Professional Documents

Culture Documents

Tenalloy 120G: LOW ALLOY STEEL (High Strength)

Tenalloy 120G: LOW ALLOY STEEL (High Strength)

Uploaded by

Devender NegiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tenalloy 120G: LOW ALLOY STEEL (High Strength)

Tenalloy 120G: LOW ALLOY STEEL (High Strength)

Uploaded by

Devender NegiCopyright:

Available Formats

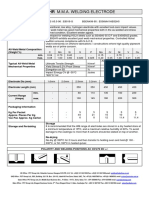

TENALLOY 120G

LOW ALLOY STEEL (High Strength)

Welding Electrode for Joining High Strength Steel

CLASSIFICATION : EN ISO 18275-A

E 69 4 Z B 32 H5

KEY FEATURES :

• Basic type coating • High strength and toughness at -50°C

• Ni-Mn-Mo-Cr alloyed electrode • Radiographic weld quality

• Excellent crack resistance

WELDING POSITION : AC (70 OCV)/DCEP

TYPICAL APPLICATIONS :

• Welding of high tensile steels and fine grained • Joining high strength, low alloy or

steels like HY 80, HY 90, HY 100 micro-alloyed steels to themselves or

to lower strength steels, including

carbon steels

REDRYING CONDITION : 250-300OC for minimum 1 hr. (Also available in vacuum packed condition)

CHEMICAL COMPOSITION OF UNDILUTED WELD METAL, Wt % :

C Mn Si Ni Mo

Typical 0.05 1.80 0.4 2.2 0.4

Cr V S P

Typical 0.4 0.01 0.015 0.015

MECHANICAL PROPERTIES OF ALL WELD METAL :

YS at 0.2% CVN Impact

Condition UTS, MPa EL%

offset, MPa at -50°C, J

Typical As Welded 870 780 20 50

Diffusible H2 Content: <5 ml/100 gm

PARAMETERS - PACKING DATA :

Ø x L, mm Amperage, A Approx. Pcs/ Carton/Box Approx. wt. of

Carton 1000 pcs, Kg.

2.5 x 350 60-90 215 4 23

3.15 x 450 100-140 113 4 44

4.0 x 450 140-180 78 4 63

5.0 x 450 190-250 51 4 96

www.adorwelding.com

You might also like

- Iso1295 1Document23 pagesIso1295 1Corina Stanculescu100% (3)

- Electrode Booklet F Web 73Document1 pageElectrode Booklet F Web 73satnamNo ratings yet

- Electrode Booklet F Web 23Document1 pageElectrode Booklet F Web 23satnamNo ratings yet

- Tenalloy 70D11Document1 pageTenalloy 70D11pach-thNo ratings yet

- Nimoten: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten: LOW ALLOY STEEL (Nimoten Series)satnamNo ratings yet

- Electrode Booklet F Web 22Document1 pageElectrode Booklet F Web 22satnamNo ratings yet

- Electrode Booklet F Web 85Document1 pageElectrode Booklet F Web 85satnamNo ratings yet

- Electrode Booklet F Web 21Document1 pageElectrode Booklet F Web 21satnamNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- Electrode Booklet F Web 20Document1 pageElectrode Booklet F Web 20satnamNo ratings yet

- Electrode Booklet F Web 24Document1 pageElectrode Booklet F Web 24satnamNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)satnam100% (1)

- Metalbond: Mild Steel General Purpose (MSGP)Document1 pageMetalbond: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Nimoten Plus 535 A: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten Plus 535 A: LOW ALLOY STEEL (Nimoten Series)satnamNo ratings yet

- Topstar 110: C-MN STEEL (High Efficiency)Document1 pageTopstar 110: C-MN STEEL (High Efficiency)satnamNo ratings yet

- Electrode Booklet F Web 9Document1 pageElectrode Booklet F Web 9satnamNo ratings yet

- Ebondm: Mild Steel General Purpose (MSGP)Document1 pageEbondm: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Electrode Booklet F Web 105Document1 pageElectrode Booklet F Web 105satnamNo ratings yet

- Celwel - 70P (Ador Electrodes)Document1 pageCelwel - 70P (Ador Electrodes)Harish KandollaNo ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- Electrode Booklet F Web 80Document1 pageElectrode Booklet F Web 80satnamNo ratings yet

- Betanox D Welding ElectrodeDocument1 pageBetanox D Welding ElectrodearavindpeetaNo ratings yet

- Electrode Booklet F Web 101Document1 pageElectrode Booklet F Web 101satnamNo ratings yet

- Kingbond S: Mild Steel General Purpose (MSGP)Document1 pageKingbond S: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Electrode Booklet F Web 104Document1 pageElectrode Booklet F Web 104satnamNo ratings yet

- Nicalloy Mo-12: NON FERROUS (Ni Alloys)Document1 pageNicalloy Mo-12: NON FERROUS (Ni Alloys)krupesh patelNo ratings yet

- Electrode Booklet F Web 120Document1 pageElectrode Booklet F Web 120satnamNo ratings yet

- Electrode Booklet F Web 14Document1 pageElectrode Booklet F Web 14satnamNo ratings yet

- Electrode Booklet F Web 13Document1 pageElectrode Booklet F Web 13satnamNo ratings yet

- Electrode Booklet F Web 96Document1 pageElectrode Booklet F Web 96satnamNo ratings yet

- Electrode Booklet F Web 8Document1 pageElectrode Booklet F Web 8satnamNo ratings yet

- Electrode Booklet F Web 121Document1 pageElectrode Booklet F Web 121satnamNo ratings yet

- F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageF For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationTolga UZUNERNo ratings yet

- Electrode Booklet F Web 110Document1 pageElectrode Booklet F Web 110satnamNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- Carbocast 1 - eDocument1 pageCarbocast 1 - eali torabiNo ratings yet

- Nicalloy Fe 3 Basic Coated Nickel Based ElectrodeDocument1 pageNicalloy Fe 3 Basic Coated Nickel Based ElectroderravibharathNo ratings yet

- Cu ZN 15Document2 pagesCu ZN 15wjjt6chgtmNo ratings yet

- Electrode Booklet F Web 97Document1 pageElectrode Booklet F Web 97satnamNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Electrode Booklet F Web 93Document1 pageElectrode Booklet F Web 93satnamNo ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Cu ZN 20Document2 pagesCu ZN 20wjjt6chgtmNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999No ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Celwel - 60 (Adore Electrodes)Document1 pageCelwel - 60 (Adore Electrodes)Harish KandollaNo ratings yet

- Esab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument1 pageEsab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesraghubhaimantra4136No ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Flow Control Valves: Catalog HY15-3502/USDocument51 pagesFlow Control Valves: Catalog HY15-3502/USPartsGopher.comNo ratings yet

- DS BI Mining Oracle Data Mining 10gR2 0706Document4 pagesDS BI Mining Oracle Data Mining 10gR2 0706Dumbrava Caius FlorinNo ratings yet

- Ahmed Muhammad Abd El-Azim MuhammadDocument3 pagesAhmed Muhammad Abd El-Azim MuhammadEng MessiNo ratings yet

- OSE 10-0196-. - 10 - Parts ListDocument51 pagesOSE 10-0196-. - 10 - Parts ListCentrifugal Separator100% (1)

- ExpressJS ReferenceDocument246 pagesExpressJS ReferenceTr TzaraNo ratings yet

- Unit-5 Maintenance of Hydraulic SystemDocument46 pagesUnit-5 Maintenance of Hydraulic SystemprabhathNo ratings yet

- AE May 2015 98 Pet B5Document11 pagesAE May 2015 98 Pet B5Jummah DaquNo ratings yet

- SDS AeroShell Turbine Oil 500Document19 pagesSDS AeroShell Turbine Oil 500Jerome Cardenas TablacNo ratings yet

- Co-Trimoxazole TabletDocument2 pagesCo-Trimoxazole TabletYessi LopezNo ratings yet

- IT Assignment 2Document2 pagesIT Assignment 2syed02No ratings yet

- Intrinsic Safety MaintenanceDocument2 pagesIntrinsic Safety MaintenanceRoadieNo ratings yet

- Basic Cryptography PresentationDocument58 pagesBasic Cryptography PresentationmwakondoNo ratings yet

- GBE-KPO-2-012-00 JidokaDocument40 pagesGBE-KPO-2-012-00 JidokaEduardo Magana100% (1)

- Nobles+Forklift+Jib Care+in+UseDocument5 pagesNobles+Forklift+Jib Care+in+UsePablo Valenzuela ArredondoNo ratings yet

- Chiyoda's High-Pressure Gas Control System and EquipmentDocument40 pagesChiyoda's High-Pressure Gas Control System and EquipmentNIZAM NIZAMNo ratings yet

- DM Fadg 2017Document51 pagesDM Fadg 2017wal1547No ratings yet

- MHZ4357 Assignment 2Document4 pagesMHZ4357 Assignment 2Nawam UdayangaNo ratings yet

- MIL-S-38249 Superseded by AMS 3374Document13 pagesMIL-S-38249 Superseded by AMS 3374HenryNo ratings yet

- NTB02 090bDocument10 pagesNTB02 090bPMNo ratings yet

- Properties Value: Ug-23 Maximum Allowable Stress ValuesDocument2 pagesProperties Value: Ug-23 Maximum Allowable Stress ValuesMohamad Faiz ZulkipliNo ratings yet

- Daftar PustakaDocument6 pagesDaftar Pustakasemester5No ratings yet

- MCG3130 Full NotesDocument84 pagesMCG3130 Full NotesBrian Pham VuNo ratings yet

- 12 W20-Engine PDFDocument64 pages12 W20-Engine PDFСаша НемешNo ratings yet

- LK 2 - Battery Inspection - OKDocument3 pagesLK 2 - Battery Inspection - OKmurti sapto wahyudi100% (1)

- Art of Programming Contest SE For Uva PDFDocument35 pagesArt of Programming Contest SE For Uva PDFgauravNo ratings yet

- As 1554.5-1995 Amdt 1-1998 Structural Steel Welding - WeldiDocument7 pagesAs 1554.5-1995 Amdt 1-1998 Structural Steel Welding - WeldiThaiminh VoNo ratings yet

- 6WE Symbol LS 5800 ReferenceGuideDocument352 pages6WE Symbol LS 5800 ReferenceGuideDavi CavalcanteNo ratings yet

- RTR 1633.30-01-18Document4 pagesRTR 1633.30-01-18LHYT NTUANo ratings yet

- Hydraulics Manual - Drainage DesignDocument690 pagesHydraulics Manual - Drainage DesignAnita100% (1)