Professional Documents

Culture Documents

Research Base

Research Base

Uploaded by

karleth angelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Research Base

Research Base

Uploaded by

karleth angelCopyright:

Available Formats

© DEC 2021 | IRE Journals | Volume 5 Issue 6 | ISSN: 2456-8880

Banana Pseudo-Stem Face Masks as Post-Pandemic

Future Business Venture

JENNIFER A. CARAG

San Sebastian College Recoletos - Manila, Philippines

Abstract- The world’s constant combat towards in demand at the pinnacle of this pandemic. Massive

global issues such as climate change, pollution, waste from discarded PPE from the health-care

violence, security, terrorism, etc., all rooted from facilities and the general public is continually growing

danger inflicted activities or interests has taken its as we approach the post COVID stage.

toll accelerating our extinction. The list goes on and

in just a snap, we were all consumed by the infamous The Philippines is known as the second largest banana

COVID-19. This pneumonia-like disease has exporter in the world producing approximately 3.5

launched a global economic tsunami and disruption million metric tons of bananas annually. Bananas are

to our lives that was later on declared as a pandemic. considered the most useful and significant plant in the

With no available cure yet, there were few safety world. All parts of it like its fruit, flower bud, trunk,

measures practiced globally namely social leaves and pseudo-stem can be used for various

distancing, quarantine, and mass testing. In order to purposes. The banana pseudo-stem has natural

contain and avoid further spread of the virus, we cellulose fiber that is elastic that makes it suitable in

were forced to adapt to the new normal. Personal producing textiles, diapers, and even bank notes. Its

Protective Equipment (PPE) has become an eco-friendly attributes make it the best alternative for

inseparable part of our daily lives ergo, the increase an artificial polymer matrix which is a thermoplastic

in PPE production, which is considered inevitable, or a thermoset material generally known as glass

leads to a surge in global plastic waste. COVID-19 reinforced plastic (GRP).

waste has become a new form of pollution caused by

mass production of single-use PPE with no The worldwide production of plastic was recorded at

structured waste management that floods our ocean 367 million metric tons in 2020. The statistic shows

beds. Manufacturers are now looking for alternatives enormous opportunity for the utilization of cellulose

to decrease plastic waste and to shift to a more fiber as an alternative. With a soaring demand for face

sustainable and circular PPE ecosystem. masks as basic PPE, face masks made from

Philippines, as the second top exporter of bananas in pseudostem fiber are environmentally friendly as it

the world, would a banana pseudo-stem fiber be the can potentially decrease growing COVID-19 PPE

most promising business venture opportunity at post- waste, and economical as it supports job growth of

COVID stage? farmers.

Indexed Terms- Face mask, pollution, PPE, banana, II. STATEMENT OF THE PROBLEM

fiber, COVID-19, business venture

Our reliance on personal protective equipment (PPE)

I. INTRODUCTION as primary health-care supply to control the spread of

the virus consequently aggravate the global waste.

The world has been battling climate change caused by About 1200 percent increase in demand on medical

plastic pollution for years now. Into the bargain, the mask manufacturing was observed in December 2020

pandemic has further contributed to the current that leads to shortage to the general public. Most PPE

predicament. The use of Personal Protective is considered cheap, single-use, and contains ranges of

Equipment (PPE) such as disposable face masks, different plastics. They are not compostable and can

gloves, etc. serves as a new hygiene habit and last forever. The immortality of the plastics along with

protection against the virus resulting in 300% increase the sudden increase in PPE production has pushed

IRE 1703031 ICONIC RESEARCH AND ENGINEERING JOURNALS 74

© DEC 2021 | IRE Journals | Volume 5 Issue 6 | ISSN: 2456-8880

manufacturers and researchers to innovate material Acid and water afterwards. The soaked pile will be

science that can make disposable PPE such as masks, placed under sunlight for 1-2 days or for faster

gowns, and gloves reusable and eco-friendly. The production in 100°C to 120°C for 4-5 hours. It will be

approach involves exploring organic, renewable, bio- added to a starch solution and shaked multiple times.

based, recyclable materials such as banana plants. Banana fibers are chemically composed of 60%

cellulose, 19% hemicellulose, 5% lignin, and others

Over the past decades, the face mask has been the best making smaller solid biomass. Banana peels

protection against diseases. This is mandatory to all underwent pretreatment through thermal and medical

frontliners like health workers, police and people characterization, chemical and mechanical analysis,

related to health care even the general public to protect then dissolution methods like infrasound and

the face and nose from contamination. Its main cryogenic grinding to extract nano fibers to be used in

objective is to block viruses through droplet making masks. Nanocellulose from banana

transmission. One of the most important attributes of pseudostem has immense potential as bioplastic which

a face mask is its filtration ability. is recyclable and compostable.

Banana pseudostem fiber as sustainable PPE promises Face masks are usually made with 3 layers - an inner,

the future of reduced global waste but with the recent outer, and filter layer. Masks made from banana

advances in mask engineering, emerging discovery of pseudostems or biomasks went to filtration efficiency

new materials, etc., how marketable and sustainable tests that focused on air permeability, water

banana pseudostem is as a business venture at post absorbency, and water repellency. Moreover, its

pandemic? Moreover, what are its advantages and antibacterial properties, bacterial penetration and

disadvantages to consider? breathability. Mann-Whitney U Test was used to

measure the mentioned characteristics. It confirms 3-

III. COURSES OF ACTION layer or 4-layer biomask is favorable at a rate of 95 out

of 100 in terms of water repellency with a baseline of

Banana plants belong to the family of Musaceae that 70 out of 100, and air permeability of 0.001 compared

typically grow in tropical and subtropical countries of to baseline of 0.05. Given its high air permeability, the

South-east Asia. It is considered the most useful plant banana fiber filters can provide extra comfort in terms

as almost all of its parts can be exploited from its fruit, of breathability. However, it lacks efficacy on water

leaves, peel, leaves, stalk, flower to pseudo-stem for absorbency. It shows that the water is being absorbed

different applications such as flavoring, coloring, for 60+ seconds compared to the baseline of less than

thickener, livestock feeds, organic fertilizer, nutrient 55 seconds and this may result in discomfort to the

source and fibers. wearer.

Banana fiber, a lignocellulosic fiber, is a natural bast Results show that banana pseudostem made masks met

fiber used in artisanship products such as baskets, and somehow exceeded the baseline standards for

bags, rope, twines, mat, etc. Only 10%-12% of its facial masks. Water repellency measures the

pseudo stem is being utilized in making other effectiveness of biomask against droplet-based

products; anything in excess is discarded or used as a transmission vectors which are common in respiratory

fertilizer. Its properties such as impermeability, illnesses like COVID-19. Air permeability is crucial to

hygroscopicity, UV protection and filtration efficiency ensure the wearer can breathe easily. Although water

makes masks made from pseudostem fibers absorbency is almost at par with the baseline, bioface

environmentally friendly, economical, and recyclable. masks are still a safe and acceptable alternative.

The nanofiber from the banana peel is synthesized CONCLUSION

through various methods such as preparatory

treatment by hand stripping then grinding it through a The heightened demand on Personal Protective

mixer, then subject to chemical treatment under 1% Equipment such as face masks has produced enormous

Sodium Hydroxide then to be washed with 1% Acetic global waste in addition to the existing.

IRE 1703031 ICONIC RESEARCH AND ENGINEERING JOURNALS 75

© DEC 2021 | IRE Journals | Volume 5 Issue 6 | ISSN: 2456-8880

Approximately 5 billion people have added to the REFERENCES

waste volume since pandemic hits. This challenge has

led to the manufacturers and researchers to innovate [1] Chia-Yuan Chang, & Feng-Cheng Chang.

mask engineering and exploit organic and raw (2016). Development of Electrospun Lignin-

materials to produce cheap, recyclable but quality based Fibrous Materials for Filtration

masks. Natural composite fiber from banana Applications. BioResources, 11(1), 2202.

pseudostems can be an alternative for polymer https://doi.org/10.15376/ biores.11.1.2202-2213

compounds commonly found in plastics. Banana [2] Wu, F.; Zhao, S.; Mei Chen, Y.; Gana Song, Z.

pseudostem masks have the potential to be an A new coronavirus associated with human

alternative face mask. It is cheaper than usual surgical respiratory disease in China. Nature 2020, 579,

masks, more environmentally friendly as the materials 270-273, https://doi.org/10.1038/s41586-020-

are compostable, and with its strong fiber, it can 2008-3.

substantially protect us from the virus.

[3] D. Savanna Bavan and G.C.Mohan Kumar,

“Finite Element Analysis of Natural Fiber

COVID-19 virus is expected to stay and continue to

Composite Beam”, which permits unrestricted

mutate as time goes by. This is a great business venture

use, distribution of elements, Volume 2013,

opportunity worth investing in. No country can sustain

Article ID 450381, 10.1155/2013/450381.

the increase of ongoing demand for medical supplies

like face masks, hence trading is essential. Advantages [4] Jennifer Farrin “Biodegradable plastics from

of biomasks are not only limited to the agricultural Natural Resources”, Rochester Institute of

sector but also transportation infrastructure, logistics, Technology.

manufacturing, and as well as stocks. [5] Davies, A., Thompson, K., Giri, K., Kafatos, G.,

Walker, J., & Bennett, A. (2013). Testing the

With all the challenges continuously piling up with the efficacy of homemade masks: Would they

pandemic, nothing can stop innovative entrepreneurs protect in an influenza pandemic? Disaster

and businesses to quickly pivot to meet the increasing Medicine and Public Health Preparedness, 7(4),

demands for masks. Not just limited to humanitarian 413-418. doi:

reasons but also a new source of revenue amid the http://dx.doi.org/10.1017/dmp.2013.43

economic tsunami. Business owners take advantage of [6] Asmanto Subagyo and Achmad Chafidz

the masks and use it as a powerful tool to attract new (November 28th 2018). Banana Pseudo-Stem

customers to their stores, products, services and Fiber: Preparation, Characteristics, and

websites. Few companies have found themselves Applications, Banana Nutrition - Function and

growing as a result of mask ventures. It results in Processing Kinetics, Afam I. O. Jideani and

hiring more full-time and temporary workers and Tonna A. Anyasi, IntechOpen, DOI:

increases new partnership opportunities, vendors, and 10.5772/intechopen.82204. Available from:

suppliers. https://www.intechopen.com/chapters/64570

[7] Sakthivel M, Ramesh S, Mechanical properties

To all COVID-19 inspired entrepreneurs and business of natural fiber (banana coir, sisal) polymer

owners who see opportunities and breed innovation composites, Science Park, 1, (1), ISSN 2321-

amid crisis, the two questions you must ask yourself 8045, 2013.

are: “Are we providing an innovation that everybody

[8] Das P K, Nag D, Debanath S and Nayak L K,

is passionate about?” and “will there be enough

Machinery for extraction and traditional spinning

customers to grow a business with at post-covid

of plant fibers, Indian Journal of Traditional

future?”. Both answers are affirmative towards the

Knowledge, 9(2), 2010, 328-332

maximization of banana pseudo-stem made masks as

it is environmentally friendly and economical. [9] Singh, Narendra, Yuanyuan Tang, and Oladele

A. Ogunseitan. 2020. “Environmentally

Sustainable Management of Used Personal

Protective Equipment.” Environmental Science

IRE 1703031 ICONIC RESEARCH AND ENGINEERING JOURNALS 76

© DEC 2021 | IRE Journals | Volume 5 Issue 6 | ISSN: 2456-8880

& Technology 54 (14): 8,500–2.

https://pubs.acs.org/doi/10.1021/acs.est.0c03022

[10] UK Foreign, Commonwealth & Development

Office (FCDO). 2020. “COVID-19—PPE

Demand and Supply Perspectives.” Updated in

March 2021. https://

www.ifc.org/wps/wcm/connect/1d32e536-

76cc-4023-9430-

1333d6b92cc6/210402_FCDO_

GlobalPPE_Final+report_v14updated_gja.

pdf?MOD=AJPERES&CVID=nyiUnTU.

[11] Parashar, Neha, and Subrata Hait. 2021. “Plastics

in the Time of COVID-19 Pandemic: Protector

or Polluter?” Science of the Total Environment

759. https://www.sciencedirect.com/science/

article/pii/S0048969720378050?via%3Dihub.

[12] Sangkham, Sarawut. 2020. “Face Mask and

Medical Waste Disposal during the Novel

COVID-19 Pandemic in Asia.” Case Studies in

Chemical and Environmental Engineering 2.

https://www.sciencedirect.com/science/

article/pii/S2666016420300505?via%3Dihub.

[13] https://www.cnbc.com/2020/04/02/small-

businesses-retool-to-make-products-needed-for-

coronavirus-crisis.html

[14] https://www.weforum.org/agenda/2020/03/covi

d-responsible-businesses-during-the-

coronavirus-pandemic/

IRE 1703031 ICONIC RESEARCH AND ENGINEERING JOURNALS 77

You might also like

- Birkeland P.W.-Soils and Geomorphology PDFDocument391 pagesBirkeland P.W.-Soils and Geomorphology PDFAndres David Jaramillo ParedesNo ratings yet

- A Study of Banana Stem As A Eco Friendly Alternative To Disposable Face MaskDocument2 pagesA Study of Banana Stem As A Eco Friendly Alternative To Disposable Face Maskkarleth angelNo ratings yet

- A Study of Banana Stem As A Eco Friendly Alternative To Disposable Face MaskDocument2 pagesA Study of Banana Stem As A Eco Friendly Alternative To Disposable Face Maskkarleth angelNo ratings yet

- Ec Mask: Product Innovation CharterDocument15 pagesEc Mask: Product Innovation CharterYamato De Jesus NakazawaNo ratings yet

- Saba Turned Into Eco-Friendly Mask (Stem) : Musa (Banana) As A Biodegradable Alternative To Disposable Facemask The Problem and Its BackgroundDocument15 pagesSaba Turned Into Eco-Friendly Mask (Stem) : Musa (Banana) As A Biodegradable Alternative To Disposable Facemask The Problem and Its Backgroundadrianpaul villenaNo ratings yet

- Biodegradable Water Lily Based Face MaskDocument31 pagesBiodegradable Water Lily Based Face MaskMarietoni PallanNo ratings yet

- The Problem and Its ScopeDocument5 pagesThe Problem and Its Scoperoses the cupcakeNo ratings yet

- Marine Pollution Bulletin: SciencedirectDocument7 pagesMarine Pollution Bulletin: Sciencedirectchemist.msalehNo ratings yet

- Research Initial Final Paper For Reference 1Document12 pagesResearch Initial Final Paper For Reference 1Jordan RiversNo ratings yet

- Abaca Based Face Mask Chapter 1 3Document11 pagesAbaca Based Face Mask Chapter 1 3Rhea Gamao RarogalNo ratings yet

- Review Related Literature Ni JAKE1Document6 pagesReview Related Literature Ni JAKE1Johnrick Ryan AyaldeNo ratings yet

- Surgical Face Masks As A Potential Source For Microplastic Pollution in The COVID-19 ScenarioDocument8 pagesSurgical Face Masks As A Potential Source For Microplastic Pollution in The COVID-19 ScenarioGiselleNo ratings yet

- The Effectiveness of Cornhusks As An Alternative Material For Making Face Mask in Response With The Continuous Increase of Solid Waste During This COVID-19 PandemicDocument6 pagesThe Effectiveness of Cornhusks As An Alternative Material For Making Face Mask in Response With The Continuous Increase of Solid Waste During This COVID-19 PandemicZyra De GuzmanNo ratings yet

- ResearchtitledefensefinalDocument7 pagesResearchtitledefensefinalRon Y ANNo ratings yet

- Banana Pseudo-Stem Fiber: A Sustainable Face MaskDocument7 pagesBanana Pseudo-Stem Fiber: A Sustainable Face Maskkarleth angelNo ratings yet

- UntitledDocument7 pagesUntitledKurt Ivan AdvinculaNo ratings yet

- Republic of The Philippines Seminario de Jesus Nazareno, Inc. Diocese of Borongan Borongan City, Eastern SamarDocument4 pagesRepublic of The Philippines Seminario de Jesus Nazareno, Inc. Diocese of Borongan Borongan City, Eastern SamarChristen Antonette CadaNo ratings yet

- A Research Proposal PresentedDocument13 pagesA Research Proposal Presentedkarleth angelNo ratings yet

- Research Chapter 1 4 1Document31 pagesResearch Chapter 1 4 1MarkJan PepitoNo ratings yet

- Concept Paper (Final)Document2 pagesConcept Paper (Final)Junsan, Mark James A.No ratings yet

- Agriculture 13 00152 v2Document12 pagesAgriculture 13 00152 v2Nelson SouzaNo ratings yet

- Covid-19 Face Masks A Potential Source of Microplastic Fibers in The EnvironmentDocument4 pagesCovid-19 Face Masks A Potential Source of Microplastic Fibers in The EnvironmentDevita AmeliaNo ratings yet

- For PrintingDocument47 pagesFor PrintingAsh MicoNo ratings yet

- Title Hearing KUNODocument19 pagesTitle Hearing KUNORose Ann AbelardeNo ratings yet

- DocumentDocument3 pagesDocumentallanvictordavidNo ratings yet

- Biodegradable Face Mask 1Document5 pagesBiodegradable Face Mask 1whapseyNo ratings yet

- Biodegradable PPE Made of Pineapple Fiber Paper: Stephanie Graciela Wiryadinata, Innamia Indriani, Sabrina Ilma SakinaDocument9 pagesBiodegradable PPE Made of Pineapple Fiber Paper: Stephanie Graciela Wiryadinata, Innamia Indriani, Sabrina Ilma SakinaLeine Vidette Taylaran100% (1)

- New UpdateDocument5 pagesNew UpdateallanvictordavidNo ratings yet

- Review of Related Literature and StudiesDocument8 pagesReview of Related Literature and StudiesChristopher CastroNo ratings yet

- Post-Coronavirus - Defensive TextilesDocument19 pagesPost-Coronavirus - Defensive TextilesNataliaMaceiraNo ratings yet

- Assignment 3: Research Methodology Hafsa 20l-2506Document3 pagesAssignment 3: Research Methodology Hafsa 20l-2506Hafsa MehmoodNo ratings yet

- Galleto RationaleDocument28 pagesGalleto Rationalechristine galletoNo ratings yet

- Waste Management During Covid 19 ResponseDocument9 pagesWaste Management During Covid 19 ResponseASHUTOSH CHAURASIANo ratings yet

- St. Lawrence Group 4 Bio Facemask Derived From Manihot Esculenta As An Alternative For Surgical FacemaskDocument13 pagesSt. Lawrence Group 4 Bio Facemask Derived From Manihot Esculenta As An Alternative For Surgical FacemaskAnn Glaizel Colinares BasaranNo ratings yet

- Disposable Mask: Necessity or A Problem?Document2 pagesDisposable Mask: Necessity or A Problem?Sabiha Mehzabin OisheeNo ratings yet

- The Growing Waste & Recycling Problems From Ppe, Masks, and Covid-19Document34 pagesThe Growing Waste & Recycling Problems From Ppe, Masks, and Covid-19Erj YbanezNo ratings yet

- Bambuseaeco Mask: The Newly Enhanced Face Mask For Stem Students in The University of San Jose-RecoletosDocument22 pagesBambuseaeco Mask: The Newly Enhanced Face Mask For Stem Students in The University of San Jose-RecoletosEjay VillaverNo ratings yet

- COVID-19 A Global Pollution IGCSE Global Perspectives Individual Report SampleDocument5 pagesCOVID-19 A Global Pollution IGCSE Global Perspectives Individual Report SampleDalal AbdulrahmanNo ratings yet

- Reducing Toxic Substances: The Feasibility of Using Banana Fiber and Abacca Fiber As Disposable Facemask. Review Related LiteratureDocument4 pagesReducing Toxic Substances: The Feasibility of Using Banana Fiber and Abacca Fiber As Disposable Facemask. Review Related LiteraturecassseeeyyyNo ratings yet

- Waste MGMT During COVIDDocument6 pagesWaste MGMT During COVIDkarthikNo ratings yet

- Group No.1 - BambuseaECO Think Gree and Live Green!Document4 pagesGroup No.1 - BambuseaECO Think Gree and Live Green!Ejay VillaverNo ratings yet

- Recommendations For: Recommendations For The Tourism Sector To The Tourism Sector ToDocument12 pagesRecommendations For: Recommendations For The Tourism Sector To The Tourism Sector ToNkosiphile DhlodhloNo ratings yet

- Chapter 1 OLGraceDocument10 pagesChapter 1 OLGraceLolas TitasNo ratings yet

- Shen Shi 2023 Post Pandemic Investigation of The Degradation of Various Commercial Masks in The Marine EnvironmentDocument12 pagesShen Shi 2023 Post Pandemic Investigation of The Degradation of Various Commercial Masks in The Marine EnvironmentvalentinaNo ratings yet

- Assignment 3: Research Methodology Hafsa 20l-2506Document3 pagesAssignment 3: Research Methodology Hafsa 20l-2506Hafsa MehmoodNo ratings yet

- COVID-19 Pandemic and Emerging Plastic-Based Personal ProtectiveDocument11 pagesCOVID-19 Pandemic and Emerging Plastic-Based Personal ProtectiveNovela Sari, SKM, M.KesNo ratings yet

- PH InventionsDocument7 pagesPH Inventionshal lyuNo ratings yet

- Making Brick Using MaskDocument2 pagesMaking Brick Using MaskRAHUL VR Snm18ce015No ratings yet

- The Positive and Negative Impacts of Coronavirus Pandemic On The Environment and World HealthDocument4 pagesThe Positive and Negative Impacts of Coronavirus Pandemic On The Environment and World HealthInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intro 02262020Document6 pagesIntro 02262020chicken nuggetsNo ratings yet

- The Effectivity of Banana Leaf-Filtered Cloth Face Masks As An Alternative Protection During The PandemicDocument10 pagesThe Effectivity of Banana Leaf-Filtered Cloth Face Masks As An Alternative Protection During The PandemicIJPHSNo ratings yet

- Water 14 02403 v2Document16 pagesWater 14 02403 v2numajunNo ratings yet

- Banana (Pseudo-Stem) As Eco-Friendly Alternative To Disposable Face MaskDocument12 pagesBanana (Pseudo-Stem) As Eco-Friendly Alternative To Disposable Face Maskkarleth angel100% (1)

- Face Mask For Covid-19: A Social Responsibility: Sirisha Deepthi Sornapudi & Meenu SrivastavaDocument6 pagesFace Mask For Covid-19: A Social Responsibility: Sirisha Deepthi Sornapudi & Meenu SrivastavaTJPRC PublicationsNo ratings yet

- Disposable Over Reusable Face Masks: Public Safety or Environmental Disaster?Document10 pagesDisposable Over Reusable Face Masks: Public Safety or Environmental Disaster?Yaya HizmiNo ratings yet

- Disposable Over Reusable Face Masks: Public Safety or Environmental Disaster?Document10 pagesDisposable Over Reusable Face Masks: Public Safety or Environmental Disaster?Damelys Evelyn Fernandez PeñaNo ratings yet

- Chap1 3Document33 pagesChap1 3Lorie Camille CasaclangNo ratings yet

- Bioresearch Communications: Sustainable Alternatives For Producing Biodegradable Sanitary NapkinsDocument7 pagesBioresearch Communications: Sustainable Alternatives For Producing Biodegradable Sanitary Napkinsabcde123No ratings yet

- Making Masks Using Water Lilies-NewDocument9 pagesMaking Masks Using Water Lilies-NewArmeaNo ratings yet

- Importance of Fungi in The Petroleum, Agro-Allied, Agriculture and Pharmaceutical IndustriesDocument9 pagesImportance of Fungi in The Petroleum, Agro-Allied, Agriculture and Pharmaceutical Industriesluisa gonzalez hernandezNo ratings yet

- PEE TermPaperDocument6 pagesPEE TermPaperZhainna SilvestreNo ratings yet

- Principles of Home Pres PPT 1416cDocument14 pagesPrinciples of Home Pres PPT 1416ckarleth angelNo ratings yet

- What'S in THE Reaction?Document24 pagesWhat'S in THE Reaction?karleth angelNo ratings yet

- Conservation of Mass Lesson 1 NotesDocument14 pagesConservation of Mass Lesson 1 Noteskarleth angelNo ratings yet

- Department of Education: 4 QUARTER - Module 4Document16 pagesDepartment of Education: 4 QUARTER - Module 4karleth angelNo ratings yet

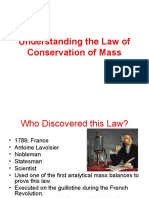

- Understanding The Law of Conservation of MassDocument10 pagesUnderstanding The Law of Conservation of Masskarleth angelNo ratings yet

- Final Research Paper Eco Friendly Face MaskDocument38 pagesFinal Research Paper Eco Friendly Face Maskkarleth angelNo ratings yet

- Group 4 Final Research HahahaDocument36 pagesGroup 4 Final Research Hahahakarleth angelNo ratings yet

- Balancing Chemical EquationsDocument13 pagesBalancing Chemical Equationskarleth angelNo ratings yet

- FNH 02Document6 pagesFNH 02karleth angelNo ratings yet

- Final Research Paper Eco Friendly Face MaskDocument38 pagesFinal Research Paper Eco Friendly Face Maskkarleth angelNo ratings yet

- A Research Proposal PresentedDocument18 pagesA Research Proposal Presentedkarleth angelNo ratings yet

- A Research Proposal PresentedDocument13 pagesA Research Proposal Presentedkarleth angelNo ratings yet

- A Research Proposal PresentedDocument13 pagesA Research Proposal Presentedkarleth angelNo ratings yet

- Science: Quarter 1 - Module 5 Plate TectonicsDocument31 pagesScience: Quarter 1 - Module 5 Plate Tectonicskarleth angelNo ratings yet

- Banana Pseudo-Stem Fiber: A Sustainable Face MaskDocument7 pagesBanana Pseudo-Stem Fiber: A Sustainable Face Maskkarleth angelNo ratings yet

- Research 10 Face MaskDocument11 pagesResearch 10 Face Maskkarleth angelNo ratings yet

- Science: Quarter 1 - Module 4 Plate Tectonics: Processes That Occur Along Plate BoundariesDocument27 pagesScience: Quarter 1 - Module 4 Plate Tectonics: Processes That Occur Along Plate Boundarieskarleth angel100% (2)

- Banana (Pseudo-Stem) As Eco-Friendly Alternative To Disposable Face MaskDocument12 pagesBanana (Pseudo-Stem) As Eco-Friendly Alternative To Disposable Face Maskkarleth angel100% (1)

- Preparation of PH Buffer SolutionsDocument5 pagesPreparation of PH Buffer SolutionsAndrew Sumaya AldeNo ratings yet

- Aniline Point Exp 4Document9 pagesAniline Point Exp 4hayder alaliNo ratings yet

- Lesson 1 (MATTER)Document2 pagesLesson 1 (MATTER)Benedict De Los ReyesNo ratings yet

- Aggregate Tests For Hot Mix Asphalt: State of The PracticeDocument22 pagesAggregate Tests For Hot Mix Asphalt: State of The PracticeProf. Prithvi Singh KandhalNo ratings yet

- PrismaSeT G Active - LVS08311Document3 pagesPrismaSeT G Active - LVS08311GUEZEI HAROUNNo ratings yet

- Poster de MetalografiasDocument1 pagePoster de MetalografiasFernando GonzalezNo ratings yet

- 1.0 Test Report of Reaction Mass Step-03 For Thermal Stability PDFDocument3 pages1.0 Test Report of Reaction Mass Step-03 For Thermal Stability PDFPrathmesh GujaratiNo ratings yet

- Medical Device Materials - Stainless SteelDocument5 pagesMedical Device Materials - Stainless Steelmaran.suguNo ratings yet

- Metalshield Premium Aug 2018Document2 pagesMetalshield Premium Aug 2018Biju_PottayilNo ratings yet

- Sikaflex® PRO-3 WF: Product Data SheetDocument4 pagesSikaflex® PRO-3 WF: Product Data Sheetsugiarto budiNo ratings yet

- GeberDocument67 pagesGeberNCSASTRONo ratings yet

- Mycelium Compsite Insulation Panel Project-ThesisDocument41 pagesMycelium Compsite Insulation Panel Project-ThesisATITHEE NANDANWAR100% (2)

- Thursday 03 To Determine Diametrical Deflection of A Circular Bar Subjected To Diametrical LoadingDocument7 pagesThursday 03 To Determine Diametrical Deflection of A Circular Bar Subjected To Diametrical LoadingFatima ImamNo ratings yet

- Estudio de Caso: Comportamiento Mecanico Del Hierro Fundido Gris Perlitico Sometido Al Fenómeno de TermofluenciaDocument16 pagesEstudio de Caso: Comportamiento Mecanico Del Hierro Fundido Gris Perlitico Sometido Al Fenómeno de TermofluenciaEduardoPulidoNo ratings yet

- Friction: The Surface Offers A Force That Opposes The Motion Called As Frictional ForceDocument6 pagesFriction: The Surface Offers A Force That Opposes The Motion Called As Frictional Forcechhabra navdeep100% (1)

- Vertically Aligned Graphene Coating Is BactericidalDocument9 pagesVertically Aligned Graphene Coating Is BactericidalBogdanNo ratings yet

- Oxidation of Tetrahydrofuran and 1,4-Butanediol With Nitric AcidDocument3 pagesOxidation of Tetrahydrofuran and 1,4-Butanediol With Nitric Acidkanak parmarNo ratings yet

- خوست-موسی خیلDocument23 pagesخوست-موسی خیلwafiullah sayedNo ratings yet

- 2022 - Dynamic Response of RC Beam-Slab Substructures FolDocument16 pages2022 - Dynamic Response of RC Beam-Slab Substructures FolbenNo ratings yet

- Crystic Ve671Document2 pagesCrystic Ve671M Taufik WijayaNo ratings yet

- 基于聚苯胺导电聚合物的可变红外发射率电致变色器件机理的进一步研究Document23 pages基于聚苯胺导电聚合物的可变红外发射率电致变色器件机理的进一步研究Van HenryNo ratings yet

- Deign Project Review 1 (120me0012)Document15 pagesDeign Project Review 1 (120me0012)VfhhdfvhhNo ratings yet

- PC 20 Data SheetDocument2 pagesPC 20 Data SheetSanthoshKumarSharmaCHNo ratings yet

- Recovery Boiler Ash, Plugging, Sootblowers, and Ash Induced Corrosion. - LinkedInDocument9 pagesRecovery Boiler Ash, Plugging, Sootblowers, and Ash Induced Corrosion. - LinkedInlacoste11111No ratings yet

- Avogadro Exam 2014Document8 pagesAvogadro Exam 2014葡萄蘿蔔No ratings yet

- Surface Coating: Toxicology Considerations in NanomedicineDocument3 pagesSurface Coating: Toxicology Considerations in NanomedicineMuhammad farhanNo ratings yet

- Answer Sheet PHYSICAL SCIENCE m1 4Document8 pagesAnswer Sheet PHYSICAL SCIENCE m1 4Mark James RicoNo ratings yet

- VTA Brochure Thermal Separation enDocument16 pagesVTA Brochure Thermal Separation enZoran VranesevitchNo ratings yet

- Introduction To DSCDocument144 pagesIntroduction To DSCsecateNo ratings yet