Professional Documents

Culture Documents

Suction Mouth 1 Adjustment Standard: 1-1 Parallelism

Suction Mouth 1 Adjustment Standard: 1-1 Parallelism

Uploaded by

Md. Hanif SanketOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Suction Mouth 1 Adjustment Standard: 1-1 Parallelism

Suction Mouth 1 Adjustment Standard: 1-1 Parallelism

Uploaded by

Md. Hanif SanketCopyright:

Available Formats

Chapter

4Ea Suction Mouth

Sec 1 Adjustment Standard

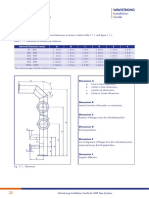

1-1 Parallelism

1. Attach the package on the side with the larger

diameter (dia. 160).

2. Loosen the bolt that fixes the suction mouth Φ160

and adjust the suction mouth so that it runs

parallel with the Φ160 mm size package.

Suction

* The tightening torque for the fixing bolt is between mouth and

20.0 and 25.0 N•m. package run

* To change the angle, always adjust the home

parallel to

each other

1

Sec

position of the suction mouth.

Fixing bolt

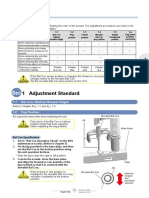

1-2 Arm Home Position

● After leveling the angle of the suction mouth,

adjust the home position. Hose band

If the suction mouth does not run parallel (not

level) with the package, the home position

cannot be adjusted correctly.

Perform the adjustment while the power is turned on.

If the mouth has been removed, refer to section 2-1 for Jig for

directions on how to mount the suction mouth. mounting

the suction

mouth

1. Remove the lower front panel.

2. Perform the “Suction mouth adjustment”

procedure, mount the arm, put it in the home Lower front

panel

position and fix it in place using the VOS

maintenance screen settings.

(Refer to Chapter 3)

3. Check the position using the suction mouth mounting jig, and loosen the hose band to make

adjustments.

* Adjustment the standard value for the arm home position

A = 124.3 ± 0.5 mm (forward and backward)

B = 4 ± 1 mm (right and left)

* As a general guideline, the tightening torque for the hose band is between 3.6 and 4.1 N•m.

B

A

1 Doc No. P225

Chapter 4Ea Version 120902

4. Set the arm in the home correction position, and adjust or correct the home position using the jig.

Press the alarm reset button (middle), and adjust the arm position using the top and bottom alarm reset

buttons so that the arm moves to the home correction position and lightly touches the jig for correcting the

home position.

Press down the alarm reset button (middle) for one second to return the arm to the standby position.

* The arm’s standard home position is ± 0.5 mm from the jig.

Jig for the suction mouth’s home position

The mouth and jig lightly touch each other.

1

Sec

Line up the front of the

jig protrusion with the

casing rib.

1-3 Comb

Loosen the screws and adjust.

When there are a lot of “Yarn End Find Errors,” the

problem can sometimes be fixed or improved by

adjusting the comb. Screw

● Standard position setting

Mount so that it fulfils the following dimensions.

Standard

A = 3 ± 0.5 mm

specification

C

Comb cover D (Comb cover) = 5 ± 0.5 mm B

specification D

E (Comb) = 0.5 ± 0.5 mm

● When using yarn that does not come out the

end smoothly

Pull out towards you in the direction indicated by “B,” A E

and fix the position. [Standard] [With comb cover]

● When frequent double yarn end finding occurs with the yarn

Push back all the way in the direction indicated by “C,” and fix the position.

1-4 VOS Settings

The VOS settings are listed below. Change the setting conditions when necessary.

For standard use, select “STD” (Value range: -10 to STD to +10)

* Set a value closer to +10 to adjust the suction mouth position closer to the

Suction Mouth Proximity

package, and set a value closer to -10 to adjust the suction mouth position

further away from the package.

Suction mouth motion mode Normally set to mode 1, but you can select from modes 1, 2 or 3

Normally set to STD, but you can select any level from -5 to STD

Suction force for mouth

* To reduce the suction force, set the level closer to -5.

2 Doc No. P225

Chapter 4Ea Version 150802

Sec 2 Maintenance

2-1 Mouth Attachment

Mount so that the cutout on the shaft is on top and the

The cutout faces up.

arm faces down.

Always adjust the home position for the arm (refer to

1-2).

The tightening torque for the hose band is between 3.6

and 4.1 N•m.

Hose band

2

Sec

2-2 Tightening the Timing Belt

Turn and adjust the motor.

Ensure that the belt is not too slack

or too taut. (Recommended tension:

30.2 – 40.6 N)

Malfunctions could occur if the

tension is out of the recommended

range.

2-3 Pulley Attachment

The tightening torque for the fixing bolt is between 16.0 and 18.0 N•m.

Fixing Bolt

3 Doc No. P225

Chapter 4Ea Version 150801

Sec 3 Consumables

If the parts below are worn causing a failure or problem, replace the worn part or parts with a new one.

Ring

3

Sec

DU bush Collar

Timing belt

4 Doc No. P225

Chapter 4Ea Version 150801

You might also like

- Arema FullDocument2,686 pagesArema Fulldiablopapanatas88% (8)

- Hino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Parts, PDFDocument3 pagesHino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Parts, PDFArnold Mhlanga50% (2)

- Washing Machine: Service ManualDocument57 pagesWashing Machine: Service ManualSantacruzmateo SantacruzmateoNo ratings yet

- Toplok Adapter: Adapter and Pin Installation Instructions For The T410/T417-70SV2 SeriesDocument12 pagesToplok Adapter: Adapter and Pin Installation Instructions For The T410/T417-70SV2 SeriesAndree Ayma NuñezNo ratings yet

- 2019-2-16 Fiber Cut Parts ListDocument50 pages2019-2-16 Fiber Cut Parts ListNguyen Van Hoi100% (3)

- LG wd-8016f 10160 65160 80160 Service-ManualDocument35 pagesLG wd-8016f 10160 65160 80160 Service-Manualkoutsour27No ratings yet

- Volleyball One Day League Certificate SampleDocument8 pagesVolleyball One Day League Certificate SampleJohn Paul George EguiaNo ratings yet

- Re-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionDocument4 pagesRe-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionMd. Hanif SanketNo ratings yet

- Procedure Replacement Linier Scale Yasda 2Document8 pagesProcedure Replacement Linier Scale Yasda 2rizki adha riyovaNo ratings yet

- MFL40322181Sapience 23inch CSA - Service Manual - 131014Document58 pagesMFL40322181Sapience 23inch CSA - Service Manual - 131014Cesar Calderon Gr100% (1)

- Quick Review of Damaon SystemDocument8 pagesQuick Review of Damaon SystemDr ZarniNo ratings yet

- Drill Grinder Instructions 0CECFEC7086BDDocument8 pagesDrill Grinder Instructions 0CECFEC7086BDMIGUEL ANGEL GARCIA BARAJASNo ratings yet

- Veritas Low-Angle Jack Plane 62Document7 pagesVeritas Low-Angle Jack Plane 62opilio100% (1)

- Dana Ring and Pinion PatternDocument2 pagesDana Ring and Pinion PatternMohammed gNo ratings yet

- Type CMR, Instalacion.Document4 pagesType CMR, Instalacion.Mario MarquezNo ratings yet

- Enduro 2Document2 pagesEnduro 2Srdjan MalinicNo ratings yet

- Calibration and Fault Finding and Fault Finding For Lal20X & Lal24X Dumpy Levels Dumpy LevelsDocument15 pagesCalibration and Fault Finding and Fault Finding For Lal20X & Lal24X Dumpy Levels Dumpy LevelsStephenNo ratings yet

- TI 07 006 DF AdjustmentDocument12 pagesTI 07 006 DF Adjustmenteko sunaryoNo ratings yet

- Phorovist 200 Instruction Manual ENDocument28 pagesPhorovist 200 Instruction Manual ENTerrence JonesNo ratings yet

- DamonquickstartguideDocument8 pagesDamonquickstartguideaNo ratings yet

- Control Buttons Notes: Adjustment NutDocument2 pagesControl Buttons Notes: Adjustment Nutluca ardenziNo ratings yet

- Cradle 1 Adjustment Standard: 1-1 Compressed Air PressureDocument10 pagesCradle 1 Adjustment Standard: 1-1 Compressed Air PressureMd. Hanif SanketNo ratings yet

- TRANZX INSTALL MANUAL 2x INTERNAL v0Document5 pagesTRANZX INSTALL MANUAL 2x INTERNAL v0dan nadNo ratings yet

- How To Service A Sewing MachineDocument102 pagesHow To Service A Sewing MachinelafeevNo ratings yet

- Magazine: 1-1 Chute GuideDocument5 pagesMagazine: 1-1 Chute GuideMd. Hanif SanketNo ratings yet

- Special Tool Users Manual (Amada Type) : Forming Tool Technical InformationDocument1 pageSpecial Tool Users Manual (Amada Type) : Forming Tool Technical InformationأبومحمدالزياتNo ratings yet

- Celmac - Wirquin - Instructions - Soft - Close - Quick - Release - Top - Fix - HingDocument4 pagesCelmac - Wirquin - Instructions - Soft - Close - Quick - Release - Top - Fix - HingMelvyn GambleNo ratings yet

- Rear Axle PatternDocument4 pagesRear Axle PatternRocker-Arm PinedaNo ratings yet

- Ohaus 310 311 ManualDocument8 pagesOhaus 310 311 ManualRick LinseNo ratings yet

- Veritas Bench PlanesDocument8 pagesVeritas Bench PlaneskeirgalNo ratings yet

- Wavistrong Installation Guide - Part38Document1 pageWavistrong Installation Guide - Part38gfhf dgdNo ratings yet

- Auto leveling feaure user guide(Z9V5Pro-PL-08N Sensor)-V2Document8 pagesAuto leveling feaure user guide(Z9V5Pro-PL-08N Sensor)-V2eleniltonRsNo ratings yet

- Precision Mini Lathe: To StartDocument2 pagesPrecision Mini Lathe: To StartdustinindanaNo ratings yet

- AM2 Adjustment Module: DatasheetDocument2 pagesAM2 Adjustment Module: Datasheetbenoit.devillersNo ratings yet

- 7400 Cem40 QSGDocument6 pages7400 Cem40 QSGsudhangshu_ghoseNo ratings yet

- Final-Installation Manual of Model 6510 148mm X 210mm @ 20230608Document8 pagesFinal-Installation Manual of Model 6510 148mm X 210mm @ 20230608Sai Ram KumarNo ratings yet

- Washing Machine: Service ManualDocument59 pagesWashing Machine: Service ManualHama AieaNo ratings yet

- Platinum 55eDocument18 pagesPlatinum 55eAndreiNo ratings yet

- LG WF-T6600PP - SvcMnls Ipul PDFDocument56 pagesLG WF-T6600PP - SvcMnls Ipul PDFMoh HamNo ratings yet

- On-Center Compliant Contacts Reference Guide REV ADocument5 pagesOn-Center Compliant Contacts Reference Guide REV AAlainckv MaligadNo ratings yet

- Platinum 70eDocument18 pagesPlatinum 70eAndreiNo ratings yet

- Alineamiento LaserDocument2 pagesAlineamiento LaserpatograndonNo ratings yet

- Quantel Optimis II Service Manual 51 60Document10 pagesQuantel Optimis II Service Manual 51 60Vladimir LevchenkoNo ratings yet

- Professional Series: PGP Installation: Arc Adjustments: Nozzle InstallationDocument2 pagesProfessional Series: PGP Installation: Arc Adjustments: Nozzle InstallationDaus AlexandruNo ratings yet

- Dial Indicators and Digital Indicators: Mounting A Dial IndicatorDocument1 pageDial Indicators and Digital Indicators: Mounting A Dial IndicatorozanNo ratings yet

- Yt 1000R 20081Document2 pagesYt 1000R 20081Ion CimirinschiNo ratings yet

- Hino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine PartsDocument3 pagesHino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Partszakki ahmadNo ratings yet

- Dealer's Manual: (English)Document10 pagesDealer's Manual: (English)Rodney AtibulaNo ratings yet

- KONE 3000 TranSys - Part Brake AdjustDocument9 pagesKONE 3000 TranSys - Part Brake Adjustthanggimme.phanNo ratings yet

- Important - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingDocument1 pageImportant - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingKonstantinos SynodinosNo ratings yet

- VZH-1820 CatalogDocument5 pagesVZH-1820 CatalogVinhNo ratings yet

- 605 00 139 FLOAT DPS Tuning Guide White Revb PDFDocument8 pages605 00 139 FLOAT DPS Tuning Guide White Revb PDFIanMarchantNo ratings yet

- Control Buttons Notes: Weaver LockDocument2 pagesControl Buttons Notes: Weaver Lockluca ardenziNo ratings yet

- XL FDD Tech 1Document2 pagesXL FDD Tech 1byokarinisNo ratings yet

- Rob S Snare Drum Tuning Guide PDFDocument6 pagesRob S Snare Drum Tuning Guide PDFFabioNo ratings yet

- V-Brake Adjustment Guide: Required ToolsDocument2 pagesV-Brake Adjustment Guide: Required ToolsStephane Le VuNo ratings yet

- MN4027 PDFDocument4 pagesMN4027 PDFAntonio Juan AntonioNo ratings yet

- Blade PDFDocument2 pagesBlade PDFMunyaradzi MarizaniNo ratings yet

- BASS SETUP - Yamaha Bass - ManualDocument7 pagesBASS SETUP - Yamaha Bass - ManualVirgil Popescu100% (1)

- Thin Wall and Solid Cube CalibrationDocument2 pagesThin Wall and Solid Cube CalibrationOmar AL-halawanyNo ratings yet

- Instruction Manual: Aluminum Site-Rite Hand Benders AND Iron Site-Rite Hand BendersDocument28 pagesInstruction Manual: Aluminum Site-Rite Hand Benders AND Iron Site-Rite Hand BendersAymeeenNo ratings yet

- Lavadora LG Wfs1338etd Wfs1358etdDocument59 pagesLavadora LG Wfs1338etd Wfs1358etdJohn SalsaNo ratings yet

- Mill Vise: InstructionsDocument1 pageMill Vise: InstructionsJF LuisNo ratings yet

- PC Sensor: WarningDocument2 pagesPC Sensor: WarningMd. Hanif SanketNo ratings yet

- 1-1 Bal-Con / Balloon Breaker Height 1-2 Peg PositionDocument5 pages1-1 Bal-Con / Balloon Breaker Height 1-2 Peg PositionMd. Hanif SanketNo ratings yet

- Cradle 1 Adjustment Standard: 1-1 Compressed Air PressureDocument10 pagesCradle 1 Adjustment Standard: 1-1 Compressed Air PressureMd. Hanif SanketNo ratings yet

- Magazine: 1-1 Chute GuideDocument5 pagesMagazine: 1-1 Chute GuideMd. Hanif SanketNo ratings yet

- Upper Yarn Sensor 1 Adjustment Standard: 1-1 VOS SettingsDocument2 pagesUpper Yarn Sensor 1 Adjustment Standard: 1-1 VOS SettingsMd. Hanif SanketNo ratings yet

- Drum 1 Adjustment Standard: 1-1 Removing & Mounting The DrumDocument4 pagesDrum 1 Adjustment Standard: 1-1 Removing & Mounting The DrumMd. Hanif SanketNo ratings yet

- Re-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionDocument4 pagesRe-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionMd. Hanif SanketNo ratings yet

- Adjustment Standards & ManitenanceDocument24 pagesAdjustment Standards & ManitenanceMd. Hanif SanketNo ratings yet

- Magazine Conveyor 1 Adjustment StandardDocument4 pagesMagazine Conveyor 1 Adjustment StandardMd. Hanif SanketNo ratings yet

- Air SplicerDocument11 pagesAir SplicerMd. Hanif SanketNo ratings yet

- Cantenna Building Instructions: Here's How To Build Your OwnDocument2 pagesCantenna Building Instructions: Here's How To Build Your OwnMohammed ShakilNo ratings yet

- Des-1008D: 10/100M Nway Fast Ethernet Switch Quick Installation GuideDocument13 pagesDes-1008D: 10/100M Nway Fast Ethernet Switch Quick Installation GuideverdessotoNo ratings yet

- Yale Crane Component - Crane Bridge Kits Thru 5 Ton ManualDocument24 pagesYale Crane Component - Crane Bridge Kits Thru 5 Ton ManualRizky MahendraNo ratings yet

- MPT Unit: MPT Power Connector - J4Document3 pagesMPT Unit: MPT Power Connector - J4Sandeep Reddy VellapalemNo ratings yet

- Spindle - Taper - Maintenance - VMCDocument3 pagesSpindle - Taper - Maintenance - VMCHải TạNo ratings yet

- Porton DKSDocument52 pagesPorton DKSHugo GarciaNo ratings yet

- Ethernet 802 3Document12 pagesEthernet 802 3manolo orozcoNo ratings yet

- LE2 LA2 Rotary SwitchesDocument22 pagesLE2 LA2 Rotary Switchesevangelion5010No ratings yet

- Mark Keterangan: Acuan Perencanaan Alat Kesehatan Kode Rs 1273106 Form f3Document28 pagesMark Keterangan: Acuan Perencanaan Alat Kesehatan Kode Rs 1273106 Form f3Pasca Sari TambaNo ratings yet

- VALVES - NotesDocument17 pagesVALVES - NotesPortifer Harrison Ray Mubanga100% (1)

- Tools List of BSL, Angul, OdishaDocument5 pagesTools List of BSL, Angul, OdishaSukhdeb BiswakarmaNo ratings yet

- Exp 1 Introduction UTMDocument6 pagesExp 1 Introduction UTMSusmit AloneNo ratings yet

- Hydraulic Retriever Catalogue 10kDocument2 pagesHydraulic Retriever Catalogue 10kAlfian JunaidiNo ratings yet

- RSM, RCS-Series Low Height Cylinders EN-GBDocument2 pagesRSM, RCS-Series Low Height Cylinders EN-GBErick Morales UrbinaNo ratings yet

- Joslyn Clark Fire Pump Controller Diesel Engine Type B SeriesDocument6 pagesJoslyn Clark Fire Pump Controller Diesel Engine Type B SeriesJimmy F HernandezNo ratings yet

- Flexible Coil Current Transformer Installation GuideDocument19 pagesFlexible Coil Current Transformer Installation GuideTrần Quang TuyênNo ratings yet

- FN - Engineering Guide - 115.26-EG3Document28 pagesFN - Engineering Guide - 115.26-EG3Michael FutolNo ratings yet

- SyTech ISPACE - ICD Telex ProductsDocument20 pagesSyTech ISPACE - ICD Telex ProductsSyTech CorporationNo ratings yet

- Lorentz Ps Manual enDocument48 pagesLorentz Ps Manual enOsama Wais100% (1)

- Travel Brake Valve Test and AdjustDocument6 pagesTravel Brake Valve Test and Adjustmuftah76100% (1)

- Yihua 992da DsDocument4 pagesYihua 992da DsquartNo ratings yet

- What Causes Cables To Get Heated Up and Melt in A Circuit?Document6 pagesWhat Causes Cables To Get Heated Up and Melt in A Circuit?Fawaaz KhurwolahNo ratings yet

- Lap 2Document3 pagesLap 2Hussein Alaa AltaiNo ratings yet

- MWU2904-01 Technical ManualDocument7 pagesMWU2904-01 Technical ManualptlsNo ratings yet

- Japan Radio Company JRCDocument8 pagesJapan Radio Company JRCvu minh tien100% (1)

- ATO Instructionsv11.8.23FINALDocument4 pagesATO Instructionsv11.8.23FINALHajj BornalesNo ratings yet