Professional Documents

Culture Documents

Acoustic Louvers: ..... A Perfect Partner in Performance ..... A Perfect Partner in Performance

Acoustic Louvers: ..... A Perfect Partner in Performance ..... A Perfect Partner in Performance

Uploaded by

Ahmed MontashOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acoustic Louvers: ..... A Perfect Partner in Performance ..... A Perfect Partner in Performance

Acoustic Louvers: ..... A Perfect Partner in Performance ..... A Perfect Partner in Performance

Uploaded by

Ahmed MontashCopyright:

Available Formats

ACOUSTIC LOUVERS

1 .....a perfect partner in performance

Acoustic Louvers

Our Product Ranges

1 Fire Dampers

2 Fire / Smoke Dampers

Dampers 3 Volume Control Dampers

4 Motorized Control Dampers

5 Pressure Relief Dampers /Non Return Dampers

6 Pressure Independent VAV

Variable Air Volumes 7 Constant Air Volume VAV

8 By Pass VAV

9 Sand Trap Louvers

10 Acoustic Louvers

Louvers 11

12

Stationery Louvers / Architectural Louvers

Storm Louvers

13 Weather Louvers

14 Rectangular Sound Attenuators

Sound

SoundAttenuators

Attenuators 15 Circular Sound Attenuators

16 Crosstalk Attenuators

17 Flange & Slip 'n' Type

Electric

ElectricDuct

Duct Heaters

Heaters 18 Modulating & On/Off Type

19 Registers & Grilles

Diffusers (Linear Diffusers, Sq. & Rect. Ceiling

20

Air

AirOutlets

Outlets Diffusers, Round Diffusers, Jetflow Diffusers

21 Swirl Diffusers & Disc Valves

22 Drum Louvers

.....a perfect partner in performance 2

Acoustic Louvers

INDEX

Page

Introduction......................................................................................................................................... 04

Louver Model - ASB 100/150/200 & 250 AL ( Single Bank).................... 05

Louver Model - ADB 300 AL (Double Bank)......................................................... 06

Louver Model - ADB-I 300 AL (Industrial Type).............................................. 07

Louver Model - ADB 600 AL (Double Bank)........................................................ 08

Acoustic Louvered Doors........................................................................................................ 09

Finish, Colour & Optional Construction...................................................................... 10

Frame & Louver Blade configuration............................................................................... 11

Construction Details................................................................................................................... 12

Engineering Guidelines........................................................................................................ 13-15

Material Storage, Operation & Mantenance............................................................. 16

Installation Details........................................................................................................................... 17

Project Highlights...................................................................................................................... 18-19

3 .....a perfect partner in performance

Acoustic Louvers

Overview

Airwellcare Acoustic Louvers are

effectively restrict the transmission of high

and low frequency sound energy produced

by the operation of mechanical equipment

of building openings.

Forecasting the ever increasing noise

reduction demands of future, Airwellcare

is striving towards enhancement of

our ability to reduce the unwanted and

excessive noise in industiral, commercial

as well residential environment with a

faster, innovating and delivering solutions Selection & Design

for the upcoming generation.

Acoustic Louvers are constructed of Airwellcare Acoustic Louvers are designed and

customized options in galvanized steel manufactured in compliance with international

or high quality Aluminium with variety standards, to achieve the optimum results through

of finishes, to meet the Architecture and Acoustic Louver Software Selection Method

project requirements. supported by our Acoustic Engineering Consultant.

Acoustic and aerodynamic performance varies with

the design, and the sizing of the louvers are important

to minimize concerns of pressure drop and water

ingress.

All Airwellcare Acoustic Louvers are designed for

multi purpose, permitting air to flow, while protecting

the environment from unwanted noise, to suit the

application, from offshore environments to extreme

weather and ambient tempreature.

Airwellcare Acoustic Louvers can produce a highly engineered solution to your unwanted noise

problem and any noise control issue.

Acoustic Louver applications

Airwellcare Acoustic Louver • District Cooling Plants. • Offshore & Onshore.

solutions will help to combact • Generator Rooms in • Chemical treatment plants.

environmental noise problems Commercial & Industrial • Aviation industries.

that affect mixed, commercial Sectors.

and residential areas, reducing • Commercial and Industrial

• Electrical Substations. Duct Systems.

noise from a wide variety of • Power Generating plants. • Fresh air intakes for

applications that include: • Healthcare & Hospitals. ventilation systems.

.....a perfect partner in performance 4

Acoustic Louvers

Model : ASB 100/150/ 200 & 250 AL

Airwellcare ASB 100 - 250mm single bank

Acoustic Louvers are manufactured in galvanized

steel, as standard.

Louver Frame

Louver frame is made of 18 Gauge (1.2mm) thick.

Galvanized Steel.

Louver Depth: 100, 150, 200 and 250 depending

on application & nature of project.

Frame with 16 Guage (1.5mm) extruded aluminium

is optional.

Acoustic Property

Louver Blade • 75mm Thick Rockwool of 32-35 Kg/M3 Density.

75mm thick. Louver external blades are made of • Thickness & density can be changed according to

20 Gauge (1.0mm) galvanized steel or aluminium, the Technical Acoustic Calculations, to obtain the

positioned at 45°Angle. Exterior surface with optimum performance of the Louver.

0.8 mm thick. Galvanized perforated steel or • Non combustible when tested in accordance with

perforated aluminium panel. BS 476 : Part 4: 1970 & ASTM E-136.

• Fill material is class-1 as tested in accordance with

Acoustic In-fill ASTM-84.

Each Blade, Top and Bottom frame cavity shall • Fiberglass shall be density calculated to provide

be filled with fiberglass acoustic insulation of 32 the acoustic and aerodynamic performace.

-35 Kg/M³ density, to absorb the transmission of • Tested for Temp. upto 750° C in accordance with

sound. DIN 52271.

• Meet the requirements of BS 2972 Sec.22

Bird Screen / Insect Screen & ASTM C-871, ASTM-C-795, ASTM C-692.

12 x 12 x 1.0 mm thick. Galvanized Screen ASTM C-177/C-518 & DIN 52612 for low thermal

conductivity.

( Refer to Page No.10 —optional accessories)

• Sound absorption in accordance with BS 3638 &

Nominal Free Area ISO 0354.

30-40% (may vary based on actual calculations) • Inert, vermin-proof, weather rated non combustible

acoustic infill.

Key Features

• Design Flexibility. • Customized material selection with

• Hurdle free installation. galvanized or aluminum construction.

• Swift delivery upon 100% Production • Architecturally aesthetic appearance.

confirmation & drawing approval. • All sizes are custom fabricated to meet

• Technical & after sales support. project requirements.

• AutoCAD drawings are incorporated in • Acoustical attenuation across all eight

compliance with project requirement for octave bands.

every project. • Good water penetration performance.

5 .....a perfect partner in performance

Acoustic Louvers

Model : ADB 300 AL

Airwellcare ADB 300 AL is a double bank

sightproof Acoustic Louver manufactured in

galvanized steel, as standard with chevron blade

configurations.

Louver Frame

Louver frame is made of 16 Gauge (1.5mm)

Galvanized Steel.

Louver Depth: 300mm

Frame with 2.0 mm thick. Aluminium is optional.

Acoustic Property Louver Blade

• 75mm Thick Rockwool of 32-35 Kg/M3 Density.

75 - 100 mm thick. (depending on application)

• Thickness & density can be changed according to external blades are made of 20 Gauge (1.0mm)

the Technical Acoustic Calculations, to obtain the galvanized steel or aluminium, positioned at

optimum performance of the Louver.

45°Angle. Exterior surface with 0.8 mm

• Non combustible when tested in accordance with thick. galvanized perforated steel or perforated

BS 476 : Part 4: 1970 & ASTM E-136. aluminium panel.

• Fill material is class-1 as tested in accordance with

ASTM-84. Acoustic In-fill

• Fiberglass shall be density calculated to provide the Each Blade, Top and Bottom frame cavity shall

acoustic and aerodynamic performace. be filled with fiberglass acoustic insulation of 32

• Tested for Temp. upto 750° C in accordance with -35 Kg/M³ density, to absorb the transmission of

DIN 52271. sound.

• Meet the requirements of BS 2972 Sec.22 Bird Screen / Insect Screen

& ASTM C-871, ASTM-C-795, ASTM C-692.

ASTM C-177/C-518 & DIN 52612 for low thermal 12 x 12 x 1.0 mm thick. Galvanized Screen

conductivity. ( Refer to Page No.10 —optional accessories)

• Sound absorption in accordance with BS 3638 & Nominal Free Area

ISO 0354.

30-40% (may vary based on actual calculations)

• Inert, vermin-proof, weather rated non combustible

acoustic infill.

Key Features

• Design Flexibility. • Customized material selection with

• Hurdle free installation. galvanized or aluminum construction.

• Swift delivery upon 100% Production • Architecturally aesthetic appearance.

confirmation & drawing approval. • All sizes are custom fabricated to meet

• Technical & after sales support. project requirements.

• AutoCAD drawings are incorporated in • Acoustical attenuation across all eight

compliance with project requirement for octave bands.

every project. • Good water penetration performance.

.....a perfect partner in performance 6

Acoustic Louvers

Model : ADB-I 300 AL ( INDUSTRIAL )

Airwellcare High performance industrial type

sightproof double bank Acoustic Louvers are

manufactured in galvanized steel as standard,

with chevron blade configuration, where extreme

levels of noise to be attenuated and controlled.

Louver Frame

Louver frame is made of 2.0 mm thick. galvanized

steel.

Louver Depth: 300mm

Frame with 16 Guage (1.5mm) aluminium is Acoustic Property

optional.

• 75mm Thick Rockwool of 32-35 Kg/M3 Density.

Louver Blade • Thickness & density can be changed according to

the Technical Acoustic Calculations, to obtain the

75 - 100 mm thick. (depending on application)

optimum performance of the Louver.

external blades are made of 20 Gauge (1.0mm)

galvanized steel or aluminium, positioned at • Non combustible when tested in accordance with

BS 476 : Part 4: 1970 & ASTM E-136.

45°Angle. Exterior surface with 0.8 mm

thick. galvanized perforated steel or perforated • Fill material is class-1 as tested in accordance

aluminium panel. with ASTM-84.

• Fiberglass shall be density calculated to provide

Acoustic In-fill the acoustic and aerodynamic performace.

Each Blade, Top and Bottom frame cavity shall • Tested for Temp. upto 750° C in accordance with

be filled with fiberglass acoustic insulation of 32 DIN 52271.

-35 Kg/M³ density, to absorb the transmission of • Meet the requirements of BS 2972 Sec.22

sound. & ASTM C-871, ASTM-C-795, ASTM C-692.

ASTM C-177/C-518 & DIN 52612 for low thermal

Bird Screen / Insect Screen conductivity.

12 x 12 x 1.0 mm thick. Galvanized Screen • Sound absorption in accordance with BS 3638 &

( Refer to Page No.10 —optional accessories) ISO 0354.

• Inert, vermin-proof, weather rated non

Nominal Free Area combustible acoustic infill.

30-40% (may vary based on actual calculations)

Key Features

• Design Flexibility. • Customized material selection with

• Hurdle free installation. galvanized or aluminum construction.

• Swift delivery upon 100% Production • Architecturally aesthetic appearance.

confirmation & drawing approval. • All sizes are custom fabricated to meet

• Technical & after sales support. project requirements.

• AutoCAD drawings are incorporated in • Acoustical attenuation across all eight

compliance with project requirement for octave bands.

every project. • Good water penetration performance.

7 .....a perfect partner in performance

Acoustic Louvers

Model : ADB 600 AL

Airwellcare ADB 600 AL is a high performance

double bank sightproof Acoustic Louver

manufactured in galvanized steel, as standard,

with chevron blade configurations, for excessive

noise attenuation.

Louver Frame

Louver frame is made of 16 Gauge (1.5mm)

Galvanized Steel.

Louver Depth: 600mm

Acoustic Property Frame with 2.0 mm thick. Aluminium is optional.

• 75mm Thick Rockwool of 32-35 Kg/M3 Density.

• Thickness & density can be changed according to

Louver Blade

the Technical Acoustic Calculations, to obtain the 75 - 100 mm thick. (depending on application)

optimum performance of the Louver. external blades are made of 20 Gauge (1.0mm)

• Non combustible when tested in accordance with galvanized or aluminium, positioned at 45°Angle.

BS 476 : Part 4: 1970 & ASTM E-136. Exterior surface with 0.8 mm thick. galvanized

• Fill material is class-1 as tested in accordance with perforated steel or perforated aluminium panel.

ASTM-84.

Acoustic In-fill

• Fiberglass shall be density calculated to provide the

acoustic and aerodynamic performace. Each Blade, Top and Bottom frame cavity shall

• Tested for Temp. upto 750° C in accordance with be filled with fiberglass acoustic insulation of 32

DIN 52271. -35 Kg/M³ density, to absorb the transmission of

sound.

• Meet the requirements of BS 2972 Sec.22

& ASTM C-871, ASTM-C-795, ASTM C-692.

ASTM C-177/C-518 & DIN 52612 for low thermal

Bird Screen / Insect Screen

conductivity. 12 x 12 x 1.0 mm thick. Galvanized Screen

• Sound absorption in accordance with BS 3638 & ( Refer to Page No.10 —optional accessories)

ISO 0354.

Nominal Free Area

• Inert, vermin-proof, weather rated non combustible

acoustic infill.

30-40% (may vary based on actual calculations)

Key Features

• Design Flexibility. • Customized material selection with

• Hurdle free installation. galvanized or aluminum construction.

• Swift delivery upon 100% Production • Architecturally aesthetic appearance.

confirmation & drawing approval. • All sizes are custom fabricated to meet

• Technical & after sales support. project requirements.

• AutoCAD drawings are incorporated in • Acoustical attenuation across all eight

compliance with project requirement for octave bands.

every project. • Good water penetration performance.

.....a perfect partner in performance 8

Acoustic Louvers

ACOUSTIC LOUVERED DOORS

Door Features

• Single and double doors are available • All doors are supplied with heavy duty

based on the project requirements. hinges, lock and pull handle.

• The standard single door is available • Acoustic louvered doors can be fitted

upto 1250 x 2950mm height & Double with birdscreen and or insect screens

Door is upto 2500 x 2950mm height. on request.

• Customized optional dimensions for • Please refer to page No 10 for Louver

the doors are also available upon Door powder coated finishes and

request. colours.

9 .....a perfect partner in performance

Acoustic Louvers

FINISH / COLOUR / OPTIONAL CONSTRUCTION

All sound calculations meet international

standards ASTM E90, ASTM E477, ISO 7235, ISO

TF

3741, ISO 140, ISO 3744, ISO 3746, ISO 6798, ISO

8528-10, ASHRAE Handbook & Sound Research B

Laboratory.

2B

Airwellcare Acoustic Louvers design flexibility 2A

A

and Sound Calculations allows to adjust :

h

• The Louver depth

• Louver blade shape

• Louver blade thickness

• Airway gap between blades

• Acoustic filling properties BF

The design flexibility and calculations are based

on Louver Application & nature of project.

TF : Top frame dimension.

BF : Bottom frame dimension.

FINISH & COLOUR H : Total height of the louver (aperture height).

Standard Powder Coating finish as per RAL Colour A : Blade thickness.

Codes. The following custom based optional B : Air way width.

coatings / finish are also available on request.

• Super-Durable Polyester Powder Coating Optional Construction,

(SDF) Accessories and Fittings

• Hyper-Durable Flurocarbon Polymer Coating Many optional accessories to the basic design

(HDF) are available at an additional cost.

They include:

• Polyvinylidene fluoride coating/KYNAR

Coating (PVDF/KYNAR) • Construction with Aluminium material.

• Extended sill flashing.

The above finishes complies to AAMA 2603 /

2604 / 2605 requirements with 20-year limited • Bird Screen / Insect Screen in Galvanized

warranty against failure or excessive fading. Steel / Stainless Steel / Aluminium in

various sizes.

WARRANTY • Flanged frames of various sizes.

• All materials and workmanship are warranted • Hinged access panels Sub-frames.

for a period of one year from date of shipment • Continuous perimeter / Support angles.

/ Delivery. • Visible mullions for multiple section

• Extended Warranty is available upon request requirements.

at an additional cost. • Anodized, Baked Enamel or Kynar finish.

.....a perfect partner in performance 10

Acoustic Louvers

FRAME & LOUVER BLADE CONFIGURATIONS

Louver depth

Louver depth

Louver depth Louver depth Louver depth

Type 1 Type 2 Type 3 Type 4 Type 5

Type 1 : Straight 45 degrees blade.

Type 2 : Chevron 90 degrees sharp bend.

Type 3 : Chevron 90 degrees rounded bend.

Type 4 : Chevron two 45 degrees bends.

Type 5 : Straight 45 degrees blade with two bends of 45 degree each.

Airwellcare Acoustic

Louvers with diffrent

blade configurations

and styles can match

perfectly the overall

scale and aesthetics

of a new building.

Louver Frame Depth Louver Frame Depth

(100 to 300mm) (300 to 600mm)

11 .....a perfect partner in performance

Acoustic Louvers

CONSTRUCTION DETAILS

Double Bank

Single Bank

.....a perfect partner in performance 12

Acoustic Louvers

ENGINEERING GUIDELINES

Free Area

Model - ASB 100-250 AL, ADB 300 AL, ADB-I 300 AL & ADB 600 AL

The above Free Areas are in Sq. Ft.

Data required for Technical Calculations

The following Technical details of the project to be forwarded to us, to design and to

sunbmit the technical calculation of the Acoustic Louver :

g Louver Type (Single Bank / Double Bank)

g Louver Dimensions (Width x Height)

g Sound Pressure Level Or Power level of Equipment / Engine (SPL or SWL)

g Total Airflow through Louver

g The Maximum (permissible) Pressure Drop

g Room / Area Dimensions (W x H x L)

Refer to final project technical acoustic calculation for the exact Louver Free Area (%), Resultant Noise (dBA),

Transmission Loss (TL), Pressure Drop (Pd), Airway Velocity (V), Free field Noise Reduction etc. which may vary

based on Engine / Equipment’s parameters and Louver applications.

13 .....a perfect partner in performance

Acoustic Louvers

ENGINEERING GUIDELINES

MULTIPLE SECTIONS Free Area Velocity & Pressure Drop

1

Louvers larger than 60 In. wide x 120 In. height 0.9

0.8

will be fabricated in multiple sections.

0.7

0.6

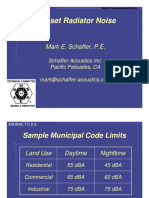

SOUND TRANSMISSION CLASS (STC) 0.5

0.4

The Sound Transmission Class (STC) is a rating

of the effectiveness of an assembly in isolating 0.3

or reducing airborne sound transmission. STC

Static Pressure Drop ( Inch W.G)

is a single number that summarizes airborne

sound transmission loss data. 0.2

t

aus

OUTDOOR / INDOOR TRANSMISSION

Exh

ake

CLASS (OITC)

Int

0.1

0.09

Transmission Loss (TL) is a measurement of 0.08

the reduction of sound power transmission 0.07

(dB) through an assembly at a given frequency. 0.06

The more sound power that is reduced, the 0.05

greater the TL.

0.04

SUBMITTALS 0.03

Airwellcare shall submit shop drawings 0.02

incorporating Elevations, Section details and 0.5 1 2 3 4 5 6 7 8 9 10

other details showing profiles of louver blades

and frames, unit dimensions to Louver openings Free Area Velocity ( meter / second)

and construction etc. Submit theoretical

calculations prepared by a professional

Pressure Drop varies depending on louver application

engineer specialized in Acoustic application.

(Inlet or Discharge), nature of project & final Technical

Acoustic calculation. Free Area Velocities shown

SAMPLES above are higher than average velocity through the

over all louver size.

Airwellcare provides Sample of proposed

louvers, showing the full range of colors WIND LOAD

available, for each type of product specified.

Airwellcare shall design and furnish all supports

required to withstand a Windforce of not less than

11.0kgs per Square foot.

.....a perfect partner in performance 14

Acoustic Louvers

ENGINEERING GUIDELINES

20

Transmission Loss (dB)

15

Model ASB 100 - 300 AL

Octave Band Centre

10 63 125 250 500 1000 2000 4000 8000

Frequency(Hz)

*Transmission Loss (TL) dB 7 7 9 12 16 19 17 16

Free Field Noise Reduction 13 13 15 18 22 25 23 22

5

0

63 125 250 500 1000 2000 4000 8000

Frequency (Hz)

40

35

Transmission Loss (dB)

30

25

Model ADB 300 AL & ADB-I 300 AL ( INDUSTRIAL )

20 Octave Band Centre

63 125 250 500 1000 2000 4000 8000

Frequency(Hz)

15 *Transmission Loss (TL) dB 5 7 17 20 27 22 18 16

Free Field Noise Reduction 11 13 23 26 33 28 24 22

10

0

63 125 250 500 1000 2000 4000 8000

Frequency (Hz)

40

35

Transmission Loss (dB)

30

25 Model ADB 600 AL

Octave Band Centre

20 63 125 250 500 1000 2000 4000 8000

Frequency(Hz)

*Transmission Loss (TL) dB 5 8 11 25 32 33 30 29

15

Free Field Noise Reduction 11 14 17 31 38 39 36 35

10

0 *The above mentioned Transmission Losses (TL) varies depending on louver

63 125 250 500 1000 2000 4000 8000 applications & nature of project. Refer to the final technical calculations for

the exact transmission losses.

Frequency (Hz)

15 .....a perfect partner in performance

Acoustic Louvers

MATERIAL STORAGE, OPERATION AND MAINTENANCE

Material Storage

The Louvers required to be handled Airwellcare Louvers are not designed

carefully during offloading as per the to be used in areas where they may

upright arrow marks given on the be exposed to contaminants such as

unit in the right position. Care should water treatment or cleaning chemicals.

be taken in lifting the product in all 4

corners and placing them on a raised If the louvers are exposed to such

floor level. Store the product always

contaminants, they should be cleaned

in dry environment. After receiving

the Louvers, check for both obvious immediately to reduce the detrimental

and hidden damages. If damage is impact of the chemicals.

found due to manufacturing defect /

workmanship, record all necessary Cleaning of the louvers should be

information with photographs and completed using a soft, clean cloth and

forward to Airwellcare. soft wash gel cleaner. Surfaces should

be thoroughly rinsed with fresh water

Maintenance after cleaning.

Airwellcare Acoustic Louvers are In coastal or industrial environments,

designed for least maintenance. cleaning should be carried out more

However, it is recommended to have

frequently paying particular attention

periodical inspection of blades for

damage, wear and tear etc. to areas that are not normally washed

by rain.

Once installed, it is important to

ensure the louvers are not damaged, DO NOT use harsh cleaning fluids,

as this may affect both their acoustic strong solvents or abrasive cleaning

and airflow performance. The louvers materials, as these will damage the

may, over time begin to collect dust surface finish on the acoustic louvers.

and grime due to their location

Once the louver surface finish is

and exposure to varying weather

conditions. The louvers should damaged, it cannot be repaired and in

be cleaned to refresh their visual many cases may lead to deterioration

appearance at six monthly intervals. of the base metal.

.....a perfect partner in performance 16

Acoustic Louvers

INSTALLATION DETAILS

17 .....a perfect partner in performance

Acoustic Louvers

PROJECT HIGHLIGHTS

IKEA - District Cooling Plant at Doha Festival city Doha, Qatar

ADNOC - New Head Quarters District Cooling Plant at Abu Dhabi, U.A.E.

.....a perfect partner in performance 18

Acoustic Louvers

PROJECT HIGHLIGHTS

Etisalat - Data Center

Generator Room at

Fujairah, U.A.E.

Dubai Metro

District Cooling Plant at

Dubai, U.A.E.

19 .....a perfect partner in performance

P.O Box 42707

Factory at LV-16 A, Logistic Village, Phase 2, Hamriyah Free Zone

Sharjah, United Arab Emirates

Tel. +971 (6) 526 4061 / Fax. + 971 (6) 526 4062

Email : sales@airwellcare.com

Web : www.airwellcare.com

The contents of the catalogue is subject to change without notice / All rights reserved — Airwellcare

.....a perfect partner in performance 20

You might also like

- Group1 - Determination Relationship Between Air Speed and Opening in Ventilation SystemDocument12 pagesGroup1 - Determination Relationship Between Air Speed and Opening in Ventilation SystemNoradila RoslanNo ratings yet

- Swing Doors - Overlap vs. Flush Doors Detail SheetDocument1 pageSwing Doors - Overlap vs. Flush Doors Detail Sheetজেত বনNo ratings yet

- Building Services 1Document17 pagesBuilding Services 1SubhraJyotiBorahNo ratings yet

- Sound Attenuators LeafletDocument7 pagesSound Attenuators LeafletSundar Ramasamy0% (1)

- Acoustic Louver SpecificationDocument2 pagesAcoustic Louver Specificationsameeh kadourahNo ratings yet

- Acoustic Floor Insulating MaterialsDocument18 pagesAcoustic Floor Insulating MaterialsGokulNo ratings yet

- Kairos Thermo CF-2Document2 pagesKairos Thermo CF-2Green FilterNo ratings yet

- Wdrive BoostersDocument72 pagesWdrive BoostersAnonymous 7lcVBaOPNgNo ratings yet

- Ac 001 List of DrawingsDocument1 pageAc 001 List of Drawingswael hassanNo ratings yet

- Zamil DY - Series PDFDocument23 pagesZamil DY - Series PDFgagokapalaNo ratings yet

- Caice Acoustic Design GuideDocument12 pagesCaice Acoustic Design GuideBuddhikaNo ratings yet

- Kitchen Exhaust Air Cleaning System Technical SpecificationsDocument2 pagesKitchen Exhaust Air Cleaning System Technical SpecificationskpvfNo ratings yet

- AcousticDocument36 pagesAcousticMehtab AhmadNo ratings yet

- Sound Absorption, Reflection & Transmission, Mechanism of Absorption Reverberation TimeDocument31 pagesSound Absorption, Reflection & Transmission, Mechanism of Absorption Reverberation TimeAnonymous 5kOS4tNo ratings yet

- Building Science 2 ReportDocument13 pagesBuilding Science 2 ReportLucas Wong100% (1)

- Structural Systems Over View and Auditoriums Structural SystemDocument33 pagesStructural Systems Over View and Auditoriums Structural SystemC'Lman Mhmud100% (2)

- Hvac Systems For TheatresDocument18 pagesHvac Systems For Theatresagitent100% (1)

- Environmental Control Systems 1 VentilationDocument39 pagesEnvironmental Control Systems 1 VentilationTauseef AhmadNo ratings yet

- Lighting Design Guide For Offices: 1) Working PlaneDocument31 pagesLighting Design Guide For Offices: 1) Working PlaneGiancarlo MerlottiNo ratings yet

- Duct Liner (AFICO)Document4 pagesDuct Liner (AFICO)hshoooma65No ratings yet

- Genset Noise Outdoor Environment Sound SilencerDocument18 pagesGenset Noise Outdoor Environment Sound SilencerTrần Quang ToánNo ratings yet

- 6 LightingDocument26 pages6 LightingIssei HyoudouNo ratings yet

- Air Distribution System PDFDocument25 pagesAir Distribution System PDFMateo L. Tapdasan100% (1)

- Silencers For HVACDocument12 pagesSilencers For HVACZaw Moe KhineNo ratings yet

- 03 DM BLDG U-Value+Calculation V01Document1 page03 DM BLDG U-Value+Calculation V01AburvarajNo ratings yet

- Insulation Floors P65 76Document12 pagesInsulation Floors P65 76Jennifer NavarroNo ratings yet

- Daylight FactorDocument16 pagesDaylight FactorAnthi Valavani0% (1)

- Louvres Bro enDocument84 pagesLouvres Bro entagiriNo ratings yet

- Ribbed Floor SlabDocument1 pageRibbed Floor SlabEricka BagonNo ratings yet

- AcousticsDocument1 pageAcousticsSOOFIYA SAMAR barch2020100% (1)

- HCW 14-Us HalfenDocument36 pagesHCW 14-Us HalfenALBERT100% (1)

- Twin City Fan&BlowerDocument24 pagesTwin City Fan&BloweryaidragonNo ratings yet

- NFPA101 Occupant LoadDocument1 pageNFPA101 Occupant LoadjanechuacruzNo ratings yet

- Sound Absorption DataDocument4 pagesSound Absorption DataJeofrey Awingan CodiamatNo ratings yet

- Lecture 4 - Auditorium Design & Sound Reinforcement ManshaDocument24 pagesLecture 4 - Auditorium Design & Sound Reinforcement ManshaRahul NawaniNo ratings yet

- Architecks Metal Systems Inc PDFDocument16 pagesArchitecks Metal Systems Inc PDFZdep OniuqaNo ratings yet

- Louver Design ConsiderationsDocument4 pagesLouver Design ConsiderationsArt JamesNo ratings yet

- Building ScienceDocument34 pagesBuilding ScienceEvon LowNo ratings yet

- Sports Training CenterDocument73 pagesSports Training CenterLanie TreyesNo ratings yet

- Specifications TemplateDocument4 pagesSpecifications TemplateJewel Vincent PalomarNo ratings yet

- Housing ReviewerDocument9 pagesHousing Reviewermark gauranoNo ratings yet

- Titus Engineering GuideDocument23 pagesTitus Engineering Guideteri-scribdNo ratings yet

- W 36Document12 pagesW 36matsiasNo ratings yet

- Air Distribution SystemDocument21 pagesAir Distribution SystemRohit JainNo ratings yet

- Sustainable Design Requirements-ADDDocument16 pagesSustainable Design Requirements-ADDsreedeviNo ratings yet

- 04-SECTION 15070 - Mechanical Sound, Vibration and Seismic ControlDocument17 pages04-SECTION 15070 - Mechanical Sound, Vibration and Seismic Controlabdul rasheedNo ratings yet

- Terms and Definitions For Building Utilities 3Document15 pagesTerms and Definitions For Building Utilities 3RoseAnneSacilTabilismaNo ratings yet

- Vinyl Composition TileDocument37 pagesVinyl Composition TileJehanzeb SiddiquiNo ratings yet

- 30 29 121Document37 pages30 29 121Santiago J. ramos jrNo ratings yet

- APEC Engineering Practice Report FormDocument2 pagesAPEC Engineering Practice Report FormkhayagskiNo ratings yet

- Acoustical Causes in ArchitectureDocument31 pagesAcoustical Causes in Architecture622 MANSI TANJILANo ratings yet

- 5.1 Background Noise Criteria: EchanicalDocument11 pages5.1 Background Noise Criteria: EchanicalNeeskens D'melloNo ratings yet

- Floor Deck Profile TS 47/180: Product Data SheetDocument3 pagesFloor Deck Profile TS 47/180: Product Data SheetMohamed KareemNo ratings yet

- Louver SpecDocument10 pagesLouver SpecCyril J PadiyathNo ratings yet

- Knauf Alutop Technical DatasheetDocument16 pagesKnauf Alutop Technical DatasheetAmin ChhipaNo ratings yet

- Rooftop Package PRC-MYADocument8 pagesRooftop Package PRC-MYAMMMSLOUHNo ratings yet

- Understanding Sound Transmission Class (STC)Document10 pagesUnderstanding Sound Transmission Class (STC)David BeggNo ratings yet

- Psychrometrics e Thermal ComfortDocument85 pagesPsychrometrics e Thermal ComfortBruno de RossoNo ratings yet

- BD Systems Brochure 2016 05Document164 pagesBD Systems Brochure 2016 05Rajat KatyalNo ratings yet

- 1B PPT Plumbing Roughing-InDocument80 pages1B PPT Plumbing Roughing-InGail GenturalezNo ratings yet

- Sand Trap LoaversDocument17 pagesSand Trap LoaversAnas AhmedNo ratings yet

- Acoustic Louvers 2019Document9 pagesAcoustic Louvers 2019Ahmed MontashNo ratings yet

- VAW Systems AL Product SheetDocument2 pagesVAW Systems AL Product SheetAhmed MontashNo ratings yet

- Sarnafil® G 410-15 L: Product Data SheetDocument4 pagesSarnafil® G 410-15 L: Product Data SheetAhmed MontashNo ratings yet

- Sarnafil® TS 77-18: Product Data SheetDocument5 pagesSarnafil® TS 77-18: Product Data SheetAhmed MontashNo ratings yet

- Sarnacol®-2142 S: Product Data SheetDocument3 pagesSarnacol®-2142 S: Product Data SheetAhmed MontashNo ratings yet

- Sarnafil® S 327-20 L: Product Data SheetDocument5 pagesSarnafil® S 327-20 L: Product Data SheetAhmed MontashNo ratings yet

- Sarnacol®-2170: Product Data SheetDocument3 pagesSarnacol®-2170: Product Data SheetAhmed MontashNo ratings yet

- Pressure Loss Calculation Ariobimo Project MGS 2300R & 3100RDocument4 pagesPressure Loss Calculation Ariobimo Project MGS 2300R & 3100RRangga SetaNo ratings yet

- Tecflex 400 Series Flexible Ducting: Linda B - We Simplif y Const Ruc T IonDocument6 pagesTecflex 400 Series Flexible Ducting: Linda B - We Simplif y Const Ruc T IonEN LeedNo ratings yet

- Acoustic Louvers: ..... A Perfect Partner in Performance ..... A Perfect Partner in PerformanceDocument20 pagesAcoustic Louvers: ..... A Perfect Partner in Performance ..... A Perfect Partner in PerformanceAhmed MontashNo ratings yet

- Trox Quick Selection QuideDocument48 pagesTrox Quick Selection QuideThinh NguyenNo ratings yet

- Noise Control in IC EnginesDocument20 pagesNoise Control in IC EnginesClassic PrintersNo ratings yet

- Catalog OGV PrihodaDocument32 pagesCatalog OGV PrihodaQuốc Huy HoàngNo ratings yet

- Vsd35 3 AzDocument8 pagesVsd35 3 AzUpendra Priyanka KumaraNo ratings yet

- MS PD 2022 07 20 DE enDocument22 pagesMS PD 2022 07 20 DE enDan RotariNo ratings yet

- Louvers and Its PerformancesDocument10 pagesLouvers and Its PerformancesGENGATHARAN MNo ratings yet

- Prime CatalogDocument12 pagesPrime CatalogALINo ratings yet

- AHU Design GuideDocument37 pagesAHU Design Guidesachin100% (1)

- 2016 NSV Catalog (Ver.S)Document36 pages2016 NSV Catalog (Ver.S)MohammedIrfanNo ratings yet

- ESPDocument3 pagesESPAdnan Ahmed KidwaiNo ratings yet

- Acoustic Barrier - Not A Total Solution To Reducing Cooling Towers' NoiseDocument5 pagesAcoustic Barrier - Not A Total Solution To Reducing Cooling Towers' NoisemelieneideaNo ratings yet

- Sound Attenuator-AMCA-21-11-2020Document17 pagesSound Attenuator-AMCA-21-11-2020AT 98No ratings yet

- ATAI - Sound AttenuatorsDocument56 pagesATAI - Sound AttenuatorsLejinNo ratings yet

- Adwea Addc Approved Vendors ListDocument315 pagesAdwea Addc Approved Vendors ListMohammed AnasNo ratings yet

- Sound Attenuator: Featured Standard ConstructionDocument2 pagesSound Attenuator: Featured Standard ConstructionAli MustafaNo ratings yet

- Sand Trap LoaversDocument17 pagesSand Trap LoaversAnas AhmedNo ratings yet

- Sound AttenuatorDocument4 pagesSound AttenuatorFareethAbdullahNo ratings yet

- Adwea Approved Vendors ListDocument316 pagesAdwea Approved Vendors ListMy HarvNo ratings yet

- Mranal Gupta 2009Document43 pagesMranal Gupta 2009Ravi HarperNo ratings yet

- Adwea Approved Vendors ListDocument315 pagesAdwea Approved Vendors Listjohndavsg8022No ratings yet

- Green HVAC DuctworkDocument50 pagesGreen HVAC DuctworkdheerajdorlikarNo ratings yet

- Sound Attenuators CatalogDocument16 pagesSound Attenuators CatalogYoga PristlinNo ratings yet

- ESP Calculation (External Static Pressure Calculation)Document54 pagesESP Calculation (External Static Pressure Calculation)Ajeet KumarNo ratings yet

- 19-VAV-2022-Rev04 (Updated)Document20 pages19-VAV-2022-Rev04 (Updated)Siddique AhmedNo ratings yet

- Rectangular & Circular Types: Rsa, Casa & Cbsa: Duct Ventilation Air Conditioning Co. (W.L.L.)Document32 pagesRectangular & Circular Types: Rsa, Casa & Cbsa: Duct Ventilation Air Conditioning Co. (W.L.L.)ThanhNo ratings yet

- Kruger Tunnel Ventilation Products BrochureDocument12 pagesKruger Tunnel Ventilation Products BrochureMarino AyalaNo ratings yet