Professional Documents

Culture Documents

Integrated Autosampler (I-AS) : Agilent ICP-MS

Integrated Autosampler (I-AS) : Agilent ICP-MS

Uploaded by

Nik Abel Zanabria AguilarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Integrated Autosampler (I-AS) : Agilent ICP-MS

Integrated Autosampler (I-AS) : Agilent ICP-MS

Uploaded by

Nik Abel Zanabria AguilarCopyright:

Available Formats

Agilent ICP-MS

Integrated Autosampler (I-AS)

Notices

Manual Part Number Warranty Safety Notices

G3160-90027 Revision A The material contained in this document

October 2018 is provided “as is,” and is subject to being

changed, without notice, in future

NOTE

Copyright editions. Further, to the maximum extent

permitted by applicable law, Agilent A NOTE contains helpful

© Agilent Technologies, Inc. 2018 disclaims all warranties, either express or information on the usage - it does

No part of this manual may be implied, with regard to this manual and not denote a hazard.

reproduced in any form or by any means any information contained herein,

(including electronic storage and retrieval including but not limited to the implied

or translation into a foreign language) warranties of merchantability and fitness CAUTION

without prior agreement and written for a particular purpose. Agilent shall not

consent from Agilent Technologies, Inc. be liable for errors or for incidental or A CAUTION notice denotes a

as governed by United States and consequential damages in connection hazard. It calls attention to an

international copyright laws. with the furnishing, use, or performance

operating procedure, practice, or

of this document or of any information

Agilent Technologies, Inc. the like that, if not correctly

contained herein. Should Agilent and the

9-1 Takakura-machi, Hachioji-shi, performed or adhered to, could

user have a separate written agreement

Tokyo 192-8510 Japan

with warranty terms covering the result in damage to the product or

material in this document that conflict loss of important data. Do not

Printed in USA with these terms, the warranty terms in proceed beyond a CAUTION

the separate agreement shall control.

notice until the indicated

Technology Licenses conditions are fully understood

and met.

The hardware and/or software described

in this document are furnished under a

license and may be used or copied only in WARNING

accordance with the terms of such

license. A WARNING notice denotes a

hazard. It calls attention to an

Restricted Rights Legend operating procedure, practice, or

U.S. Government Restricted Rights. the like that, if not correctly

Software and technical data rights performed or adhered to, could

granted to the federal government

result in personal injury or death.

include only those rights customarily

provided to end user customers. Agilent Do not proceed beyond a

provides this customary commercial WARNING notice until the

license in Software and technical data indicated conditions are fully

pursuant to FAR 12.211 (Technical Data) understood and met.

and 12.212 (Computer Software) and, for

the Department of Defense, DFARS

252.227-7015 (Technical Data -

Commercial Items) and DFARS

227.7202-3 (Rights in Commercial

Computer Software or Computer

Software Documentation).

Content

1 Integrated Autosampler Overview and Configuration 5

Overview 6

Features 8

Operations Overview 8

Rinse System 9

System Configuration 10

Main Unit Components 10

Specifications 15

Main Unit 15

External Bottle 15

Single Sample Position 15

Utility Requirements 16

Electromagnetic Compatibility 17

Operating Environment 17

Symbols Used on this Instrument 18

Serial Number 18

Safety Information 19

2 Setup 21

Unpacking the I-AS 22

Setting up the I-AS 24

Preparation of the Arm 24

Installing the Support Table or Bracket 26

Tubing and Wiring 27

Installing the Sample Tray 32

Installing the Tray Cover 33

Single Sample Position Setup 34

Software Settings 35

G7201C (ICP-MS MassHunter 4.1 or later) Configuration 35

G7201A/B Configuration 38

Integrated Autosampler (I-AS) 3

Content

G7200B Configuration 42

Settings 44

Checking and Adjusting Operations 46

Checking Operations 46

Installing and Adjusting the Needle 53

3 Operation 63

Measuring with Single Sample Position

(Using the G7200B ICP-MS Software) 64

Measuring with Single Sample Position 64

Single Sample Position Run Dialog Box 65

4 Maintenance 67

Daily Maintenance 68

Power Cable Fuse 69

4 Integrated Autosampler (I-AS)

1 Integrated Autosampler Overview and

Configuration

Overview 6

Features 8

Operations Overview 8

Rinse System 9

System Configuration 10

Main Unit Components 10

Specifications 15

Main Unit 15

External Bottle 15

Single Sample Position 15

Utility Requirements 16

Electromagnetic Compatibility 17

Operating Environment 17

Operating Conditions 17

Storage Conditions 17

Symbols Used on this Instrument 18

Serial Number 18

Safety Information 19

The Integrated Autosampler (I-AS) is a very flexible automated sample

introduction system capable of handling multiple sample vials. The I-AS is a

dedicated peripheral for the Agilent ICP-MS, designed to optimize instrument

capability.

This chapter describes the features, configuration and specifications of the I-AS.

Integrated Autosampler (I-AS) 5

1 Integrated Autosampler Overview and Configuration

Overview

Overview

The I-AS is designed to automate analysis and improve productivity for chemical

research and industrial testing facilities.

The I-AS has six types of sample trays. Replacing the sample tray allows the

instrument to handle sample vials of different sizes. Also, using the Single

Sample Position feature enables the use of a single bottle for analysis.

OPM070-2

Figure 1. Agilent 7800/7900/8900 ICP-MS equipped with the I-AS

6 Integrated Autosampler (I-AS)

1 Integrated Autosampler Overview and Configuration

Overview

OPM070

Figure 2. Agilent 8800/7700 ICP-MS equipped with the I-AS

Integrated Autosampler (I-AS) 7

1 Integrated Autosampler Overview and Configuration

Features

Features

Equipped with the I-AS, the ICP-MS is able to introduce a sample from a vial on

the I-AS sample tray, or introduce a sample directly from Single sample position.

The I-AS is equipped with a rinse port and an external bottle for cleaning the

needle. Depending on the option selected, up to three external bottles can be

used.

Needle

Three external

bottles

Tray cover

Rinse port

Sample tray Main unit

Figure 3. I-AS

Operations Overview

I-AS operation is controlled by MassHunter Workstation.

The I-AS uses command settings from MassHunter Workstation to rotate the

sample tray and select a sample vial, rotate the arm and move the needle up or

down, and remove the sample from the needle.

To prevent sample contamination, the needle tip is cleaned in the overflow rinse

port and from the external bottles when needed.

8 Integrated Autosampler (I-AS)

1 Integrated Autosampler Overview and Configuration

Rinse System

Rinse System

The overflow rinse system (rinse port) uses the peristaltic pump for rinse and

waste fluids.

The internal diameter of the peristaltic pump tubing outlet is larger than inlet.

This prevents rinse fluids from overflowing from the rinse port.

Integrated Autosampler (I-AS) 9

1 Integrated Autosampler Overview and Configuration

System Configuration

System Configuration

Main Unit Components

In addition to the sample tray driver and other peripheral equipment, the main

unit is equipped with a needle, arm, and a rinse port for cleaning the needle.

The I-AS is mounted on the ICP-MS and connected to MassHunter Workstation.

The sample tray mounts onto the I-AS.

Arm

Needle

Tray cover

Three external

Sample tray

bottles

Power display LED

Rinse port

Main unit

Reset switch

Figure 4. I-AS Components

10 Integrated Autosampler (I-AS)

1 Integrated Autosampler Overview and Configuration

Main Unit Components

Needle

The needle is installed on the arm of the main unit. The needle tube is connected

to the sample introduction tube.

Arm

The needle is installed on the arm. The arm can rotate and move up and down to

position the needle in the necessary location.

Reset switch

On the right side of the main unit is a red reset switch. Push this switch to

interrupt or stop the instrument in an emergency situation.

Pushing the reset switch will cancel Autosampler operation, return the needle to

home position, and initialize the I-AS. It will also cancel any analyses in process.

Rinse Port

The rinse port uses an overflow feature to supply rinsing fluid to clean the tip of

the needle.

External Bottle

In addition to cleaning with the rinse port, the external bottle is used when

cleaning with other types of cleaning fluids. Up to three external bottles can be

used. These may also be filled with standard tuning solution.

Power Display LED

The LED illuminates when the I-AS is powered ON.

Integrated Autosampler (I-AS) 11

1 Integrated Autosampler Overview and Configuration

Main Unit Components

Sample Tray

The sample tray contains slots for holding sample vials. Insert a sample vial into

a slot on the sample tray.

The following six types of sample trays are available as options. Select the

sample tray that matches the sample vials to be used.

Table 1 Sample Tray Types

Sample Tray Max. No. of Vials Sample Vial Specifications

Type A 89 6 mL

Type B 53 18 mL

Type C 18 50 mL

Type D 89 1.5 mL or 2 mL, 18 mL

Type E 89 6 mL, 18 mL

Type F 15 Used for 48 (OD) × 55 (H) mm vial

Figure 5. Sample Tray Types (Photo Shows Type A)

12 Integrated Autosampler (I-AS)

1 Integrated Autosampler Overview and Configuration

Main Unit Components

Single Sample Position

The Single Sample Position allows the user to do a single sample. To use this

function, place the bottle containing the sample in the Single Sample Position.

Bottle for Single

Sample Position

Single Sample

Position stand

Figure 6. Introducing a sample with Single Sample Position

Power switch

Power cable

connector

Communications network connector

Figure 7. Rear side of I-AS main unit

Integrated Autosampler (I-AS) 13

1 Integrated Autosampler Overview and Configuration

Main Unit Components

Power Switch

I-AS power switch.

Power Cable Connector

This connects the power cable.

Communications Network Connector

This part connects to the communications network cable.

Rinse Fluid Inlet

Tube Connector Rinse Fluid Outlet

Tube Connector

Figure 8.

Rinse Fluid Inlet Tube Connector

This is labelled “IN” on the instrument. This is the clean fluid inlet for the rinse

port and connects to the rinse fluid inlet tube.

Rinse Fluid Outlet Tube Connector

This is labelled “OUT” on the instrument. This is the waste outlet for the rinse port

and connects to the rinse fluid outlet tube.

14 Integrated Autosampler (I-AS)

1 Integrated Autosampler Overview and Configuration

Specifications

Specifications

The following specifications are subject to change without notice.

Main Unit

Dimensions: 290 (W) x 360 (D) x 220 (280, probe included) (H) mm

Weight: 5 kg

External Bottle

Dimensions: 56 (Diameter) x 61 (H) mm

Single Sample Position

The client must provide this bottle. Bottles up to 100 mL may be used. The

allowable bottle dimensions are shown below.

Dimensions: A diameter of 55 mm or less and a height of: 126 mm or less.

Integrated Autosampler (I-AS) 15

1 Integrated Autosampler Overview and Configuration

Utility Requirements

Utility Requirements

The following utilities are required to operate the I-AS:

Electrical Power: 100-120 V AC, 50/60 Hz, 1 A

200-240 V AC, 50/60 Hz, 0.5 A

Overvoltage Category: II (see Note)

Pollution Degree: 2 (see Note)

Fuses: Main fuses in appliance inlet (see Figure 57)

2 x T 1AL/250 V

Secondary fuses in DC 5 V and DC 24 V line

(inside the Autosampler, left of the power supply)

F1: T 2 AL/250 V

F2: T 2 AL/250 V

16 Integrated Autosampler (I-AS)

1 Integrated Autosampler Overview and Configuration

Electromagnetic Compatibility

Electromagnetic Compatibility

This device complies with the requirements of EN550011, Group 1, Class B.

EN55011

Group 1 ISM equipment: Group 1 contains all ISM equipment in which there is

intentionally generated and/or used conductively coupled radio-frequency energy

which is necessary for the internal functioning of the equipment itself.

Class B equipment is equipment suitable for use in domestic establishments and

in establishments directly connected to a low voltage power supply network

which supplies buildings used for domestic purposes.

ICES/NMB-001

This ISM device complies with Canadian ICES-001

Cet appareil ISM est conforme à la norme NMB-001 du Canada.

The “Installation category” implies the regulation for impulse withstand voltage. It

NOTE is also called the “Over voltage category.” “II” applies to electrical equipment.

“Pollution degree” describes the degree to which a solid, liquid, or gas which

deteriorates dielectric strength is adhering. “2” applies to a normal indoor

atmosphere.

Operating Environment

Use the I-AS only under the following operating conditions:

Operating Conditions

Ambient temperature: 5 - 35 °C (41 - 95 °F)

Relevant humidity: 20 - 80 % (no condensation)

Storage Conditions

Ambient temperature: -35 - 65 °C (-31 - 149 °F)

Relevant humidity: 15 - 85 %

Integrated Autosampler (I-AS) 17

1 Integrated Autosampler Overview and Configuration

Symbols Used on this Instrument

Symbols Used on this Instrument

The following symbols are used on this instrument:

To avoid personal injury, death, or damage to the instrument, the operator must refer to an

explanation in the Manual.

Protective grounding terminal.

Alternating current.

ON (power)

OFF (power)

Serial Number

The Integrated Autosampler is identified with a serial number on a label on the

instrument.

When corresponding with Agilent about your Integrated Autosampler, be sure to

include the model type and the full 15-digit serial number.

18 Integrated Autosampler (I-AS)

1 Integrated Autosampler Overview and Configuration

Safety Information

Safety Information

The I-AS has been designed and tested in accordance with IEC publication

1010-1, Safety Requirements for Electrical Equipment for Measurement, Control,

and Laboratory Use.

Only connect the I-AS to a power source with a protective earth contact. Use

WARNING only a certificated power cord to make a connection. Connecting the I-AS to a

power source that is not equipped with a protective earth contact creates a

shock hazard for the operator and can damage the instrument. Likewise,

interrupting the protective conductor inside or outside the I-AS or defeating the

power cord ground creates a shock hazard for the operator and can damage

the instrument.

• Do not use organic solvents and other combustible or flammables in the

WARNING rinse port fluid. Combustibles or flammables can ignite during use. Also,

some organic solvents can damage the internal elements of the instrument.

• When the external bottle contains combustible or flammable fluid, make

sure the area is well ventilated. If the area is permeated with flammable or

combustible gas, it could ignite.

If an overflow of the rinse receptacle caused by blockage of the peristaltic

WARNING pump or a liquid spillage is noted, switch off the sampler and unplug the main

cords. The sampler then should be cleaned and wiped dry.

Never use the I-AS in a way not described in the manual. Improper use may

WARNING result in danger to the user.

If rinse fluid, sample fluid, standard fluid or other liquids spill, wipe up

WARNING immediately. These liquids can short circuit or corrode the instruments. Highly

alkaline or acidic fluids can injure the skin and mucus membranes. Exercise

caution when handling these fluids.

Integrated Autosampler (I-AS) 19

1 Integrated Autosampler Overview and Configuration

Safety Information

Do not cover the air circulation outlet holes on the right side of the I-AS.

CAUTION

Precautions when moving the I-AS are listed below:

CAUTION

• Make sure the I-AS Power switch is turned OFF.

• Make sure all cables between other units are unplugged and the utility

tubing is disconnected before moving equipment (small adjustments can be

made without unplugging and disconnecting).

• When shipping the I-AS, secure the arm prior to shipping.

Do not remove or install the tray on to the I-AS while the needle is moving. The

CAUTION I-AS can be damaged if the needle is touched during operation.

If you change the tray type used, you must change the tray type in the I-AS

Configuration dialog box.

Verify the following before beginning measurements with the I-AS:

CAUTION

• Is the rinse port waste bottle empty?

• Are the rinse fluid, external bottles, and sample vials ready, and does each

bottle contain the required amount of fluid prior to measuring?

• Do not use organic solvents and other combustible or flammables in the

WARNING rinse port fluid. Combustibles or flammables can ignite during use. Also,

some organic solvents can damage the internal elements of the instrument.

• When the external bottle contains combustible or flammable fluid, make

sure the area is well ventilated. If the area is permeated with flammable or

combustible gas, it could ignite.

• Always make sure there is at least 10mm or more distance between the

CAUTION surface of the sample fluid to the top edge of the vial. This is to keep the

sample fluid lower than the rinse port fluid, and ensure the entire needle is

thoroughly cleaned.

• If rinse fluid, sample fluid, standard fluid or other liquids spill, wipe up

immediately. These liquids can short circuit or corrode the instruments.

Highly alkaline or acidic fluids can injure the skin and mucus membranes.

Be very careful when handling these fluids.

20 Integrated Autosampler (I-AS)

2 Setup

Unpacking the I-AS 22

Setting up the I-AS 24

Preparation of the Arm 24

Installing the Support Table or Bracket 26

Tubing and Wiring 27

Installing the Sample Tray 32

Installing the Tray Cover 33

Single Sample Position Setup 34

Software Settings 35

G7201C (ICP-MS MassHunter 4.1 or later) Configuration 35

G7201A/B Configuration 38

G7200B Configuration 42

Settings 44

Checking and Adjusting Operations 46

Checking Operations 46

Installing and Adjusting the Needle 53

Integrated Autosampler (I-AS) 21

2 Setup

Unpacking the I-AS

Unpacking the I-AS

The I-AS arrives packaged in multiple boxes. Below is a packing list of the

contents. Check to make sure all the necessary components are included.

The number of sample vials and sample trays will differ depending on the option

ordered.

Be careful not to drop or hit the components against anything when removing

CAUTION them from their packaging. Many parts are heavy or can be easily damaged.

Table 2 I-AS Packaging Contents

Name Quantity

Main Unit 1

Tray Cover 1

Table 3 Peripheral Equipment Packaging Contents

Name Quantity

Bracket with Screws 1

Needle 1

Rinse Fluid Inlet Tube 1

Rinse Fluid Outlet Tube 1

Power Cable 1

Communications Network Cable 1

External Bottle(s) with cover(s) 3

External Bottle(s) with Slotted Cover(s) 3

Tube Clip(s) 2

22 Integrated Autosampler (I-AS)

2 Setup

Unpacking the I-AS

Table 4 Sample Tray Packaging Contents

Name Vial Types

Type A 6 mL

Type B 18 mL

Type C 50 mL

Type D 1.5 mL or 2 mL, 18 mL

Type E 6 mL, 18 mL

Type F 55 (OD) × 48 (H) mm vial

50 mL Vial

18 mL Vial

6 mL Vial

2 mL Vial

1.5 mL Vial

The number of boxes will differ depending on the options ordered. Make sure to

NOTE verify that all the necessary components are present.

Integrated Autosampler (I-AS) 23

2 Setup

Setting up the I-AS

Setting up the I-AS

The following describes how to install the I-AS.

Preparation of the Arm

• Do not work on the underside of the instrument alone. Turning the

CAUTION instrument upside down can deform or damage the arm.

• After removing the arm shipping screw, store it for future use. The base of

the main unit is equipped with a shipping screw storage hole.

• When shipping the I-AS, secure the arm prior to shipping.

1 Remove the arm screw.

2 Store the screw.

Store the screw

Remove the arm

shipping screw

Figure 9.

24 Integrated Autosampler (I-AS)

2 Setup

Preparation of the Arm

3 Loosen the two fixed arm block screws and slide the arm block with screws to

the right.

Loose these two screws and

slide to the right

Figure 10.

Do not remove the two fixed arm block screws. This will cause the arm block to

CAUTION be removed from the bracket.

4 Secure the screws after sliding to the right.

Secure these two

screws

Figure 11.

Integrated Autosampler (I-AS) 25

2 Setup

Installing the Support Table or Bracket

Installing the Support Table or Bracket

For 7800/7900/8900, place the support table next to ICP- MS as shown in

Figure 12. And for 8800/7700, install the bracket to ICP- MS as shown in

Figure 13.

Sample Introduction Tray

Support Table

OPM075-2

Figure 12. Installing to 7800/7900/8900

26 Integrated Autosampler (I-AS)

2 Setup

Tubing and Wiring

Screw

Screw

Screw

Sample Introduction Tray

Support Bracket

Screw Leg

OPM075

Figure 13. Installing to 8800/7700

Tubing and Wiring

1 To install the tubing and wiring, place the I-AS on the bracket installed on the

ICP-MS with its power display LED facing front.

2 Connect the Peristaltic Pump inlet (sample uptake) and outlet (drain) tubes.

Connect the rinse fluid inlet and outlet tubes to the IN and OUT ports. Tighten

the connectors by hand.

Do not connect sample tubing for Outlet and drain tubing for Inlet. The internal

NOTE diameter of the drain tubing is larger than the sample tubing to prevent rinse fluid

from overflowing.

When sample tubing is connected to Outlet and drain tubing is connected to Inlet,

rinse fluid could overflow from the rinse port.

Integrated Autosampler (I-AS) 27

2 Setup

Tubing and Wiring

Rinse fluid outlet tube

Rinse fluid inlet tube

Figure 14.

Do not touch the Peristaltic Pump while it is rotating.

CAUTION

3 Connect the communications cable.

Communications

cable

Figure 15.

28 Integrated Autosampler (I-AS)

2 Setup

Tubing and Wiring

4 Connect the communications cable to the PC.

The connection cable differs between G7201A/B/C and G7200B ICP-MS

software.

• G7201A/B/C Connection

Connect the other end of the communications cable to the serial-USB

converter cable, then connect to the PC USB port.

Connect to PC USB port

Serial-USB Converter Cable

Figure 16. Serial-USB converter cable

• G7200B Connection

Connect the other end of the communications network cable to the PC

RS-232C connector.

When ISIS is used with I-AS, connect the communication network cable to

the ISIS controller (COM1).

5 Make sure the I-AS power switch is in the OFF position.

Make sure to check the following prior to connecting the power cable. Skipping

CAUTION this procedure can result in damage to the instrument.

• Before connecting the power cable, make sure it is designated for this

purpose.

• Make sure the protective grounding is secure.

• Only use the provided cables and properly connect them in their designated

locations. Do not use unauthorized cords or cables. Do not uses these

cables on instruments other than those listed in this manual.

Integrated Autosampler (I-AS) 29

2 Setup

Tubing and Wiring

6 Connect the power cable to the connector. The connector is designed to be

inserted in only one direction.

Power cable

Figure 17.

7 Connect the other end of the power cable to a properly grounded wall outlet.

Leave the I-AS power switch in the OFF position.

In the case of leakage (liquid under the I-AS), disconnect the power cable and

WARNING contact your local Agilent office.

30 Integrated Autosampler (I-AS)

2 Setup

Tubing and Wiring

8 Connect the rinse fluid outlet tube to the rinse port waste bottle.

Use the tube clip to secure the tube to the bottle.

Tube

Tube clip

Bottle

Figure 18.

9 Connect the rinse fluid inlet tube to the rinse port rinse fluid bottle.

Use the tube clip to secure the tube to the bottle.

Integrated Autosampler (I-AS) 31

2 Setup

Installing the Sample Tray

Installing the Sample Tray

1 Slide the sample tray onto the shaft of the main unit and set into place.

Line up the sample tray mating pin with the mating grove on the shaft. After

inserting the sample tray, rotate it slightly until the pin and groove line

interlock.

Sample tray underside

Mating pin

Mating groove

Figure 19.

Sample tray

Main unit

Figure 20.

32 Integrated Autosampler (I-AS)

2 Setup

Installing the Tray Cover

Installing the Tray Cover

1 Place the tray cover over the sample tray.

Line up the groove on the tray cover with the projections on the main unit and

place the cover in position.

Tray cover groove

Projection on main unit

Figure 21.

Tray cover

Figure 22.

The tray cover is acrylic. Organic solvents and some sample materials may

CAUTION cause the cover to become discolored.

Integrated Autosampler (I-AS) 33

2 Setup

Single Sample Position Setup

Single Sample Position Setup

Use the Single Sample Position when sequencing a single sample.

Use the Single Sample Position with the sample tray removed from the

NOTE instrument.

The Single Sample Position sits in the designated stand. Make sure the mouth of

the bottle is centered on the Single Sample Position stand.

The Single Sample Position is not included with the peripheral equipment. An

appropriate bottle measuring 50 mm or less in diameter and 126 mm or less in

height must be provided.

When using the Single Sample Bottle, the lowest needle position is the upper

surface of the top plate of the Single Sample Position stand. The needle will not

reach the bottom of the bottle.

Bottle

Lowest needle

position

Lower stand plate

Screw

Lower screw slot

Figure 23. Single Sample Position

The mouth on the Single Sample Position bottle should be lower than the rinse

port. If the mouth is higher than the rinse port, remove the two screws holding

the lower plate and re-attach the stand it in a lower position.

34 Integrated Autosampler (I-AS)

2 Setup

Software Settings

Software Settings

The configuration procedure differs between G7201C (ICP-MS MassHunter 4.1

or later), G7201A/B, and G7200B ICP-MS software.

G7201C (ICP-MS MassHunter 4.1 or later)

Configuration

The term "ALS" has been changed to "Autosampler" in MassHunter 4.4.

NOTE

1 Launch MassHunter, and then click the Settings gadget on the dashboard.

The Settings dialog box appears.

2 On MassHunter 4.2 or later, click System, and then click at the side of

Hardware.

On MassHunter 4.1, skip this step.

3 Click Sample Introduction, and then select Use Autosampler in Properties.

MassHunter 4.1 MassHunter 4.2 or later

Figure 24.

Integrated Autosampler (I-AS) 35

2 Setup

G7201C (ICP-MS MassHunter 4.1 or later) Configuration

4 Click Edit in Properties.

The Configure Autosampler dialog box appears.

5 Click the Type tab, and then select Agilent I-AS from the Autosampler Type list

box.

Figure 25.

6 Click the Rack tab, and then select the rack that will be used from the

Autosampler Rack list box.

Figure 26.

You need MassHunter 4.4 or later to use the 28-vial sample tray (28 Samples

Rack). If the software installed is earlier than MassHunter 4.4, update to

MassHunter 4.4 or later.

The I-AS needle does not move to the correct position if the Autosampler Rack

CAUTION is not configured correctly.

36 Integrated Autosampler (I-AS)

2 Setup

G7201C (ICP-MS MassHunter 4.1 or later) Configuration

7 Click the COM Port tab, and then select the COM port number for the

Autosampler.

You should normally select the highest port number from the COM port

setting. (for example: if COM 1 to COM 3 are available, usually use COM 3)

Figure 27.

8 Click the Probe Depth tab, and then set the appropriate probe depth.

Figure 28.

Be very careful when setting the values for the Rinse Port, Tray/Single, and

CAUTION standard/Rinse to prevent the needle from coming into contact with anything

else. Start with smaller values and gradually increase until an appropriate

setting is achieved. If the value is too high, the tip of the needle makes contact

and may bend or break.

Integrated Autosampler (I-AS) 37

2 Setup

G7201A/B Configuration

9 Click the Other tab, and then select Escape Mode.

Figure 29.

10 Click OK.

11 Click Close to close the Settings dialog box.

G7201A/B Configuration

1 Launch MassHunter, and then select Hardware from the task menu.

2 Click on the Mainframe illustration and select Communication... from the

popup menu.

Select Online from the Set Communication dialog box, check Use ALS and click

OK.

Figure 30. Set Communication dialog box

38 Integrated Autosampler (I-AS)

2 Setup

G7201A/B Configuration

3 When the Autosampler (ALS) illustration appears, select the Autosampler from

Autosampler Type.

4 Select the number of samples from each available setting in the sample rack

list box.

Figure 31.

The I-AS needle does not move to the correct position if the Autosampler Rack

CAUTION is not configured correctly.

5 Click on the I-AS illustration and select Set Communication... from the popup

menu.

You should normally select the highest port number from the COM port

setting in the Set ALS Communication dialog box.

Integrated Autosampler (I-AS) 39

2 Setup

G7201A/B Configuration

6 Click on the I-AS illustration and select Set Sampling Depth of I-AS... from the

popup menu.

Figure 32.

7 Configure each setting in the Set Sampling Depth of I-AS dialog box.

Figure 33. Set Sampling Depth of I-AS dialog box

Be very careful when setting the values for the Rinse Port, Tray/Single, and

CAUTION standard/Rinse to prevent the needle from coming into contact with anything

else. Start with smaller values and gradually increase until an appropriate

setting is achieved. If the value is too high, the tip of the needle makes contact

and may bend or break.

40 Integrated Autosampler (I-AS)

2 Setup

G7201A/B Configuration

8 Configuring Escape Mode.

Click on the I-AS illustration and select Escape Mode from the popup menu.

Figure 34.

Integrated Autosampler (I-AS) 41

2 Setup

G7200B Configuration

G7200B Configuration

Configure the I-AS to ensure proper operation.

The following procedure describes I-AS configuration.

1 Close down all tasks.

2 Double-click the Configuration icon located on the desktop.

The ICP-MS Configuration dialog box will be displayed.

3 Select Autosampler >> I-AS.

Select I-AS from the

Autosampler menu

Setup button

Figure 35.

4 Click the Setup button located to the right of the Autosampler menu.

The I-AS Configuration dialog box will be displayed.

5 Set the menu items in the I-AS Configuration dialog box.

42 Integrated Autosampler (I-AS)

2 Setup

G7200B Configuration

Be very careful when setting the values for the Rinse Port, Tray/Single, and

CAUTION STD/Rinse to prevent the needle from making contact. Start with smaller

values and gradually increase until an appropriate setting is achieved. If the

value is too high, the tip of the needle will make contact and may bend or

break.

Figure 36. I-AS Configuration dialog box

6 After all menu items have been correctly input, click the OK button.

The I-AS Configuration dialog box will close, returning to the ICP-MS

Configuration dialog box.

7 Click the Save button in the ICP-MS Configuration dialog box.

The ICP-MS Configuration dialog box will close and save the new settings.

Integrated Autosampler (I-AS) 43

2 Setup

Settings

Settings

COM port for Set the connection port for the I-AS communications

Autosampler: network cable. If the software dialog box shows that

ISIS is using the port, this port cannot be used for the

I-AS.

Sample Tray: Select the sample tray type that will be used.

Single Sample

89 Samples: Type A, D, E, F

53 Samples: Type B

18 Samples: Type C

28 Samples: Type G (Available on MassHunter 4.4 or

later)

Sampling Depth: In the positions below, set the travel distance for the

I-AS arm from its highest to lowest positions. The drive

motor moves in increments of 0.125 mm. Any smaller

settings will be automatically rounded up to this value.

Rinse Port: Set the distance the arm will lower from its highest

point in the rinse port position. Start with small values

and slowly increase (approx. 10 mm) to avoid contact.

The maximum setting is 55.00 mm.

Tray/Single: Set the distance the arm will lower from its highest

point in the sample vial or Single Sample Position. Start

with small values and slowly increase (approx. 10 mm)

to avoid contact. The maximum setting is 63.75 mm.

STD/Rinse: Set the distance the arm will lower from its highest

point in the external bottle (for standard and cleaning

fluid) position. Start with small values and slowly

increase (approx. 10 mm) to avoid contact. The

maximum setting is 63.75 mm.

Enable ESC Mode: Check this to enter escape mode. In escape mode, to

move the needle over the sample tray, the sample tray

is moved to a pre-determined position before moving

the needle. The position of the needle in escape mode

will be the last (highest) sample number on the inner

radius of the sample tray, as illustrated in the following

table. Samples in this row cannot be measured in

escape mode.

44 Integrated Autosampler (I-AS)

2 Setup

Settings

Table 5 Location of the vial that cannot measured in escape mode

Tray Type Location of Vial Not Measured in Escape Mode

89-Vial Sample Trays (Types A, D, E) 32, 57, 77, 89

53-Vial Sample Tray (Type B) 25, 41, 53

18-Vial Sample Tray (Type C) 12,18

15-Vial Sample Tray (Type F) 57, 89 (At 89-Vial sample tray setting)

28-Vial Sample Tray (Type G) 22, 28

An executed analysis will stop if it is configured with a vial number unavailable

CAUTION for use in Escape Mode.

Integrated Autosampler (I-AS) 45

2 Setup

Checking and Adjusting Operations

Checking and Adjusting Operations

This section explains how to check the operation of the I-AS and install the

needle.

Checking Operations

Before operating the I-AS, check the following items.

CAUTION

• Verify that the settings in the software are correct. If the distance allotted

for arm travel is too great, the needle can contact the table, twist and/or

break off.

• Make sure there is nothing to interfere with the operations of the arm,

needle, and tubing. Any contact with foreign objects can damage or deform

the I-AS, and cause fluids to squirt or leak out of the instrument.

Using the G7201C ICP-MS Software

1 Turn the I-AS power switch on.

Verify that the LED on the front of the I-AS main body is on.

2 Initialize the I-AS before performing the operation check.

Click the Autosampler icon on the toolbar, and then select Initialize from the

pull-down menu.

Figure 37. Initialize menu

46 Integrated Autosampler (I-AS)

2 Setup

Checking Operations

3 Display the Select Vial dialog box.

Click the Autosampler gadget on the dashboard to display the Select Vial

dialog box.

Figure 38. Select Vial dialog box

Buttons

Home button: Moves the arm to the home position (directly over the rinse

port) and to the highest possible position without lowering

the arm.

1 button: Moves the arm to the first external bottle and lowers the

arm to the setting in the Select Vial dialog box. It then

closes this dialog box.

2 button: Moves the arm to the second external bottle and lowers

the arm to the setting in the Select Vial dialog box. It then

closes this dialog box.

3 button: Moves the arm to the third external bottle and lowers the

arm to the setting in the Select Vial dialog box. It then

closes this dialog box.

Sampler Rack Displays the type of sample tray configured in the

Type: Autosampler Rack drop down menu.

Integrated Autosampler (I-AS) 47

2 Setup

Checking Operations

Vial No. [ ]: Click on the desired sample position number icon or enter

the sample position number in the edit box to move

sample position numbers.

The configurable sample numbers are displayed in the

Select Vial dialog box. External bottles are numbered 1-3.

Sample vials are numbered sequentially with four digits

starting from 1000 (1001, 1002,...). The Single Sample

Position is numbered 1000.

Go to button: Moves the arm to the sample position configured in Vial

No. and lowers the arm to the setting in the dialog box. It

then closes this dialog box.

Move button: Moves the arm to the sample position configured in Vial

No. and maintains the high position of the arm. The dialog

box remains open.

Close button: Closes the dialog box without performing any operations.

Pressing Enter key after inputting the Vial No.[ ] in the Edit Box will have the same

NOTE effect as clicking the Go to button.

4 From the Select Vial dialog box designate an optional vial, press the Move

button and verify that the I-AS moves properly.

5 Press the Go to button on the Select Vial dialog box and verify that the arm

lowers.

Each operation can be initiated from the pull-down menu of the Autosampler

NOTE icon on the toolbar.

Figure 39. Autosampler icon pull-down menu

48 Integrated Autosampler (I-AS)

2 Setup

Checking Operations

Using the G7201A/B ICP-MS Software

1 Turn the I-AS power switch to I to power ON.

Verify that the LED on the front of the I-AS main body is on.

2 Initialize the I-AS before performing the operation check.

Click on the ALS Initialize button on the toolbar.

Figure 40. ALS Initialize toolbar button

3 Display the Select Vial dialog box.

Click on the ASL Vial Number combo box to display the Select Vial dialog box.

Figure 41. Select Vial dialog box

Buttons

Home button: Moves the arm to the home position (directly over the rinse

port) and to the highest possible position without lowering

the arm.

Integrated Autosampler (I-AS) 49

2 Setup

Checking Operations

1 button: Moves the arm to the first external bottle and lowers the

arm to the setting in the Select Vial dialog box. It then

closes this dialog box.

2 button: Moves the arm to the second external bottle and lowers

the arm to the setting in the Select Vial dialog box. It then

closes this dialog box.

3 button: Moves the arm to the third external bottle and lowers the

arm to the setting in the Select Vial dialog box. It then

closes this dialog box.

Sampler Rack Displays the type of sample tray configured in the

Type: Autosampler Rack drop down menu.

Vial No. [ ]: Click on the desired sample position number icon or enter

the sample position number in the edit box to move

sample position numbers.

The configurable sample numbers are displayed in the

Select Vial dialog box. External bottles are numbered 1-3.

Sample vials are numbered sequentially with four digits

starting from 1000 (1001, 1002,...). The Single Sample

Position is numbered 1000.

Go to button: Moves the arm to the sample position configured in Vial

No. and lowers the arm to the setting in the dialog box. It

then closes this dialog box.

Move button: Moves the arm to the sample position configured in Vial

No. and maintains the high position of the arm. The dialog

box remains open.

Close button: Closes the dialog box without performing any operations.

Pressing Enter key after inputting the Vial No.[ ] in the Edit Box will have the same

NOTE effect as clicking the Go to button.

4 From the Select Vial dialog box designate an optional vial, press the Move

button and verify that the I-AS moves properly.

5 Press the Go to button on the Select Vial dialog box and verify that the arm

lowers.

Each operation can be initiated from the ALS icons on the toolbar.

NOTE

50 Integrated Autosampler (I-AS)

2 Setup

Checking Operations

Figure 42. ALS toolbar icons

Using the G7200B ICP-MS Software

1 Turn the I-AS power switch to “I” to power up the instrument.

Make sure the LED on the front of the I-AS illuminates.

2 Display the ALS GoTo dialog box.

There are three ways to display the ALS GoTo dialog box.

• From the ICP-MS top, select Acquire Data >> Main Panel... to display the

ICP-MS Acquisition window. From this window, select ALS >> GoTo to display

the ALS GoTo dialog box.

• From the ICP-MS top, select Instrument >> Instrument Control... to display the

ICP-MS Instrument Control window. From this window, select ALS >> GoTo to

display the ALS GoTo dialog box.

• From the ICP-MS top, select Instrument >> Tune... to display the ICP-MS

Tuning window. From this window, select ALS >> GoTo to display the ALS

GoTo dialog box.

Sample tray type

Figure 43. ALS GoTo dialog box

Buttons

HOME button: Moves the arm to the home position (directly over the rinse

port) and to the highest possible position without lowering

the arm.

Integrated Autosampler (I-AS) 51

2 Setup

Checking Operations

1 button: Moves the arm to the first external bottle and lowers the

arm to the setting in the I-AS Configuration dialog box. It

then closes this dialog box.

2 button: Moves the arm to the second external bottle and lowers

the arm to the setting in the I-AS Configuration dialog box.

It then closes this dialog box.

3 button: Moves the arm to the third external bottle and lowers the

arm to the setting in the I-AS Configuration dialog box. It

then closes this dialog box.

Sample Tray Type: Displays the type of sample tray as selected in the I-AS

Configuration dialog box.

Vial No. [ ]: The number in brackets represents the sample number

that can be set. External bottles are displayed with the

numbers 1 to 3. Sample vials are displayed in four-digit

numbers, represented by 1000 and the sequential number

of the vial. (1001, 1002...). The Single Sample Position is

displayed as 1000.

GoTo button: Moves the arm to the location set for the Vial No. and

lowers it to the position in the I-AS Configuration dialog

box. This then closes the dialog box.

Move button: Moves the arm to the location set for the Vial No. and

keeps the arm at the upper position. The dialog box

remains open.

Cancel button: Closes the dialog box without performing any operations.

Help button: Displays the help screen.

Pressing Enter key after inputting the Vial No.[ ] in the Edit Box will have the same

NOTE effect as clicking the GoTo button.

3 Operate the buttons in the ALS GoTo dialog box and verify that the I-AS is

operating normally.

52 Integrated Autosampler (I-AS)

2 Setup

Installing and Adjusting the Needle

Installing and Adjusting the Needle

The procedure differs between G7201A/B/C and G7200B ICP-MS software.

Installation on G7201A/B/C

1 Set the sample tray or Single Sample Position to match the setting in the

software.

2 Click on the Autosampler illustration and select Set Sampling Depth of I-AS...

G7201A/B

G7201C

Figure 44. [Set Sampling Depth of I-AS...] dialog box

Integrated Autosampler (I-AS) 53

2 Setup

Installing and Adjusting the Needle

3 Input the following settings in the Set Sampling Depth of I-AS dialog box.

Figure 45. Set Sampling Depth of I-AS dialog box

Rinse Port: 55.00 mm

Tray/Single: 60.00 mm

Standard/Rinse: 3.00 mm

After inputting these values, click the OK button.

4 Display the Select Vial dialog box.

Figure 46. Select Vial dialog box

54 Integrated Autosampler (I-AS)

2 Setup

Installing and Adjusting the Needle

5 Click the Home button in the Select Vial dialog box.

Click the button with the needle unattached.

The arm will move to the home position.

6 Click on the position number that the sample vial is set to in the Select Vial

dialog box or enter the position number in the edit box.

The location of the sample vial on the sample tray is identified as a four digit

NOTE number consisting of 1000 and the number displayed on the sample tray (1001,

1002...).

7 Click the Go to button.

The arm will move to the sample vial location and lower.

8 Turn the knob located on the end of the arm counterclockwise to loosen.

Arm

Holder

Knob

Needle

Figure 47.

9 Insert the needle into the end of the arm.

Adjust the length to that the tip of the needles sits 2 to 3 mm above the

bottom of the vial. Tighten the knob on the end of the arm.

Integrated Autosampler (I-AS) 55

2 Setup

Installing and Adjusting the Needle

The needle is made of a pliable material and can bend easily. Handle the

CAUTION needle with care. Pay careful attention to the following when determining the

height of the needle tip:

• The tip of the needle should be completely submerged in the sample fluid.

• The tip of the needle should not touch the bottom of the sample vial.

• The needle should not touch anything when the arm is rotating.

If the needle is positioned too low, it can hit something when the arm is moving

and break, bend, or cause liquid to spurt or leak from the instrument.

Use the Micro Flow nebulizer needle when using a Micro Flow nebulizer.

NOTE

The lowest position of the needle should be the upper surface of the Single

Sample Position stand when using the Single Sample Position feature (See the

figure below).

If the tip of the needle is set lower than the lowest position, it will hit the tray

CAUTION cover and other objects when the arm is rotating.

Arm

Needle

The lowest

position of the

needle when using

the Single Sample

Position feature

Figure 48.

56 Integrated Autosampler (I-AS)

2 Setup

Installing and Adjusting the Needle

10 Display the Select Vial dialog box and click the Home button.

The arm will move to the home position. Verify that the needle is directly over

the rinse port.

Needle

(Home position)

Rinse port

Figure 49.

11 Display the Set Sampling Depth of I-AS dialog box.

12 Input 60.00 mm for the Standard/Rinse field in the Set Sampling Depth of I-AS

dialog box and click the OK button.

60.00 mm is the standard setting. Input an appropriate value so that the tip of

CAUTION the needle does not touch the bottom of the external bottle.

13 Display the Select Vial dialog box and click the 1 button.

The arm will move to the first external bottle location and the needle will

lower.

Verify that the needle properly lowers into the external bottle.

14 Connect the peristaltic pump tube.

• This step is not necessary if using a Micro Flow nebulizer as the Micro

Flow nebulizer needle is used. Continue to the next step.

• If a Micro Flow nebulizer is not used, attach the end of the tube coming

from the needle to the peristaltic pump tube.

Integrated Autosampler (I-AS) 57

2 Setup

Installing and Adjusting the Needle

Installation on G7200B

1 Set the sample tray or Single Sample Position to match the setting in the I-AS

Configuration dialog box.

2 Display the I-AS Configuration dialog box.

Figure 50. I-AS Configuration dialog box

3 Input the following settings in the I-AS Configuration dialog box.

Rinse Port: 55.00 mm

Tray/One Bottle: 60.00 mm

STD/Rinse: 3.00 mm

After inputting these values, click the OK button.

58 Integrated Autosampler (I-AS)

2 Setup

Installing and Adjusting the Needle

4 Display the ALS GoTo dialog box.

See “ALS GoTo Dialog Box” for an explanation of how to display the ALS GoTo

dialog box.

Figure 51. ALS GoTo dialog box

5 Click the HOME button in the ALS GoTo dialog box.

Click the button with the needle unattached.

The arm will move to the home position.

6 Input the location number of the sample vial in the Vial No. field in the ALS

GoTo dialog box.

The location of the sample vial on the sample tray is identified as a four digit

NOTE number consisting of 1000 and the number displayed on the sample tray (1001,

1002...).

7 Click the GoTo button.

The arm will move to the sample vial location and lower.

Integrated Autosampler (I-AS) 59

2 Setup

Installing and Adjusting the Needle

8 Turn the knob located on the end of the arm counterclockwise to loosen.

Arm

Holder

Knob

Needle

Figure 52.

9 Insert the needle into the end of the arm.

Adjust the length to that the tip of the needles sits 2 to 3 mm above the

bottom of the vial. Tighten the knob on the end of the arm.

The needle is made of a pliable material and can bend easily. Handle the

CAUTION needle with care. Pay careful attention to the following when determining the

height of the needle tip:

• The tip of the needle should be completely submerged in the sample fluid.

• The tip of the needle should not touch the bottom of the sample vial.

• The needle should not touch anything when the arm is rotating.

If the needle is positioned too low, it can hit something when the arm is moving

and break, bend, or cause liquid to spurt or leak from the instrument.

Use the Micro Flow nebulizer needle when using a Micro Flow nebulizer.

NOTE

60 Integrated Autosampler (I-AS)

2 Setup

Installing and Adjusting the Needle

The lowest position of the needle should be the upper surface of the Single

Sample Position stand when using the Single Sample Position feature (See the

figure below).

If the tip of the needle is set lower than the lowest position, it will hit the tray

CAUTION cover and other objects when the arm is rotating.

Arm

Needle

The lowest

position of the

needle when using

the Single Sample

Position feature

Figure 53.

Integrated Autosampler (I-AS) 61

2 Setup

Installing and Adjusting the Needle

10 Display the ALS GoTo dialog box and click the HOME button.

The arm will move to the home position. Verify that the needle is directly over

the rinse port.

Needle

(Home position)

Rinse port

Figure 54.

11 Display the I-AS Configuration dialog box.

12 Input 60.00 mm for the STD/Rinse field in the I-AS Configuration dialog box

and click the OK button.

60.00 mm is the standard setting. Input an appropriate value so that the tip of

CAUTION the needle does not touch the bottom of the external bottle.

13 Display the ALS GoTo dialog box and click the 1 button.

The arm will move to the first external bottle location and the needle will

lower.

Verify that the needle properly lowers into the external bottle.

14 Connect the peristaltic pump tube.

• This step is not necessary if using a Micro Flow nebulizer as the Micro

Flow nebulizer needle is used. Continue to the next step.

• If a Micro Flow nebulizer is not used, attach the end of the tube coming

from the needle to the peristaltic pump tube.

62 Integrated Autosampler (I-AS)

3 Operation

Measuring with Single Sample Position (Using the G7200B ICP-MS

Software) 64

Measuring with Single Sample Position 64

Single Sample Position Run Dialog Box 65

Integrated Autosampler (I-AS) 63

3 Operation

Measuring with Single Sample Position (Using the G7200B ICP-MS Software)

Measuring with Single Sample Position

(Using the G7200B ICP-MS Software)

Measuring with Single Sample Position

Verify the following before beginning measurement with the Single Sample

Position feature:

• Is the sample tray type field set to “Single Sample” in the I-AS Configuration

dialog box?

Figure 55.

• Has the sample tray been removed and the Single Sample Position properly

set up?

• Is the sample vial number set at “1000”? (The vial number for Single Sample

Position is “1000”)

• Is the LED on the I-AS illuminated? (If not, make sure the power switch is ON.)

In addition to setting the sample vial location to “1000” when using the Single

Sample Position feature for measurement, make sure the other settings are the

same as when using the sample tray.

64 Integrated Autosampler (I-AS)

3 Operation

Single Sample Position Run Dialog Box

Single Sample Position Run Dialog Box

The Single Sample Position Run dialog box can be used to run single samples.

Use the following procedure to display the Single Sample Position Run dialog box.

1 From the ICP-MS Top window, select Acquire Data >> Main Panel.

The ICP-MS Acquisition window will be displayed on the screen.

2 In the ICP-MS Acquisition window, select Acquire Data >> Single Sample

Position Run.

The Single Sample Position Run dialog box will be displayed on the screen.

Figure 56.

Integrated Autosampler (I-AS) 65

3 Operation

Single Sample Position Run Dialog Box

The following procedure explains how to use the Run Options in the Single

Sample Position Run dialog box.

PreRun Uptake/ Select this option to move the needle to the single sample

Stabilization: position before measuring (collecting data). If the needle is

already in the single sample position, it will not move.

When the PreRun Uptake/Stabilization check box is selected,

the system will follow the settings in the Peristaltic Pump

Program dialog box and uptake (replace) the sample

(increase the peristaltic pump speed) and then stabilize

(return the pump to its original speed and wait a specified

amount of time) prior to measuring.

Unselect the PreRun Uptake/Stabilization check box and the

system will bypass the sample uptake and stabilization

processes, and proceed directly to measuring the sample

(collecting data).

PostRun Rinse: Select this option to rinse the needle (includes rinsing at the

rinse port, and cleaning external bottles and sample vials)

according to the Peristaltic Pump Program dialog box

settings after the measurement (data collection) is

complete.

Unselect this check box to bypass the rinse process. The

needle will remain in the bottle after measurement is

complete.

Data Analysis: Select this option for analysis by method.

66 Integrated Autosampler (I-AS)

4 Maintenance

Daily Maintenance 68

Power Cable Fuse 69

Integrated Autosampler (I-AS) 67

4 Maintenance

Daily Maintenance

Daily Maintenance

Perform the following to maintain normal operation of the I-AS:

• Peristaltic Pump Tubing.

Change the Peristaltic Pump Tubing in the following cases:

When the tube becomes too loose to uptake a solution.

When the inside of tube is damaged and dregs come off.

When tubing in the above conditions is used, rinse fluid could overflow from

the rinse port, or dregs tend to come off and result in an impure rinse fluid.

• Use only filtered purified rinse fluid to prevent clogging.

If the Autosampler is not going to be used for a long period of time, replace

the rinse solution with pure water. This prevents the rinse port from clogging.

• Do not use rinse fluid that will harden when mixed with the samples.

• Always keep the rinse system clean.

• Clean the housing with a cloth slightly moistened with water. Do not allow

water to get into the inside of the device.

68 Integrated Autosampler (I-AS)

4 Maintenance

Power Cable Fuse

Power Cable Fuse

To replace the fuse for the power cable, open the fuse holder and replace.

Use a 2AT (time delay) fuse.

Confirm that the power cable has been removed from the wall outlet before

CAUTION replacing a fuse.

Fuse holder

Power switch

Power cable

connector

Figure 57. Fuse holder

Integrated Autosampler (I-AS) 69

This page is intentionally left blank.

70 Integrated Autosampler (I-AS)

In This Book

The Integrated Autosampler (I-AS) explains

the procedures necessary to use the

Integrated Autosampler to enhance sample

analysis.

www.agilent.com

© Agilent Technologies, Inc. 2018

Printed in USA

October 2018

*G3160-90027*

G3160-90027 Revision A

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Standard Welded Wire Mesh For Concrete ReinforcementDocument3 pagesStandard Welded Wire Mesh For Concrete Reinforcementmarksantana100% (2)

- The Psychoanalyzer - FinalDocument25 pagesThe Psychoanalyzer - Finalalvinlarano11No ratings yet

- Global Ethical Issues Unit 3Document15 pagesGlobal Ethical Issues Unit 3aditi anandNo ratings yet

- 236D3 Plano Hidráulico PDFDocument4 pages236D3 Plano Hidráulico PDFFerreira Anibal Paredes100% (1)

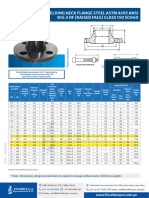

- Bridas WN Clase 150Document1 pageBridas WN Clase 150juan ormacheaNo ratings yet

- PAEDS OSCE ReviewDocument64 pagesPAEDS OSCE Reviewamanda deonananNo ratings yet

- Dr. Fixit Product Guide For Field PDFDocument52 pagesDr. Fixit Product Guide For Field PDFDhirajBothraNo ratings yet

- Design of Sensor Less Sliding-Mode BLDC Motor Speed Regulator Using Class of Uncertain Takagi-Sugeno Nonlinear SystemsDocument5 pagesDesign of Sensor Less Sliding-Mode BLDC Motor Speed Regulator Using Class of Uncertain Takagi-Sugeno Nonlinear SystemsijcnesNo ratings yet

- PDFDocument41 pagesPDFRonak SolgamaNo ratings yet

- Soal Pas 1 PD 2 - Xii - Bahasa InggrisDocument8 pagesSoal Pas 1 PD 2 - Xii - Bahasa InggrisDita AnugerahNo ratings yet

- User Manual: Ac750 Wifi RouterDocument138 pagesUser Manual: Ac750 Wifi RouterKevin KimNo ratings yet

- Contribution of Plato in Political ThoughtDocument18 pagesContribution of Plato in Political ThoughtKOTUB UDDIN AHMED100% (2)

- Analyser Shelter ATEC Italy - WWW - AtecsrlDocument3 pagesAnalyser Shelter ATEC Italy - WWW - AtecsrlMalyshAVNo ratings yet

- 14Φ Series Metal Oxide Varistor (MOV) Data Sheet: FeaturesDocument12 pages14Φ Series Metal Oxide Varistor (MOV) Data Sheet: Featuresirensy vivasNo ratings yet

- Tec CHFX R Eflow 3 .0 Contr Roller An ND Techf FX Reflo Ow Tools SDocument58 pagesTec CHFX R Eflow 3 .0 Contr Roller An ND Techf FX Reflo Ow Tools Smyself248No ratings yet

- E Exe Ef Fluorescent: Standard S Specification FeaturesDocument4 pagesE Exe Ef Fluorescent: Standard S Specification FeaturesrelaxjackNo ratings yet

- TM 9 2320 304 14 and PDocument1,321 pagesTM 9 2320 304 14 and PjordanloNo ratings yet

- Human Anatomy NotesDocument2 pagesHuman Anatomy NotesSamantha LiberatoNo ratings yet

- Lynyrd Skynyrd - Steve Gaines Equipment HistoryDocument10 pagesLynyrd Skynyrd - Steve Gaines Equipment HistorySean88% (8)

- CatálogoDocument21 pagesCatálogoJabith CastilloNo ratings yet

- Security Management Services and Security Culture. I Am Interested in Gaining A MoreDocument1 pageSecurity Management Services and Security Culture. I Am Interested in Gaining A MoreDirgaNo ratings yet

- Workmanship Standard For Crimping, Interconnecting Cables, Harnesses, and WiringDocument101 pagesWorkmanship Standard For Crimping, Interconnecting Cables, Harnesses, and WiringCemy IraclyNo ratings yet

- 4TM1 and 2 Jan 24 PresentersDocument8 pages4TM1 and 2 Jan 24 PresentersMark QuizonNo ratings yet

- Project On Shear Strength Fly AshDocument42 pagesProject On Shear Strength Fly AshSUMIT SENAPATINo ratings yet

- Fetal BehaviourDocument1 pageFetal BehaviourJuan José Espinoza OsoresNo ratings yet

- Chouvy 2014Document8 pagesChouvy 2014Fadwa BADRANANo ratings yet

- Religion of The Tangkhul Naga in North-East India: Continuity and ChangeDocument15 pagesReligion of The Tangkhul Naga in North-East India: Continuity and ChangeThkNo ratings yet

- Preparation of Salt (Worksheet)Document11 pagesPreparation of Salt (Worksheet)terencechen1225No ratings yet

- Changes From Rev AK To Rev AL Skyview Installation GuideDocument608 pagesChanges From Rev AK To Rev AL Skyview Installation GuideF BakımNo ratings yet