Professional Documents

Culture Documents

Steel Mill As Cast Billet and Rolled Bar Submission Process

Steel Mill As Cast Billet and Rolled Bar Submission Process

Uploaded by

Janak LalCopyright:

Available Formats

You might also like

- Aashto M 251 06 R2016 PDFDocument17 pagesAashto M 251 06 R2016 PDFBudhi Kurniawan75% (4)

- John Deere - 240DLC - EnglishDocument234 pagesJohn Deere - 240DLC - Englishjeeva50% (2)

- Literature Review On Cyber CrimeDocument4 pagesLiterature Review On Cyber CrimePaul Isaiah57% (7)

- Materials System SpecificationDocument23 pagesMaterials System SpecificationGovind JhaNo ratings yet

- Free-Cutting Brass Rod, Bar and Shapes For Use in Screw MachinesDocument5 pagesFree-Cutting Brass Rod, Bar and Shapes For Use in Screw Machinesanurag yadavNo ratings yet

- 02 Samss 012Document9 pages02 Samss 012slan79bisNo ratings yet

- Materials System SpecificationDocument11 pagesMaterials System Specificationimranb_001100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Bic PolicyDocument12 pagesBic PolicyRose JeffriesNo ratings yet

- Javascript CodesDocument3 pagesJavascript CodessmilesonuNo ratings yet

- Service Manual SOP 2nd Generation MP c3004 - 6004-mp 501 PDFDocument88 pagesService Manual SOP 2nd Generation MP c3004 - 6004-mp 501 PDFzoranNo ratings yet

- BHEL Creep Test Boiler Tube PDFDocument3 pagesBHEL Creep Test Boiler Tube PDFGopal RamalingamNo ratings yet

- GM6442MDocument5 pagesGM6442MFelipao DelacruzNo ratings yet

- Fairfield Atlas Limited Shinoli Metallurgical Technical Delivery Specification TDS No: TDS/ P 0110790 Rev No: 02 Page No: 1 of 3Document4 pagesFairfield Atlas Limited Shinoli Metallurgical Technical Delivery Specification TDS No: TDS/ P 0110790 Rev No: 02 Page No: 1 of 3Andras StegerNo ratings yet

- Expediting Report MIL-18AugDocument3 pagesExpediting Report MIL-18AugjasmineammaNo ratings yet

- BHEL Creep-Testing-Requirements-As-Per-Ibr-1526376134Document3 pagesBHEL Creep-Testing-Requirements-As-Per-Ibr-1526376134pradhankruhsnaNo ratings yet

- SAE J1993 - FEB2019 High-Carbon Cast-Steel GritDocument3 pagesSAE J1993 - FEB2019 High-Carbon Cast-Steel Gritmarcio de rossiNo ratings yet

- Saudi Aramco Stamdard 01-SAMSS-005 Cement Mortor Lining of Steel PipeDocument5 pagesSaudi Aramco Stamdard 01-SAMSS-005 Cement Mortor Lining of Steel PipeansarimehmoodNo ratings yet

- Materials System SpecificationDocument22 pagesMaterials System SpecificationAwais CheemaNo ratings yet

- Attachment 0Document39 pagesAttachment 0Azur MandžukićNo ratings yet

- B 93 - B 93m - 00 - Qjkzl0i5m00tukveDocument5 pagesB 93 - B 93m - 00 - Qjkzl0i5m00tukvemalika_00No ratings yet

- Materials System SpecificationDocument6 pagesMaterials System SpecificationAwais CheemaNo ratings yet

- Rate Analyses For ConcreteDocument9 pagesRate Analyses For ConcreteLOKESH PUNJNo ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationAbdullahNo ratings yet

- SAIC M 2012 (Structural Welding)Document30 pagesSAIC M 2012 (Structural Welding)rubda11100% (1)

- Silicon Metal: Standard Specification ForDocument2 pagesSilicon Metal: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- 12 SAMSS 018 - HighlightedDocument14 pages12 SAMSS 018 - HighlightedDhaval PatelNo ratings yet

- A247 06Document2 pagesA247 06Teby RodoNo ratings yet

- City of WinnipegDocument4 pagesCity of WinnipegNguyễn Kiều Yến ThanhNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Ajesh Kumar MuraleedharanNo ratings yet

- Irst 19 2012Document65 pagesIrst 19 2012krischaever100% (1)

- Irs T19-1994Document24 pagesIrs T19-1994vpmohammed0% (1)

- Is 4759 - 2006 - Hot-Dip Zinc Coatings On Structural Steel and Other Allied ProductsDocument9 pagesIs 4759 - 2006 - Hot-Dip Zinc Coatings On Structural Steel and Other Allied ProductsabhibmaneNo ratings yet

- A276A 276M.17 Norma Aceros Inoxidables Composicion PDFDocument8 pagesA276A 276M.17 Norma Aceros Inoxidables Composicion PDFalucard375No ratings yet

- Irst 19 1994 11 12 PDFDocument51 pagesIrst 19 1994 11 12 PDFRITES LTD. SITE OFFICE ,ROURKELANo ratings yet

- Stainless Steel Bars and Shapes: Standard Specification ForDocument8 pagesStainless Steel Bars and Shapes: Standard Specification ForkrkmurthyNo ratings yet

- Indian Standard Carbon Steel Billets, Blooms, Slabs Bars For Forgings - Specu3Catio'N (Fifih Revision)Document13 pagesIndian Standard Carbon Steel Billets, Blooms, Slabs Bars For Forgings - Specu3Catio'N (Fifih Revision)jbt1311No ratings yet

- Structural Steel-Microalloyed (Medium and High Strength Qualities) - Specification (Document16 pagesStructural Steel-Microalloyed (Medium and High Strength Qualities) - Specification (Achuthan Kannankutty100% (2)

- Draft - Is - Code PDFDocument12 pagesDraft - Is - Code PDFdbhawal6388No ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)mulong83No ratings yet

- 01 Samss 005Document5 pages01 Samss 005Moustafa BayoumiNo ratings yet

- Brass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForDocument6 pagesBrass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForOscar OriasNo ratings yet

- A159-83 R11 Automotive Gray Iron CastingsDocument5 pagesA159-83 R11 Automotive Gray Iron CastingsAnand KumarNo ratings yet

- Sampling, Testing and Tagging of Rebar Ir-17 PDFDocument3 pagesSampling, Testing and Tagging of Rebar Ir-17 PDFKidd Torno100% (1)

- Item SpecificationDocument10 pagesItem Specificationrskolate1965No ratings yet

- Door Frame TrialDocument1 pageDoor Frame TrialRakesh KumarNo ratings yet

- Production - Technology Lab Manual 181903Document29 pagesProduction - Technology Lab Manual 181903jhpatelNo ratings yet

- 3PS Gaw 005 - 06Document46 pages3PS Gaw 005 - 06Viveck VivekNo ratings yet

- Brass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForDocument6 pagesBrass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForedwinbadajosNo ratings yet

- Paint For Iron and Steel Work: Approval & Reception ProcedureDocument2 pagesPaint For Iron and Steel Work: Approval & Reception ProcedureDavidNo ratings yet

- ASTM A 240 2015b, Standard SpecificationDocument14 pagesASTM A 240 2015b, Standard SpecificationAyyappa k cNo ratings yet

- Rolled Zinc: Standard Specification ForDocument4 pagesRolled Zinc: Standard Specification ForCarlos HerreraNo ratings yet

- Astm A874Document3 pagesAstm A874DendeNo ratings yet

- LRPC StrandDocument3 pagesLRPC Strandanon_655956777100% (1)

- General Specification FOR Material, Fabrication and Installation of StructureDocument58 pagesGeneral Specification FOR Material, Fabrication and Installation of Structuredang_noex56% (9)

- 02 Samss 001Document6 pages02 Samss 001Florante NoblezaNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- New TestingDocument2 pagesNew TestingJanak LalNo ratings yet

- 2008 - Immersion Multi-Zone Ultrasonic Inspection System of Large-Diameter Special BilletsDocument9 pages2008 - Immersion Multi-Zone Ultrasonic Inspection System of Large-Diameter Special BilletsJanak LalNo ratings yet

- Hazard Communication Quiz-2: (B) DangerDocument3 pagesHazard Communication Quiz-2: (B) DangerJanak LalNo ratings yet

- Facts On IATFDocument3 pagesFacts On IATFJanak LalNo ratings yet

- DX DiagDocument33 pagesDX Diagbaiq nani ramdaniNo ratings yet

- Simple Chat Room AbstractDocument2 pagesSimple Chat Room Abstractvipin rawatNo ratings yet

- Q-000 - CPI (Checklist - SMO CS WUR MD C1668423)Document27 pagesQ-000 - CPI (Checklist - SMO CS WUR MD C1668423)Erick Savrinaldo100% (2)

- MC33078 Dual High-Speed Low-Noise Operational Amplifier: D (Soic), DGK (Msop), or P (Pdip) Package (Top View)Document24 pagesMC33078 Dual High-Speed Low-Noise Operational Amplifier: D (Soic), DGK (Msop), or P (Pdip) Package (Top View)Ravi JagtianiNo ratings yet

- JCCC HVAC SamHui PDFDocument60 pagesJCCC HVAC SamHui PDFSam C M HuiNo ratings yet

- ADAM'SDocument8 pagesADAM'SRixccy SirjooNo ratings yet

- VArisco Pumpe1Document76 pagesVArisco Pumpe1RamoNo ratings yet

- The SCUMM Manual - GlossaryDocument19 pagesThe SCUMM Manual - GlossaryMasami Mks WavestationNo ratings yet

- 18-08-Todoist Setup GuideDocument14 pages18-08-Todoist Setup GuideNickNo ratings yet

- 3512 B H.D All Rating 1750kVA Fiche TechniqueDocument9 pages3512 B H.D All Rating 1750kVA Fiche Techniquemajed al.madhajiNo ratings yet

- Universal Testing MachineDocument14 pagesUniversal Testing MachineMoreno, Leanne B.No ratings yet

- Cupluri DELTAAAAAADocument2 pagesCupluri DELTAAAAAAAlexTocuNo ratings yet

- Fidelity OFBS-FAQsDocument7 pagesFidelity OFBS-FAQsRichard Abalos BarilloNo ratings yet

- Accu VarDocument4 pagesAccu Varvjvijay88No ratings yet

- SIGAWMSDocument434 pagesSIGAWMSsoncoelhoNo ratings yet

- Zenlayer IP Advertisement For SerpongDocument4 pagesZenlayer IP Advertisement For SerpongAlthof HAFIZNo ratings yet

- KAT-A 1360 EKN-H Edition3 05.02.2021 ENDocument6 pagesKAT-A 1360 EKN-H Edition3 05.02.2021 ENkad-7No ratings yet

- Amateur Band PlanDocument19 pagesAmateur Band PlandeanNo ratings yet

- Methods of Testing Batteries For Solar PVDocument23 pagesMethods of Testing Batteries For Solar PVsamirdudhandeNo ratings yet

- Elic & Coll Input OutputDocument1 pageElic & Coll Input OutputdeshpandedhaneshNo ratings yet

- Material Borrow From F&DDocument1 pageMaterial Borrow From F&DRizkiHusniNo ratings yet

- Dell N4030 Wistron Dj1 Calpella Uma Rev x01Document82 pagesDell N4030 Wistron Dj1 Calpella Uma Rev x01Thanh Phuong LyNo ratings yet

- Java MLDocument7 pagesJava MLRahul ChauhanNo ratings yet

- MPT BBU ComparisonDocument7 pagesMPT BBU ComparisonRandy Alonzo BondocNo ratings yet

Steel Mill As Cast Billet and Rolled Bar Submission Process

Steel Mill As Cast Billet and Rolled Bar Submission Process

Uploaded by

Janak LalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Mill As Cast Billet and Rolled Bar Submission Process

Steel Mill As Cast Billet and Rolled Bar Submission Process

Uploaded by

Janak LalCopyright:

Available Formats

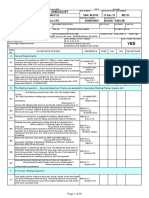

Steel Mill as cast Billet and Rolled bar submission Process

Scope : Submission & Inspection procedure of Billet / Bloom & Rolled/Coil bar to MTOR Mysore Lab for approval.

Objective : Approval on Steel mill / Specific Grade steel / Caster & Rolled bar size for new part development.

1) Purchase team will interact with Supplier development(SD) – Metallurgist about new part development Material Grade,

Steel mill , Caster & Rolled bar size details.

2) SD– Metallurgist will check for the steel mill which is approved in B1-A ( Pre-qualified Vendor list ).

3) If steel mill name is not listed in the B-1-A list , SD-Metallurgist will share B1 specification & Steel mill Metallurgical

survey form to Steel mill.

4) Steel mill must fill steel mill Metallurgical survey form and send to MTOR ( SD India ) .

5) SD India will review the steel mill form and send it to Materials Engineering .

6) Materials engineering will review the steel mill survey form , provide feedback for further information if necessary , followed

by audit the steel mill .

7) Materials Engineering provides approval / Reject / Next steps for improvement .

8) After Materials Engineering approval , Steel mill will submit Billet / Bloom & Rolled bar sample to MTOR Mysore Lab for

approval as per the procedure defined in this std, along with the reports to SD India for review .The sample is to be

collected as First , Middle & Last from each strand of the selected steel grade .

9) For steel mill which is already listed in B1-A,Caster and Rolled bar for that particular grade approval is to be checked with

SD India. If not approved following procedure is applicable.

Example :

Fig-1: No. of strands taken as 3 ( A,B,C...) & No of blooms per strand considered as 10.(sample collection start ,

middle , end )

Prepared Approved Rev No. :- 02 Page :- 1 of 6

Dasi Sundar Kumar Ramakrishna T. 16 April 2020

10) Samples shall be of 25mm thickness & free of rust and surface imperfections as below in the picture (proper finish

Grinding is mandatory on both sides without turning marks) and dipped with RPO and leakproof packing

before sending to MTOR Mysore Lab.

Thickness

of 25mm

11) Samples should be identified properly with Heat number, Strand number, Billet / bloom number.

12) Rolled bar sample to be collected randomly and submitted to MTOR Mysore Lab of sample quantity 3 bars each

have length 300mm.

300mm

13) If the supply condition is in coil form, Coil sample to be collected randomly and submitted to MTOR Mysore Lab of

sample quantity 3 Nos each have length 300mm.

Prepared by Approved Rev No.:- 02 Page :- 2 of 6

Dasi Sundar Kumar Ramakrishna T. 16 April 2020

Steel Mill sample selection and Inspection Procedure

14) Before sending the Caster and Rolled bar samples to MTOR Mysore lab for approval. Steel mill must ensure that

particular Heat no. # which is being sent for approval is meeting the MTOR requirements as mentioned in std.B-1

(General Wrought Steel Standard) with latest revision level.

15) Macroscopic inspection has to be conducted by Steel mill and Supplier and the respective reports must be sent to

SD India for clearance of samples for shipment to MTOR Mysore lab.

15)The Caster / Rolled bar which are used (A2,A6,A9 as per e.g. defined in Fig -1) for cutting the samples should be

cut in the below defined procedure and sample should be checked at steel mill at defined locations(L1 &L2) and the

other samples should be clearly identified and sent to MTOR Mysore lab for inspection.

➢ Black portion is the Caster / Rolled bar end which needs to be discarded.

➢ Steel Mill should inspect at location( L1 ) identified with Red color as preliminary inspection on main caster

or rolled bar.

➢ 25mm thickness caster sample or 300mm rolled bar with Green color identified location should be cut &

Ground on both sides ( mandatory ) of the caster or Rolled bar . This sample is for MTOR test lab

verification and approval .

➢ Steel Mill should inspect at Location ( L2 ) with Red color as Secondary inspection on main caster or rolled

bar.

➢ Both Preliminary and secondary samples if meeting MTOR B-1 specification requirements , Pl. share macro

images with steel mill comments to SD India for review .

➢ If above samples are meeting the MTOR requirements , MTOR SD India will provide clearance to ship the

green color samples to MTOR Mysore lab for testing and approval.

Fig 2:Sample Inspection location on Caster /Rolled bar by Steel Mill

➢ The samples qty to be inspected by Steel mill relies on the Strands qty for example as defined in Fig-1. If

there are 3 strands all the 6 (A2,A6,A9,B2,B6,B9,C2,C6,C9)samples must be inspected by steel mill as

defined in Fig-2.

➢ For Rolled bars/Coils 3 random bars are selected and inspected by Steel Mill as defined in Fig-2.The

Green color identified area (300mm) ground on both surfaces sample is carefully identified and sent to

MTOR Mysore lab for inspection with RPO applied.

Prepared Approved Rev No. :- 02 Page :- 3 of 6

Dasi Sundar Kumar Ramakrishna T. 16 April 2020

Macro Inspection Procedure

Fig 3 :Process flow for Macro Inspection

Inspect the sample for any presence of defects as mentioned in B-1 or refer std ASTM E 381.

Prepared Verified Approved Rev No. :- 02 Page :- 4 of 6

Dasi Sundar Kumar Ramakrishna T. Ramakrishna T. 16 April 2020

Some common defects ref :

e.g. Linear Ruptures e.g. Pinholes e.g. Hinge crack

e.g. Dis cont. Hinge Crack

Prepared Approved Rev No. :- 02 Page :- 5 of 6

Dasi Sundar Kumar Ramakrishna T. 16 April 2020

NOT ACCEPTABLE ACCEPTABLE

**Refer B-1 for better understanding of Defects which are NOT ALLOWED in Strand and Bloom

Material Engg – Contact person

AP Region : Raghuram /Assumpta.

Revision History

Revision Date Change information

3 10/06/2020 Acceptable and unacceptable images included

2 16/04/2020 Steel Mill sample selection and Inspection procedure

1 22/12/2017 Coil samples submission requirements

0 13/2/2017 First release

Prepared Approved Rev No. :- 02 Page :- 6 of 6

Dasi Sundar Kumar Ramakrishna T. 16 April 2020

You might also like

- Aashto M 251 06 R2016 PDFDocument17 pagesAashto M 251 06 R2016 PDFBudhi Kurniawan75% (4)

- John Deere - 240DLC - EnglishDocument234 pagesJohn Deere - 240DLC - Englishjeeva50% (2)

- Literature Review On Cyber CrimeDocument4 pagesLiterature Review On Cyber CrimePaul Isaiah57% (7)

- Materials System SpecificationDocument23 pagesMaterials System SpecificationGovind JhaNo ratings yet

- Free-Cutting Brass Rod, Bar and Shapes For Use in Screw MachinesDocument5 pagesFree-Cutting Brass Rod, Bar and Shapes For Use in Screw Machinesanurag yadavNo ratings yet

- 02 Samss 012Document9 pages02 Samss 012slan79bisNo ratings yet

- Materials System SpecificationDocument11 pagesMaterials System Specificationimranb_001100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Bic PolicyDocument12 pagesBic PolicyRose JeffriesNo ratings yet

- Javascript CodesDocument3 pagesJavascript CodessmilesonuNo ratings yet

- Service Manual SOP 2nd Generation MP c3004 - 6004-mp 501 PDFDocument88 pagesService Manual SOP 2nd Generation MP c3004 - 6004-mp 501 PDFzoranNo ratings yet

- BHEL Creep Test Boiler Tube PDFDocument3 pagesBHEL Creep Test Boiler Tube PDFGopal RamalingamNo ratings yet

- GM6442MDocument5 pagesGM6442MFelipao DelacruzNo ratings yet

- Fairfield Atlas Limited Shinoli Metallurgical Technical Delivery Specification TDS No: TDS/ P 0110790 Rev No: 02 Page No: 1 of 3Document4 pagesFairfield Atlas Limited Shinoli Metallurgical Technical Delivery Specification TDS No: TDS/ P 0110790 Rev No: 02 Page No: 1 of 3Andras StegerNo ratings yet

- Expediting Report MIL-18AugDocument3 pagesExpediting Report MIL-18AugjasmineammaNo ratings yet

- BHEL Creep-Testing-Requirements-As-Per-Ibr-1526376134Document3 pagesBHEL Creep-Testing-Requirements-As-Per-Ibr-1526376134pradhankruhsnaNo ratings yet

- SAE J1993 - FEB2019 High-Carbon Cast-Steel GritDocument3 pagesSAE J1993 - FEB2019 High-Carbon Cast-Steel Gritmarcio de rossiNo ratings yet

- Saudi Aramco Stamdard 01-SAMSS-005 Cement Mortor Lining of Steel PipeDocument5 pagesSaudi Aramco Stamdard 01-SAMSS-005 Cement Mortor Lining of Steel PipeansarimehmoodNo ratings yet

- Materials System SpecificationDocument22 pagesMaterials System SpecificationAwais CheemaNo ratings yet

- Attachment 0Document39 pagesAttachment 0Azur MandžukićNo ratings yet

- B 93 - B 93m - 00 - Qjkzl0i5m00tukveDocument5 pagesB 93 - B 93m - 00 - Qjkzl0i5m00tukvemalika_00No ratings yet

- Materials System SpecificationDocument6 pagesMaterials System SpecificationAwais CheemaNo ratings yet

- Rate Analyses For ConcreteDocument9 pagesRate Analyses For ConcreteLOKESH PUNJNo ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationAbdullahNo ratings yet

- SAIC M 2012 (Structural Welding)Document30 pagesSAIC M 2012 (Structural Welding)rubda11100% (1)

- Silicon Metal: Standard Specification ForDocument2 pagesSilicon Metal: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- 12 SAMSS 018 - HighlightedDocument14 pages12 SAMSS 018 - HighlightedDhaval PatelNo ratings yet

- A247 06Document2 pagesA247 06Teby RodoNo ratings yet

- City of WinnipegDocument4 pagesCity of WinnipegNguyễn Kiều Yến ThanhNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Ajesh Kumar MuraleedharanNo ratings yet

- Irst 19 2012Document65 pagesIrst 19 2012krischaever100% (1)

- Irs T19-1994Document24 pagesIrs T19-1994vpmohammed0% (1)

- Is 4759 - 2006 - Hot-Dip Zinc Coatings On Structural Steel and Other Allied ProductsDocument9 pagesIs 4759 - 2006 - Hot-Dip Zinc Coatings On Structural Steel and Other Allied ProductsabhibmaneNo ratings yet

- A276A 276M.17 Norma Aceros Inoxidables Composicion PDFDocument8 pagesA276A 276M.17 Norma Aceros Inoxidables Composicion PDFalucard375No ratings yet

- Irst 19 1994 11 12 PDFDocument51 pagesIrst 19 1994 11 12 PDFRITES LTD. SITE OFFICE ,ROURKELANo ratings yet

- Stainless Steel Bars and Shapes: Standard Specification ForDocument8 pagesStainless Steel Bars and Shapes: Standard Specification ForkrkmurthyNo ratings yet

- Indian Standard Carbon Steel Billets, Blooms, Slabs Bars For Forgings - Specu3Catio'N (Fifih Revision)Document13 pagesIndian Standard Carbon Steel Billets, Blooms, Slabs Bars For Forgings - Specu3Catio'N (Fifih Revision)jbt1311No ratings yet

- Structural Steel-Microalloyed (Medium and High Strength Qualities) - Specification (Document16 pagesStructural Steel-Microalloyed (Medium and High Strength Qualities) - Specification (Achuthan Kannankutty100% (2)

- Draft - Is - Code PDFDocument12 pagesDraft - Is - Code PDFdbhawal6388No ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)mulong83No ratings yet

- 01 Samss 005Document5 pages01 Samss 005Moustafa BayoumiNo ratings yet

- Brass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForDocument6 pagesBrass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForOscar OriasNo ratings yet

- A159-83 R11 Automotive Gray Iron CastingsDocument5 pagesA159-83 R11 Automotive Gray Iron CastingsAnand KumarNo ratings yet

- Sampling, Testing and Tagging of Rebar Ir-17 PDFDocument3 pagesSampling, Testing and Tagging of Rebar Ir-17 PDFKidd Torno100% (1)

- Item SpecificationDocument10 pagesItem Specificationrskolate1965No ratings yet

- Door Frame TrialDocument1 pageDoor Frame TrialRakesh KumarNo ratings yet

- Production - Technology Lab Manual 181903Document29 pagesProduction - Technology Lab Manual 181903jhpatelNo ratings yet

- 3PS Gaw 005 - 06Document46 pages3PS Gaw 005 - 06Viveck VivekNo ratings yet

- Brass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForDocument6 pagesBrass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForedwinbadajosNo ratings yet

- Paint For Iron and Steel Work: Approval & Reception ProcedureDocument2 pagesPaint For Iron and Steel Work: Approval & Reception ProcedureDavidNo ratings yet

- ASTM A 240 2015b, Standard SpecificationDocument14 pagesASTM A 240 2015b, Standard SpecificationAyyappa k cNo ratings yet

- Rolled Zinc: Standard Specification ForDocument4 pagesRolled Zinc: Standard Specification ForCarlos HerreraNo ratings yet

- Astm A874Document3 pagesAstm A874DendeNo ratings yet

- LRPC StrandDocument3 pagesLRPC Strandanon_655956777100% (1)

- General Specification FOR Material, Fabrication and Installation of StructureDocument58 pagesGeneral Specification FOR Material, Fabrication and Installation of Structuredang_noex56% (9)

- 02 Samss 001Document6 pages02 Samss 001Florante NoblezaNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- New TestingDocument2 pagesNew TestingJanak LalNo ratings yet

- 2008 - Immersion Multi-Zone Ultrasonic Inspection System of Large-Diameter Special BilletsDocument9 pages2008 - Immersion Multi-Zone Ultrasonic Inspection System of Large-Diameter Special BilletsJanak LalNo ratings yet

- Hazard Communication Quiz-2: (B) DangerDocument3 pagesHazard Communication Quiz-2: (B) DangerJanak LalNo ratings yet

- Facts On IATFDocument3 pagesFacts On IATFJanak LalNo ratings yet

- DX DiagDocument33 pagesDX Diagbaiq nani ramdaniNo ratings yet

- Simple Chat Room AbstractDocument2 pagesSimple Chat Room Abstractvipin rawatNo ratings yet

- Q-000 - CPI (Checklist - SMO CS WUR MD C1668423)Document27 pagesQ-000 - CPI (Checklist - SMO CS WUR MD C1668423)Erick Savrinaldo100% (2)

- MC33078 Dual High-Speed Low-Noise Operational Amplifier: D (Soic), DGK (Msop), or P (Pdip) Package (Top View)Document24 pagesMC33078 Dual High-Speed Low-Noise Operational Amplifier: D (Soic), DGK (Msop), or P (Pdip) Package (Top View)Ravi JagtianiNo ratings yet

- JCCC HVAC SamHui PDFDocument60 pagesJCCC HVAC SamHui PDFSam C M HuiNo ratings yet

- ADAM'SDocument8 pagesADAM'SRixccy SirjooNo ratings yet

- VArisco Pumpe1Document76 pagesVArisco Pumpe1RamoNo ratings yet

- The SCUMM Manual - GlossaryDocument19 pagesThe SCUMM Manual - GlossaryMasami Mks WavestationNo ratings yet

- 18-08-Todoist Setup GuideDocument14 pages18-08-Todoist Setup GuideNickNo ratings yet

- 3512 B H.D All Rating 1750kVA Fiche TechniqueDocument9 pages3512 B H.D All Rating 1750kVA Fiche Techniquemajed al.madhajiNo ratings yet

- Universal Testing MachineDocument14 pagesUniversal Testing MachineMoreno, Leanne B.No ratings yet

- Cupluri DELTAAAAAADocument2 pagesCupluri DELTAAAAAAAlexTocuNo ratings yet

- Fidelity OFBS-FAQsDocument7 pagesFidelity OFBS-FAQsRichard Abalos BarilloNo ratings yet

- Accu VarDocument4 pagesAccu Varvjvijay88No ratings yet

- SIGAWMSDocument434 pagesSIGAWMSsoncoelhoNo ratings yet

- Zenlayer IP Advertisement For SerpongDocument4 pagesZenlayer IP Advertisement For SerpongAlthof HAFIZNo ratings yet

- KAT-A 1360 EKN-H Edition3 05.02.2021 ENDocument6 pagesKAT-A 1360 EKN-H Edition3 05.02.2021 ENkad-7No ratings yet

- Amateur Band PlanDocument19 pagesAmateur Band PlandeanNo ratings yet

- Methods of Testing Batteries For Solar PVDocument23 pagesMethods of Testing Batteries For Solar PVsamirdudhandeNo ratings yet

- Elic & Coll Input OutputDocument1 pageElic & Coll Input OutputdeshpandedhaneshNo ratings yet

- Material Borrow From F&DDocument1 pageMaterial Borrow From F&DRizkiHusniNo ratings yet

- Dell N4030 Wistron Dj1 Calpella Uma Rev x01Document82 pagesDell N4030 Wistron Dj1 Calpella Uma Rev x01Thanh Phuong LyNo ratings yet

- Java MLDocument7 pagesJava MLRahul ChauhanNo ratings yet

- MPT BBU ComparisonDocument7 pagesMPT BBU ComparisonRandy Alonzo BondocNo ratings yet