Professional Documents

Culture Documents

Magazine Conveyor 1 Adjustment Standard

Magazine Conveyor 1 Adjustment Standard

Uploaded by

Md. Hanif SanketCopyright:

Available Formats

You might also like

- Global Divide - North & SouthDocument13 pagesGlobal Divide - North & SouthJohn Carlo Faderon94% (31)

- ANSI:BIFMA E3 - Level® Sustainability Certification For Furniture SGSDocument2 pagesANSI:BIFMA E3 - Level® Sustainability Certification For Furniture SGSPaolo BartoliNo ratings yet

- Mastercard CaseStudyDocument20 pagesMastercard CaseStudyapi-3757737No ratings yet

- 417-Removing and Installing 7000Document3 pages417-Removing and Installing 7000Greg ReynekeNo ratings yet

- Dealer's Manual: (English)Document10 pagesDealer's Manual: (English)Rodney AtibulaNo ratings yet

- R Type Scraper InstallationDocument4 pagesR Type Scraper InstallationubabNo ratings yet

- Circular Machine Practical TrainingDocument70 pagesCircular Machine Practical TrainingLiyew WorkieNo ratings yet

- MSP300 0078 Conica 17Document1 pageMSP300 0078 Conica 17aktivrudarpNo ratings yet

- Replacement Plumb Bobs Manual ME 9868ADocument3 pagesReplacement Plumb Bobs Manual ME 9868A이지민No ratings yet

- Group 2 Removal and Installation of Unit: 1. MastDocument17 pagesGroup 2 Removal and Installation of Unit: 1. MastAndré TarginoNo ratings yet

- 小立式320E 说明书Manul of gummies packing machineDocument19 pages小立式320E 说明书Manul of gummies packing machineNataniel ChoqueNo ratings yet

- Group 2 Removal and Installation of Unit: 1. MastDocument21 pagesGroup 2 Removal and Installation of Unit: 1. MastAndré TarginoNo ratings yet

- 51Document19 pages51Cleber SouzaNo ratings yet

- Filatex Project - O & M MANUAL - VOLUME I OF IIDocument48 pagesFilatex Project - O & M MANUAL - VOLUME I OF IID.V.S.S Ram PrasadNo ratings yet

- Cradle 1 Adjustment Standard: 1-1 Compressed Air PressureDocument10 pagesCradle 1 Adjustment Standard: 1-1 Compressed Air PressureMd. Hanif SanketNo ratings yet

- Group 2 Removal and Installation of UnitDocument18 pagesGroup 2 Removal and Installation of UnitGIANNo ratings yet

- T1 Tension Break Alarm: Appearance/IssueDocument2 pagesT1 Tension Break Alarm: Appearance/IssueTushar SangamnerkarNo ratings yet

- Ridgid Precision Flaring Tools ManualDocument1 pageRidgid Precision Flaring Tools ManualmaftmutoNo ratings yet

- Level 4: CHOKING HAZARD: This Product Contains Small Parts and Is Not Intended For Children Under 3Document16 pagesLevel 4: CHOKING HAZARD: This Product Contains Small Parts and Is Not Intended For Children Under 3NoerNo ratings yet

- Removal & Assembly: 1. Guide Roller UnitDocument5 pagesRemoval & Assembly: 1. Guide Roller UnitRheana DomingoNo ratings yet

- QL5, DHD350: Disassembly Exploded ViewDocument1 pageQL5, DHD350: Disassembly Exploded ViewJORGE C. CHAO R.No ratings yet

- Qpro 8W EN Searcher.Document7 pagesQpro 8W EN Searcher.MdNo ratings yet

- Cleaver CI-03AT - 4+ż (Auto Rotation Blade) User Manual 0601 (Eng) PDFDocument2 pagesCleaver CI-03AT - 4+ż (Auto Rotation Blade) User Manual 0601 (Eng) PDFAli Yudi0% (1)

- Weight FeederDocument4 pagesWeight Feedercakhokhe100% (1)

- Vessel Pedestal Crane Student ManualDocument19 pagesVessel Pedestal Crane Student Manualabhibho12345100% (1)

- Belt AdjustmentDocument10 pagesBelt AdjustmentDaffa SaputraNo ratings yet

- HPB AssemblyDocument34 pagesHPB AssemblygulfengsolutionsNo ratings yet

- Janome MC9900 Sewing Machine Service ManualDocument41 pagesJanome MC9900 Sewing Machine Service ManualiliiexpugnansNo ratings yet

- 2012513单亮片英文说明书 -Ia User Manual for Sequin DeviceDocument5 pages2012513单亮片英文说明书 -Ia User Manual for Sequin DeviceMohamed NadirNo ratings yet

- CL608e/612e Mechanical AdjustmentsDocument15 pagesCL608e/612e Mechanical AdjustmentsLukáš KadeřábekNo ratings yet

- Perator'S Anual: Zero Turn Tractor Model NumbersDocument52 pagesPerator'S Anual: Zero Turn Tractor Model NumbersWoodrow DoughertyNo ratings yet

- Group 4 Attachment Holder: 1. RemovalDocument2 pagesGroup 4 Attachment Holder: 1. RemovalTaha RdmanNo ratings yet

- Singer 121D200A Service ManualDocument36 pagesSinger 121D200A Service ManualJulian EmpraNo ratings yet

- Conveyor Belt SafetyDocument7 pagesConveyor Belt SafetyAz CorkerNo ratings yet

- Power Failure of Plug Drop Off V-BELT Dropped OffDocument2 pagesPower Failure of Plug Drop Off V-BELT Dropped OffCharlton Benedict BernabeNo ratings yet

- End Cap Cross Bar: Actual Side Rails May Be DifferentDocument3 pagesEnd Cap Cross Bar: Actual Side Rails May Be Differentisrael rojelNo ratings yet

- 3gr-Fse-Em6-Drive BeltDocument3 pages3gr-Fse-Em6-Drive BeltHuỳnh Minh ĐứcNo ratings yet

- Janome Skyline S5 Sewing Machine Service ManualDocument38 pagesJanome Skyline S5 Sewing Machine Service ManualiliiexpugnansNo ratings yet

- exp-5(b) Tom lab pdfDocument2 pagesexp-5(b) Tom lab pdfmamtakanwar.mech26No ratings yet

- Drum Section: (Removal and Assembly)Document15 pagesDrum Section: (Removal and Assembly)Thinkplus TradingNo ratings yet

- Adjustment: 1. Parallelism of Timing RollerDocument6 pagesAdjustment: 1. Parallelism of Timing RollerRheana DomingoNo ratings yet

- Blade Control Handle: Need Help? Call 1-888-TO-HELP-UDocument2 pagesBlade Control Handle: Need Help? Call 1-888-TO-HELP-Upverlander9165No ratings yet

- Section VII: Coupling DesignDocument6 pagesSection VII: Coupling DesignFood burstNo ratings yet

- Telescopic Handlers: Service Training MalagaDocument4 pagesTelescopic Handlers: Service Training Malagaarturo laosNo ratings yet

- Lynx Cleaver Operating InstructionsDocument2 pagesLynx Cleaver Operating InstructionsMANCO MANKONYNo ratings yet

- RHOWPA Pole Mount: Installation GuideDocument2 pagesRHOWPA Pole Mount: Installation GuideunstrainNo ratings yet

- NEW QR Instruction ManualDocument2 pagesNEW QR Instruction ManualDante BindaNo ratings yet

- Product Information: 90558 Universal Tri-Max Elevator TripodDocument4 pagesProduct Information: 90558 Universal Tri-Max Elevator TripodAnonymous FLndM4ZNo ratings yet

- Group 2 Removal and Installation of Unit: 1. MastDocument14 pagesGroup 2 Removal and Installation of Unit: 1. MastAndré TarginoNo ratings yet

- ShaftpullerinstructionsDocument2 pagesShaftpullerinstructionsjitmarineNo ratings yet

- Elevator Belt and Splice Installation GuideDocument17 pagesElevator Belt and Splice Installation Guide4B Braime ComponentsNo ratings yet

- 16 PRDocument10 pages16 PRlone_anarchistNo ratings yet

- kx80 Página 173Document1 pagekx80 Página 173PabloNo ratings yet

- PUMA M4.3 DHD 340 TD40 Maint June 2018Document1 pagePUMA M4.3 DHD 340 TD40 Maint June 2018Marco LeivaNo ratings yet

- Group 2 Removal and Installation of Unit: 1. MastDocument15 pagesGroup 2 Removal and Installation of Unit: 1. MastAndré TarginoNo ratings yet

- Elevator Belt and Splice Installation GuideDocument17 pagesElevator Belt and Splice Installation GuideawfahNo ratings yet

- Rock BR InstructionsDocument8 pagesRock BR Instructionsborn2vetteNo ratings yet

- Electric Chainsaw: Instruction ManualDocument10 pagesElectric Chainsaw: Instruction Manualshabab_14No ratings yet

- Instruction Manual AK-157Document10 pagesInstruction Manual AK-157Kalim KamNo ratings yet

- Instruction Manual: Spring BalancerDocument7 pagesInstruction Manual: Spring Balancerjaskaran singhNo ratings yet

- Basic of LoomDocument9 pagesBasic of LoomShantnu MittalNo ratings yet

- Normativa Técnica Salvadoreña de AccesibilidadDocument2 pagesNormativa Técnica Salvadoreña de AccesibilidadmattkidoNo ratings yet

- PC Sensor: WarningDocument2 pagesPC Sensor: WarningMd. Hanif SanketNo ratings yet

- 1-1 Bal-Con / Balloon Breaker Height 1-2 Peg PositionDocument5 pages1-1 Bal-Con / Balloon Breaker Height 1-2 Peg PositionMd. Hanif SanketNo ratings yet

- Cradle 1 Adjustment Standard: 1-1 Compressed Air PressureDocument10 pagesCradle 1 Adjustment Standard: 1-1 Compressed Air PressureMd. Hanif SanketNo ratings yet

- Magazine: 1-1 Chute GuideDocument5 pagesMagazine: 1-1 Chute GuideMd. Hanif SanketNo ratings yet

- Upper Yarn Sensor 1 Adjustment Standard: 1-1 VOS SettingsDocument2 pagesUpper Yarn Sensor 1 Adjustment Standard: 1-1 VOS SettingsMd. Hanif SanketNo ratings yet

- Drum 1 Adjustment Standard: 1-1 Removing & Mounting The DrumDocument4 pagesDrum 1 Adjustment Standard: 1-1 Removing & Mounting The DrumMd. Hanif SanketNo ratings yet

- Re-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionDocument4 pagesRe-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionMd. Hanif SanketNo ratings yet

- Adjustment Standards & ManitenanceDocument24 pagesAdjustment Standards & ManitenanceMd. Hanif SanketNo ratings yet

- Suction Mouth 1 Adjustment Standard: 1-1 ParallelismDocument4 pagesSuction Mouth 1 Adjustment Standard: 1-1 ParallelismMd. Hanif SanketNo ratings yet

- Air SplicerDocument11 pagesAir SplicerMd. Hanif SanketNo ratings yet

- GSRTCDocument1 pageGSRTCHeena RathodNo ratings yet

- Chapter 5 - Introduction To Macroeconomics WMNDocument24 pagesChapter 5 - Introduction To Macroeconomics WMNNur IrfanNo ratings yet

- Econ Ua 1 Syllabus F2018 PDFDocument4 pagesEcon Ua 1 Syllabus F2018 PDFSally HeNo ratings yet

- Madurai District Co-Operative Milk Producers' Union LTD: About UsDocument3 pagesMadurai District Co-Operative Milk Producers' Union LTD: About UsSaravana KumarNo ratings yet

- Communist Manifesto PDF FullDocument1 pageCommunist Manifesto PDF FullJeremyNo ratings yet

- Assignment On Coca ColaDocument11 pagesAssignment On Coca ColaΛδΙτλά ΧοΗηηίε100% (2)

- PFMS Transaction Details Sr. No. DDO Name Account No Ifsc Code Id Amount Scroll Status Beneficiary NameDocument18 pagesPFMS Transaction Details Sr. No. DDO Name Account No Ifsc Code Id Amount Scroll Status Beneficiary Nameajay kumarNo ratings yet

- Unilever in India - Project ShaktiDocument4 pagesUnilever in India - Project ShaktiRafaa Dalvi0% (1)

- Maria Flor M. Pabelonia: Filipino EntrepreneursDocument3 pagesMaria Flor M. Pabelonia: Filipino EntrepreneursMaria Flor PabeloniaNo ratings yet

- Final AssignmentDocument15 pagesFinal AssignmentUttam DwaNo ratings yet

- (Hond) Managing Corporate Social Responsibility inDocument280 pages(Hond) Managing Corporate Social Responsibility inDr. Keivan simetgoNo ratings yet

- Eiteman PPT CH06Document39 pagesEiteman PPT CH06DiegoFradeNo ratings yet

- Project SummaryDocument6 pagesProject SummaryAmos OnhanNo ratings yet

- Sustainable Design N Constn - 2nd Penang Bridge-PUODocument75 pagesSustainable Design N Constn - 2nd Penang Bridge-PUORakesh Kapoor100% (3)

- Plant LocationDocument19 pagesPlant Locationaditig2286% (7)

- Project List Steel PlantsDocument33 pagesProject List Steel PlantsRoch battousaiNo ratings yet

- Salvatore Ch03Document30 pagesSalvatore Ch03tadesse-w100% (1)

- Bank of The South An Alternative To The IMF World BankDocument45 pagesBank of The South An Alternative To The IMF World BankCADTMNo ratings yet

- Orld Rade Rganization: United States - Sections 301-310 of The Trade Act OF 1974Document383 pagesOrld Rade Rganization: United States - Sections 301-310 of The Trade Act OF 1974Lei MorteraNo ratings yet

- Econ 11 Problem Set 4Document5 pagesEcon 11 Problem Set 4DadedidoduNo ratings yet

- Boletin Enero2018Document359 pagesBoletin Enero2018pedro cayoNo ratings yet

- The Political Economy of The Jat Agitation For Other Backward Class StatusDocument10 pagesThe Political Economy of The Jat Agitation For Other Backward Class StatusAnkit LatharNo ratings yet

- Assignment: Answer Q1Document6 pagesAssignment: Answer Q1kindye fekade75% (4)

- Liebherr Floating Transfer Solutions OverviewDocument16 pagesLiebherr Floating Transfer Solutions OverviewHùng Lê VănNo ratings yet

- Candlestick PattrenDocument2 pagesCandlestick Pattrentariqmahnoor42No ratings yet

- The Secret To True Happiness - Joyce MeyerDocument9 pagesThe Secret To True Happiness - Joyce MeyerRoger TrujilloNo ratings yet

- Grade 7 Fact and Opinion PDFDocument4 pagesGrade 7 Fact and Opinion PDFCristine Mae E. ArevaloNo ratings yet

Magazine Conveyor 1 Adjustment Standard

Magazine Conveyor 1 Adjustment Standard

Uploaded by

Md. Hanif SanketOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magazine Conveyor 1 Adjustment Standard

Magazine Conveyor 1 Adjustment Standard

Uploaded by

Md. Hanif SanketCopyright:

Available Formats

Chapter

5Ha Magazine Conveyor

Sec 1 Adjustment Standard

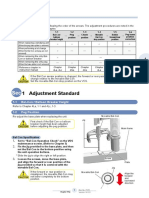

1-1 Conveyor Belt Tension

1. Loosen the screws (Qty. 4) on the side cover

on the drive end side, and remove the cover. Screw

2. Slightly loosen bolts A, (both sides) which fix

the tension pulley, and then loosen the nuts Tension Bolt A

pulley

(both sides) attached to bolts B.

3. Turn bolts B to tighten the belt tension.

* The belt tension ratio should be between 0.3% and

0.5%.

4. Refer to the tension marks on the belt surface

to adjust the tension. 1

Sec

5. Use bolts B to adjust the belt alignment so that

the belt is centered exactly in the middle when

it runs through the pulley.

Side cover Nut

Bolt B

Check the forward direction of the

belt as marked on the underside

of the belt to ensure that the belt

is attached correctly. If the belt is

attached backwards, the belt may

tear apart.

Tension measurement marks

(Pitch = 500 mm)

1 Doc No. P345

Chapter 5Ha Version 120401

1-2 Adjusting the Alignment on the Conveyor Motor Side

1. Slightly loosen bolts A (2 bolts: top and

bottom).

2. Loosen the nut and move bolt B forward or

backwards to adjust the belt alignment so that Bolt A

the belt is centered exactly in the middle when

it runs through the pulley.

Nut

Bolt B

1

1-3 Adjusting the Alignment for the Ascending Section of the Conveyor Belt Sec

1. Slightly loosen bolts A (Both sides: 2 bolts).

2. Loosen the nut (both sides) and move bolt B forward or backwards to adjust the belt alignment so

that the belt is centered exactly in the middle when it runs through the pulley.

Ascending pulley

Bolt A

Nut Bolt B

2 Doc No. P345

Chapter 5Ha Version 120401

Sec 2 Maintenance

Perform regular inspections and cleaning following the table below to ensure that the magazine conveyor

functions properly.

Frequency Item Guideline

Weekly Conveyor brush Clean the conveyor, wire spring and rotating brushes

Monthly Yarn waste in pulley Clean the yarn waste around the pulley

Conveyor Brush Cleaning

Any yarn waste or cotton fly that builds up on the conveyor brush can lead to motor damage and belt cracking.

● Drive end side ● Ascending side

Wire spring brush

2

Sec

Rotating brush

Conveyor

brush

Yarn Waste in Pulley Cleaning

Any yarn waste or cotton fly that builds up around the pulley or the jack bolt can lead to motor damage and belt

cracking.

● Drive end side ● Motor side

Pulley

Jack bolt

3 Doc No. P345

Chapter 5Ha Version 130401

Sec 3 Consumables

If the parts below are worn causing a failure or problem, replace the worn part or parts with a new one.

Conveyor belt

3

Sec

Conveyor brush

Conveyor drive belt (tube type)

Ascending conveyor rotating brush

Ascending conveyor belt

4 Doc No. P345

Chapter 5Ha Version 120401

You might also like

- Global Divide - North & SouthDocument13 pagesGlobal Divide - North & SouthJohn Carlo Faderon94% (31)

- ANSI:BIFMA E3 - Level® Sustainability Certification For Furniture SGSDocument2 pagesANSI:BIFMA E3 - Level® Sustainability Certification For Furniture SGSPaolo BartoliNo ratings yet

- Mastercard CaseStudyDocument20 pagesMastercard CaseStudyapi-3757737No ratings yet

- 417-Removing and Installing 7000Document3 pages417-Removing and Installing 7000Greg ReynekeNo ratings yet

- Dealer's Manual: (English)Document10 pagesDealer's Manual: (English)Rodney AtibulaNo ratings yet

- R Type Scraper InstallationDocument4 pagesR Type Scraper InstallationubabNo ratings yet

- Circular Machine Practical TrainingDocument70 pagesCircular Machine Practical TrainingLiyew WorkieNo ratings yet

- MSP300 0078 Conica 17Document1 pageMSP300 0078 Conica 17aktivrudarpNo ratings yet

- Replacement Plumb Bobs Manual ME 9868ADocument3 pagesReplacement Plumb Bobs Manual ME 9868A이지민No ratings yet

- Group 2 Removal and Installation of Unit: 1. MastDocument17 pagesGroup 2 Removal and Installation of Unit: 1. MastAndré TarginoNo ratings yet

- 小立式320E 说明书Manul of gummies packing machineDocument19 pages小立式320E 说明书Manul of gummies packing machineNataniel ChoqueNo ratings yet

- Group 2 Removal and Installation of Unit: 1. MastDocument21 pagesGroup 2 Removal and Installation of Unit: 1. MastAndré TarginoNo ratings yet

- 51Document19 pages51Cleber SouzaNo ratings yet

- Filatex Project - O & M MANUAL - VOLUME I OF IIDocument48 pagesFilatex Project - O & M MANUAL - VOLUME I OF IID.V.S.S Ram PrasadNo ratings yet

- Cradle 1 Adjustment Standard: 1-1 Compressed Air PressureDocument10 pagesCradle 1 Adjustment Standard: 1-1 Compressed Air PressureMd. Hanif SanketNo ratings yet

- Group 2 Removal and Installation of UnitDocument18 pagesGroup 2 Removal and Installation of UnitGIANNo ratings yet

- T1 Tension Break Alarm: Appearance/IssueDocument2 pagesT1 Tension Break Alarm: Appearance/IssueTushar SangamnerkarNo ratings yet

- Ridgid Precision Flaring Tools ManualDocument1 pageRidgid Precision Flaring Tools ManualmaftmutoNo ratings yet

- Level 4: CHOKING HAZARD: This Product Contains Small Parts and Is Not Intended For Children Under 3Document16 pagesLevel 4: CHOKING HAZARD: This Product Contains Small Parts and Is Not Intended For Children Under 3NoerNo ratings yet

- Removal & Assembly: 1. Guide Roller UnitDocument5 pagesRemoval & Assembly: 1. Guide Roller UnitRheana DomingoNo ratings yet

- QL5, DHD350: Disassembly Exploded ViewDocument1 pageQL5, DHD350: Disassembly Exploded ViewJORGE C. CHAO R.No ratings yet

- Qpro 8W EN Searcher.Document7 pagesQpro 8W EN Searcher.MdNo ratings yet

- Cleaver CI-03AT - 4+ż (Auto Rotation Blade) User Manual 0601 (Eng) PDFDocument2 pagesCleaver CI-03AT - 4+ż (Auto Rotation Blade) User Manual 0601 (Eng) PDFAli Yudi0% (1)

- Weight FeederDocument4 pagesWeight Feedercakhokhe100% (1)

- Vessel Pedestal Crane Student ManualDocument19 pagesVessel Pedestal Crane Student Manualabhibho12345100% (1)

- Belt AdjustmentDocument10 pagesBelt AdjustmentDaffa SaputraNo ratings yet

- HPB AssemblyDocument34 pagesHPB AssemblygulfengsolutionsNo ratings yet

- Janome MC9900 Sewing Machine Service ManualDocument41 pagesJanome MC9900 Sewing Machine Service ManualiliiexpugnansNo ratings yet

- 2012513单亮片英文说明书 -Ia User Manual for Sequin DeviceDocument5 pages2012513单亮片英文说明书 -Ia User Manual for Sequin DeviceMohamed NadirNo ratings yet

- CL608e/612e Mechanical AdjustmentsDocument15 pagesCL608e/612e Mechanical AdjustmentsLukáš KadeřábekNo ratings yet

- Perator'S Anual: Zero Turn Tractor Model NumbersDocument52 pagesPerator'S Anual: Zero Turn Tractor Model NumbersWoodrow DoughertyNo ratings yet

- Group 4 Attachment Holder: 1. RemovalDocument2 pagesGroup 4 Attachment Holder: 1. RemovalTaha RdmanNo ratings yet

- Singer 121D200A Service ManualDocument36 pagesSinger 121D200A Service ManualJulian EmpraNo ratings yet

- Conveyor Belt SafetyDocument7 pagesConveyor Belt SafetyAz CorkerNo ratings yet

- Power Failure of Plug Drop Off V-BELT Dropped OffDocument2 pagesPower Failure of Plug Drop Off V-BELT Dropped OffCharlton Benedict BernabeNo ratings yet

- End Cap Cross Bar: Actual Side Rails May Be DifferentDocument3 pagesEnd Cap Cross Bar: Actual Side Rails May Be Differentisrael rojelNo ratings yet

- 3gr-Fse-Em6-Drive BeltDocument3 pages3gr-Fse-Em6-Drive BeltHuỳnh Minh ĐứcNo ratings yet

- Janome Skyline S5 Sewing Machine Service ManualDocument38 pagesJanome Skyline S5 Sewing Machine Service ManualiliiexpugnansNo ratings yet

- exp-5(b) Tom lab pdfDocument2 pagesexp-5(b) Tom lab pdfmamtakanwar.mech26No ratings yet

- Drum Section: (Removal and Assembly)Document15 pagesDrum Section: (Removal and Assembly)Thinkplus TradingNo ratings yet

- Adjustment: 1. Parallelism of Timing RollerDocument6 pagesAdjustment: 1. Parallelism of Timing RollerRheana DomingoNo ratings yet

- Blade Control Handle: Need Help? Call 1-888-TO-HELP-UDocument2 pagesBlade Control Handle: Need Help? Call 1-888-TO-HELP-Upverlander9165No ratings yet

- Section VII: Coupling DesignDocument6 pagesSection VII: Coupling DesignFood burstNo ratings yet

- Telescopic Handlers: Service Training MalagaDocument4 pagesTelescopic Handlers: Service Training Malagaarturo laosNo ratings yet

- Lynx Cleaver Operating InstructionsDocument2 pagesLynx Cleaver Operating InstructionsMANCO MANKONYNo ratings yet

- RHOWPA Pole Mount: Installation GuideDocument2 pagesRHOWPA Pole Mount: Installation GuideunstrainNo ratings yet

- NEW QR Instruction ManualDocument2 pagesNEW QR Instruction ManualDante BindaNo ratings yet

- Product Information: 90558 Universal Tri-Max Elevator TripodDocument4 pagesProduct Information: 90558 Universal Tri-Max Elevator TripodAnonymous FLndM4ZNo ratings yet

- Group 2 Removal and Installation of Unit: 1. MastDocument14 pagesGroup 2 Removal and Installation of Unit: 1. MastAndré TarginoNo ratings yet

- ShaftpullerinstructionsDocument2 pagesShaftpullerinstructionsjitmarineNo ratings yet

- Elevator Belt and Splice Installation GuideDocument17 pagesElevator Belt and Splice Installation Guide4B Braime ComponentsNo ratings yet

- 16 PRDocument10 pages16 PRlone_anarchistNo ratings yet

- kx80 Página 173Document1 pagekx80 Página 173PabloNo ratings yet

- PUMA M4.3 DHD 340 TD40 Maint June 2018Document1 pagePUMA M4.3 DHD 340 TD40 Maint June 2018Marco LeivaNo ratings yet

- Group 2 Removal and Installation of Unit: 1. MastDocument15 pagesGroup 2 Removal and Installation of Unit: 1. MastAndré TarginoNo ratings yet

- Elevator Belt and Splice Installation GuideDocument17 pagesElevator Belt and Splice Installation GuideawfahNo ratings yet

- Rock BR InstructionsDocument8 pagesRock BR Instructionsborn2vetteNo ratings yet

- Electric Chainsaw: Instruction ManualDocument10 pagesElectric Chainsaw: Instruction Manualshabab_14No ratings yet

- Instruction Manual AK-157Document10 pagesInstruction Manual AK-157Kalim KamNo ratings yet

- Instruction Manual: Spring BalancerDocument7 pagesInstruction Manual: Spring Balancerjaskaran singhNo ratings yet

- Basic of LoomDocument9 pagesBasic of LoomShantnu MittalNo ratings yet

- Normativa Técnica Salvadoreña de AccesibilidadDocument2 pagesNormativa Técnica Salvadoreña de AccesibilidadmattkidoNo ratings yet

- PC Sensor: WarningDocument2 pagesPC Sensor: WarningMd. Hanif SanketNo ratings yet

- 1-1 Bal-Con / Balloon Breaker Height 1-2 Peg PositionDocument5 pages1-1 Bal-Con / Balloon Breaker Height 1-2 Peg PositionMd. Hanif SanketNo ratings yet

- Cradle 1 Adjustment Standard: 1-1 Compressed Air PressureDocument10 pagesCradle 1 Adjustment Standard: 1-1 Compressed Air PressureMd. Hanif SanketNo ratings yet

- Magazine: 1-1 Chute GuideDocument5 pagesMagazine: 1-1 Chute GuideMd. Hanif SanketNo ratings yet

- Upper Yarn Sensor 1 Adjustment Standard: 1-1 VOS SettingsDocument2 pagesUpper Yarn Sensor 1 Adjustment Standard: 1-1 VOS SettingsMd. Hanif SanketNo ratings yet

- Drum 1 Adjustment Standard: 1-1 Removing & Mounting The DrumDocument4 pagesDrum 1 Adjustment Standard: 1-1 Removing & Mounting The DrumMd. Hanif SanketNo ratings yet

- Re-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionDocument4 pagesRe-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionMd. Hanif SanketNo ratings yet

- Adjustment Standards & ManitenanceDocument24 pagesAdjustment Standards & ManitenanceMd. Hanif SanketNo ratings yet

- Suction Mouth 1 Adjustment Standard: 1-1 ParallelismDocument4 pagesSuction Mouth 1 Adjustment Standard: 1-1 ParallelismMd. Hanif SanketNo ratings yet

- Air SplicerDocument11 pagesAir SplicerMd. Hanif SanketNo ratings yet

- GSRTCDocument1 pageGSRTCHeena RathodNo ratings yet

- Chapter 5 - Introduction To Macroeconomics WMNDocument24 pagesChapter 5 - Introduction To Macroeconomics WMNNur IrfanNo ratings yet

- Econ Ua 1 Syllabus F2018 PDFDocument4 pagesEcon Ua 1 Syllabus F2018 PDFSally HeNo ratings yet

- Madurai District Co-Operative Milk Producers' Union LTD: About UsDocument3 pagesMadurai District Co-Operative Milk Producers' Union LTD: About UsSaravana KumarNo ratings yet

- Communist Manifesto PDF FullDocument1 pageCommunist Manifesto PDF FullJeremyNo ratings yet

- Assignment On Coca ColaDocument11 pagesAssignment On Coca ColaΛδΙτλά ΧοΗηηίε100% (2)

- PFMS Transaction Details Sr. No. DDO Name Account No Ifsc Code Id Amount Scroll Status Beneficiary NameDocument18 pagesPFMS Transaction Details Sr. No. DDO Name Account No Ifsc Code Id Amount Scroll Status Beneficiary Nameajay kumarNo ratings yet

- Unilever in India - Project ShaktiDocument4 pagesUnilever in India - Project ShaktiRafaa Dalvi0% (1)

- Maria Flor M. Pabelonia: Filipino EntrepreneursDocument3 pagesMaria Flor M. Pabelonia: Filipino EntrepreneursMaria Flor PabeloniaNo ratings yet

- Final AssignmentDocument15 pagesFinal AssignmentUttam DwaNo ratings yet

- (Hond) Managing Corporate Social Responsibility inDocument280 pages(Hond) Managing Corporate Social Responsibility inDr. Keivan simetgoNo ratings yet

- Eiteman PPT CH06Document39 pagesEiteman PPT CH06DiegoFradeNo ratings yet

- Project SummaryDocument6 pagesProject SummaryAmos OnhanNo ratings yet

- Sustainable Design N Constn - 2nd Penang Bridge-PUODocument75 pagesSustainable Design N Constn - 2nd Penang Bridge-PUORakesh Kapoor100% (3)

- Plant LocationDocument19 pagesPlant Locationaditig2286% (7)

- Project List Steel PlantsDocument33 pagesProject List Steel PlantsRoch battousaiNo ratings yet

- Salvatore Ch03Document30 pagesSalvatore Ch03tadesse-w100% (1)

- Bank of The South An Alternative To The IMF World BankDocument45 pagesBank of The South An Alternative To The IMF World BankCADTMNo ratings yet

- Orld Rade Rganization: United States - Sections 301-310 of The Trade Act OF 1974Document383 pagesOrld Rade Rganization: United States - Sections 301-310 of The Trade Act OF 1974Lei MorteraNo ratings yet

- Econ 11 Problem Set 4Document5 pagesEcon 11 Problem Set 4DadedidoduNo ratings yet

- Boletin Enero2018Document359 pagesBoletin Enero2018pedro cayoNo ratings yet

- The Political Economy of The Jat Agitation For Other Backward Class StatusDocument10 pagesThe Political Economy of The Jat Agitation For Other Backward Class StatusAnkit LatharNo ratings yet

- Assignment: Answer Q1Document6 pagesAssignment: Answer Q1kindye fekade75% (4)

- Liebherr Floating Transfer Solutions OverviewDocument16 pagesLiebherr Floating Transfer Solutions OverviewHùng Lê VănNo ratings yet

- Candlestick PattrenDocument2 pagesCandlestick Pattrentariqmahnoor42No ratings yet

- The Secret To True Happiness - Joyce MeyerDocument9 pagesThe Secret To True Happiness - Joyce MeyerRoger TrujilloNo ratings yet

- Grade 7 Fact and Opinion PDFDocument4 pagesGrade 7 Fact and Opinion PDFCristine Mae E. ArevaloNo ratings yet