Professional Documents

Culture Documents

PT Tekniko Indonesia Inspection and Test Plan Procedure Field Density Test With Sandcone Test

PT Tekniko Indonesia Inspection and Test Plan Procedure Field Density Test With Sandcone Test

Uploaded by

Rangga Gautama0 ratings0% found this document useful (0 votes)

44 views1 pageThis inspection and test plan outlines procedures for field density testing using the sandcone test for a power plant project in Asam Asam, Indonesia. Key steps include:

1) Reviewing technical specifications and ensuring all documentation is the latest revision

2) Preparing the work area through activities like clearing, grubbing, stripping, and excavation

3) Testing fill and backfill material based on specifications, including tests for moisture content, gradation, and compaction frequency

4) Documenting test results and equipment calibration certificates and reviewing quality control documents.

Original Description:

Original Title

contohbackfill(ITR)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis inspection and test plan outlines procedures for field density testing using the sandcone test for a power plant project in Asam Asam, Indonesia. Key steps include:

1) Reviewing technical specifications and ensuring all documentation is the latest revision

2) Preparing the work area through activities like clearing, grubbing, stripping, and excavation

3) Testing fill and backfill material based on specifications, including tests for moisture content, gradation, and compaction frequency

4) Documenting test results and equipment calibration certificates and reviewing quality control documents.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

44 views1 pagePT Tekniko Indonesia Inspection and Test Plan Procedure Field Density Test With Sandcone Test

PT Tekniko Indonesia Inspection and Test Plan Procedure Field Density Test With Sandcone Test

Uploaded by

Rangga GautamaThis inspection and test plan outlines procedures for field density testing using the sandcone test for a power plant project in Asam Asam, Indonesia. Key steps include:

1) Reviewing technical specifications and ensuring all documentation is the latest revision

2) Preparing the work area through activities like clearing, grubbing, stripping, and excavation

3) Testing fill and backfill material based on specifications, including tests for moisture content, gradation, and compaction frequency

4) Documenting test results and equipment calibration certificates and reviewing quality control documents.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

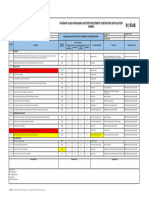

PT TEKNIKO INDONESIA

INSPECTION AND TEST PLAN

PROCEDURE FIELD DENSITY TEST WITH SANDCONE TEST

Contract doc No : IKCP0-YYB-G-05-… Subcon: TEKNIKO

DESCRIPTION PLTU CFSPP ( 2 x 100 MW ) PAGE : 2

PROJECT ASAM ASAM KASELTENG 2 REV : 0

Inspection Activity

Inspection

NO Item Activity Referance Document Verifying Document CONTRAC- Owner Remarks

Location SUBCON

TOR PLN

Technical Specification & Procedure

Review all technical specifications, drawing, procedures & work instructions

1.1

1.1.1 All Tech. Spec., Drawings, Proc. are latest revision

Management System Manual, Standard

All tech. spec., drawing, procedures, work instruction shall be clarified, Approved General Instruction, Technical P/R R/A R/A

1.0. 1.2 Operating Procedure, Document Contract -

understood and implemented accordingly Specification & Procedures, drawings, etc.

Agreement, Standard & Code

1.3 Finalise deviation, generate new procedure and work instruction

if required

1.4 Handover work area document W W R

Surface Preparation

2.1 Site clearance condition (Clearing, Grubbing And Stripping)

Clearing includes removal and disposal of trees and downed timber, bush, hedges, bushes and other

2.2 vegetation or organic materials; and rubbish, debris or other foreign or objectionable materials at

grade, except the removal of topsoil.

Grubbing includes removal and disposal of stumps, large roots, buried logs and other objectionable

2.3 Tech. Spec., Drawing, Proc., Gen. Applicable Specification, Official Certificate Subcontractor

2.0 materials to 1,000 mm below ground surface. H W RW

Instruction & Material Inspection Report Workshop

2.4 Measurement of existing ground profile before excavation

2.5 Routing of dewatering discharge lines

Removing of all rubbish , humus, vegetable matter and all or part of the organic topsoil in the

2.6

respective areas, which can be removed by simple excavation methods.

All materials excavated during clearing, grubbing and stripping operations shall be wasted in disposal

2.7

areas

Excavation

Excavation including construction of temporary diversion ditches, culverts, temporary access road

3.1

etc.

Applicable Specification Approved Drawing,

3.2 Coordinate and leveling must be check with refer to benchmark Tech. Spec., Drawing, , Proc., Gen.

3.0 Applicable Specification & Report FIELD (ON SITE) H W RW

3.3 Bottoms of all excavations must be trimmed to line and grade. Instruction, Standard & Code.

Fabrication

Protection and Support shall be arranged for minimum interference with Electrical, mechanical,

3.4

Piping etc if any.

3.5 Minimum excavation from pipelines, conduits, and the side of trench.

Fill / Backfill Material

General fill material shall be well graded, no more than 15 % passing

4.1

4.0 No. 200 screen, maximum particle size 75 mm

4.2 Type structural fill material

4.3 Optimum moisture content

4.4 Trench Fill material Sand material Applicable Specification Approved Drawing,

Tech. Spec., Drawing, , Proc., Gen.

4.5 Field Compacted around Structures Applicable Specification & Report FIELD (ON SITE) H W W

Instruction, Standard & Code.

4.6 Field Compacted Backfill around pipe trench Fabrication

4.7 Field Compacted Backfill around Fiberglass Reinforced Pipe (FRP)

4.8 Height of backfill

4.9 Maximum size of stone in the backfill material

4.10 Lab test for General backfill materials with gradations / Sieve analisys Test

4.11 Heavy Equipment compacted rolling around structure

Fill/Back Fill Test Frequency Tech. Spec., Drawing, , Proc., Gen. Applicable Specification Approved Drawing,

5,0 FIELD (ON SITE)

5.1 Bearing test interval frequency Instruction, Standard & Code. Applicable Specification H W W

Documentation

6.1 Summary monitoring or Quality Inspection report activity Approved Drawing ,Applicable R&A R&A

6,0 6.2 Calibration Certificate of equipment test Contract, Tech. Spec., Proc. Specification,All Quality Document as per R

6.3 QAQC review of site generated document Contract (Inspection Reports, NCR, R R

6.4 Mill certificate material & manufacture certificate MDR,Warranty, Punch List, Etc.)

Legend : P = Preparation, W = Witness, SW = Spot Witness, RW = Random Witness, R = Document Review, H = Hold Points, A=Approved

Standard and code : ASTM Mechanical Test : Destructive Test

: DIN : Non Destructive Test

: AS/NZS

You might also like

- Inspection and Test Plan For Waterproofing WorksDocument8 pagesInspection and Test Plan For Waterproofing WorksResearcher100% (1)

- Quality Assurance Plan For Building ConstructionDocument18 pagesQuality Assurance Plan For Building ConstructionANup GhiMire100% (3)

- ITP - 004 - Static Equipment - IFRDocument3 pagesITP - 004 - Static Equipment - IFRMari BelajarNo ratings yet

- Itp Installation of 11kv HV Switchgear Rev.00Document2 pagesItp Installation of 11kv HV Switchgear Rev.00syed fazluddin100% (1)

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Etihad Towers Project: Inspection & Test Plan - Hollow Core SlabsDocument2 pagesEtihad Towers Project: Inspection & Test Plan - Hollow Core SlabsjiniNo ratings yet

- GroutingDocument1 pageGroutingAlif Rahmat FebriantoNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- Plant Location Company Doc. No. NADocument8 pagesPlant Location Company Doc. No. NAsivaNo ratings yet

- Inspection Test Plan For Erection of Tower CraneDocument5 pagesInspection Test Plan For Erection of Tower CraneMarco AragonesNo ratings yet

- HSCM BRL ITP 001 Ventılatıon Installatıon WorksDocument1 pageHSCM BRL ITP 001 Ventılatıon Installatıon WorksHabib BagciNo ratings yet

- ITP Boiler InstallationDocument6 pagesITP Boiler InstallationSetyahadi WinartoNo ratings yet

- Itp - Water ProofingDocument1 pageItp - Water ProofingUbaidullah KhanNo ratings yet

- Inspection and Test Plan (ITP) - Civil WorksDocument1 pageInspection and Test Plan (ITP) - Civil WorksNaveen GladsonNo ratings yet

- SBG1-00-0K-1-CLD-0008-A ITP For Thermal Control Actuator Installation PDFDocument6 pagesSBG1-00-0K-1-CLD-0008-A ITP For Thermal Control Actuator Installation PDFsalamlinNo ratings yet

- ITP For Structural Cabling System Testing and CommissioningDocument1 pageITP For Structural Cabling System Testing and CommissioningRommel Espinosa ParasNo ratings yet

- Asitp P 001 02Document2 pagesAsitp P 001 02MosabAhmedNo ratings yet

- Inspection and Test Plan Ventılatıon Installatıon Works 21 MarchDocument1 pageInspection and Test Plan Ventılatıon Installatıon Works 21 MarchHabib BagciNo ratings yet

- Insulation WorksDocument2 pagesInsulation WorksBangkit SamosirNo ratings yet

- NS2-DH01-P0ZEN-140011 - ITP For Cable Pulling and Termination - REV.CDocument8 pagesNS2-DH01-P0ZEN-140011 - ITP For Cable Pulling and Termination - REV.CAnh VàngNo ratings yet

- Insulation WorksDocument8 pagesInsulation WorksBangkit SamosirNo ratings yet

- HKN Energy LTD Sarsang Development, Wellsitebased Production Facility Epc ExecutionDocument4 pagesHKN Energy LTD Sarsang Development, Wellsitebased Production Facility Epc ExecutionDelil OzanNo ratings yet

- S96029-F07C-ITP-006 Rev0-OSM Exhaust Duct WorkDocument2 pagesS96029-F07C-ITP-006 Rev0-OSM Exhaust Duct WorktinzarmoeNo ratings yet

- 4172-GENON-1-25-0019 - Rev 1Document16 pages4172-GENON-1-25-0019 - Rev 1Rajesh SinghNo ratings yet

- Interior Painting: Inspection & Test PlanDocument3 pagesInterior Painting: Inspection & Test PlanDominguez MegoNo ratings yet

- ITP Inspection and Testing Plan For Above Ground Water Supply PipesDocument1 pageITP Inspection and Testing Plan For Above Ground Water Supply Pipessarmad spectrumNo ratings yet

- Itp Installation of Ats Panel Rev.00Document2 pagesItp Installation of Ats Panel Rev.00syed fazluddinNo ratings yet

- NFS-DHA-E-TC-05 - Testing of Earthing and LPSDocument25 pagesNFS-DHA-E-TC-05 - Testing of Earthing and LPSirshadNo ratings yet

- Electrostatic Precipitator Installation: Field Inspection & Test Plan (F-Itp) : 1: 16-Feb-10Document40 pagesElectrostatic Precipitator Installation: Field Inspection & Test Plan (F-Itp) : 1: 16-Feb-10Alif Rahmat FebriantoNo ratings yet

- HSCM BRL ITP 002 Fire Installation WorksDocument1 pageHSCM BRL ITP 002 Fire Installation WorksHabib BagciNo ratings yet

- ASE-Inspection Test PlanDocument2 pagesASE-Inspection Test PlanAdnanNo ratings yet

- Inspection & Test Plan - Site ClearanceDocument1 pageInspection & Test Plan - Site ClearanceJohan BurgerNo ratings yet

- ITP - Conduit Metal (GI) & PVC InstallationDocument5 pagesITP - Conduit Metal (GI) & PVC InstallationGultom Juliana LiliesNo ratings yet

- Inspection & Test Plan (Itp)Document6 pagesInspection & Test Plan (Itp)Pahlevi MattasanNo ratings yet

- Sadara Inspection and Test Plan: Low Voltage (Up To 1Kv) Power and Control Cable SPITP-P-0B031-02 ElectricalDocument3 pagesSadara Inspection and Test Plan: Low Voltage (Up To 1Kv) Power and Control Cable SPITP-P-0B031-02 ElectricalJawaid GhazaliNo ratings yet

- Inspection & Test PlanDocument1 pageInspection & Test PlanRonNo ratings yet

- ITP For Access Control SystemTesting and CommissioningDocument1 pageITP For Access Control SystemTesting and CommissioningTamer EidNo ratings yet

- 2.ITP For Excavation & Laying of 33kV & FO CableDocument2 pages2.ITP For Excavation & Laying of 33kV & FO Cabletahirsaleem100% (1)

- Cap General ItpDocument3 pagesCap General ItpPutraArifWardhanaNo ratings yet

- NNEG3-30-LAA-SP-M0131 - A Technical Specification For Feed Water Storage and DeaerationDocument18 pagesNNEG3-30-LAA-SP-M0131 - A Technical Specification For Feed Water Storage and Deaerationsatvata.foodsNo ratings yet

- ITP & Checklist FOR Excavation & Backfilling and CompactionDocument7 pagesITP & Checklist FOR Excavation & Backfilling and CompactionAmran Hossain100% (4)

- Itp For Installation of Ahu FahuDocument1 pageItp For Installation of Ahu FahuSamer AliNo ratings yet

- HSCM-BRL-ITP-003 Heating and Cooling Installation WorksDocument1 pageHSCM-BRL-ITP-003 Heating and Cooling Installation WorksHabib BagciNo ratings yet

- HSCM-BRL-ITP-004 Sanitary İnstallation WorksDocument1 pageHSCM-BRL-ITP-004 Sanitary İnstallation WorksHabib BagciNo ratings yet

- Inspection and Test Plan Fire Installation WorksDocument1 pageInspection and Test Plan Fire Installation WorksHabib BagciNo ratings yet

- Process Map Project Construction Reporting Requirements: in Amenas Gas ProjectDocument2 pagesProcess Map Project Construction Reporting Requirements: in Amenas Gas ProjectChiheb KaanicheNo ratings yet

- Inspection and Test Plan Piling: 1. Document ReviewDocument3 pagesInspection and Test Plan Piling: 1. Document ReviewZara BhaiNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- TWJO-ITP-PRC-0005 Revc ITP For Box Culvert at LB DepotDocument9 pagesTWJO-ITP-PRC-0005 Revc ITP For Box Culvert at LB DepotBangkit SamosirNo ratings yet

- Itp For Painting WorksDocument28 pagesItp For Painting WorksAhmed saberNo ratings yet

- Itp For Formworks (Ringlock System)Document3 pagesItp For Formworks (Ringlock System)damianNo ratings yet

- Enppi Inspection and Test PlanDocument3 pagesEnppi Inspection and Test PlanTariqMalikNo ratings yet

- (M107 - Mec.6) PBTMZ7535002 - Tzp00fl1205200apti001 - 02 - Terminal Points ListDocument2 pages(M107 - Mec.6) PBTMZ7535002 - Tzp00fl1205200apti001 - 02 - Terminal Points ListrezaNo ratings yet

- Itp Plastering Works BlogDocument5 pagesItp Plastering Works BlogMohasin KhanNo ratings yet

- 001 Itp For Painting Rev 0Document7 pages001 Itp For Painting Rev 0Alif Rahmat FebriantoNo ratings yet

- ITP For ChilledPump and Pressurization Unit (Testing and Commissioning) 1Document5 pagesITP For ChilledPump and Pressurization Unit (Testing and Commissioning) 1akram hussein100% (1)

- TWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTDocument6 pagesTWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTBangkit SamosirNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- WiMAX Evolution: Emerging Technologies and ApplicationsFrom EverandWiMAX Evolution: Emerging Technologies and ApplicationsMarcos KatzNo ratings yet

- Design and Characterization of Integrated Varactors for RF ApplicationsFrom EverandDesign and Characterization of Integrated Varactors for RF ApplicationsNo ratings yet

- Rauf Khan Column EstimationDocument4 pagesRauf Khan Column EstimationRauf KhanNo ratings yet

- Electrical Heating of Bars PDFDocument15 pagesElectrical Heating of Bars PDFsotos raptopoulosNo ratings yet

- Cara Tiles ProfileDocument10 pagesCara Tiles ProfileHussain BagasrawalaNo ratings yet

- Panasonic & Nano Conduit PipeDocument38 pagesPanasonic & Nano Conduit PipeRahmadani AwhyNo ratings yet

- 1C02-01 Conceptual Design of Buildings PDFDocument14 pages1C02-01 Conceptual Design of Buildings PDFmutashima100% (1)

- Sheet Pile Retaining Walls Design and Construction in Brown Fields EnvironmentDocument29 pagesSheet Pile Retaining Walls Design and Construction in Brown Fields EnvironmentOky Mahertwo SeptianNo ratings yet

- Rhino Raised Access Perforated FloorsDocument6 pagesRhino Raised Access Perforated FloorsJoseph MissionNo ratings yet

- BBC Class - A AramcoDocument135 pagesBBC Class - A Aramcomido_20067581No ratings yet

- Clarification On FastenersDocument3 pagesClarification On FastenersHershit GargNo ratings yet

- Testing Concrete AggregatesDocument3 pagesTesting Concrete AggregatesJoe A. CagasNo ratings yet

- 6 Financial Ceilings For Works ContractorsDocument3 pages6 Financial Ceilings For Works ContractorsNeo MothaoNo ratings yet

- 15A 8 Fabrication PDFDocument25 pages15A 8 Fabrication PDFBruno MiguelNo ratings yet

- I S Code ListDocument8 pagesI S Code Listvani1986100% (1)

- DOWs THEORYDocument4 pagesDOWs THEORYHemant SinghNo ratings yet

- Shipyard LayoutDocument9 pagesShipyard Layoutcaptnathan100% (3)

- Arches or Catenary StructureDocument9 pagesArches or Catenary Structure34 Shefali MishraNo ratings yet

- 1.final Concept Sheet PDFDocument1 page1.final Concept Sheet PDFShruti JhaNo ratings yet

- This Area: Vicinity Map Site Development PlanDocument12 pagesThis Area: Vicinity Map Site Development PlanSaem DecaNo ratings yet

- Samtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutDocument3 pagesSamtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutFrancois-No ratings yet

- Et&p Profile 1-8-19Document8 pagesEt&p Profile 1-8-19Ar Frank EpeNo ratings yet

- Inputs: Structural Strength Design of Foundation W Y (+) Ve Z (+) V e W b1 X (+) VeDocument3 pagesInputs: Structural Strength Design of Foundation W Y (+) Ve Z (+) V e W b1 X (+) VeAsmita JondhaleNo ratings yet

- Pedestal Column Design For SabbiRDocument2 pagesPedestal Column Design For SabbiRAdam Michael GreenNo ratings yet

- PTQM Plant Location and LayoutDocument19 pagesPTQM Plant Location and LayoutAyush AnandNo ratings yet

- A Study On Use of Bottom Ash and Fly Ash in Concrete Used in Pavement ConstructionDocument11 pagesA Study On Use of Bottom Ash and Fly Ash in Concrete Used in Pavement ConstructionIJRASETPublications100% (1)

- Simplified Structural Analysis of Retaining Walls On Stepped FootingsDocument15 pagesSimplified Structural Analysis of Retaining Walls On Stepped Footingsalvaro sangurimaNo ratings yet

- Interim Guidelines On Use of Fibre-ReinforcedDocument38 pagesInterim Guidelines On Use of Fibre-ReinforcedDevesh Kumar PandeyNo ratings yet

- Procurement ModelsDocument7 pagesProcurement ModelsNikhil MathewNo ratings yet

- Box System Construction PDFDocument11 pagesBox System Construction PDFHadeel MahmoudNo ratings yet

- Installation of Sump PumpsDocument6 pagesInstallation of Sump PumpsHishamGharbiahNo ratings yet