Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

Abdul HannanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

Abdul HannanCopyright:

Available Formats

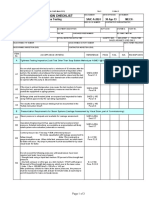

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.

00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Receiving Inspection of Fabricated Structural Attachments

SAIC-D-2004 15-Nov-17 MECH-

to Equipment (Access and Supports)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Walkways & Platforms

Each item or bundle of walkways and platforms are marked with a unique

12-SAMSS-007,

A1 tag number to clearly indicate its associated equipment. Each item or

Par. 6.4.8

bundle of walkways and platforms are indicated on the erection drawings.

The buyer's purchase order number are shown on all erection and shop 12-SAMSS-007,

A2

drawings. Par. 6.4.11

A Shipping List (including total weight), a Bolt List, and a minimum of two

12-SAMSS-007,

A3 sets of final erection and shop drawings are with the first shipment of each

Par. 6.5.1

release.

Material test reports for each heat of structural steel, each lot of high- 12-SAMSS-007,

A4

strength and ASTM A307 bolts are available for review . Par. 7.7

Connections for secondary structural members (purlins, girts, stair

framing, stair treads, stair bracing, toe plate, handrail, ladders, small SAES-M-001,

A5

miscellaneous platforms, stiles, etc.) are bolted with machine bolts Par. 7.1.12.5

conforming to ASTM A307.

ASTM A307 bolts supplied with the structures are to be limited to sizes 16 SAES-M-001,

A6

mm (5/8 inch) diameter and smaller. Par. 7.1.12.5

The thickness of gusset and stiffener plates are 10 mm (3/8 inch) SAES-M-001,

A7

minimum. Par. 7.1.12.6

SAES-M-001,

A8 All structural strength welding are continuous.

Par. 7.1.13.2

The edges of all tightly contacting surfaces are completely seal welded

SAES-M-001,

A9 with a minimum of 3 mm fillet weld regardless of the base metal

Par. 7.1.13.3

thickness.

Re-entrant corners of steel structures are shaped, notched-free, to a 12-SAMSS-007,

A10

radius. Par. 6.1.10

12-SAMSS-007,

A11 Galvanized washers and nuts furnished on galvanized bolts.

Par. 6.2.5.4

All bolts, nuts, and washers are properly identified and marked with the 12-SAMSS-007,

A12

material grade and manufacturer's logo. Par. 6.2.5.5

To ensure electrical continuity when shop-applying non-conductive

12-SAMSS-007,

A13 coatings (i.e., epoxies), all contact surfaces shall be masked and noted on

Par. 6.2.7.3

the shop drawings.

All cross-bracing are bolted at intersections, with one bolt minimum for 12-SAMSS-007,

A14

angles and two bolts minimum for tees. Par. 6.2.8.2

Saudi Aramco: Company General Use

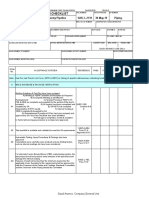

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Receiving Inspection of Fabricated Structural Attachments

SAIC-D-2004 15-Nov-17 MECH-

to Equipment (Access and Supports)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

12-SAMSS-007,

A15 The bottom of base plates are clean and free of any rust or corrosion.

Par. 6.3.1.6

Galvanizing of steel shapes, plates & hardware were in accordance with 12-SAMSS-007

A16

ASTM A123/A123M as verified through mill test certificates Par. 5.2.2

Galvanizing of bolts were in accordance with the following ASTM

specifications as verified through the mill Test Certificates.

a) ASTM A325 Type 1 or ASTM A325M Type 1 bolts and

corresponding nuts and washers -ASTM B695 12-SAMSS-007,

A17

or ASTM F2329 Par. 5.2.2

b) ASTM A36 / ASTM A36M threaded bar or ASTM A307 bolts and

corresponding nuts and washers - ASTM F2329

or ASTM B695

Galvanized steel coatings have been inspected in accordance with the

12-SAMSS-007,

A18 provisions of ASTM A123/A123M and ASTM E376 and accepted by

Par. 5.2.5

buyers rep.

Any nonadhering galvanizing were removed until the surrounding

12-SAMSS-007,

galvanizing is integral and adherent to the base metal.

A19 Par. 5.2.6.2 &

(NOTE: When surface defects exceed 2% of a member's area, the

Par. 5.2.6.3

defects shall be repaired by redipping the member in the zinc bath.)

Any cold repair to galvanized structure using an organic zinc rich coating

(primer in APCS-1C) is allowed with following conditions:

12-SAMSS-007,

A20 a) The total damaged area is less than 1% of the total coated area

Par. 5.2.6.4

of the member being repaired

b) No single repair is greater than 2 square inches (1300 mm²)

Coating system applied conformed with the selection requirements of

SAES-H-001,

A21 SAES-H-001, Section 7.1.K/M/O, or as per the project Coating Schedule

Section 7.1

and subject to their limitations on service conditions.

External coating shows no physical damage (gouge, cracks, runs, sags,

drips, dry spray, porous, foreign matter) or pre-mature breakdown/rusting SAES-H-001

A22

and meet the DFT requirements as specified in SAES-H-001 Sec 10

APCS-System ------------- as specified by the Purchase Order

Where fireproofing of structural steel is specified, the steel are coated in

12-SAMSS-007,

A23 accordance with SAES-H-001, APCS-1B, Epoxy Coated System with

Par. 5.1

Epoxy Primer.

Variations in straightness of structural columns and beams are required to

12-SAMSS-007,

A24 be within the allowed variations stated in ASTMA6/A6M, Tables 21, 22,

Sec. 7

23, 24 & 25. See M-SATIP as needed.

B Ladders and Cages

12-SAMSS-007,

B1 Fixed Ladders and Cages shall comply with PIP STF05501

Par. 5.4

12-SAMSS-007,

B2 Ladder cages are shop assembled on ladders.

Par. 6.1.17

C Walkways and Railings

Pipe Railing for Walkway and Working Surfaces shall comply with PIP 12-SAMSS-007,

C1

standard STF05520. Angle railing shall not be used. Par. 5.6

The bending radius of the top handrail shall be 190 mm. Mitered

SAES-B-054,

C2 construction shall not be used in place of bending handrails.

Sec. 7, Par. 6.18

Except on removable railing section as shown in PIP STF05520.

Ends of rails are terminated at terminal posts. Rails do not overhang the SAES-B-054,

C3

posts to pose a projection hazard (ANSI A1264.1, Par. 5.4) Sec. 7

All open ends of steel pipes or tubing are sealed to prevent internal 12-SAMSS-007,

C4

corrosion. Par. 6.1.4

Exposed corners, edges, burrs or rough spots on handrail, guards,

12-SAMSS-007,

C5 ladders, platforms and stairs, which might cause injury to personnel using

Par. 6.1.16

the assembled structure, shall be ground or filed smooth.

Grating / checkered plate openings dimensioned on design dwgs are cut 12-SAMSS-007,

C6

and banded in the shop as shown on the design drawing. Par. 6.1.19

SAES-B-054,

C7 Gratings cut from a standard length are provided with end banding.

Sec. 7, (6.23)

Saudi Aramco: Company General Use

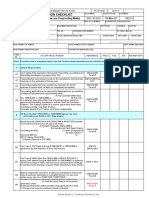

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Receiving Inspection of Fabricated Structural Attachments

SAIC-D-2004 15-Nov-17 MECH-

to Equipment (Access and Supports)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

Checkered plate have ½ inch (12 mm) diameter drain holes (when

12-SAMSS-007,

C8 specified on contract drawings) provided for each 20 ft² (2 m²) of area,

Par. 6.1.21

with a minimum of one hole per panel.

Floor Steel plate with plain or with diamond or other patterns are coated SAES-B-054,

C9

with anti-skid paint, SAES-H-101 APCS-12. Par. 4.9.3

Toe boards have minimum height of 3-1/2" (89 mm). (ANSI A1264.1 Par. SAES-B-054,

C10

5.7) Sec. 7, (6.15)

D Stairs

SAES-B-054,

D1 Stair treads are made of a steel grating type with an abrasive nosing.

Par. 4.9.1

Treads of fixed stairs are installed with a rise of 190 mm and a tread run

SAES-B-054,

D2 of 254 mm (Minimum). (Tolerance for Riser: +/-3mm and +/-13mm for

Sec. 7, (6.4)

bottom step. Refer to Dwg AB-36106 & AC-36198)

SAES-B-054,

D3 Height of stair rail is 3'-6" (850 mm) per PIP-STF05520.

Sec. 7, (5.5)

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-M-001 -- Structural Design Criteria for Non-Building Structures, 17 April 2016

2- SAES-B-054 -- Access, Egress, and Materials Handling for Plant Facilities, 29August 2010

3- 12-SAMSS-007 -- Fabrication of Structural and Miscellaneous Steel, 17 May 2011

4- SAES-H-001 -- Coating Selection and Application Requirements for Industrial Plants and Equipment, 5 April 2016

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Chop Saw - 251938 - M2500LW2 - Task Force 10in Cmpd. Miter SawDocument64 pagesChop Saw - 251938 - M2500LW2 - Task Force 10in Cmpd. Miter SawJacob B100% (3)

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- SATR-W-2006 Rev 6Document1 pageSATR-W-2006 Rev 6Manoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioNo ratings yet

- SAIC-L-2074 Rev 0Document1 pageSAIC-L-2074 Rev 0philipyapNo ratings yet

- SAIC-A-2016 Rev 0Document2 pagesSAIC-A-2016 Rev 0philipyapNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishNo ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument2 pagesSaudi Aramco Typical Inspection PlanMAZHARULNo ratings yet

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18nadeem shaikhNo ratings yet

- Satr-W-2008 Atyb TRDocument6 pagesSatr-W-2008 Atyb TRDeo MNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMINo ratings yet

- SATIP-W-011-01 Rev 8Document10 pagesSATIP-W-011-01 Rev 8saravananmenmathiNo ratings yet

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- Incr - XXXDocument2 pagesIncr - XXXsadik coolsadyNo ratings yet

- Saes L 132Document38 pagesSaes L 132BM TECH100% (1)

- SAIC-A-2024 Rev 6 Leakness Tightness TestDocument3 pagesSAIC-A-2024 Rev 6 Leakness Tightness Testpookkoya thangalNo ratings yet

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-L-2014 Flange Joint Insp PDFDocument7 pagesSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- SATIP B 019 01 (Revision 4)Document2 pagesSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWNo ratings yet

- 175 010600Document1 page175 010600Abu Anas M.Salaheldin100% (1)

- Satip F 001 04Document4 pagesSatip F 001 04Anonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- 175 010700 PDFDocument2 pages175 010700 PDFAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- 00 Saip 12Document8 pages00 Saip 12aamirtec301No ratings yet

- SATIP-A-004-01 Rev 7Document2 pagesSATIP-A-004-01 Rev 7Bebin Mathew100% (1)

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Active Doc ListDocument405 pagesActive Doc Listnadeem UddinNo ratings yet

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument5 pagesSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNo ratings yet

- Saep 324 PDFDocument13 pagesSaep 324 PDFArvind ShakyaNo ratings yet

- Saudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalDocument11 pagesSaudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalRijwan MohammadNo ratings yet

- A A A A A A: Saudi Aramco Inspection ChecklistDocument2 pagesA A A A A A: Saudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saep 325Document43 pagesSaep 325AbdullahNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- SAIC-D-2004 Rev 8Document3 pagesSAIC-D-2004 Rev 8Syed ImranNo ratings yet

- Saic M 2010Document17 pagesSaic M 2010jerinNo ratings yet

- Saic M 2004Document6 pagesSaic M 2004Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechDocument2 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechAnonymous S9qBDVkyNo ratings yet

- Saic M 1073Document6 pagesSaic M 1073Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1034Document2 pagesSaic M 1034noor mohamedazeezNo ratings yet

- Saic M 1033Document7 pagesSaic M 1033noor mohamedazeezNo ratings yet

- Civil ITPs ChecklistsDocument183 pagesCivil ITPs ChecklistsmunirNo ratings yet

- SKBR HR NP 19111712022Document4 pagesSKBR HR NP 19111712022Abdul HannanNo ratings yet

- 12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Document30 pages12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Abdul HannanNo ratings yet

- RFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREADocument4 pagesRFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREAAbdul Hannan100% (1)

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- 01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentDocument13 pages01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentAbdul HannanNo ratings yet

- 09-SAMSS-068 Qualification Requirements For Coal Tar Epoxy in Buried or Immersion Services (APCS-3) For Steel and ConcreteDocument7 pages09-SAMSS-068 Qualification Requirements For Coal Tar Epoxy in Buried or Immersion Services (APCS-3) For Steel and ConcreteAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic A 2009Document5 pagesSaic A 2009Abdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Rexnord Marbett Issue 14-English. Part 1 Componenten PDFDocument246 pagesRexnord Marbett Issue 14-English. Part 1 Componenten PDFKoen Bidlot100% (1)

- Market Study of Alloy Steel With Special Reference To RMG Alloy Steel LTDDocument75 pagesMarket Study of Alloy Steel With Special Reference To RMG Alloy Steel LTDabhinavNo ratings yet

- TOR of SINTO Shot Blasting MachineDocument1 pageTOR of SINTO Shot Blasting MachineImags GamiNo ratings yet

- SANS29Document15 pagesSANS29Amenaw MulunehNo ratings yet

- Sutton Tools L343 Engineers Black Book - 3rd Edition 235 PagesDocument3 pagesSutton Tools L343 Engineers Black Book - 3rd Edition 235 PagesmanjuNo ratings yet

- Economical Metal Anchor For Drywall and Hollow BlockDocument3 pagesEconomical Metal Anchor For Drywall and Hollow BlockPedro LanuzaNo ratings yet

- Nyrstar FactSheet Balen 2018Document2 pagesNyrstar FactSheet Balen 2018Mehdi AğayiNo ratings yet

- Focus On The Fundamentals of Shielded MV Power CableDocument3 pagesFocus On The Fundamentals of Shielded MV Power CableMrNo ratings yet

- 4UB18ME402 Anup Betageri Internship Report 2021Document26 pages4UB18ME402 Anup Betageri Internship Report 2021Anup BetageriNo ratings yet

- Vedanta Integrated Report 2019-20Document254 pagesVedanta Integrated Report 2019-20RupasinghNo ratings yet

- Asme Sa-358Document7 pagesAsme Sa-358Lora BoydNo ratings yet

- ME8793 - Process Planning and Cost Estimation (Ripped From Amazon Kindle Ebooks by Sai Seena)Document364 pagesME8793 - Process Planning and Cost Estimation (Ripped From Amazon Kindle Ebooks by Sai Seena)Johnson Johnson100% (2)

- CARDBOARD Robotic Hydraulic ArmDocument12 pagesCARDBOARD Robotic Hydraulic ArmRAVI RanjanNo ratings yet

- Part 3 Execution: Bujairi F&B Architectural Specification Section 08 71 00 Door HardwareDocument2 pagesPart 3 Execution: Bujairi F&B Architectural Specification Section 08 71 00 Door Hardwaremus3b1985No ratings yet

- Exam IA 6 - Tools and Their Functions Part 1Document2 pagesExam IA 6 - Tools and Their Functions Part 1VICTORIANO DONOSONo ratings yet

- AIRCRAFT SPECIAL FASTENERS PowerpointDocument60 pagesAIRCRAFT SPECIAL FASTENERS PowerpointNahshon YbañezNo ratings yet

- Seminar Report On Heat Treatment Process For Shear Machining Blade, Hexoblade, Nozzle of Ajm, Plier ToolsDocument20 pagesSeminar Report On Heat Treatment Process For Shear Machining Blade, Hexoblade, Nozzle of Ajm, Plier ToolsChetan PrajapatiNo ratings yet

- 5 Drawing ZTT Line HardwareDocument2 pages5 Drawing ZTT Line HardwareVictor DoyoganNo ratings yet

- Sutton Tools L343 Engineers Black Book - 3rd Edition 235 PagesDocument3 pagesSutton Tools L343 Engineers Black Book - 3rd Edition 235 PagesPloop2000No ratings yet

- Interwire 2017 and Wire Russia 2017: Show PreviewsDocument28 pagesInterwire 2017 and Wire Russia 2017: Show PreviewsQC ĐNNo ratings yet

- Komatsu Crawler Excavator Pc800 7 Shop ManualDocument20 pagesKomatsu Crawler Excavator Pc800 7 Shop ManualgeorgeNo ratings yet

- Advanced Injection MouldingDocument29 pagesAdvanced Injection MouldingShubham ChaudharyNo ratings yet

- Materials System SpecificationDocument6 pagesMaterials System SpecificationFAPM1285No ratings yet

- A05-S02 Rev 4 Mar 2019Document10 pagesA05-S02 Rev 4 Mar 201915150515715No ratings yet

- PHP Catalog CD PDFDocument119 pagesPHP Catalog CD PDFAaron EasleyNo ratings yet

- Trade Setups For Intraday Trades: Commodity Trading Ready ReckorDocument4 pagesTrade Setups For Intraday Trades: Commodity Trading Ready ReckorLeo JoyNo ratings yet

- Getting Graphite Prices RightDocument5 pagesGetting Graphite Prices RightMochammad AdamNo ratings yet

- ZTT-540 Application GuideDocument8 pagesZTT-540 Application GuidesejlNo ratings yet

- BS en 12070 PDFDocument13 pagesBS en 12070 PDFMina RemonNo ratings yet