Professional Documents

Culture Documents

Test On Fenestration System: Eu Standard: Air Tightness: Uni en 12207

Test On Fenestration System: Eu Standard: Air Tightness: Uni en 12207

Uploaded by

Andrea Nicola TurcatoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test On Fenestration System: Eu Standard: Air Tightness: Uni en 12207

Test On Fenestration System: Eu Standard: Air Tightness: Uni en 12207

Uploaded by

Andrea Nicola TurcatoCopyright:

Available Formats

TEST ON FENESTRATION SYSTEM: EU STANDARD

AIR TIGHTNESS: UNI EN 12207

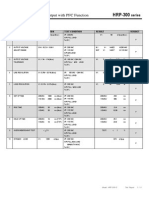

European standard identifies 5 class of efficiency for air permeability of the fenestration

system. Tests are conducted applying a pressure of 100 Pa (2.1 psf) and measuring the

flow that comes out from the specimen.

Pressure Permeability

Class

3 2

Pa psf m /h m cfm/ft2

0 \ \ \ \

1 100 2.1 50 2,734

2 100 2.1 27 1,476

3 100 2.1 9 0,492

4 100 2.1 3 0,164

Class 0 identifies all the products that weren’t tested or did not reach to pass the limit for

class 1.

In order to have an idea of the limit prescribed by US standard:

Pressure Permeability

STANDARD

Pa psf m3/h m2 cfm/ft2

AAMA/WDMA/CSA

101/IS 2/A440-11

75 1.57 5.5 0.30

MIAMI DADE 300 6.24 1.1 0.06

Form No: BWT-DOC-026 page 1 of 3

rev.A | 22/03/2018

WATER RESISTANCE: UNI EN 12208

European standard for water resistance classifies the specimen with the following method:

the specimen is assembly to the test wall with the interior face that watch outside the

pressure chamber. Water are supplied from interior, with a flow around 2 L/min 26.4 gal per

hour, and inside the chamber is applied a positive pressure.

The test time is divided in this way:

1. 15 min applying water and no pressure;

2. 5 min with the second pressure step;

3. 5 min with the second pressure step;

4. ;..

Pressure Classification

STEP Time

Pa psf Method A Method B

0 - - 0 0 \

1 0 0 1A 1B 15 min

2 50 1.04 2A 2B 5 min

3 100 2.09 3A 3B 5 min

4 150 3.13 4A 4B 5 min

5 200 4.18 5A 5B 5 min

6 250 5.22 6A 6B 5 min

7 300 6.27 7A 7B 5 min

8 450 9.40 8A / 5 min

9 600 12.53 9A / 5 min

10 >600 >12.53 Exxx / 5 min

Method A is for product completely exposed, for Method B sprinklers doesn’t spray water

onto the head of the specimen.

Above 600 Pa, specimen class is identify with Exxx and the xxx is substitute with the

pressure test, from class to class the pressure step is 150 Pa (3.13). As example a class

E1200 for water penetration test is a specimen tested @ 1200 Pa (25.06 psf).

US standard prescribes a test pressure for water penetration in this way:

STANDARD Pressure

AAMA/WDMA/CSA

Class R, LC, CW 15% of Design Pressure

101/IS 2/A440-11

AAMA/WDMA/CSA

Class AW 20% of Design Pressure

101/IS 2/A440-11

MIAMI DADE 15% of Design Pressure

Form No: BWT-DOC-026 page 2 of 3

rev.A | 22/03/2018

STRUCTURAL LOAD: UNI EN 12210

European standard identifies the structural resistance with two identification code, one for

the test pressure and another for the deformation.

A product is identifies as Class A1 or CExxx following these tables:

Test Pressure Classification

Class P1 P2 P3

Pa psf Pa psf Pa psf

0 NOT TESTED

1 400 8.35 200 4.18 600 12.53

2 800 16.71 400 8.35 1200 25.06

3 1200 25.06 600 12.53 1800 37.59

4 1600 33.42 800 16.71 2400 50.12

5 2000 41.77 1000 20.9 3000 62.65

Exxxx xxxx

Each specimen need to pass all the three test pressure to obtain that class identification

without any damage or failure. Test pressure P1 and P3 are applied with positive and negative

sign, P2 is applied for 50 times both positive and negative.

The last Class Exxxx identifies the product tested at a different pressure greater than 2000

Pa (41.77 psf). P2 and P3 for class Exxxx are obtained multiply xxxx by 0,5 for P2 and 1.5

for P3.

The second identification code described the deformation limit registered during the test with

P1 pressure.

Class Deformation

A < 1/150

B < 1/200

C < 1/300

So for example a product could be identified as Class A3, a specimen test with a pressure

of 1200 Pa (25.06 psf) with a deformation less than 1/150. Class BE4000 means a specimen

test at 4000 Pa (83.54 psf) with a deformation less than 1/200.

Form No: BWT-DOC-026 page 3 of 3

rev.A | 22/03/2018

You might also like

- Latin America Payments Solution: November 2018Document19 pagesLatin America Payments Solution: November 2018Jairo MartinezNo ratings yet

- Testing Procedure of Dual Plate Check ValveDocument2 pagesTesting Procedure of Dual Plate Check Valverajesh100% (2)

- Testing Procedure of Ball ValveDocument2 pagesTesting Procedure of Ball Valverajesh100% (2)

- Lab Report 1Document13 pagesLab Report 1Faiq AhmadNo ratings yet

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocument1 pageMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatNo ratings yet

- HAFLEN Mechanical Couplers ReportDocument71 pagesHAFLEN Mechanical Couplers ReportdeshNo ratings yet

- Cabeza de Inyeccion de GrasaDocument100 pagesCabeza de Inyeccion de GrasaPierre MejiaNo ratings yet

- APV Test Procedure API 598Document3 pagesAPV Test Procedure API 598Zain AlwaliNo ratings yet

- IO09 - Hydrostatic Test - R3Document3 pagesIO09 - Hydrostatic Test - R3bafivuitinhNo ratings yet

- GSL Test Procedure API 598 PDFDocument3 pagesGSL Test Procedure API 598 PDFParag S. DicholkarNo ratings yet

- Test Procedure API 598Document3 pagesTest Procedure API 598Raktim DasNo ratings yet

- Method of Statement For Duct Pressure TestDocument30 pagesMethod of Statement For Duct Pressure Testmodava67% (3)

- 300W Single Output With PFC Function: SeriesDocument6 pages300W Single Output With PFC Function: SeriesJuan David Velasquez BranNo ratings yet

- Enclosure 5 - PRESSURE TEST DIAGRAMDocument2 pagesEnclosure 5 - PRESSURE TEST DIAGRAMFaruk OcalNo ratings yet

- Documentatie Flowserve NAF 2 4 Vana Bila Model Setball FK SIALCO (2) 11Document8 pagesDocumentatie Flowserve NAF 2 4 Vana Bila Model Setball FK SIALCO (2) 11AntonNo ratings yet

- Globe Valve LWR 217: Inspection Report Defect-C0LD WorkDocument4 pagesGlobe Valve LWR 217: Inspection Report Defect-C0LD WorkMuhammad ZariqNo ratings yet

- Acrylic RotameterDocument2 pagesAcrylic RotameterqajjeplNo ratings yet

- Gas Pressure RegulatorDocument5 pagesGas Pressure RegulatormusaveerNo ratings yet

- Written Test For Process Engineer - Solution Part 1Document4 pagesWritten Test For Process Engineer - Solution Part 1FlowealthNo ratings yet

- Using Flange Joint in Duct SiystemDocument23 pagesUsing Flange Joint in Duct Siystematamete100% (1)

- Acoustic Emission Testing of Pressure Vessel - ASME Section V, ASNT - 24 Feb 2011Document84 pagesAcoustic Emission Testing of Pressure Vessel - ASME Section V, ASNT - 24 Feb 2011concord1103No ratings yet

- Hydrostatic TestDocument6 pagesHydrostatic TestalfredoNo ratings yet

- Pressure & Functional Testing Api 6D Ball Valves: Technical Instruction AP/PT6 00 05/03/19 1/3Document7 pagesPressure & Functional Testing Api 6D Ball Valves: Technical Instruction AP/PT6 00 05/03/19 1/3hari100% (1)

- Hydraulicsystemdesign 240304145623 6202be91Document76 pagesHydraulicsystemdesign 240304145623 6202be91masrydrarNo ratings yet

- A5 20 Post Installation Testing of HP StormDocument4 pagesA5 20 Post Installation Testing of HP StormbetojulioNo ratings yet

- Fox 3-RFP Rapid Filling Preventor With MeshDocument2 pagesFox 3-RFP Rapid Filling Preventor With MeshSpoonful BurnsideNo ratings yet

- LUNACEL HC H14 610 X 610 X 149 MMDocument1 pageLUNACEL HC H14 610 X 610 X 149 MMSantiago FalusNo ratings yet

- Surge Arrest Test ProceduresDocument11 pagesSurge Arrest Test Proceduresmarevey100% (3)

- Saudi Aramco Pre-Commissioning Form: Testing Guide LinesDocument4 pagesSaudi Aramco Pre-Commissioning Form: Testing Guide Linesverzehre100% (2)

- 4 29a e Ae50s Automatic Air and Gas Vents For Liquids DN 15 25Document4 pages4 29a e Ae50s Automatic Air and Gas Vents For Liquids DN 15 25auxiliar.termicaNo ratings yet

- Hdpe Pipe presentation-PressureTest Procedure PDFDocument18 pagesHdpe Pipe presentation-PressureTest Procedure PDFSubhash KumarNo ratings yet

- V11100-1 Fox 3-RFP Rapid Filling Preventor With MeshDocument2 pagesV11100-1 Fox 3-RFP Rapid Filling Preventor With MeshSpoonful BurnsideNo ratings yet

- Rate of Flow Non-Surge Check Valve: ModelDocument2 pagesRate of Flow Non-Surge Check Valve: ModelAndrzej BąkałaNo ratings yet

- FCVN-TR2210-016 - VN-FH6801-PP1-CW058 - Air Performance TestDocument1 pageFCVN-TR2210-016 - VN-FH6801-PP1-CW058 - Air Performance TestVan Ba VuNo ratings yet

- Control Valve Specifications: Educational ServicesDocument16 pagesControl Valve Specifications: Educational Serviceslovely_phussNo ratings yet

- PressedDocument79 pagesPressedANDRES LOPEZNo ratings yet

- Mechanical Part BDocument30 pagesMechanical Part BAhmad HashmiNo ratings yet

- EVO Moduler ENDocument38 pagesEVO Moduler ENsinan.kahramanNo ratings yet

- M2BAX 200MLA 2,3GBA201410-DF, 30kW, 400VD, 50HzDocument1 pageM2BAX 200MLA 2,3GBA201410-DF, 30kW, 400VD, 50HzPein AkatsukiNo ratings yet

- 05 Exercise-1Document15 pages05 Exercise-1aliNo ratings yet

- Meanwell MPT-45 Series Power SupplyDocument5 pagesMeanwell MPT-45 Series Power SupplyRon WhittingtonNo ratings yet

- Atc Transponder Sys Test-R1Document1 pageAtc Transponder Sys Test-R1Sani IhsanNo ratings yet

- Aml SF 4 100 PsiDocument5 pagesAml SF 4 100 Psijvicher61No ratings yet

- Temporary Specification For ReferenceDocument8 pagesTemporary Specification For ReferencevijayNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- XDS Range BrochureDocument8 pagesXDS Range BrochureJose QuincosNo ratings yet

- Unique SPC-1 ValveDocument8 pagesUnique SPC-1 ValveAngelito_HBKNo ratings yet

- Engineering Technical Bulletin: Air Leakage and Water Penetration Test DataDocument1 pageEngineering Technical Bulletin: Air Leakage and Water Penetration Test DataYUK LAM WONGNo ratings yet

- Design of Concrete Columns Based On EC2 Tabulated PDFDocument19 pagesDesign of Concrete Columns Based On EC2 Tabulated PDFDanielaFinizzaNo ratings yet

- AP.E - Engineering: Electromagnetic Flow ConverterDocument2 pagesAP.E - Engineering: Electromagnetic Flow ConverterSlman MahmoudNo ratings yet

- AEC-6910 En-50155 Test ReportDocument29 pagesAEC-6910 En-50155 Test Reportd157952No ratings yet

- Description: P900 October 2012 1/6Document6 pagesDescription: P900 October 2012 1/6Agus Sri HartonoNo ratings yet

- PEI Filament: Ultem 1010Document3 pagesPEI Filament: Ultem 1010Rui MatiasNo ratings yet

- LPS100Document2 pagesLPS100MartinNo ratings yet

- Appendix Field Manual For Concrete AnchoringDocument3 pagesAppendix Field Manual For Concrete AnchoringZed BaladrafNo ratings yet

- HydroTest ProcedureDocument3 pagesHydroTest Procedureusama aliNo ratings yet

- MFR-111 - Valve Test Record 01Document1 pageMFR-111 - Valve Test Record 01Rafiq RashidiNo ratings yet

- Water Meter Flanged PN16Document6 pagesWater Meter Flanged PN16sunilNo ratings yet

- 0611 - HPS200-250Document2 pages0611 - HPS200-250Rufus D SNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Fenestration Standard/Specification For Windows, Doors, and SkylightsDocument13 pagesFenestration Standard/Specification For Windows, Doors, and SkylightsAndrea Nicola TurcatoNo ratings yet

- EM7 Performance of Mid-Rise Cladding Systems-V3Document17 pagesEM7 Performance of Mid-Rise Cladding Systems-V3Andrea Nicola TurcatoNo ratings yet

- Win 1824 SJW 2013011Document42 pagesWin 1824 SJW 2013011Andrea Nicola TurcatoNo ratings yet

- AZT0606.22 ShortDocument5 pagesAZT0606.22 ShortAndrea Nicola TurcatoNo ratings yet

- Noa One Time ApprovalDocument1 pageNoa One Time ApprovalAndrea Nicola TurcatoNo ratings yet

- Multilite A440 Test ReportDocument16 pagesMultilite A440 Test ReportAndrea Nicola TurcatoNo ratings yet

- Blackwater 2023Document11 pagesBlackwater 2023Andrea Nicola TurcatoNo ratings yet

- 78609.01-301-44-r0 5820SGDDocument26 pages78609.01-301-44-r0 5820SGDAndrea Nicola TurcatoNo ratings yet

- Connectors WoodDocument1 pageConnectors WoodAndrea Nicola TurcatoNo ratings yet

- 1556 Picture Window (72 X 72)Document11 pages1556 Picture Window (72 X 72)Andrea Nicola TurcatoNo ratings yet

- 2.1.13-Commercial Envelope ModuleDocument182 pages2.1.13-Commercial Envelope ModuleAndrea Nicola TurcatoNo ratings yet

- TAS 201-94 - Impact Test ProceduresDocument7 pagesTAS 201-94 - Impact Test ProceduresAndrea Nicola TurcatoNo ratings yet

- Testing Application Standards (TAS) Chapter No. 301-94 - Testing LaboratoryDocument4 pagesTesting Application Standards (TAS) Chapter No. 301-94 - Testing LaboratoryAndrea Nicola TurcatoNo ratings yet

- TAS 203-94 - Criteria For Testing Products Subject To Cyclic Wind Pressure LoadingDocument6 pagesTAS 203-94 - Criteria For Testing Products Subject To Cyclic Wind Pressure LoadingAndrea Nicola TurcatoNo ratings yet

- As 4420.2 Serviceability Strenght: Australian and New Zeland Test PressureDocument2 pagesAs 4420.2 Serviceability Strenght: Australian and New Zeland Test PressureAndrea Nicola TurcatoNo ratings yet

- As2047-Load For TestDocument3 pagesAs2047-Load For TestAndrea Nicola TurcatoNo ratings yet

- NFRCSim7 July2016Document423 pagesNFRCSim7 July2016Andrea Nicola TurcatoNo ratings yet

- STP 124-1952Document120 pagesSTP 124-1952Andrea Nicola TurcatoNo ratings yet

- DC 995Document3 pagesDC 995Andrea Nicola TurcatoNo ratings yet

- Uso Su Tre Casi Dei Modelli CFD Per Prevedere L'andamento Dei Fumi in Ambienti Chiusi ComplessiDocument114 pagesUso Su Tre Casi Dei Modelli CFD Per Prevedere L'andamento Dei Fumi in Ambienti Chiusi ComplessiAndrea Nicola TurcatoNo ratings yet

- Climate Region GuideDocument50 pagesClimate Region GuideAndrea Nicola TurcatoNo ratings yet

- Arpa Related TermsDocument2 pagesArpa Related TermsPrince100% (1)

- Article 11 Internal Audit of Quality in 5s EnvironmentDocument11 pagesArticle 11 Internal Audit of Quality in 5s EnvironmentMohd Noor FakhrullahNo ratings yet

- Full Stack Engineer - SploreDocument2 pagesFull Stack Engineer - SploreSujay VadavadagiNo ratings yet

- ARM1176 Reference ManualDocument759 pagesARM1176 Reference ManualMelanie WallaceNo ratings yet

- Resume Gaurav MBADocument2 pagesResume Gaurav MBAAkshay singhNo ratings yet

- Fms BulletinDocument31 pagesFms BulletinalphaNo ratings yet

- Rhetorical Appeals and Techniques Graphic OrganizerDocument3 pagesRhetorical Appeals and Techniques Graphic OrganizermaleahrfornaNo ratings yet

- Pen Type Multimeter User ManualDocument6 pagesPen Type Multimeter User Manualjuan José riosNo ratings yet

- Revision CP 4Document35 pagesRevision CP 4Victor OdipoNo ratings yet

- Groundwater Exploration With The Magnetic Resonance SoundingDocument9 pagesGroundwater Exploration With The Magnetic Resonance SoundingYoussef Waled MohamedNo ratings yet

- NMDCAT 2021 Electromagnetism-1Document5 pagesNMDCAT 2021 Electromagnetism-1Umer Ali100% (1)

- FAR-0004 Design and Test PDFDocument10 pagesFAR-0004 Design and Test PDFMSNo ratings yet

- Nyquist Plots For EDLCDocument13 pagesNyquist Plots For EDLCLoga NathanNo ratings yet

- Innovations in Nursing EducationDocument18 pagesInnovations in Nursing EducationTapodhan VishuNo ratings yet

- FinGAT Financial Graph Attention Networks For Recommending Top-KK Profitable StocksDocument13 pagesFinGAT Financial Graph Attention Networks For Recommending Top-KK Profitable StocksSivaramakrishnan KanagarajNo ratings yet

- World Conference On Floating Solutions 2019Document10 pagesWorld Conference On Floating Solutions 2019CharlieNo ratings yet

- 2007 Sajc GP Prelim p1 AnsDocument12 pages2007 Sajc GP Prelim p1 AnspopthudlerNo ratings yet

- Mobile Broadband For Emerging Markets 2011 Programme CoverDocument2 pagesMobile Broadband For Emerging Markets 2011 Programme Covereugene_azucenaNo ratings yet

- Asessment BurnoutDocument10 pagesAsessment BurnoutSMA N 1 TOROHNo ratings yet

- QUAD BLACK FRAME - N Type - 420-440 - 2304 - ENDocument2 pagesQUAD BLACK FRAME - N Type - 420-440 - 2304 - ENTorrealba GerardoNo ratings yet

- Combination Resume - Multimedia - r5Document7 pagesCombination Resume - Multimedia - r5olgaNo ratings yet

- Electrical Conductivity and Resistivity of Water: Standard Test Methods ForDocument8 pagesElectrical Conductivity and Resistivity of Water: Standard Test Methods ForAngel MurilloNo ratings yet

- 1 Course Notes - Dry Docking and Planned MaintenanceDocument19 pages1 Course Notes - Dry Docking and Planned Maintenancedarrelsilva100% (2)

- MGE Galaxy 3000 - G3KUPS15Document3 pagesMGE Galaxy 3000 - G3KUPS15Last Juan StandingNo ratings yet

- 9.18 Hvac Guide: Chapter 9 - Design GuidesDocument25 pages9.18 Hvac Guide: Chapter 9 - Design Guidessolarstuff100% (1)

- Sunset and Sunrise TipsDocument4 pagesSunset and Sunrise TipsAvinash ReddyNo ratings yet

- Air Conditioning System For Your CarDocument9 pagesAir Conditioning System For Your CarSanjeev GuptaNo ratings yet

- Vol3 No1 Art3 Philippine GamesDocument11 pagesVol3 No1 Art3 Philippine Gameslmao pre xd lamawNo ratings yet

- Gambella WASH Physical Construction BOQ - For WASH StaffDocument25 pagesGambella WASH Physical Construction BOQ - For WASH StaffDavid TabangNo ratings yet