN package option added to Page 1 Features and avail-

able parts Table 5.1. DFN Small Flag drawing and dimensions table added as Figure 6.2.

Figure 6.1, DFN Package, cleaned up with better quality drawing and dimension table. No

specifications were changed in Figure 6.1.

Reformatted tables for Section 3 Electrical Characteristics and timing parameters, Table

4.4. Revised Ordering Part Numbers Table 5.1. Removed MDF and MDFR options. MDC

October 19,

8 and MDCR options are now qualified. Added Small Flag DFN illustrations. Revised 8-DFN

2012

package drawing to show correct proportion for flag and package. Corrected errors in DFN

package outline drawings. Corrected VDD range for AEC-Q100 tV specification.

9 April 17, 2013 Added Automotive Grade AEC-Q100 Grade 1 for Small Flag DFN package.

9.1 May 19, 2015 Revised Everspin contact information.

9.2 June 11, 2015 Corrected Japan Sales Office telephone number.

Changed all large flag DFN optoins to “The DC pckage option (8-DFN) is not recom-

December 13,

9.3 mended for new designs. Please select the DF (small flag 8-DFN) option for new

2016

designs.”

9.4 February 2, 2017 Added tHO and tV relationship to Synchronous Data Timing

9.5 March 23, 2018 Updated the Contact Us table

Copyright © Everspin Technologies 2018 19 MR25H10 Rev. 9.5 3/2018

MR25H10

Everspin Technologies, Inc.

How to Reach Us:

Home Page: Information in this document is provided solely to enable system and software

www.everspin.com implementers to use Everspin Technologies products. There are no express or

implied licenses granted hereunder to design or fabricate any integrated circuit

World Wide Information Request or circuits based on the information in this document. Everspin Technologies

WW Headquarters - Chandler, AZ

5670 W. Chandler Blvd., Suite 100

reserves the right to make changes without further notice to any products

Chandler, Arizona 85226 herein. Everspin makes no warranty, representation or guarantee regarding the

Tel: +1-877-480-MRAM (6726) suitability of its products for any particular purpose, nor does Everspin Technol-

Local Tel: +1-480-347-1111 ogies assume any liability arising out of the application or use of any product

Fax: +1-480-347-1175

support@everspin.com or circuit, and specifically disclaims any and all liability, including without

orders@everspin.com limitation consequential or incidental damages. “Typical” parameters, which

sales@everspin.com may be provided in Everspin Technologies data sheets and/or specifications can

and do vary in different applications and actual performance may vary over

Europe, Middle East and Africa

Everspin Europe Support

time. All operating parameters including “Typicals” must be validated for each

support.europe@everspin.com customer application by customer’s technical experts. Everspin Technologies

does not convey any license under its patent rights nor the rights of others.

Japan Everspin Technologies products are not designed, intended, or authorized for

Everspin Japan Support

support.japan@everspin.com

use as components in systems intended for surgical implant into the body, or

other applications intended to support or sustain life, or for any other applica-

Asia Pacific tion in which the failure of the Everspin Technologies product could create a

Everspin Asia Support situation where personal injury or death may occur. Should Buyer purchase or

support.asia@everspin.com

use Everspin Technologies products for any such unintended or unauthorized

application, Buyer shall indemnify and hold Everspin Technologies and its of-

ficers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fees arising out

of, directly or indirectly, any claim of personal injury or death associated with

such unintended or unauthorized use, even if such claim alleges that Everspin

Technologies was negligent regarding the design or manufacture of the part.

Everspin™ and the Everspin logo are trademarks of Everspin Technologies, Inc.

All other product or service names are the property of their respective owners.

Copyright © Everspin Technologies, Inc. 2018

Copyright © Everspin Technologies 2018 20 MR25H10 Rev. 9.5 3/2018

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Everspin Technologies:

MR25H10CDC MR25H10CDCR MR25H10MDC MR25H10MDCR MR25H10CDF MR25H10CDFR MR25H10MDF

MR25H10MDFR

You might also like

- Features: 128Kb Serial SPI MRAMDocument21 pagesFeatures: 128Kb Serial SPI MRAMsupNo ratings yet

- MB85RS256: 256 K (32 K 8) Bit SPIDocument20 pagesMB85RS256: 256 K (32 K 8) Bit SPIJC_RoseNo ratings yet

- MB85RS64V DS501 00015 5v0 E-2515457Document37 pagesMB85RS64V DS501 00015 5v0 E-2515457ManunoghiNo ratings yet

- MB85RS4MT: 8) Bit SPIDocument33 pagesMB85RS4MT: 8) Bit SPI20c552244bNo ratings yet

- Features: 16Kb FRAM Serial 3V MemoryDocument14 pagesFeatures: 16Kb FRAM Serial 3V Memorybengkel_ericNo ratings yet

- CAT25C32/64: 32K/64K-Bit SPI Serial CMOS E Prom FeaturesDocument9 pagesCAT25C32/64: 32K/64K-Bit SPI Serial CMOS E Prom FeaturesTeyfik koyuncuNo ratings yet

- CAT25C11/03/05/09/17: 1K/2K/4K/8K/16K SPI Serial CMOS E Prom FeaturesDocument10 pagesCAT25C11/03/05/09/17: 1K/2K/4K/8K/16K SPI Serial CMOS E Prom FeaturesAgnaldo Oliveira SantosNo ratings yet

- MB85RS128B: 128K (16 K 8) Bit SPIDocument36 pagesMB85RS128B: 128K (16 K 8) Bit SPISivi KarudijanNo ratings yet

- Features: 512K-Bit (X 1) Cmos Serial FlashDocument39 pagesFeatures: 512K-Bit (X 1) Cmos Serial FlashPedro VeraNo ratings yet

- MB85AS4MT DS501 00045 1v0 EDocument28 pagesMB85AS4MT DS501 00045 1v0 EseacerNo ratings yet

- 25L8005 MxicDocument44 pages25L8005 MxicdgsilvaufgNo ratings yet

- NM93C06 256-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)Document13 pagesNM93C06 256-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)fabiansandezNo ratings yet

- NM93C66 4096-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)Document13 pagesNM93C66 4096-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)insomnium86No ratings yet

- NM93CS66 (MICROWIRE™ Bus Interface) 4096-Bit Serial EEPROM With Data Protect and Sequential ReadDocument16 pagesNM93CS66 (MICROWIRE™ Bus Interface) 4096-Bit Serial EEPROM With Data Protect and Sequential Readinsomnium86No ratings yet

- SST25VF040B: 4 Mbit SPI Serial FlashDocument33 pagesSST25VF040B: 4 Mbit SPI Serial FlashDario EzequielNo ratings yet

- Datasheet - HK Mx25l4005am2c-12g 4351093Document44 pagesDatasheet - HK Mx25l4005am2c-12g 4351093Jairo GuerraNo ratings yet

- 1K/2K/4K Spi Serial Cmos Eeprom Features: Logen FreeDocument11 pages1K/2K/4K Spi Serial Cmos Eeprom Features: Logen FreeDiab ChekkalNo ratings yet

- Macronix MX25L8005M2C 15G DatasheetDocument44 pagesMacronix MX25L8005M2C 15G DatasheetAlex CrofordNo ratings yet

- MX25 L2005 Ver 14Document40 pagesMX25 L2005 Ver 14Robby SitanalaNo ratings yet

- At25128b 5eb PDFDocument22 pagesAt25128b 5eb PDFMurat BaybükeNo ratings yet

- Atmel DatasheetDocument27 pagesAtmel DatasheetKhoa DangNo ratings yet

- Nor Flash Datasheet MicrochipDocument33 pagesNor Flash Datasheet MicrochipsupNo ratings yet

- Atmel 5082 Seeprom At25080a 160a 320a 640a Auto DatasheetDocument20 pagesAtmel 5082 Seeprom At25080a 160a 320a 640a Auto DatasheetalaitsevNo ratings yet

- SST25VF080B: 8 Mbit SPI Serial FlashDocument32 pagesSST25VF080B: 8 Mbit SPI Serial Flashantonio joseNo ratings yet

- 24C16 FairchildSemiconductorDocument14 pages24C16 FairchildSemiconductorRavi ChavhanNo ratings yet

- GD25LQ40 Rev1.5Document63 pagesGD25LQ40 Rev1.5mirage0706No ratings yet

- SST26VF064BDocument76 pagesSST26VF064Bmar_barudjNo ratings yet

- 32 Mbit SPI Serial Flash: SST25VF032BDocument33 pages32 Mbit SPI Serial Flash: SST25VF032Bedward blancoNo ratings yet

- F25l01pa (2D)Document31 pagesF25l01pa (2D)mirage0706No ratings yet

- Bus Serial EEPROMDocument12 pagesBus Serial EEPROMMatiasNo ratings yet

- SPI Flash MX25L1605ADocument43 pagesSPI Flash MX25L1605AopenstorebussinesNo ratings yet

- SST25VF040B 4 Mbit SPI Serial Flash Data Sheet 20005051F 1Document31 pagesSST25VF040B 4 Mbit SPI Serial Flash Data Sheet 20005051F 1Drew AlbaneseNo ratings yet

- Microchiptechnology Sst25vf020b804csaet Datasheets 1062Document33 pagesMicrochiptechnology Sst25vf020b804csaet Datasheets 1062sara mehdipourNo ratings yet

- NM24C04/05 - 4K-Bit Standard 2-Wire Bus Interface Serial EEPROMDocument14 pagesNM24C04/05 - 4K-Bit Standard 2-Wire Bus Interface Serial EEPROMAbel RodriguezNo ratings yet

- SST25VF016B: 16 Mbit SPI Serial FlashDocument30 pagesSST25VF016B: 16 Mbit SPI Serial Flashzigmund zigmundNo ratings yet

- 64-Kbit (8K × 8) Serial (SPI) F-RAM: Features Functional DescriptionDocument21 pages64-Kbit (8K × 8) Serial (SPI) F-RAM: Features Functional DescriptionsupNo ratings yet

- FM93C66A 4K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)Document13 pagesFM93C66A 4K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)insomnium86No ratings yet

- FM24C08U/09U - 8K-Bit Standard 2-Wire Bus Interface Serial EEPROMDocument15 pagesFM24C08U/09U - 8K-Bit Standard 2-Wire Bus Interface Serial EEPROMlord_beast2.05No ratings yet

- Features: 1M-Bit (X 1) Cmos Serial FlashDocument40 pagesFeatures: 1M-Bit (X 1) Cmos Serial Flashzigmund zigmundNo ratings yet

- 25c256ke PDFDocument11 pages25c256ke PDFMizael Medeiros dos SantosNo ratings yet

- Spi Eeprom PDFDocument44 pagesSpi Eeprom PDFEma HarmaNo ratings yet

- 25AA320/25LC320/25C320: 32K Spi Bus Serial EEPROMDocument24 pages25AA320/25LC320/25C320: 32K Spi Bus Serial EEPROMHebertAlexMamaniSalomaNo ratings yet

- Please Note That Cypress Is An Infineon Technologies CompanyDocument22 pagesPlease Note That Cypress Is An Infineon Technologies Company20c552244bNo ratings yet

- Fm93c86an 177Document12 pagesFm93c86an 177ISAJEVS IGORSNo ratings yet

- SST26VF064B SST26VF064BA 2 5V 3 0V 64 Mbit Serial - 2935898Document91 pagesSST26VF064B SST26VF064BA 2 5V 3 0V 64 Mbit Serial - 2935898ManunoghiNo ratings yet

- Programmazione - AssemblerDocument36 pagesProgrammazione - AssemblerArthNo ratings yet

- 25AA640A/25LC640A: 64K SPI Bus Serial EEPROMDocument36 pages25AA640A/25LC640A: 64K SPI Bus Serial EEPROMmarino246No ratings yet

- NM93C66A 4K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)Document13 pagesNM93C66A 4K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)insomnium86No ratings yet

- PIC16F87XA: TABLE 8-5: Registers Associated With PWM and Timer2Document5 pagesPIC16F87XA: TABLE 8-5: Registers Associated With PWM and Timer2vitor valeNo ratings yet

- 24C320-EP MicrochipTechnologyDocument12 pages24C320-EP MicrochipTechnologyMateus CorrêaNo ratings yet

- MB85RC64TA: 64 K (8 K 8) Bit I CDocument28 pagesMB85RC64TA: 64 K (8 K 8) Bit I CRohit MoreNo ratings yet

- IS24C01 IS24C02 IS24C04 IS24C08 IS24C16: 1K-bit/2K-bit/4K-bit/8K-bit/16K-bit 2-Wire Serial Cmos EepromDocument16 pagesIS24C01 IS24C02 IS24C04 IS24C08 IS24C16: 1K-bit/2K-bit/4K-bit/8K-bit/16K-bit 2-Wire Serial Cmos EepromPablo Diego Cecere CasadoNo ratings yet

- IS24C01 IS24C02 IS24C04 IS24C08 IS24C16: 1K-bit/2K-bit/4K-bit/8K-bit/16K-bit 2-Wire Serial Cmos EepromDocument16 pagesIS24C01 IS24C02 IS24C04 IS24C08 IS24C16: 1K-bit/2K-bit/4K-bit/8K-bit/16K-bit 2-Wire Serial Cmos EepromPablo Diego Cecere CasadoNo ratings yet

- FM93C86A 16K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)Document13 pagesFM93C86A 16K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)insomnium86No ratings yet

- Preliminary: Uniform Sector 16mbit Dual and Quad Spi Flash Gd25Q16Document33 pagesPreliminary: Uniform Sector 16mbit Dual and Quad Spi Flash Gd25Q16Erick OliveiraNo ratings yet

- X24C44 256 Bit 16 X 16 Bit: Features DescriptionDocument15 pagesX24C44 256 Bit 16 X 16 Bit: Features DescriptionJosé FariaNo ratings yet

- X24C44 256 Bit 16 X 16 Bit: Features DescriptionDocument16 pagesX24C44 256 Bit 16 X 16 Bit: Features DescriptionAgustin AndrokaitesNo ratings yet

- X24C44 256 Bit 16 X 16 Bit: Features DescriptionDocument16 pagesX24C44 256 Bit 16 X 16 Bit: Features DescriptionMarinaBogaoNo ratings yet

- S25fl512sagbhia13 Fab024Document145 pagesS25fl512sagbhia13 Fab024中井一朗No ratings yet

- Spansion SLC NAND Flash Memory For Embedded: Data SheetDocument77 pagesSpansion SLC NAND Flash Memory For Embedded: Data SheetsupNo ratings yet

- 1 Mbit SPI Serial SRAM With Battery Backup and SDI InterfaceDocument30 pages1 Mbit SPI Serial SRAM With Battery Backup and SDI InterfacesupNo ratings yet

- MRAM 4mbit EST00459 MR2xH40 DatasheetDocument31 pagesMRAM 4mbit EST00459 MR2xH40 DatasheetsupNo ratings yet

- Nand - 1 GBDocument43 pagesNand - 1 GBsupNo ratings yet

- Nor Flash Datasheet MicrochipDocument33 pagesNor Flash Datasheet MicrochipsupNo ratings yet

- Features: 128Kb Serial SPI MRAMDocument21 pagesFeatures: 128Kb Serial SPI MRAMsupNo ratings yet

- Macronix - Flash-256mbit - MX25L25673G, 3V, 256Mb, V1.4Document118 pagesMacronix - Flash-256mbit - MX25L25673G, 3V, 256Mb, V1.4supNo ratings yet

- 64-Kbit (8K × 8) Serial (SPI) F-RAM: Features Functional DescriptionDocument21 pages64-Kbit (8K × 8) Serial (SPI) F-RAM: Features Functional DescriptionsupNo ratings yet

- Jedec Standard: Electrically Erasable Programmable ROM (EEPROM) Program/Erase Endurance and Data Retention Stress TestDocument23 pagesJedec Standard: Electrically Erasable Programmable ROM (EEPROM) Program/Erase Endurance and Data Retention Stress TestsupNo ratings yet

- Most Out of Your Scope: 6 Oscilloscope Tricks To Get TheDocument20 pagesMost Out of Your Scope: 6 Oscilloscope Tricks To Get TheJhon Fredy Diaz CorreaNo ratings yet

- INS Journal VikasDocument54 pagesINS Journal Vikashaashboi5No ratings yet

- Least Learned Skills 4TH Q 2019 2020Document1 pageLeast Learned Skills 4TH Q 2019 2020Arben Joy UrmatanNo ratings yet

- Chemistry Lecturer Short Notes & MCQs PDFDocument24 pagesChemistry Lecturer Short Notes & MCQs PDFPolitical CornerNo ratings yet

- Ficha-Ingl-4to. A-B - Semana 3Document3 pagesFicha-Ingl-4to. A-B - Semana 3wilder chiroqueNo ratings yet

- SL - No Questions: MODULE 1: Discrete Fourier TransformDocument5 pagesSL - No Questions: MODULE 1: Discrete Fourier TransformarunNo ratings yet

- Math T STPM Semester 1 2014Document2 pagesMath T STPM Semester 1 2014tchinhuat82No ratings yet

- Music Theory (Jason Allen) (Summarized by Elve)Document28 pagesMusic Theory (Jason Allen) (Summarized by Elve)elveNo ratings yet

- Solution Manual For Engineering Fluid Mechanics 10th Edition by Elgerpdf PDF FreeDocument54 pagesSolution Manual For Engineering Fluid Mechanics 10th Edition by Elgerpdf PDF FreeAdriod DeNo ratings yet

- Preliminary Data Sheet: Product DescriptionDocument3 pagesPreliminary Data Sheet: Product Descriptionfar333No ratings yet

- Characterization and Evaluation of Portuguese Opuntia Spp. GermplasmDocument176 pagesCharacterization and Evaluation of Portuguese Opuntia Spp. GermplasmcarlosmgreisNo ratings yet

- Batangas State UniversityDocument4 pagesBatangas State UniversitychrstnmrsgnNo ratings yet

- A Quick Introduction To Quantum Espresso: Simone Di Cataldo September 27, 2019Document32 pagesA Quick Introduction To Quantum Espresso: Simone Di Cataldo September 27, 2019Jay Bee SharmaNo ratings yet

- Ordinary Differential EquationsDocument317 pagesOrdinary Differential Equationsaaa1235No ratings yet

- Assignment Fluid MechanicsDocument8 pagesAssignment Fluid MechanicsPhanna MongNo ratings yet

- B) CH (D) 9.43 G: Sal Govt. College Mirpurkhas Class: XI-C Subject: Chemistry M.Marks. 20Document2 pagesB) CH (D) 9.43 G: Sal Govt. College Mirpurkhas Class: XI-C Subject: Chemistry M.Marks. 20Zia RathoreNo ratings yet

- Design PDFDocument202 pagesDesign PDFLorraine100% (1)

- Eegame LogcatDocument42 pagesEegame LogcatKelvin AlexanderNo ratings yet

- Es Model ExamDocument3 pagesEs Model ExamAarun ArasanNo ratings yet

- Lecture 2. Nature of Inquiry ResearchDocument43 pagesLecture 2. Nature of Inquiry ResearchJon David Ancheta100% (2)

- Linear SeperabilityDocument11 pagesLinear SeperabilityNetaji GandiNo ratings yet

- A Formula For Resistance Substation Grounding Grid in Two-Layer SoilDocument8 pagesA Formula For Resistance Substation Grounding Grid in Two-Layer SoilGabriel A. Gabriel MarmolejosNo ratings yet

- Zimsec A Level African History NotesDocument2 pagesZimsec A Level African History NotesDutchess KareNo ratings yet

- 21mab102t Model MCQ Unit I To VDocument16 pages21mab102t Model MCQ Unit I To Vsd9422No ratings yet

- Ye Tu19 Turning IDocument36 pagesYe Tu19 Turning IferNo ratings yet

- Cơ Sở Toán Học Cho Mật Mã - Huỳnh Trọng ThưaDocument34 pagesCơ Sở Toán Học Cho Mật Mã - Huỳnh Trọng ThưaHồng HuyNo ratings yet

- Seismic Performance of Post-Tensioned Precast ConcDocument9 pagesSeismic Performance of Post-Tensioned Precast ConcAbderrahmane SaidNo ratings yet

- 205i Innova SonicDocument4 pages205i Innova SonictengmorganNo ratings yet

- Page No 9 1-5 To 7-5-2012Document1 pagePage No 9 1-5 To 7-5-2012Gulam Rabbani FidaNo ratings yet

- Design and Development of Automatic Wheelchair Cum Patient BedDocument90 pagesDesign and Development of Automatic Wheelchair Cum Patient BedSRL MECHNo ratings yet