Professional Documents

Culture Documents

API STD 53 Degasser Inspection Requirements

API STD 53 Degasser Inspection Requirements

Uploaded by

Terry SmithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API STD 53 Degasser Inspection Requirements

API STD 53 Degasser Inspection Requirements

Uploaded by

Terry SmithCopyright:

Available Formats

BLOWOUT PREVENTION EQUIPMENT SYSTEMS FOR DRILLING W ELLS 37

6.5.3.7.4 The equipment owner shall inform the equipment manufacturer of any well control equipment that

fails to perform in the field, in accordance with Annex B.

Table 2—Pressure Test, Surface BOP Systems, Initial Test

Pressure Test—Low Pressure a Pressure Test—High Pressure b c

Component to Be Tested

psi (MPa) psi (MPa)

Lesser of 70 % of annular RWP, RWP of

Annular preventer 250 to 350 (1.72 to 2.41)

wellhead, or ram preventer test pressure.

Maximum operating pressure recommended by

Operating chambers N/A

the annular BOP manufacturer.

Ram preventers

Fixed pipe

RWP of ram BOPs or RWP of the wellhead

Variable bore 250 to 350 (1.72 to 2.41)

system, whichever is lower.

Blind/blind shear

Maximum operating pressure recommended by

Operating chamber N/A

the ram BOP manufacturer.

Choke and kill lines and RWP of ram BOPs or RWP of the wellhead

250 to 350 (1.72 to 2.41)

valves system, whichever is lower.

Maximum operating pressure recommended by

Operating chamber N/A

the valve manufacturer.

Choke manifold

RWP of ram BOPs, RWP of the wellhead

Upstream of choke(s) system, or RWP choke(s) inlet, whichever is

250 to 350 (1.72 to 2.41) lower.

RWP of choke(s) outlet, valve(s), or line(s),

Downstream of choke(s)

whichever is lower.

Function test only; verification of

Adjustable chokes

backup system.

BOP control system

Manifold and BOP lines N/A Control system maximum operating pressure.

Accumulator pressure Verify precharge. N/A

Close time

Pump capability Function test. N/A

Control stations

Safety valves

Kelly, kelly valves, and

250 to 350 (1.72 to 2.41) RWP of components.

safety valves

Auxiliary equipment

In accordance with equipment

Poor boy degasser/MGS d owner’s PM program.

Flow test.

Trip tank, flo-show, etc. Visual and manual verification. Flow test.

a The low-pressure test shall be stabilized for at least 5 minutes with no visible leaks. Flow-type test shall be of sufficient duration to

observe for significant leaks.

b The high-pressure test shall be stabilized for at least 5 minutes with no visible leaks.

c Well control equipment may have a higher rated working pressure than required for the well site. The site-specific test requirements

shall be used for these situations.

d The MGS requires a one-time hydrostatic test during manufacturing or upon installation. Subsequent welding on the MGS vessel shall

require an additional hydrostatic test to be performed.

Copyright American Petroleum Institute

Provided by IHS under license with API Licensee=Parker Drilling Co./5931885001, User=Hofmann, William

No reproduction or networking permitted without license from IHS Not for Resale, 07/08/2016 11:53:38 MDT

You might also like

- SHENKAI Ram BOP Manual 2FZ3521Document36 pagesSHENKAI Ram BOP Manual 2FZ3521Rogerio NascimentoNo ratings yet

- Zetpol Technical ManualDocument91 pagesZetpol Technical ManualhenrychtNo ratings yet

- Series 150 OvershotsDocument25 pagesSeries 150 OvershotsNitesh Shetty100% (12)

- Relief-Well Planning and Drilling For A North Sea Underground BlowoutDocument8 pagesRelief-Well Planning and Drilling For A North Sea Underground BlowoutAli mohammadNo ratings yet

- User Manual of S-Type Ram BOPDocument26 pagesUser Manual of S-Type Ram BOPhebert perez100% (2)

- The Willis M1A Choke: Angle Body M.O.V. For Oil and Gas Production and E.O.RDocument4 pagesThe Willis M1A Choke: Angle Body M.O.V. For Oil and Gas Production and E.O.RTerry SmithNo ratings yet

- HH-Rotary Table ZP175 - ZP205 PDFDocument3 pagesHH-Rotary Table ZP175 - ZP205 PDFYosed L SantosNo ratings yet

- Stem Reports - Site 20Document4 pagesStem Reports - Site 20Mohamed El-SawahNo ratings yet

- 4) Well Control EquipmentDocument77 pages4) Well Control Equipmentoswaldo58100% (3)

- Index: Bop Repair & Machine, IncDocument53 pagesIndex: Bop Repair & Machine, IncEulises renteria ramosNo ratings yet

- Doc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualDocument12 pagesDoc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualGregory StewartNo ratings yet

- Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Document7 pagesInstructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Heri VillaNo ratings yet

- Regulator3 4 DSDocument4 pagesRegulator3 4 DSargaNo ratings yet

- Mfr. Technical OfferDocument35 pagesMfr. Technical OfferAlireza GolpesarNo ratings yet

- Cameron H2 Part NumbersDocument1 pageCameron H2 Part NumbersDavid OrtegaNo ratings yet

- XQ28-2 6Y英文说明书Document26 pagesXQ28-2 6Y英文说明书ADM MTCNo ratings yet

- Itag Ibop ValveDocument23 pagesItag Ibop ValveValmac ServicesNo ratings yet

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 pagesTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopRiski KurniawanNo ratings yet

- 1102-407 408 Manual and Certs PDFDocument260 pages1102-407 408 Manual and Certs PDFFrancisco Wilson Bezerra FranciscoNo ratings yet

- Mckissick RJ Style Drilling BlocksDocument1 pageMckissick RJ Style Drilling BlocksRichard EVNo ratings yet

- Manual - Tong XQ2.6Document19 pagesManual - Tong XQ2.6yury1102No ratings yet

- 12 - Manual Type AAX TongDocument2 pages12 - Manual Type AAX TongleoNo ratings yet

- Ton Torque ManometrosDocument16 pagesTon Torque ManometrosEliecer DiazNo ratings yet

- Bowls Bushings AOTDocument2 pagesBowls Bushings AOTcristinelbNo ratings yet

- Group Annexures 2017-18Document45 pagesGroup Annexures 2017-18rajesh_rathNo ratings yet

- Combination Hydraulic Station: Parts List (10-A)Document7 pagesCombination Hydraulic Station: Parts List (10-A)waleed100% (1)

- Hawkjaw Sr. Manual 100K-2GSR Serial Numbers 101 To 120Document165 pagesHawkjaw Sr. Manual 100K-2GSR Serial Numbers 101 To 120ahnafNo ratings yet

- 13.625 10K Double Cameron U BOP PDFDocument2 pages13.625 10K Double Cameron U BOP PDFAndung Suwarto100% (1)

- Hawk Industries: Hawkjaw Drill Pipe Power TongDocument3 pagesHawk Industries: Hawkjaw Drill Pipe Power TongShandiPrasetyoNo ratings yet

- Accumulator - Yancheng RuihuaDocument26 pagesAccumulator - Yancheng RuihuaBoedi SyafiqNo ratings yet

- BPV Specification and Drawings PDFDocument4 pagesBPV Specification and Drawings PDFParag PadoleNo ratings yet

- D1992011002 Spider BJDocument4 pagesD1992011002 Spider BJyair_segaNo ratings yet

- Chart Drives: Technical DataDocument4 pagesChart Drives: Technical DataJohn Suarez100% (1)

- Installation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Document8 pagesInstallation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Sergio Fabian VasicekNo ratings yet

- RCP-7.5 Drilling fluid agitator RCP-7.5 搅拌器: Parts List 9-D)Document6 pagesRCP-7.5 Drilling fluid agitator RCP-7.5 搅拌器: Parts List 9-D)waleedNo ratings yet

- FKDQ8007 User ManualDocument24 pagesFKDQ8007 User ManualbrasgNo ratings yet

- Circulating SwagesDocument1 pageCirculating Swageskaveh-bahiraee100% (1)

- 5.12 Bop Es 15MDocument30 pages5.12 Bop Es 15MJavier Rivas50% (2)

- IDS 350PE Flyer D392004983 MKT 001Document2 pagesIDS 350PE Flyer D392004983 MKT 001Juan Mata100% (1)

- Triplex Pump: TPH 400 Main SpecificationsDocument2 pagesTriplex Pump: TPH 400 Main SpecificationsAttou Housseyn100% (1)

- Degasser CD-1400Document3 pagesDegasser CD-1400Ruslan ZakirovNo ratings yet

- Cameron EB 555 D Rev U2 - VBR Engineering InfoDocument6 pagesCameron EB 555 D Rev U2 - VBR Engineering InfoCanrig Ramde100% (1)

- 11"-5000psi Double Ram BOP ManualDocument64 pages11"-5000psi Double Ram BOP ManualDavid EskarousNo ratings yet

- Cameron Hydraulic Gate Valves Type F & FCDocument3 pagesCameron Hydraulic Gate Valves Type F & FCJuan Sebastian Diaz CuadrosNo ratings yet

- ROVNAV Set Up Through Prizm 1Document6 pagesROVNAV Set Up Through Prizm 1Guilherme NevesNo ratings yet

- Specification:: Hammer UnionsDocument5 pagesSpecification:: Hammer Unionscmpuck100% (1)

- Daily Mechanical Inspection ChecklistDocument1 pageDaily Mechanical Inspection ChecklistAgil Wahyu PamungkasNo ratings yet

- DRAFT - Requirements For Pressure TestingDocument3 pagesDRAFT - Requirements For Pressure TestingAdhie WaelacxhNo ratings yet

- LCI 550SpecSheetDocument3 pagesLCI 550SpecSheetandy131078No ratings yet

- Uztel OrizontalDocument5 pagesUztel OrizontalDorin RaduNo ratings yet

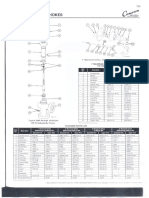

- CLE14000DPcerev9 09 PDFDocument139 pagesCLE14000DPcerev9 09 PDFAdhie WaelacxhNo ratings yet

- 21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Document28 pages21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Mehdi SoltaniNo ratings yet

- Ym16-Ii-00 Hydraulic Cathead 液压猫头: Parts List (4-C)Document7 pagesYm16-Ii-00 Hydraulic Cathead 液压猫头: Parts List (4-C)waleedNo ratings yet

- Manual de Partes KOOMEYDocument104 pagesManual de Partes KOOMEYVictor Hugo AndradeNo ratings yet

- 13-5/8" 3/5/10M Seal Kit TPU-13-TRPKIT: TRP P/N Oem P/N Description QtyDocument1 page13-5/8" 3/5/10M Seal Kit TPU-13-TRPKIT: TRP P/N Oem P/N Description QtyahnafNo ratings yet

- B 2648 PDFDocument6 pagesB 2648 PDFbcanilkumar007No ratings yet

- Specifications:: 1. Traveling Block (YG-150)Document6 pagesSpecifications:: 1. Traveling Block (YG-150)Dewantoro HarisNo ratings yet

- Tech Manual: Tech-5.12 10K Eh Dual Combi InvDocument22 pagesTech Manual: Tech-5.12 10K Eh Dual Combi InvRiski KurniawanNo ratings yet

- Gardner Denver - Bomba de Lodos PZJ-9 Part ListDocument29 pagesGardner Denver - Bomba de Lodos PZJ-9 Part ListAngel LunaNo ratings yet

- W-446 Manual-CN-EN (2ND V)Document39 pagesW-446 Manual-CN-EN (2ND V)ADM MTC100% (1)

- Cup Type TesterDocument1 pageCup Type TesterJohnsNo ratings yet

- Drawwork 1625 Manual PDF Screw Pipe (Fluid 3Document3 pagesDrawwork 1625 Manual PDF Screw Pipe (Fluid 3Mohamed ElmidanyNo ratings yet

- C12-Surface BOPSDocument119 pagesC12-Surface BOPSmissaoui100% (2)

- 1 Stack Component Codes: Halda Etroleum OmpanyDocument7 pages1 Stack Component Codes: Halda Etroleum Ompanyislam atifNo ratings yet

- VED05MJ Proportional Directional Control Valves With OBE and Position Feedback Form 1013139 Rev 06 20Document12 pagesVED05MJ Proportional Directional Control Valves With OBE and Position Feedback Form 1013139 Rev 06 20William GloverNo ratings yet

- الشاكوشDocument4 pagesالشاكوشAdel AshrafNo ratings yet

- UC2842B/3B/4B/5B UC3842B/3B/4B/5B: High Performance Current Mode PWM ControllerDocument15 pagesUC2842B/3B/4B/5B UC3842B/3B/4B/5B: High Performance Current Mode PWM Controllernita_alecsandruNo ratings yet

- Standard 53 Addendum 1Document2 pagesStandard 53 Addendum 1Terry SmithNo ratings yet

- Katch Kan SealsDocument2 pagesKatch Kan SealsTerry SmithNo ratings yet

- SCT516 Belt TongsDocument18 pagesSCT516 Belt TongsTerry SmithNo ratings yet

- Wafer Butterfly ValvesDocument8 pagesWafer Butterfly ValvesTerry SmithNo ratings yet

- MCS Valve: Minimizes Body Washout Problems and Provides Reliable Low-Pressure SealingDocument4 pagesMCS Valve: Minimizes Body Washout Problems and Provides Reliable Low-Pressure SealingTerry SmithNo ratings yet

- The Cameron FLEXPACKER Ram: Comprehensive Advancement in Multiple-Bore Pressure Control TechnologyDocument3 pagesThe Cameron FLEXPACKER Ram: Comprehensive Advancement in Multiple-Bore Pressure Control TechnologyTerry SmithNo ratings yet

- 165-60400 ManualDocument68 pages165-60400 ManualTerry SmithNo ratings yet

- API RP-9B DraftDocument10 pagesAPI RP-9B DraftTerry SmithNo ratings yet

- Inspection Process For Drilling Rigs, Service Rigs, Facilities and LeasesDocument45 pagesInspection Process For Drilling Rigs, Service Rigs, Facilities and LeasesERNESTO PERNIANo ratings yet

- CT Safety ManualDocument36 pagesCT Safety ManualFranklyn Frank100% (1)

- Assignment 2Document5 pagesAssignment 2Yong Hao Jordan JinNo ratings yet

- Workover Operations SANDocument47 pagesWorkover Operations SANArpit YadavNo ratings yet

- WellsafeDocument34 pagesWellsafeHendra Jurbon0% (1)

- Drilling Products Overview Catalog PDFDocument92 pagesDrilling Products Overview Catalog PDFgerrzen64100% (3)

- L 323 Reporting FormatDocument30 pagesL 323 Reporting FormatShraddhanand MoreNo ratings yet

- 13.625 10K BOP BrochureDocument5 pages13.625 10K BOP BrochureAli mohammadNo ratings yet

- BOP Catalog 1Document28 pagesBOP Catalog 1SebastianRomeroBeizaga100% (1)

- Bake Chamber Type 30Document222 pagesBake Chamber Type 30Luis Eduardo Albarracin RugelesNo ratings yet

- North Sea Offshore Authorities Forum: Page 1 of 18Document18 pagesNorth Sea Offshore Authorities Forum: Page 1 of 18Saeed MalikNo ratings yet

- Series 150 Overshots: Instruction Manual 1150Document28 pagesSeries 150 Overshots: Instruction Manual 1150Raul BlancoNo ratings yet

- Technology Bulletin: SUBJECT: New API Recommended Practices For Coiled Tubing Well-Control Equipment AnnouncedDocument4 pagesTechnology Bulletin: SUBJECT: New API Recommended Practices For Coiled Tubing Well-Control Equipment AnnouncedJose Leonardo Materano PerozoNo ratings yet

- Tc1001 06 Cameron TopDocument151 pagesTc1001 06 Cameron TopTopoilServNo ratings yet

- SL Manual Lock 13 58 SHAFFER RAM BOP Page-21-25Document5 pagesSL Manual Lock 13 58 SHAFFER RAM BOP Page-21-25Richard EVNo ratings yet

- CT Problem ProceduresDocument29 pagesCT Problem ProceduresMuhammad ShahrukhNo ratings yet

- Basic Rig ComponentsDocument67 pagesBasic Rig ComponentsDie HArdNo ratings yet

- Coiled Tubing Innovative Rigless InterventionsDocument14 pagesCoiled Tubing Innovative Rigless Interventionscrni rokoNo ratings yet

- Hydril - GK Annular r2Document2 pagesHydril - GK Annular r2Anonymous 48jYxR1CNo ratings yet

- Rotary Rig ComponentsDocument32 pagesRotary Rig ComponentsFahad Paracha50% (2)

- Rangkuman Soal2 Latihan Smart CompetitionDocument105 pagesRangkuman Soal2 Latihan Smart CompetitionNur ArasyiNo ratings yet

- Packard CatalogDocument22 pagesPackard Catalogcrni roko100% (1)

- Wellheads 01Document12 pagesWellheads 01arianaseriNo ratings yet

- Drilling EquipmentDocument63 pagesDrilling EquipmentYudha negaraNo ratings yet