Professional Documents

Culture Documents

On-Site FMEA Review Checklist Reverse FMEA Manufacturing Process

On-Site FMEA Review Checklist Reverse FMEA Manufacturing Process

Uploaded by

Jobs SteveCopyright:

Available Formats

You might also like

- Control Plan 1st Edition - AnalysisDocument9 pagesControl Plan 1st Edition - AnalysisYassin Serhani100% (4)

- Reverse PFMEA Worksheet 2Document1 pageReverse PFMEA Worksheet 2adochan92% (12)

- PFMEA Audit ChecklistDocument2 pagesPFMEA Audit Checklistadnans100% (3)

- SAFE LAUNCH ProcedureDocument2 pagesSAFE LAUNCH ProcedurePRAMOD88% (8)

- GP 12Document2 pagesGP 12Antonio Lara100% (9)

- Excel Tool Process Audit Services VDA 6.3 2016 en V1.0Document12 pagesExcel Tool Process Audit Services VDA 6.3 2016 en V1.0Roberto Barbosa100% (1)

- ANPQP Version 3.2 RevisionDocument33 pagesANPQP Version 3.2 RevisionFaby Mendoza50% (2)

- Audit Report VDA 6.3 Potential Analysis: Findings Question According VDA 6.3 Questionnaire 0 0Document1 pageAudit Report VDA 6.3 Potential Analysis: Findings Question According VDA 6.3 Questionnaire 0 0ssierro100% (2)

- Check List For FMEA Evaluation SupplierDocument7 pagesCheck List For FMEA Evaluation SupplierMiroslaw ONo ratings yet

- Reverse PFMEADocument5 pagesReverse PFMEASantosh BallalNo ratings yet

- Reverse FMEA PSADocument53 pagesReverse FMEA PSABES100% (9)

- Layered Process Audits TemplateDocument3 pagesLayered Process Audits TemplatemajidrashidNo ratings yet

- BIQS 2017 Slide ShowDocument202 pagesBIQS 2017 Slide Showismael cantuNo ratings yet

- VDA 6.3 Standard Questionnaire enDocument19 pagesVDA 6.3 Standard Questionnaire enFlorida Elena MitroiNo ratings yet

- Red Bin Analysis FormatDocument1 pageRed Bin Analysis FormatPRABHAT RANJAN50% (2)

- Pass Through CharacteristicsDocument10 pagesPass Through CharacteristicsmirosekNo ratings yet

- AIAG-VDA DFMEA Final ExamDocument10 pagesAIAG-VDA DFMEA Final ExamMoham'medAlthafAs'lam100% (2)

- IATF Process Audit Check Sheet FormatDocument14 pagesIATF Process Audit Check Sheet Formatukavathekar71% (7)

- VDA FMEA TemplateDocument53 pagesVDA FMEA Templatewatna0% (2)

- Daimler-Chrysler Layered Process AuditsDocument27 pagesDaimler-Chrysler Layered Process AuditsR JNo ratings yet

- Automotive Process Approach Audit For IATF 16949 - 2016Document4 pagesAutomotive Process Approach Audit For IATF 16949 - 2016isolongNo ratings yet

- Questions Process Audit: P2. Project ManagementDocument11 pagesQuestions Process Audit: P2. Project ManagementR JNo ratings yet

- Customer Specific Requirements MatrixDocument4 pagesCustomer Specific Requirements Matrixhmp9071% (7)

- CQI-11 Plating 20177Document24 pagesCQI-11 Plating 20177Jose Raul Aquino Herrera0% (1)

- NPD Check SheetDocument6 pagesNPD Check Sheets.charlie50% (2)

- Guidelines For Technical Material: Unified English BrailleDocument93 pagesGuidelines For Technical Material: Unified English Brailleluana4No ratings yet

- Reverse FMEA ProcessDocument7 pagesReverse FMEA ProcessYayi MartinezNo ratings yet

- Example To Be Adapted To Manufacturing Process (Technology) and Number of Operations Per WorkstationDocument1 pageExample To Be Adapted To Manufacturing Process (Technology) and Number of Operations Per WorkstationTHANGNo ratings yet

- AIAG-VDA PFMEA Template For Activity - (Delegate)Document38 pagesAIAG-VDA PFMEA Template For Activity - (Delegate)nadia_naaz90No ratings yet

- Reverse FMEADocument27 pagesReverse FMEAJobs Steve100% (2)

- Has Introduced The First International Guide On Failure Mode and Effects Analysis (FMEA)Document2 pagesHas Introduced The First International Guide On Failure Mode and Effects Analysis (FMEA)Ionut Eduard100% (2)

- CD6 Prototype Control PlanDocument3 pagesCD6 Prototype Control Planmpedraza-1No ratings yet

- APQP MatrixDocument4 pagesAPQP MatrixVikas KashyapNo ratings yet

- Pfmea - Aiag-VdaDocument108 pagesPfmea - Aiag-VdaGLAUCIO DOS SANTOS SILVANo ratings yet

- Reverse Fmea: AMDEC InverséeDocument12 pagesReverse Fmea: AMDEC InverséeMoez Aloui100% (2)

- P!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Document14 pagesP!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Duho ConsultoresNo ratings yet

- CSR Matrix For RefDocument6 pagesCSR Matrix For RefBard Z8No ratings yet

- Special Characteristics PDFDocument11 pagesSpecial Characteristics PDFKristof MCNo ratings yet

- Sample of PM DiagramDocument1 pageSample of PM DiagramKarim HakimNo ratings yet

- Overview - FMEA - AIAG - VDADocument1 pageOverview - FMEA - AIAG - VDAvenkatesh vajarapu100% (1)

- BIQ-S AuditDocument13 pagesBIQ-S AuditAngie Guerrero100% (1)

- Cqi 20 Summary PDFDocument30 pagesCqi 20 Summary PDFR J100% (1)

- Apqp VolvoDocument7 pagesApqp Volvofdsa01No ratings yet

- Annexure-1 Customer Specific Requirement MatrixDocument5 pagesAnnexure-1 Customer Specific Requirement MatrixSunil Shrivastava67% (3)

- IATF 16949 2016 Gap ToolDocument353 pagesIATF 16949 2016 Gap ToolOziel Cardenas33% (6)

- Iatf Process Audit Check Sheet FormatDocument14 pagesIatf Process Audit Check Sheet FormatPuspavathi S Rama NaiduNo ratings yet

- Aiag & Vda Pfmea Form (1st Edition 2019)Document10 pagesAiag & Vda Pfmea Form (1st Edition 2019)Gurcan SayaralNo ratings yet

- Oposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseDocument1 pageOposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseSethasan SrikochNo ratings yet

- Advanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial StageDocument6 pagesAdvanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial Stagerajesh sharma100% (3)

- PPAP 4th. EditionDocument75 pagesPPAP 4th. EditionGilberto FloresNo ratings yet

- Pfmea SopDocument9 pagesPfmea SopAbhijit DasNo ratings yet

- CQI-12v2: Special Process: Coating System AssessmentDocument36 pagesCQI-12v2: Special Process: Coating System AssessmentHoang TanNo ratings yet

- PFMEA AuditingDocument18 pagesPFMEA AuditingelevendotNo ratings yet

- Wi SPCDocument4 pagesWi SPCSujeet Kumar100% (1)

- 06) - Fmea For 11190722 - DDocument192 pages06) - Fmea For 11190722 - DMONISHRAJNo ratings yet

- Layered Audit ChecklistDocument4 pagesLayered Audit ChecklistNavnath TamhaneNo ratings yet

- APQP Sample FormatDocument32 pagesAPQP Sample FormatManigandan RNo ratings yet

- AIAG & VDA PFMEA FormatDocument1 pageAIAG & VDA PFMEA Formatmahesh KhatalNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- Corrective Action Report (CAR) : Form1001 CAR-KMR - e Page 1 of 1 Revision: 6 Reference: Organizational Instruction 8.5.01Document1 pageCorrective Action Report (CAR) : Form1001 CAR-KMR - e Page 1 of 1 Revision: 6 Reference: Organizational Instruction 8.5.01JOECOOL67No ratings yet

- Book 1 - Lesson 1 - HometownDocument6 pagesBook 1 - Lesson 1 - Hometown16SpeakNo ratings yet

- Math - English A Four-Week Recovery Program in Schools Grade 3Document43 pagesMath - English A Four-Week Recovery Program in Schools Grade 3Norma Najem100% (1)

- DivergentDocument3 pagesDivergentsasingNo ratings yet

- MPG Engineering and Manufacturing Software Market Brief - September 2022Document11 pagesMPG Engineering and Manufacturing Software Market Brief - September 2022joeNo ratings yet

- Crusader Communicator: "Safer at Home" Edition #5: Sheboygan Lutheran High SchoolDocument7 pagesCrusader Communicator: "Safer at Home" Edition #5: Sheboygan Lutheran High SchoolMatt ThielNo ratings yet

- Documents - Pub Sharir Kriya Ayurvedic Physiology InstrumentsDocument137 pagesDocuments - Pub Sharir Kriya Ayurvedic Physiology InstrumentsRAMESH SANAPNo ratings yet

- Test 05Document87 pagesTest 05MenaNo ratings yet

- When Key Employees ClashDocument4 pagesWhen Key Employees ClashRowell DizonNo ratings yet

- Write A Short Note On Object Oriented MethodologyDocument5 pagesWrite A Short Note On Object Oriented Methodologycokog41585No ratings yet

- SOP - Ready Mix Annual Facility AuditDocument2 pagesSOP - Ready Mix Annual Facility AuditTri widiyah VitantiNo ratings yet

- Mata PadmavatiDocument2 pagesMata Padmavatinkhera.hecateNo ratings yet

- MCQ Question Answers Class 11 Physics Chapter 4 Motion in A PlaneDocument8 pagesMCQ Question Answers Class 11 Physics Chapter 4 Motion in A PlaneDisha Tripathi - 10-ENo ratings yet

- 30 Data SheetDocument3 pages30 Data SheetGermán AndrésNo ratings yet

- Maths Unit 7 - J3 and J4Document2 pagesMaths Unit 7 - J3 and J4CynUlauNo ratings yet

- Weight and Mass SEDocument5 pagesWeight and Mass SEGabriel LouimaNo ratings yet

- ZnetworkDocument368 pagesZnetworkSaurabh SinghNo ratings yet

- Bonding CompositeDocument210 pagesBonding CompositeDinesh KumarNo ratings yet

- DR .Sharma Ji-05Document1 pageDR .Sharma Ji-05arunNo ratings yet

- PR2 Qtr1 Module 2Document50 pagesPR2 Qtr1 Module 2mememew suppasitNo ratings yet

- Junior Agronomist - On Contract: Gujarat State Fertilizers and Chemicals LTDDocument2 pagesJunior Agronomist - On Contract: Gujarat State Fertilizers and Chemicals LTDZayn AliNo ratings yet

- Src419X 192-Khz Stereo Asynchronous Sample-Rate Converters: 1 Features 3 DescriptionDocument45 pagesSrc419X 192-Khz Stereo Asynchronous Sample-Rate Converters: 1 Features 3 DescriptionNguyễn QuangNo ratings yet

- Information Management Systems, ObstetricalDocument12 pagesInformation Management Systems, ObstetricalLee ThoongNo ratings yet

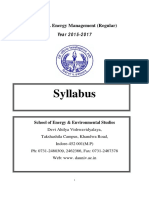

- Syllabus: M. Tech. Energy Management (Regular)Document28 pagesSyllabus: M. Tech. Energy Management (Regular)Digvijay SinghNo ratings yet

- The Union of Concerned ScientistsDocument13 pagesThe Union of Concerned ScientistsIlser ReineNo ratings yet

- Network Video Recorder: NVR308-R-B SeriesDocument4 pagesNetwork Video Recorder: NVR308-R-B Seriessyaf rudyNo ratings yet

- Siemens 3af 01Document24 pagesSiemens 3af 01Nhat Nguyen VanNo ratings yet

- On The Roll With The Environment: June 7, 20213 Min ReadDocument3 pagesOn The Roll With The Environment: June 7, 20213 Min Readkyzel colNo ratings yet

- SWE2007 - Fundamentals of Operating SystemsDocument6 pagesSWE2007 - Fundamentals of Operating SystemsmaneeshmogallpuNo ratings yet

- PR'S A-ZDocument65 pagesPR'S A-ZJesusNo ratings yet

On-Site FMEA Review Checklist Reverse FMEA Manufacturing Process

On-Site FMEA Review Checklist Reverse FMEA Manufacturing Process

Uploaded by

Jobs SteveOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

On-Site FMEA Review Checklist Reverse FMEA Manufacturing Process

On-Site FMEA Review Checklist Reverse FMEA Manufacturing Process

Uploaded by

Jobs SteveCopyright:

Available Formats

M2M006_B Rev.

1 - jun 2019

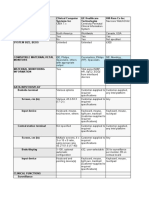

On-site FMEA review checklist

Reverse FMEA Date:

Manufacturing Process

Method leader:

Participants:

Workstation: Reference : Part name:

Operation: Component(s) reference:

Material:

Component (if relevant):

Rat. Comment:

1) Can a material / component reference error be generated? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

2) Can the operation be skipped / not performed? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

3) Can the operation be performed twice? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

4) Can the operation be performed at incorrect place on part? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

5) Can a part be deformed when ejected? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

6) Can a part be deformed when transferred to parts bin? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

7) If several parts manufactured, is there a risk of mixing them up in bin? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

8) Can manufacturing waste be mixed up with parts? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

9) Can manufacturing waste leave marks on parts? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

10) Can an unfinished part be mixed up with others? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

11) Can an isolated NC part be mixed up with others? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

12) Can a foreign part be mixed up with others? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

13) Can a part be contaminated? (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

14) Other: (yes/no)

If yes, can it be detected?

1: at workstation 2: downstream of process 3: not detected at site

Note: Does an adjustment / repair operation exist for this workstation?

If yes, conduct the on-site FMEA / reverse FMEA review also on this rework / repair workstation

Other risks Rat. Anti-error system

- material placed wrong way round / upside down

- absence of material coating

- marking (absence, readability, etc.)

- marking not acceptable for customer (problem with appearance)

- mislabelling (identification error)

Conclusion / follow-up required: Workstation monitored yes no => precautionary measure

Update FMEA

Implement precautionary measure

Modify monitoring plan

Modify other documents (to be specified)

Implement / modify / improve anti-error system (particularly for rating 3)

Date

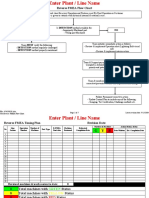

Production line

Operation

Workstation /

Team observed

observed

Product Ref.

Duration of

observation

time

Cycle

Name

Participants

REVERSE PFMEA - Activity report

Position

No. of unacceptable risks with

severity ≥ 9

No. acceptable risks with

severity ≥ 9

No. of unacceptable risks with

severity ≤ 8

No. of acceptable risks with

severity ≤ 8

before Reverse FMEA

Total no. of risks

No. of unacceptable risks with

severity ≥ 9

No. acceptable risks with

severity ≥ 9

No. of unacceptable risks with

severity ≤ 8

No. of acceptable risks with

severity ≤ 8

after Reverse FMEA

Total no. of risks

0

Total no. of modifications

M2M006_C Rev.0 - jun 2019

You might also like

- Control Plan 1st Edition - AnalysisDocument9 pagesControl Plan 1st Edition - AnalysisYassin Serhani100% (4)

- Reverse PFMEA Worksheet 2Document1 pageReverse PFMEA Worksheet 2adochan92% (12)

- PFMEA Audit ChecklistDocument2 pagesPFMEA Audit Checklistadnans100% (3)

- SAFE LAUNCH ProcedureDocument2 pagesSAFE LAUNCH ProcedurePRAMOD88% (8)

- GP 12Document2 pagesGP 12Antonio Lara100% (9)

- Excel Tool Process Audit Services VDA 6.3 2016 en V1.0Document12 pagesExcel Tool Process Audit Services VDA 6.3 2016 en V1.0Roberto Barbosa100% (1)

- ANPQP Version 3.2 RevisionDocument33 pagesANPQP Version 3.2 RevisionFaby Mendoza50% (2)

- Audit Report VDA 6.3 Potential Analysis: Findings Question According VDA 6.3 Questionnaire 0 0Document1 pageAudit Report VDA 6.3 Potential Analysis: Findings Question According VDA 6.3 Questionnaire 0 0ssierro100% (2)

- Check List For FMEA Evaluation SupplierDocument7 pagesCheck List For FMEA Evaluation SupplierMiroslaw ONo ratings yet

- Reverse PFMEADocument5 pagesReverse PFMEASantosh BallalNo ratings yet

- Reverse FMEA PSADocument53 pagesReverse FMEA PSABES100% (9)

- Layered Process Audits TemplateDocument3 pagesLayered Process Audits TemplatemajidrashidNo ratings yet

- BIQS 2017 Slide ShowDocument202 pagesBIQS 2017 Slide Showismael cantuNo ratings yet

- VDA 6.3 Standard Questionnaire enDocument19 pagesVDA 6.3 Standard Questionnaire enFlorida Elena MitroiNo ratings yet

- Red Bin Analysis FormatDocument1 pageRed Bin Analysis FormatPRABHAT RANJAN50% (2)

- Pass Through CharacteristicsDocument10 pagesPass Through CharacteristicsmirosekNo ratings yet

- AIAG-VDA DFMEA Final ExamDocument10 pagesAIAG-VDA DFMEA Final ExamMoham'medAlthafAs'lam100% (2)

- IATF Process Audit Check Sheet FormatDocument14 pagesIATF Process Audit Check Sheet Formatukavathekar71% (7)

- VDA FMEA TemplateDocument53 pagesVDA FMEA Templatewatna0% (2)

- Daimler-Chrysler Layered Process AuditsDocument27 pagesDaimler-Chrysler Layered Process AuditsR JNo ratings yet

- Automotive Process Approach Audit For IATF 16949 - 2016Document4 pagesAutomotive Process Approach Audit For IATF 16949 - 2016isolongNo ratings yet

- Questions Process Audit: P2. Project ManagementDocument11 pagesQuestions Process Audit: P2. Project ManagementR JNo ratings yet

- Customer Specific Requirements MatrixDocument4 pagesCustomer Specific Requirements Matrixhmp9071% (7)

- CQI-11 Plating 20177Document24 pagesCQI-11 Plating 20177Jose Raul Aquino Herrera0% (1)

- NPD Check SheetDocument6 pagesNPD Check Sheets.charlie50% (2)

- Guidelines For Technical Material: Unified English BrailleDocument93 pagesGuidelines For Technical Material: Unified English Brailleluana4No ratings yet

- Reverse FMEA ProcessDocument7 pagesReverse FMEA ProcessYayi MartinezNo ratings yet

- Example To Be Adapted To Manufacturing Process (Technology) and Number of Operations Per WorkstationDocument1 pageExample To Be Adapted To Manufacturing Process (Technology) and Number of Operations Per WorkstationTHANGNo ratings yet

- AIAG-VDA PFMEA Template For Activity - (Delegate)Document38 pagesAIAG-VDA PFMEA Template For Activity - (Delegate)nadia_naaz90No ratings yet

- Reverse FMEADocument27 pagesReverse FMEAJobs Steve100% (2)

- Has Introduced The First International Guide On Failure Mode and Effects Analysis (FMEA)Document2 pagesHas Introduced The First International Guide On Failure Mode and Effects Analysis (FMEA)Ionut Eduard100% (2)

- CD6 Prototype Control PlanDocument3 pagesCD6 Prototype Control Planmpedraza-1No ratings yet

- APQP MatrixDocument4 pagesAPQP MatrixVikas KashyapNo ratings yet

- Pfmea - Aiag-VdaDocument108 pagesPfmea - Aiag-VdaGLAUCIO DOS SANTOS SILVANo ratings yet

- Reverse Fmea: AMDEC InverséeDocument12 pagesReverse Fmea: AMDEC InverséeMoez Aloui100% (2)

- P!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Document14 pagesP!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Duho ConsultoresNo ratings yet

- CSR Matrix For RefDocument6 pagesCSR Matrix For RefBard Z8No ratings yet

- Special Characteristics PDFDocument11 pagesSpecial Characteristics PDFKristof MCNo ratings yet

- Sample of PM DiagramDocument1 pageSample of PM DiagramKarim HakimNo ratings yet

- Overview - FMEA - AIAG - VDADocument1 pageOverview - FMEA - AIAG - VDAvenkatesh vajarapu100% (1)

- BIQ-S AuditDocument13 pagesBIQ-S AuditAngie Guerrero100% (1)

- Cqi 20 Summary PDFDocument30 pagesCqi 20 Summary PDFR J100% (1)

- Apqp VolvoDocument7 pagesApqp Volvofdsa01No ratings yet

- Annexure-1 Customer Specific Requirement MatrixDocument5 pagesAnnexure-1 Customer Specific Requirement MatrixSunil Shrivastava67% (3)

- IATF 16949 2016 Gap ToolDocument353 pagesIATF 16949 2016 Gap ToolOziel Cardenas33% (6)

- Iatf Process Audit Check Sheet FormatDocument14 pagesIatf Process Audit Check Sheet FormatPuspavathi S Rama NaiduNo ratings yet

- Aiag & Vda Pfmea Form (1st Edition 2019)Document10 pagesAiag & Vda Pfmea Form (1st Edition 2019)Gurcan SayaralNo ratings yet

- Oposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseDocument1 pageOposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseSethasan SrikochNo ratings yet

- Advanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial StageDocument6 pagesAdvanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial Stagerajesh sharma100% (3)

- PPAP 4th. EditionDocument75 pagesPPAP 4th. EditionGilberto FloresNo ratings yet

- Pfmea SopDocument9 pagesPfmea SopAbhijit DasNo ratings yet

- CQI-12v2: Special Process: Coating System AssessmentDocument36 pagesCQI-12v2: Special Process: Coating System AssessmentHoang TanNo ratings yet

- PFMEA AuditingDocument18 pagesPFMEA AuditingelevendotNo ratings yet

- Wi SPCDocument4 pagesWi SPCSujeet Kumar100% (1)

- 06) - Fmea For 11190722 - DDocument192 pages06) - Fmea For 11190722 - DMONISHRAJNo ratings yet

- Layered Audit ChecklistDocument4 pagesLayered Audit ChecklistNavnath TamhaneNo ratings yet

- APQP Sample FormatDocument32 pagesAPQP Sample FormatManigandan RNo ratings yet

- AIAG & VDA PFMEA FormatDocument1 pageAIAG & VDA PFMEA Formatmahesh KhatalNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- Corrective Action Report (CAR) : Form1001 CAR-KMR - e Page 1 of 1 Revision: 6 Reference: Organizational Instruction 8.5.01Document1 pageCorrective Action Report (CAR) : Form1001 CAR-KMR - e Page 1 of 1 Revision: 6 Reference: Organizational Instruction 8.5.01JOECOOL67No ratings yet

- Book 1 - Lesson 1 - HometownDocument6 pagesBook 1 - Lesson 1 - Hometown16SpeakNo ratings yet

- Math - English A Four-Week Recovery Program in Schools Grade 3Document43 pagesMath - English A Four-Week Recovery Program in Schools Grade 3Norma Najem100% (1)

- DivergentDocument3 pagesDivergentsasingNo ratings yet

- MPG Engineering and Manufacturing Software Market Brief - September 2022Document11 pagesMPG Engineering and Manufacturing Software Market Brief - September 2022joeNo ratings yet

- Crusader Communicator: "Safer at Home" Edition #5: Sheboygan Lutheran High SchoolDocument7 pagesCrusader Communicator: "Safer at Home" Edition #5: Sheboygan Lutheran High SchoolMatt ThielNo ratings yet

- Documents - Pub Sharir Kriya Ayurvedic Physiology InstrumentsDocument137 pagesDocuments - Pub Sharir Kriya Ayurvedic Physiology InstrumentsRAMESH SANAPNo ratings yet

- Test 05Document87 pagesTest 05MenaNo ratings yet

- When Key Employees ClashDocument4 pagesWhen Key Employees ClashRowell DizonNo ratings yet

- Write A Short Note On Object Oriented MethodologyDocument5 pagesWrite A Short Note On Object Oriented Methodologycokog41585No ratings yet

- SOP - Ready Mix Annual Facility AuditDocument2 pagesSOP - Ready Mix Annual Facility AuditTri widiyah VitantiNo ratings yet

- Mata PadmavatiDocument2 pagesMata Padmavatinkhera.hecateNo ratings yet

- MCQ Question Answers Class 11 Physics Chapter 4 Motion in A PlaneDocument8 pagesMCQ Question Answers Class 11 Physics Chapter 4 Motion in A PlaneDisha Tripathi - 10-ENo ratings yet

- 30 Data SheetDocument3 pages30 Data SheetGermán AndrésNo ratings yet

- Maths Unit 7 - J3 and J4Document2 pagesMaths Unit 7 - J3 and J4CynUlauNo ratings yet

- Weight and Mass SEDocument5 pagesWeight and Mass SEGabriel LouimaNo ratings yet

- ZnetworkDocument368 pagesZnetworkSaurabh SinghNo ratings yet

- Bonding CompositeDocument210 pagesBonding CompositeDinesh KumarNo ratings yet

- DR .Sharma Ji-05Document1 pageDR .Sharma Ji-05arunNo ratings yet

- PR2 Qtr1 Module 2Document50 pagesPR2 Qtr1 Module 2mememew suppasitNo ratings yet

- Junior Agronomist - On Contract: Gujarat State Fertilizers and Chemicals LTDDocument2 pagesJunior Agronomist - On Contract: Gujarat State Fertilizers and Chemicals LTDZayn AliNo ratings yet

- Src419X 192-Khz Stereo Asynchronous Sample-Rate Converters: 1 Features 3 DescriptionDocument45 pagesSrc419X 192-Khz Stereo Asynchronous Sample-Rate Converters: 1 Features 3 DescriptionNguyễn QuangNo ratings yet

- Information Management Systems, ObstetricalDocument12 pagesInformation Management Systems, ObstetricalLee ThoongNo ratings yet

- Syllabus: M. Tech. Energy Management (Regular)Document28 pagesSyllabus: M. Tech. Energy Management (Regular)Digvijay SinghNo ratings yet

- The Union of Concerned ScientistsDocument13 pagesThe Union of Concerned ScientistsIlser ReineNo ratings yet

- Network Video Recorder: NVR308-R-B SeriesDocument4 pagesNetwork Video Recorder: NVR308-R-B Seriessyaf rudyNo ratings yet

- Siemens 3af 01Document24 pagesSiemens 3af 01Nhat Nguyen VanNo ratings yet

- On The Roll With The Environment: June 7, 20213 Min ReadDocument3 pagesOn The Roll With The Environment: June 7, 20213 Min Readkyzel colNo ratings yet

- SWE2007 - Fundamentals of Operating SystemsDocument6 pagesSWE2007 - Fundamentals of Operating SystemsmaneeshmogallpuNo ratings yet

- PR'S A-ZDocument65 pagesPR'S A-ZJesusNo ratings yet