Professional Documents

Culture Documents

Ultra-High Strength Concrete Filled Composite Columns For Multi-Storey Building Construction

Ultra-High Strength Concrete Filled Composite Columns For Multi-Storey Building Construction

Uploaded by

GuilhermeFregoneziOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultra-High Strength Concrete Filled Composite Columns For Multi-Storey Building Construction

Ultra-High Strength Concrete Filled Composite Columns For Multi-Storey Building Construction

Uploaded by

GuilhermeFregoneziCopyright:

Available Formats

Ultra-High Strength Concrete Filled Composite

Columns for Multi-Storey Building Construction

J.Y. Richard Liew* and D.X. Xiong

Department of Civil Engineering, National University of Singapore, Singapore

Abstract: A test programme was carried out to investigate the performance of

27 axially loaded column specimens, including 18 steel tubes infilled with ultra-high

strength concrete (UHSC) of compressive strength close to 200 MPa, 4 steel tubes

infilled with normal strength concrete (NSC) and 5 hollow steel tubes. Steel fibres

were added into the UHSC to study their effect in enhancing the ductility and strength.

Concrete filled double-tube columns were also investigated for potential application in

multi-storey and high-rise constructions. Test results showed that UHSC filled tubular

columns achieved ultra-high load-carrying capacities, but they could become brittle

after the maximum load was attained. In addition, the ductility and strength of

composite columns infilled with UHSC was improved by applying load only on the

concrete core, adding steel fibres into the concrete core or increasing the steel

contribution ratio. Comparison of test results with Eurocode 4’s predictions indicates

that the Eurocode 4 method could be safely extended to predict the compressive

resistance of UHSC filled composite stub columns. On average, Eurocode 4 approach

underestimated the resistance by 14.6% if the confinement effect was not considered

and by 3.5% if the confinement effect was considered for all the specimens involving

UHSC. However, to ensure sufficient ductility, it is recommended that a minimum

steel contribution ratio of 0.30 or 1% steel fibres should be used. Furthermore, strength

enhancement due to confinement effect should be ignored in estimating the ultimate

strength of concrete filled composite columns with Class 3 steel sections.

Key words: composite columns, confinement effect, concrete-filled steel tube, double-tube column, ductility, high

strength concrete, multi-storey building, steel fibre.

1. INTRODUCTION storey composite building in which concrete is pumped

Concrete filled steel tubular columns have been used into the hollow steel tubes after several floors above

widely for the construction of multi-storey buildings, them have been constructed.

bridge piers, and other supporting structures. They have It has been found that ultra high strength concrete

significant advantages over conventional reinforced (UHSC) is an attractive alternative to normal strength

concrete and pure steel columns as they can improve concrete (NSC) for high-rise building construction as

space efficiency by using smaller columns, utilize smaller column size can be achieved (Liew et al. 2008).

synergistic material advantages due to composite action, However, current design guides are only applicable to

result in savings in fabrication and construction costs, normal strength concrete. For example, Eurocode 4

and prevent the premature local failure (Saw and Liew limits the concrete strength class only up to C50/60.

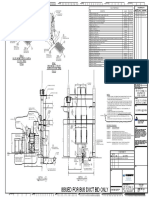

2000). Figure 1 shows a typical multi-storey building Additional work should be done to extend current

with internal core wall providing lateral bracing to the design guidelines to high strength concrete (HSC) with

structural steelwork during construction. Figure 2 shows compression strength higher than C50/60 and to UHSC

the tubular steel columns at the perimeter of the building with strength higher than C120/135.

before concrete is pumped into the columns. Figure 3 In recent years, some experimental works have

illustrates a general construction sequence of a multi- provided an important insight into the behaviour of HSC

*Corresponding author. Email address: ceeljy@nus.edu.sg; Fax: +65-6779-1635; Tel: +65-6516-2154.

Advances in Structural Engineering Vol. 15 No. 9 2012 1487

Ultra-High Strength Concrete Filled Composite Columns for Multi-Storey Building Construction

Temporary

framing

bracing

Core

Central core wall Hollow

Steel columns steel

and steel beams tubes

Steel framing

Metal decking

Castin of concrete Bracing

deck concrete

Composite beams framing

Level of

Floors of

Comosite floor slab complete

Composite columns

concrete

Max. preload

filled

on columns

column

in this floor

Figure 1. A high-rise steel-concrete composite building in

construction (Liew 2004)

Figure 3. Fast track construction of a typical steel-concrete

composite building (Liew and Xiong 2009)

performed a series of tests on HSC filled rectangular steel

tubular columns subjected to concentric and eccentric

loading. The cylinder strengths of the HSC were about

60 MPa and 90 MPa. It was concluded that Eurocode 4

underestimated the concentrically loaded columns by 1%

but overestimated the eccentrically loaded columns by less

than 5%. Liu et al. (2003, 2005) conducted some tests on

axially loaded concrete filled rectangular hollow steel

sections involving HSC with cylinder strength ranging

from 55 MPa to 106 MPa. It was shown that Eurocode 4

could predict the column strength accurately on the

average but within a range of −20% and +10%. Han et al.

(2005) tested 50 circular and square hollow structural steel

stub columns infilled with self-compacting concrete of

cube strengths between 50 MPa and 90 MPa. The

comparison showed that Eurocode 4 overestimated the

ultimate strength by 0.6% for circular sections and 2.7%

for square sections. Gho and Liu (2004) studied the

flexural behavior of 12 concrete filled rectangular steel

Figure 2. Hollow circular steel tubes before casting concrete hollow section specimens infilled with HSC of cylinder

(Liew 2004) strengths between 56.3 MPa and 90.9 MPa. It was shown

that Eurocode 4 underestimated the flexural strengths by

which would have a strong impact on the application of 11%. Varma et al. (2002, 2004) conducted a series of tests

concrete-filled steel tubular columns in multi-storey and on the seismic behavior of HSC filled square beam

high-rise constructions. Yu et al. (2008) carried out tests columns subjected to constant axial load and cyclically

on 28 thin-walled hollow square and circular steel tubes varying flexural loading. The cylinder strength of the HSC

infilled with self-compacting concrete with cube strength in the tests was up to 110 MPa. The results showed that the

of 120 MPa. The results showed that Eurocode 4 predicted elastic flexural section stiffness under cyclic loading

conservatively the ultimate strength of circular sections decreased rapidly due to tension cracking of concrete and

but overestimated the strength of square sections by 6%. local buckling of steel tubes. The total dissipated energy

Lue et al. (2007) reported tests on 24 concrete filled square was dominated by the dissipated flexural energy in the

tubes with HSC of cylinder strengths between 29 MPa and plastic hinge region. Varma et al. (2002) also

84 MPa. It was revealed that Eurocode 4 provided investigated the flexural force-deformation behavior of

conservative predictions. Liu (2004, 2005, 2006) several 110 MPa HSC filled square steel tubes subjected to

1488 Advances in Structural Engineering Vol. 15 No. 9 2012

J.Y. Richard Liew and D.X. Xiong

axial load and monotonically increasing flexural loading. For axially loaded concrete filled tubes of circular

–

The moment capacity could be accurately predicted by the cross-section with relative slenderness λ ≤ 0.5, account

American Concrete Institute code provisions. Based on may be taken of increase in strength of concrete caused

the above review, those investigations showed the by confinement effect as

outstanding unique advantage of high resistance that HSC

resulted in. However, the drawback of brittleness was not

t fy

N pl , Rk 2 = ηa Aa f y + Ac fck 1 + ηc (3)

investigated and the ductility was not assessed. In d fck

addition, all of the concrete strengths used in previous

researches were limited up to 120 MPa. No prior work has where ηa and ηc are given by the following expressions,

been done on composite columns with ultra high strength

concrete (up to 200 MPa), and the present investigation

takes a pioneer step towards the research on ultra high

( )

ηa = 0.25 3 + 2λ ( but ≤ 1.0 ) (4)

strength composite columns.

In this study, an experimental investigation was ηc = 4.9 − 18.5λ + 17λ 2 ( but ≥ 0 ) (5)

carried out on 27 axially loaded circular specimens,

including 18 steel tubes infilled with UHSC of There is no need to consider the overall buckling for

compressive strength close to 200 MPa, 4 steel tubes axially loaded

infilled with NSC and 5 hollow steel tubes. Steel fibres – composite columns with relative

slenderness, λ , less than 0.2. Local buckling can be

were added into the UHSC to study their effect in ignored when the diameter to thickness ratio satisfies

enhancing the ductility and strength. Two of the UHSC following condition,

filled steel tubes were loaded only on the UHSC cores to

investigate the performance of UHSC subjected to high

tri-axial compression. Concrete filled double-tube d 235 (6)

≤ 90

columns were also investigated with different concrete t fy

strengths for potential application in high-rise

constructions. The test results were analyzed with Eurocode 4 method is limited to columns and

respect to ultimate strengths, failure modes, load- compression members with steel grades between S235

displacement behaviour and ductility requirements. The to S460, NSC of strength classes C20/25 to C50/60, and

test results were also compared with the predictions by steel contribution ratio, δ, in the range of 0.2 to 0.9. As

Eurocode 4 method. Finally, important findings with follows, the experimental investigation work was

regard to the use of UHSC and NSC as infilling materials described in detail with an aim to extend the Eurocode 4

for tubular composite columns were highlighted. method to tubular sections infilled with UHSC of

compression strength up to 200 MPa.

2. DESIGN OF COMPOSITE COLUMNS

BASED ON EUROCODE 4 METHOD 3. EXPERIMENTAL INVESTIGATION

According to Eurocode 4, the characteristic value of the 3.1. Material Properties

plastic resistance to compression of a composite cross- The materials included NSC, UHSC, steel fibres and hollow

section without steel reinforcement may be estimated by structural steel tubes. For each batch of concrete, at least

three concrete cylinder specimens (100 mm × 200 mm) were

N pl , Rk = Aa f y + 0.85 Ac fck (1) tested to obtain their mechanical properties. For each type of

steel sections, three steel coupon samples were tested.

Eqn 1 applies for concrete encased and partially

concrete encased steel sections without reinforcement. 3.1.1. Normal strength concrete (NSC)

For concrete filled sections, the coefficient 0.85 may be The NSC was made from ordinary Portland cement,

replaced by 1.0, i.e. sand, coarse aggregates with maximum size 10 mm, and

water. For the investigation, only one batch of NSC was

N pl , Rk1 = Aa f y + Ac fck (2) cast. The mix proportions are shown in Table 1.

Table 1. Mix proportions of NSC

Water Cement Sand Coarse aggregate

Water/Cement (kg/m3) (kg/m3) (kg/m3) (kg/m3)

0.5 225 450 625 1005

Advances in Structural Engineering Vol. 15 No. 9 2012 1489

Ultra-High Strength Concrete Filled Composite Columns for Multi-Storey Building Construction

Table 2. Mix proportions of UHSC

Water Pre-blended mixture Concrete volume

Water/Pre-blended mixture (kg) (kg) (liters)

0.076 1.9 25 9.4

Table 3. Properties of steel fibre

Tensile Elastic

Diameter Length Specific strength modulus

(mm) (mm) Aspect ratio gravity (MPa) (GPa) Coating

0.16 13 80 7.85 2300 200 Brass

3.1.2. Ultra-high strength concrete (UHSC) reinforced UHSC specimens exhibited some post-peak

The UHSC was made from a commercial pre-blended ductility. Loud cracking noise was heard during the

mixture comprising cementitious material, super testing of UHSC and steel fibre reinforced UHSC. It was

plasticizer and fine aggregates with maximum sizes less found that steel fibres improved the ductility of UHSC.

than 4.75 mm. Since no coarse aggregate was used, it The mechanical properties obtained from the concrete

was actually a kind of “mortar” material rather than cylinders are summarized in Table 4, where fck,100 is the

“concrete” material. However, the term of “concrete” is compressive strength obtained from testing the 100 mm

still used in this paper for convenience. For the present diameter concrete cylinders, and fck is the compressive

investigation, three batches of UHSC were cast. The mix strength based on 150 mm diameter concrete cylinder

proportions are shown in Table 2. which is estimated to be fck,100 /1.05.

3.1.3. Steel fibre reinforced UHSC 3.1.4. Steel tubes

High tensile strength steel fibres, as shown in Figure 4, Four sizes of S355 hot finished circular hollow sections,

were used to improve the performance of UHSC. Their 114 mm × 3.6 mm, 114 mm × 6.3 mm, 219 mm × 5.0 mm

basic mechanical properties are shown in Table 3. For and 219 mm × 10 mm were used in the tests. The

the investigation, two batches of steel fibre reinforced “exact” dimensions were measured and the mechanical

UHSC were cast, one with 1% steel fibres in volume and properties were obtained by coupon tests as shown in

the other with 0.5%. Table 5. The sections were classified according to

Compression tests carried out on concrete cylinder Eurocode 3.

specimens showed that NSC had lower strength but

better ductility than UHSC. Figure 5 compares the 3.2. Test Specimens

failure modes of various types of concrete specimens. There were 27 specimens comprising 5 hollow steel

UHSC cylinders were crushed into pieces after their tubes, 18 concrete filled single-tube columns and 4

maximum loads were reached whereas NSC and fibre- concrete filled double-tube columns, as shown

schematically in Figure 6. The specimens were further

classified into three series.

Series 1 comprised 11 specimens with column height

250 mm, nominal tube diameter 114 mm, and tube

thicknesses 3.6 mm and 6.3 mm, including three hollow

steel tubes, six UHSC filled tubes and two steel fibre

reinforced UHSC filled tubes. The specimen details are

given in Table 6. The– design plastic resistance, Npl, Rd, the

relative slenderness, λ , and the steel contribution ratio, δ,

are also shown in Table 6. Specimens S1-2-1(a) and

S1-2-1(b) were axially loaded only on the concrete cores

and the other specimens were loaded simultaneously on

both of the steel tubes and concrete cores as shown in

Figure 7. Series 1 was tested to observe the performance

of the UHSC filled single-tube columns under different

loading conditions and with different steel contribution

Figure 4. Steel fibre-SF 13/80 ratios, δ.

1490 Advances in Structural Engineering Vol. 15 No. 9 2012

J.Y. Richard Liew and D.X. Xiong

(a) NSC (b) UHSC (c) SF reinforced UHSC

Figure 5. Failure modes of different concrete

Table 4. Basic mechanical properties of different batches of concrete

Batch fck,100* fck* Ecm Density

No. Type (MPa) (MPa) (GPa) νc (kg/m3) Specimens

B1 UHSC 173 165 63 0.24 S1-2-1(a, b), S1-3-1(a, b),

S1-3-3(a, b)

B2 UHSC + %1 SF 184 175 63 0.24 S1-3-2(a, b)

B3 NSC 54 51 28 0.20 2317 Specimens containing

NSC

B4 UHSC 175 167 66 0.23 2704 S3-1-2, S3-1-3, S3-2-2

B5 UHSC 185 176 66 0.23 2717 S2-1-3, S2-2-2, S3-2-3

B6 UHSC + 0.5% SF 193 184 67 0.25 2703 S2-1-4, S2-2-4,

S3-1-4, S3-2-4

*f

ck,100 representsthe strengths obtained by testing cylinders of dimension 100 mm diameter × 200 mm height

fck represents the strengths based on cylinders of dimension 150 mm diameter × 300 height, estimated by fck = fck, 100 /1.05

Table 5. Basic mechanical properties of steel tubes

Measured dimension fy fu Ea d fy Section

Circular hollow sections d (mm) t (mm) (MPa) (MPa) (GPa) t 235 class

CHS114 × 3.6 114.67 3.54 406 505 213 56 (< 70) 2

CHS114 × 6.3 114.33 6.13 428 521 209 34 (< 50) 1

CHS219 × 5 219.43 4.87 377 511 205 72 (< 90) 3

CHS219 × 10 219.43 9.69 381 509 212 37 (< 50) 1

fck fy fck2 fy2 fy1

fy

fck1

(a) Hollow section tube (b) Concrete filled single-tube (c) Concrete filled double-tubes

Figure 6. Three types of test specimens

Advances in Structural Engineering Vol. 15 No. 9 2012 1491

Ultra-High Strength Concrete Filled Composite Columns for Multi-Storey Building Construction

Table 6. Specimen details for test Series 1: Concrete filled tubes

L Section fy fck,100 Npl,Rd

No. (mm) no (MPa) (MPa) (kN) λ δ

S1-1-1(a) 250 CHS114 × 3.6 406 502 0.088

S1-1-2(a) 250 CHS114 × 6.3 428 892 0.094

S1-1-2(b) 250 CHS114 × 6.3 428 892 0.094

S1-2-1(a)* 200 CHS114 × 6.3 428 173 1836 0.105 0.486

S1-2-1(b)* 200 CHS114 × 6.3 428 173 1836 0.105 0.486

S1-3-1(a) 250 CHS114 × 3.6 406 173 1550 0.142 0.324

S1-3-1(b) 250 CHS114 × 3.6 406 173 1550 0.142 0.324

S1-3-2(a)** 250 CHS114 × 3.6 406 184 1617 0.145 0.310

S1-3-2(b)** 250 CHS114 × 3.6 406 184 1617 0.145 0.310

S1-3-3(a) 250 CHS114 × 6.3 428 173 1836 0.132 0.486

S1-3-3(b) 250 CHS114 × 6.3 428 173 1836 0.132 0.486

* Loaded only on the concrete core which was 200 mm in length; the steel tubes were 250 mm in length

** The UHSC in the two specimens was reinforced by 1% SF

Series 2 comprised 8 specimens with column height

600 mm, and nominal tube diameter 219 mm and

thicknesses 5 mm and 10 mm, including 2 hollow steel

20 mm tubes, 2 NSC filled tubes, 2 UHSC filled tubes and 2

steel fibre reinforced UHSC filled tubes. The specimen

details are shown in Table 7 and Figure 8(a). All the

specimens were loaded simultaneously on both of the

steel tubes and concrete cores. Series 2 was tested to

210 mm

verify the behavior of axially loaded UHSC filled

single-tube columns, compared to NSC filled columns.

Series 3 comprised 8 concrete filled double-tube

specimens with the length 600 mm and nominal overall

diameter 219 mm, including 2 specimens infilled with

20 mm

NSC, 2 specimens infilled with UHSC, 2 specimens

infilled with UHSC core and NSC in between tubes, and

(a) Loading applied only on the concrete core 2 specimens infilled with steel fibre reinforced UHSC

core and NSC in between tubes. The specimen details

are shown in Table 8 and Figure 8(c). All the specimens

were loaded simultaneously on both of the steel tubes

Actuator

and concrete cores. Series 3 was tested to investigate the

behavior of axially loaded UHSC and NSC filled

25 mm double-tube columns.

Hoop ring stiffener

3.3. Test Setup

250 mm

Four post yield strain gauges, placed at 900 apart, were

attached to the external surface at the mid-height of the

steel tube, as shown in Figure 9. Each strain gauge consists

of two components, one aligned in the longitudinal

direction and the other in the circumferential direction.

3~5 mm The axial shortening displacements were measured by

four linear varying displacement transducers (LVDTs)

which were also placed at 90° apart. The axial load was

(b) Loading applied on both the concrete core and steel tube

applied by a displacement control actuator with a

Figure 7. Different loading conditions for Series 1 specimens maximum capacity of 10,000 kN. To avoid premature

1492 Advances in Structural Engineering Vol. 15 No. 9 2012

J.Y. Richard Liew and D.X. Xiong

Table 7. Specimen details for test Series 2: Concrete filled tubes

L Section fy fck Npl,Rd

No. (mm) no. (MPa) (MPa) (kN) λ δ

S2-1-1 600 CHS219 × 5 377 1238 0.108

S2-1-2 600 CHS219 × 5 377 51 2412 0.141 0.513

S2-1-3 600 CHS219 × 5 377 176 5290 0.187 0.234

S2-1-4* 600 CHS219 × 5 377 184 5474 0.190 0.226

S2-2-1 600 CHS219 × 10 381 2433 0.109

S2-2-2 600 CHS219 × 10 381 51 3501 0.129 0.695

S2-2-3 600 CHS219 × 10 381 176 6121 0.166 0.397

S2-2-4* 600 CHS219 × 10 381 184 6288 0.168 0.387

* The UHSC in the two specimens was reinforced by 0.5% SF

LVDT Strain

gauges

Actuator

3∼5 mm

+ =

Hoop ring stiffener Hoop ring

Specimen

LVDT

(a) Infilled (b) Internal tube with (c) Infilled Strain gauges

single-tube shear connectors double-tubes Strain

gauges

Figure 8. Concrete filled single-tube and double-tube columns

local failure at both ends due to stress concentration, two

Hoop ring stiffener

pairs of hoop ring stiffeners made of high tensile steel

were provided to clamp the ends of the specimens so as to

induce failure near the central height of the specimens. Figure 9. Test setup and locations of strain gauges and LVDTs

3.4. Loading Procedure respectively up to 10% of its capacity estimated by Eqn 2;

A quasi-static loading procedure was introduced in four (2) unload at a rate of 0.5 mm/min and 1.0 mm/min

steps: (1) preload at a rate of 0.2 mm/min for 250 mm long respectively for the two different lengths of specimens; (3)

specimen and 0.3 mm/min for 600 mm long specimen reload at the same rate as in Step 1 to 60% ~ 70% of its

Table 8. Specimen details for test Series 3: Concrete filled double-tube system

L External Internal fy1** fy2** fck1** fck2** Npl,Rd

No. (mm) section section (MPa) (MPa) (MPa) (MPa) (kN) λ δ

S3-1-1 600 CHS219 × 5 CHS114 × 3.6 377 406 51 51 2871 0.146 0.606

S3-1-2 600 CHS219 × 5 CHS114 × 3.6 377 406 167 167 5447 0.183 0.319

S3-1-3 600 CHS219 × 5 CHS114 × 3.6 377 406 51 167 3575 0.165 0.487

S3-1-4* 600 CHS219 × 5 CHS114 × 3.6 377 406 51 184 3678 0.168 0.473

S3-2-1 600 CHS219 × 10 CHS114 × 6.3 381 428 51 51 4322 0.137 0.769

S3-2-2 600 CHS219 × 10 CHS114 × 6.3 381 428 167 167 6592 0.164 0.504

S3-2-3 600 CHS219 × 10 CHS114 × 6.3 381 428 51 176 5004 0.150 0.664

S3-2-4* 600 CHS219 × 10 CHS114 × 6.3 381 428 51 184 5048 0.151 0.659

*The UHSC in the internal tubes of the two specimens was reinforced by 0.5% SF

**f and fy2 are the yield strengths of external and internal steel tubes respectively;

y1

fck1 and fck2 are the strengths of the concrete filled in-between tubes and the center core respectively

Advances in Structural Engineering Vol. 15 No. 9 2012 1493

Ultra-High Strength Concrete Filled Composite Columns for Multi-Storey Building Construction

capacity, and then decrease the rate to 0.1 mm/min and 3000

S1-3-1 (a)

0.2 mm/min respectively until the peak load was reached; S1-3-1 (b)

(4) finally in the post-peak range, increase the rate to 2500

0.5 mm/min and 1.0 mm/min respectively until visible

2000

deformation was observed.

Load (kN)

1500

3.5. Test Results and Observations

3.5.1. Series 1: performance of small scale stub 1000

columns under different loading

conditions 500

The load-axial displacement curves obtained from

Series 1 test specimens are shown in Figures 10–14. 0

0 10 20 30 40

Figure 10 shows that specimen S1-1-1(a), which was a

Axial shortening (mm)

CHS 114 × 3.6 steel tube with Class 2 section, could

almost reach the expected plastic resistance but it Figure 12. Load-shortening curves for specimens S1-3-1(a) and

unloaded immediately after that; while Specimens S1-3-1(b)

S1-1-2(a) and S1-1-2(b), which were of Class 1

3000

S1-3-2 (a)

1200 S1-3-2 (b)

S1-1-1 (a) 2500

S1-1-2 (a)

1000 S1-1-2 (b) 2000

800 Load (kN)

1500

Load (kN)

600

1000

400 500

200

0

0 10 20 30 40

0 Axial shortening (mm)

0 10 20 30 40

Axial shortening (mm) Figure 13. Axial load-shortening curves for specimens S1-3-2(a)

and S1-3-2(b)

Figure 10. Axial load-shortening curves for specimens S1-1-1(a),

S1-1-2(a) and S1-1-2(b) 3000

3000 2500

S1-2-1 (a)

S1-2-1 (b)

2000

2500

Load (kN)

1500

2000 1200

1000

Load (kN)

900

1500

500

S1-3-3 (a)

600 S1-3-3 (b)

1000 0

Interfacial bond 0 10 20 30 40

300 Axial shortening (mm)

suddenly failed

500 Figure 14. Axial load-shortening curves for specimens S1-3-3(a)

0

0 1 2 3 4

and S1-3-3(b)

0

0 10 20 30 40

sections, could achieve the expected plastic resistances

Axial shortening (mm)

but also developed hardening effect after yielding.

Figure 11. Axial load-shortening curves for specimens S1-2-1(a) Figure 11 shows the load-displacement curves for

and S1-2-1(b) S1-2-1(a) and S1-2-1(b) which were loaded only on the

1494 Advances in Structural Engineering Vol. 15 No. 9 2012

J.Y. Richard Liew and D.X. Xiong

UHSC cores as shown in Figure 7(a). At the initial loading significantly due to much higher tri-axial compression in

stage, the steel tube was resisting the load together with specimens S1-2-1(a) and S1-2-1(b), compared with the

the UHSC core due the interfacial bond between the two other composite specimens where both of the steel tubes

materials. The bond was subsequently broken due to the and concrete cores were loaded simultaneously and thus

relative slip occurred; subsequently, the load was mainly lower confinement stresses were produced on the UHSC

resisted by the UHSC core and the load-displacement cores as shown in Figures 12–14. These figures show that

curve became softer. After that, when the axial shortening the UHSC cores were cracked suddenly at smaller axial

displacement of the UHSC core was increasing at a rate displacements, and the load dropped sharply after the

faster than the steel tube, significant confinement effect peak load. Comparing the load displacement curves in

and friction forces were developed due to the expanding of Figures 12–14, it is shown that S1-3-2(a) & (b) in which

concrete core. Thus some load was transferred from the the concrete cores were reinforced with 1% steel fibres,

core to the steel tube, and the load-displacement curve and S1-3-3(a) & (b) which had higher steel contribution

became stiffer. Finally, the steel tube and concrete core ratios had higher ultimate loads and higher residual

were compressed together again. strengths than specimens S1-3-1(a) & (b) which did not

Larger relative slip between the steel and concrete have such strong enhancement.

occurred in S1-2-1(a) than S1-2-1(b) and thus higher The test values of the ultimate strength, Ntest,u, and the

confinement stress would be produced at the peak load. residual strength, Ntest,r, are summarized in Table 9 for test

This explains the reason why the ultimate strength of series 1. The residual strength to ultimate strength ratio,

S1-2-1(a) was higher than S1-2-1(b) as shown in Ntest,r/Ntest,u, was the lowest for S1-3-1(a) & (b) at about

Figure 11, although they were identical specimens. At the 71% on average, higher for S1-3-2(a) & (b) at about 79%

peak load, the UHSC core was crushed and its strength and for S1-2-1(a) & (b) at about 85%, and the highest for

was degraded rapidly, leading to rapid softening of the S1-3-3(a) & (b) at about 92%. Therefore, the ductility and

loading curve. The confinement stress was increased strength of the composite column can be improved if steel

quickly due to the dilation effect of the UHSC core. The fibres are added, the steel contribution ratio is increased, or

residual strength of S1-2-1(a) was almost kept constant stronger triaxial confinement is provided to the concrete

for a continuous period of axial deformation up to 40 mm. cores. On the contrary, the ultimate strength of a

Residual strength is defined as the remaining strength composite column may reduce if some axial preload is

beyond 15% yield strain (see Eqn 11). For S1-2-1(b), imposed only on the steel tube (Liew and Xiong 2009).

there was some strength recovery at about 10 mm

displacement. Since the maximum confinement strength 3.5.2. Series 2: performance of NSC and UHSC

of steel tube was the same for the two specimens, the filled single-tube columns

residual strengths of both the specimens were almost The axial-load displacement curves for Series 2

identical, i.e., 2317 kN for S1-2-1(a) and 2293 kN for specimens are shown in two groups as Group S2-1 in

S1-2-1(b). The ductility of the UHSC core were enhanced Figure 15 and Group S2-2 in Figure 16. The specimens

Table 9. Comparison of test results with Eurocode 4 for test Series 1

Eurocode 4 predictions Test results Ntest,u Ntest,u Ntest,r Ntest,r

No. Npl,Rk1 (kN) Npl,Rk2 (kN) Ntest,u (kN) Ntest,r (kN) N pl,Rk 1 N pl,Rk 2 N pl,Rk 1 Ntest,u

S1-1-1(a) 502 486 0.969

S1-1-2(a) 892 1039 1.165

S1-1-2(b) 892 990 1.110

S1-2-1(a) 2307 2721 2866 2317 1.242 1.053 1.004 0.809

S1-2-1(b) 2307 2721 2595 2293 1.125 0.954 0.994 0.883

S1-3-1(a) 2075 2283 2422 1695 1.168 1.061 0.817 0.700

S1-3-1(b) 2075 2283 2340 1689 1.128 1.025 0.814 0.722

S1-3-2(a) 2175 2379 2497 1903 1.148 1.049 0.875 0.762

S1-3-2(b) 2175 2379 2314 1884 1.064 0.973 0.866 0.814

S1-3-3(a) 2307 2661 2610 2309 1.131 0.981 1.001 0.884

S1-3-3(b) 2307 2661 2633 2518 1.141 0.989 1.091 0.957

Mean* 1.130 1.013

Standard Deviation* 0.035 0.037

*Only for the last 6 specimens which were loaded simultaneously on the tubes and concrete cores

Advances in Structural Engineering Vol. 15 No. 9 2012 1495

Ultra-High Strength Concrete Filled Composite Columns for Multi-Storey Building Construction

10000

S2-1-1

in Group S2-1 consisted of CHS219 mm × 5 mm and

S2-1-2 specimens in Group S2-2 consisted of CHS219 mm ×

S2-1-3 10 mm. CHS219 mm × 5 mm was a Class 3 section and

8000 S2-1-4

it could not develop the full plastic resistance after

yielding, whereas CHS219 mm × 10 mm, which was a

Load (kN)

6000

Class 1 section, developed the full plastic resistance

4000 and hardening effect, as shown in Figure 16. Similar

effect could also be observed from the NSC filled tubes

2000

S2-1-2 and S2-2-2; however, compared with S2-1-1

and S2-2-1 respectively, S2-1-2 developed higher

0

plastic resistance and S2-2-2 achieved its ultimate

0 20 40 60 80 strength at a larger displacement due to the

Axial shortening (mm) confinement effect provided by the steel tube and the

constraint afforded by the concrete core. The other

Figure 15. Axial load-shortening curves for specimens in Group

four specimens in Series 2 achieved higher ultimate

S2-1 of Series 2

resistances due to the presence of UHSC. However, the

post-peak load-displacement behavior was more brittle

than NSC filled specimens. The UHSC core was

10000

S2-2-1 cracked suddenly and the unloading occurred sharply.

S2-2-2

S2-2-3

The ultimate load, Ntest,u, and the residual strength,

8000 S2-2-4 Ntest,r, are summarized in Table 10. The concrete core

of specimen S2-1-4 was reinforced with 0.5% steel

fibres and thus it had higher maximum strength than

6000 S2-1-3. Specimen S2-2-3 had higher steel contribution

Load (kN)

ratio and thus it had higher residual strength ratio

Ntest,r /Ntest,u than S2-1-3. This series of tests confirms

4000

the fact that steel fibres and higher steel contribution

ratio help to improve the strength and ductility of

2000 composite columns.

3.5.3. Series 3: performance of NSC and UHSC

0 filled double-tube columns

0 20 40 60 80

For concrete-filled double-tube specimens in Series 3,

Axial shortening (mm)

the axial load shortening curves are shown in two groups

Figure 16. Axial load-shortening curves for specimens in Group as Group S3-1 in Figure 17 and Group S3-2 in Figure 18.

S2-2 of Series 2 Group S3-1 specimens consisted of an external steel tube

Table 10. Comparison of test results with Eurocode 4 for test Series 2

Eurocode 4 predictions Test results Ntest,u Ntest,u Ntest,r Ntest,r

No. Npl,Rk1 (kN) Npl,Rk2 (kN) Ntest,u (kN) Ntest,r (kN) N pl,Rk 1 N pl,Rk 2 N pl,Rk 1 Ntest,u

S2-1-1 1238 1190 0.961

S2-1-2 2999 3535 3118 1.040 0.882

S2-1-3 7316 7710 7837 3803 1.071 1.017 0.520 0.485

S2-1-4 7592 7978 8664 5691 1.141 1.086 0.750 0.657

S2-2-1 2433 3050 1.254

S2-2-2 4036 5060 5241 1.299 1.036

S2-2-3 7965 8775 9085 7353 1.141 1.035 0.923 0.809

S2-2-4 8216 9014 9187 7479 1.118 1.019 0.910 0.814

Mean* 1.118 1.039

Standard Deviation* 0.033 0.032

* Only for S2-1-3, S2-1-4, S2-2-3 and S2-2-4 which contain UHSC

1496 Advances in Structural Engineering Vol. 15 No. 9 2012

J.Y. Richard Liew and D.X. Xiong

10000

S3-1-1

developed much higher ultimate strengths than the NSC

S3-1-2 filled specimens S3-1-1 and S3-2-1. However, they

S3-1-3 unloaded sharply after the peak load due to the

8000 S3-1-4 brittleness of UHSC core. The other four specimens

were infilled with NSC in between the external and

6000 internal tubes and with UHSC in the internal tubes. They

Load (kN)

demonstrated significant ductility after the peak load.

The drop in load after the peak was not too abrupt and it

4000 recovered soon. The second peak load was even higher

than the first peak load, as shown for specimens S3-2-3

and S3-2-4 in Figure 18.

2000

Loud cracking/crushing noise emanating from the

specimens was heard around the peak load during the

0 testing of the specimens with UHSC. A sharp drop in

0 20 40 60 80 the load-displacement curves after the peak load was

Axial shortening (mm) observed as shown in Figures 10–16. Soon after the

Figure 17. Axial load-shortening curves for specimens in Group load drop, visual inspection was carried out on the

S3-1 of Series 3 specimens and no visible deformation was observed.

Therefore, the noise is thought to be originated from

10000

the cracking/crushing of the UHSC core. The external

steel tubes of the failed specimens were removed to

reveal the inner UHSC core as shown in Figure 19.

8000 For S1-2-1(a) which was loaded only on the UHSC

core, its UHSC core remained intact, showing some

form of structural integrity. For specimens S1-3-1(a)

6000

and S1-3-2(b), which were loaded simultaneously on

Load (kN)

both of steel tubes and the UHSC cores, their UHSC

4000

cores were cracked apart, showing brittleness of the

concrete core. Figure 20 shows all the test specimens

S3-2-1 after the tests.

2000 S3-2-2

S3-2-3

S3-2-4

0

0 20 40 60 80

Axial shortening (mm)

Figure 18. Axial load-shortening curves for specimens in Group

S3-2 of Series 3

CHS219 mm × 5.0 mm and an internal steel tube (a) S1-2-1(a) loaded only on UHSC core

CHS114 mm × 3.6 mm, and Group S3-2 specimens

consisted of an external steel tube CHS219 mm × 10 mm

and an internal steel tube CHS114 mm × 6.3 mm. The

NSC filled specimen S3-1-1 developed significant plastic

plateau as shown in Figure 17, although both the external

and internal steel tubes were of large diameter-to-

thickness ratios. The other NSC filled specimen S3-2-1

in Series 3 developed higher plastic resistance and

hardening effect, since the external and internal tubes

were of smaller diameter-to-thickness ratios. (b) S1-3-1(a) without SF (b) S1-3-2(b) with 1% SF

Comparison between Figures 17 and 18 shows that Figure 19. Failure modes of UHSC core

the UHSC filled specimens S3-1-2 and S3-2-2

Advances in Structural Engineering Vol. 15 No. 9 2012 1497

Ultra-High Strength Concrete Filled Composite Columns for Multi-Storey Building Construction

S2-1-2 by 11.8% and S3-1-1 by 7.9%. It should be noted

that these two NSC filled specimens had Class 3 cross-

sectional steel tubes. The comparison of test results with

predictions is also shown in Figure 21 and Figure 22 for

all the composite specimens except the hollow steel tube

specimens. In conclusion, the Eurocode 4 approach can be

safely extended to predict the resistance of UHSC filled

steel tubular columns. On average for all the composite

specimens involving UHSC, Eurocode 4 approach

underestimated the resistance by 14.6% if confinement

effect was not considered and by 3.5% if confinement

effect was considered. However, it may over-predict the

confinement effect for NSC filled steel tubes with Class 3

sections and thus the confinement effect should be

ignored. Furthermore, for composite specimens only

involving UHSC, it is recommended that the confinement

effect should also be ignored, since the ultimate strengths

Figure 20. Failure of specimens after tested

were reached almost at elastic stage and thus no significant

confinement effect should have developed.

4. EVALUATION OF TEST RESULTS

4.1. Comparison with Eurocode 4’s Predictions

12000

Eqns 2 and 3 were used to predict the resistances and they

were compared with the test results as shown in Tables 9

10000

to 11. It should be noted that the values of fck,100, instead of

fck, were used in both equations for all the composite

Test results, Ntest,u (kN)

specimens in Series 1, because the concrete cores in these 8000

specimens were almost of the same size as the standard

concrete cylinder of 100 mm diameter and 200 mm height. 6000

Comparison with test results indicates that Eqn 2, without

considering the confinement enhancement, conservatively 4000

predicted the compression resistance of hollow steel tubes

S1-1-2(a), S1-1-2(b) and S2-2-1 and all the composite

2000 Series 1

specimens, but it slightly overestimated the compression Series 2

resistance of hollow steel tubes S1-1-1(a) by 3.1% and Series 3

S2-1-1 by 3.9%. Eqn 3, considering the confinement 0

0 2000 4000 6000 8000 10000 12000

effect, conservatively predicted the resistance for most of Predictions by eurocode 4, Npl,Rk1 (kN)

the composite specimens, but it overestimated the

resistance for some UHSC filled tubes in Series 1 by less Figure 21. Comparison of test results with predictions without

than 5%, and for two NSC filled composite specimens confinement effect

Table 11. Comparison of test results with Eurocode 4 for test Series 3

Eurocode 4 predictions Test results Ntest,u Ntest,u Ntest,r Ntest,r

No. Npl,Rk1 (kN) Npl,Rk2 (kN) Ntest,u (kN) Ntest,r (kN) N pl,Rk 1 N pl,Rk 2 N pl,Rk 1 Ntest,u

S3-1-1 3438 3939 3626 1.055 0.921

S3-1-2 7300 7684 8529 5069 1.168 1.110 0.694 0.594

S3-1-3 4492 4931 4968 4830 1.106 1.008 1.075 0.972

S3-1-4 4647 5077 5239 4171 1.127 1.032 0.898 0.796

S3-2-1 4821 5678 6300 1.307 1.110

S3-2-2 8226 8928 9817 6951 1.193 1.100 0.845 0.708

S3-2-3 5844 6627 7022 7022 1.201 1.060 1.201 1.000

S3-2-4 5909 6687 7160 7160 1.212 1.071 1.212 1.000

Mean* 1.168 1.063

Standard Deviation* 0.043 0.039

*S3-1-1 and S3-2-1, which do not contain UHSC, are not considered.

1498 Advances in Structural Engineering Vol. 15 No. 9 2012

J.Y. Richard Liew and D.X. Xiong

12000 500 1

10000 400 0.8

σa

Test results, Ntest,u (kN)

Poisson's ratio

Stress (MPa)

8000

300 0.6

νa

6000

200 0.4

4000 Stress (test)

100 Stress (FEM) 0.2

Poisson's ratio (test)

2000 Series 1

Poisson's ratio (FEM)

Series 2 0 0

Series 3 0 0.004 0.008 0.012 0.016 0.02

0

Longitudinal compressive strain

0 2000 4000 6000 8000 10000 12000

Predictions by eurocode 4, Npl,Rk2 (kN) Figure 23. Variation of Poisson’s ratio with longitudinal stresses

Figure 22. Comparison of test results with predictions with for steel tube S2-2-1

confinement effect

60 2

Stress (test)

4.2. Interaction Mechanics between Concrete Stress (FEM)

Poisson's ratio (test)

Core and Steel Tube 48 σc Poisson's ratio (FEM) 1.6

4.2.1. Effect of Poisson’s ratio

Poisson’s ratio, defined as the absolute value of the ratio

Poisson's ratio

Stress (MPa)

36 1.2

of transverse strain to longitudinal strain under uniaxial

loading, plays a significant role in analyzing the load νc

sharing mechanism between the concrete core and the 24 0.8

steel tube.

For mild steel, the Poisson’s ratio value is about 0.3 12 0.4

before yielding, and then it increases rapidly

approaching to 0.5 after yielding. For NSC, it is at about

0.2 under low compressive stress level and it increases 0 0

0 0.004 0.008 0.012 0.016 0.02

rapidly after reaching 80% to 90% of the ultimate Longitudinal compressive strain

strength due to the initiating of micro-cracks, and finally

approaches a value of about 0.5 at the ultimate strength. Figure 24. Variation of Poisson’s ratio with longitudinal stresses

The value exceeds 0.5 after the ultimate strength due to for NSC

dilation effect. The Poisson’s ratio for the UHSC used in 200 2

this study was about 0.25, slightly higher than that of

NSC, under low compressive stress level. σc

The longitudinal stress-strain curve for the hollow 160 1.6

steel tube S2-2-1 is plotted in Figure 23, together with Stress (test)

the Poisson’s ratio measured as the ratio of Stress (FEM)

Poisson's ratio

Stress (MPa)

120 1.2

circumferential strain to longitudinal strain. The Poisson's ratio (test)

Poisson's ratio (FEM)

measured Poisson’s ratio value was decreasing instead

of increasing right after yielding, mainly due to the 80 0.8

influence of the hoop ring stiffeners and imperfections.

Figure 24 and Figure 25 show the variations of νc

Poisson’s ratios for NSC and UHSC, respectively, 40 0.4

derived from the concrete cylinder tests. Unlike NSC,

the stress-strain curve for UHSC was almost linearly

0 0

elastic up to the maximum load. Once the ultimate load 0 0.005 0.01 0.015 0.02

was reached, the concrete cylinder was cracked and Longitudinal compressive strain

fractured into pieces. However, in composite columns,

macro cracks may be delayed or even prevented due to Figure 25. Variation of Poisson’s ratio with longitudinal stresses

the confinement stress offered by the steel tube showing for UHSC

Advances in Structural Engineering Vol. 15 No. 9 2012 1499

Ultra-High Strength Concrete Filled Composite Columns for Multi-Storey Building Construction

a gradual softening of post peak stress-strain behaviour. Considering the displacement compatibility at point

The corresponding idealized true stress strain curves “P”, urp,c ≤ urp,a, it further implies that

with softening portions are also shown in Figures 23–25

as references. It should be noted that the true stress and v < v : separationor tensile debodingoccurs

c a

strain values from the tests are converted from the vc = va : concreteandsteel tube are in contact but no int eraction

nominal values and they are shown in the three figures

vc > va : concrete core is confined bysteel tube

for comparison. (9)

Figure 26 shows a simplified model for a concrete

filled tube subjected to longitudinal compressive strain Thus, confinement effect can be produced only if the

εz. Assuming that there is no interaction at the interface Poisson’s ratio value of concrete is greater than that of

which means that the concrete core and steel tube are steel, unless effective transverse restraints are imposed

free to expand, the tensile strains at a point “P” at the on steel tubes.

interface in circumferential and radial directions are For axially loaded concrete filled composite columns

with steel materials between S275 and S460, the steel

tube will yield first before the concrete achieves its

εθp,c = ε rp,c = vc ε z ( based on the propertiesof concreete )

(7) ultimate strength. Therefore, the effective concrete

p p

εθ ,a = ε r ,a = va ε z ( based on the propertiesof steel ) confinement stresses can only start before the concrete

reaches its ultimate strength. Before that, tensile stresses

or separation may occur at the steel and concrete

The displacements at point “P” in the radial direction

interface since νc<νa. Figure 27 shows the general

of the concrete and steel materials are p

variations of longitudinal stresses and εθ / ε zp at point

“P” of the model shown in Figure 26. The values are

p d p d compared with the variations of uniaxial stresses and

ur ,c = 2 − t ε r ,c = vc 2 − t ε z urp,c vc Poisson’s ratios of mild steel and NSC. Initially, the

⇒ p = (8)

ur ,a va Poisson’s ratio value of concrete is less than that of

u p = d − t ε p = v d − t ε

r ,a 2 r ,a a

2 z steel. The concrete core and steel tube are transversely

expanding freely and hence the ratios of circumferential

strain to longitudinal strain are respectively equal to

d

their Poisson’s ratios. After that, the Poisson’s ratio

value of concrete is increasing and exceeds that of steel.

The concrete core will be confined by steel tube. Values

p p

of εθ ,c / ε z will be less than the Poisson’s ratio values of

θ r p p

0 concrete and values of εθ ,a / ε z will be greater than the

P

Poisson’s ratio values of steel. To ensure compatibility,

εθP,c εθP,a

≈ P . The confinement effect improves the

ε zP εz

500 1.5

Debonding Bonding

Z t 400 σa 1.2

εz

Longitudinal stress (MPa)

σ pa

ε pθ,c/εz

300 ε pθ,a/εz 0.9

νc

ε θ /εz

P r

0

200 0.6

νa

100 σ pc 0.3

σc

0 0

0 0.004 0.008 0.012 0.016 0.02

Longitudinal compressive strain

Figure 26. A concrete filled tube subjected to uniaxial compression Figure 27. Variation of stresses and εθ/εz in composite columns

1500 Advances in Structural Engineering Vol. 15 No. 9 2012

J.Y. Richard Liew and D.X. Xiong

longitudinal compression strength of concrete, but occurred, which means that inelastic local buckling

reduces the longitudinal compression strength of steel occurred. On the contrary, S2-2-1 could develop the full

tube since the tensile stress is produced in the plastic resistance with subsequent strain hardening effect.

circumferential direction of the tube section. For concrete filled tubes of Class 3 sections, separation

The model presented so far considers the worst case or tensile stresses may occur at the interface even after

scenario. In practice, there may be some initial yielding, which means that the concrete core cannot

confinement stresses before loading due to self- provide effective restraint to prevent local buckling of the

expanding of concrete, circumferential restraint boundary steel tube. Figure 29 shows the history curves of the

conditions and so on. Some of the initial confinement measured vertical strains at the middle height of columns,

stresses could be released at the initial stage of loading applied load and axial shortening of NSC filled tubes S2-

when the Poisson’s ratio of concrete is less than that of 1-2 of Class 3 section and S2-2-2 of Class 1 section.

steel; however, if they are not released completely, tensile Better than the pure steel specimen S2-1-1, the vertical

debonding stresses may not occur and the effective strain of S2-1-2 was increasing after yielding, but local

confinement stress could start earlier. On the other hand, buckling of the tube occurred at vertical displacement less

initial imperfections, such as loading eccentricity, than 20 mm, which was much smaller than that of the

geometrical imperfections and concrete shrinkage may pure steel specimen S2-2-2 which occurred at about

also affect the performance of confined concrete. 40 mm. Therefore, Eqn 3 should be used only to calculate

the compression capacity of concrete filled columns with

4.2.2. Effect of Class 3 section on composite Class 1 and Class 2 sections, and only Eqn 2, without the

stub column strength consideration of confinement effect, is applicable to

Specimen S2-1-1, which was a Class 3 steel tube section columns with Class 3 section.

according to Eurocode 3, developed an axial resistance

which was 4% less than the estimated squash load. This 4.3. Ductility Requirements

is probably due to some difference in the tensile strength Structures members are usually required to have

of the tube and that from the coupon tests and also due to sufficient ductility to undergo large deformations

some initial imperfections which led to eccentricity of without collapse when subjected to accidental actions.

load. For Class 3 sections, once yielding occurs, they are For axially loaded composite columns, an axial

susceptible to inelastic local buckling. Figure 28 shows shortening limit similar to the value of the structural

the history curves of the measured vertical strains at the steel ultimate strain is defined in Eurocode 3 as

middle height of columns, the applied load and axial ∆Llim fy

shortening of steel tubes S2-1-1 of Class 3 section and ϕ lim = = 15 (10)

S2-2-1 of Class 1 section. If there is no local buckling, the L Ea

vertical strains should keep increasing as long as the axial Deformations beyond the limit are significant, and

shortening displacements are increasing. However, the the remaining strength beyond this limit is regarded as

vertical strain of S2-1-1 decreased once yielding the residual strength. To meet ductility requirements,

0.04 500 0.06 6000

0.05 5000

0.032 400

Measured vertical strain

Measured vertical strain

0.04 4000

Load (MPa)

0.024 300

Load (kN)

0.03 3000

0.016 200

0.02 2000

S2-1-1 strain S2-1-2 strain

0.008 Yielding 100

S2-2-1 strain S2-2-2 strain 1000

point 0.01

S2-1-1 load S2-1-2 load

S2-2-1 load Yielding

S2-2-2 load

0 0 0 0

0 15 30 45 60 0 20 40 60 80

Axial shortening (mm) Axial shortening (mm)

Figure 28. Measured strains and load-shortening curves for hollow Figure 29. Measured strains and load-shortening curves for NSC

tubes S2-1-1 and S2-2-1 filled tubes S2-1-2 and S2-2-2

Advances in Structural Engineering Vol. 15 No. 9 2012 1501

Ultra-High Strength Concrete Filled Composite Columns for Multi-Storey Building Construction

1 of concrete, can be used with confidence for the

S1-3-3 design of concrete filled steel tubular sections.

S2-2-4 (a, b) However, the equation may overestimate the

S1-3-2

Residual strength ratio Ntest,r /Ntest.u

0.8

(a, b)

S2-2-3 strength of NSC filled steel tubes with Class 3

S1-3-1

cross-sections. For such cases, Eqn 2, which does

S2-1-4

(a, b)

not consider the confinement effect, should be

0.6

used.

S2-1-3

(3) Material Poisson’s ratio is one of the important

0.4

parameters that affect the load distribution in

concrete filled column. Before cracks are

developed in the concrete core under the applied

0.2 UHSG

compression force, the value of Poisson’s ratio for

UHSG + 0.5%SF UHSC is found to be higher than NSC and thus the

UHSG + 1%SF concrete confinement effect for UHSC filled tubes

0 should be higher than NSC filled tubes for the

0 0.2 0.4 0.6

same stress ratio. The ductility and strength of

Steel contribution ratioδ

UHSC core, as well as NSC core, can be enhanced

Figure 30. Residual strength ratios for UHSC filled due to the effective confinement of the steel tube.

single-tube columns (4) The ductility and strength of UHSC filled

composite columns can be further improved if

the residual strength should not be less than the actions the load is imposed only on the concrete core

under serviceability limit state. For concrete filled tubes, where tri-axial confinement effect is the

the service load should be less than 70% of the column maximum or by adding at least 1% volume of

ultimate strength. Therefore, to ensure a conservative steel fibres into the core materials.

design, the residual strength should be at least equal to (5) UHSC filled steel tubular columns can achieve

70% of the column ultimate strength. ultra-high compression capacities, but their post

The test results of residual strength for composite peak load behaviour is quite brittle, in

columns with UHSC are shown in Tables 9–11. Most of particularly when the steel contribution ratio is

the composite columns achieved their ultimate strengths low. To ensure sufficient ductility, the limitation

at quite small deformations, especially for the UHSC on minimum steel contribution ratio should be

filled single-tube columns loaded simultaneously on the increased to 0.30 or a minimum of 1% volume

top of tubes and concrete cores. The residual strength of steel fibres should be added to the UHSC.

ratios are plotted against the steel contribution ratios for

all the specimens as shown in Figure 30. It is observed ACKNOWLEDGEMENT

that higher steel contribution ratio and higher steel fibre The research is sponsored by Densit Asia, Yongnam

volume increase the residual strength ratio. To meet the Holdings Ltd and Continental Steel Pte Ltd, and funded

ductility requirements and to ensure residual strength by A*STAR (Grant No. P0820166). Their financial

ratio of at least 0.7, the steel contribution ratio should be supports are gratefully acknowledged.

at least 0.30, or steel fibre volume of at least 1% should

be added to UHSC filled tubes. REFERENCES

Eurocode 3 (2005). Eurocode 3: Design of Steel Structures - Part 1-1:

5. CONCLUSIONS General Rules and Rules for Buildings, European Committee for

Based on the test results and analyses, some significant Standardization, Brussels, Belgium.

conclusions can be drawn as follows: Eurocode 4 (2004). Eurocode 4: Design of Composite Steel and

(1) Limited test evidence indicates that the Concrte Structures - Part 1.1: General Rules and Rules for

Eurocode 4 limitation on concrete cylinder Buildings, European Committee for Standardization, Brussels,

strength could be safely extended to 200 N/mm2 Belgium.

(cylinder strength). The circular column sections Gho, W.M. and Liu, D.L. (2004). “Flexural behaviour of high-strength

with ultra high strength concrete of 200 N/mm2 rectangular concrete-filled steel hollow sections”, Journal of

compression strength were safe though more Constructional Steel Research, Vol. 60, No. 11, pp. 1681–1696.

tests with such high strength concrete for longer Han, L.H. and Yao, G.H. (2003). “Behaviour of concrete-filled

column length are needed to justify this. hollow structural steel (HSS) columns with pre-load on the steel

(2) For concrete filled steel tubes with Class 1 or tubes”, Journal of Constructional Steel Research, Vol. 59, No. 12,

Class 2 sections, Eqn 3, considering confinement pp. 1455–1475.

1502 Advances in Structural Engineering Vol. 15 No. 9 2012

J.Y. Richard Liew and D.X. Xiong

Han, L.H., Yao, G.H. and Zhao, X.L. (2005). “Tests and calculations Yu, Q., Tao, Z. and Wu, Y.X. (2008). “Experimental behaviour of

for hollow structural steel (HSS) stub columns filled with self- high performance concrete-filled steel tubular columns”, Thin-

consolidating concrete (SCC)”, Journal of Constructional Steel Walled Structures, Vol. 46, No. 4, pp. 362–370.

Research, Vol. 61, No. 9, pp. 1241–1269.

Liew, J.Y.R. (2004). “Buildable design of multi-storey and large NOTATION

span steel srtuctures”, Journal of Steel Structures, Vol. 4, No. 2, Αa, Αc cross-sectional areas of steel tube and

pp. 53–70. concrete core respectively

Liew, J.Y.R. and Xiong, D.X. (2009). “Effect of preload on the axial d overall diameter of circular hollow steel

capacity of concrete-filled composite columns”, Journal of section

Constructional Steel Research, Vol. 65, No. 3, pp. 709–722. Ea,Ecm modulus of elasticity of structural steel and

Liew, J.Y.R., Chia, K.S., Kazi, M.A.S. and Xiong, D.X. (2008). secant modulus of elasticity of concrete

“Innovation in composite construction – towards the extreme of fck characteristic value of the cylinder (150 mm

high strength and lightweight”, Proceeding of the 5th × 300 mm) compressive strength of concrete

International Conference on Coupled Instabilities in Metal fck,100 characteristic value of the cylinder (100 mm

Structures, Sydney, Australia, pp. 19–33. × 200 mm) compressive strength of concrete

Liu, D.L. (2006). “Behaviour of eccentrically loaded high-strength fy nominal value of the yield strength of steel

rectangular concrete-filled steel tubular columns”, Journal of tube

Constructional Steel Research, Vol. 62, No. 8, pp. 839–846. fu nominal value of the ultimate tensile

Liu, D.L. (2004). “Behaviour of high strength rectangular concrete- strength of steel tube

filled steel hollow section columns under eccentric loading”, L,∆Llim column length and limit of shortening

Thin-Walled Structures, Vol. 42, No. 12, pp. 1631–1644. displacement

Liu, D.L. (2005). “Tests on high-strength rectangular concrete-filled Npl,Rk design value of the composite sectional

steel hollow section stub columns”, Journal of Constructional plastic resistance to compression

Steel Research, Vol. 61, No. 7, pp. 902–911. Npl,Rk characteristic value of the composite

Liu, D.L. and Gho, W.M. (2005). “Axial load behaviour of high- sectional plastic resistance to compression

strength rectangular concrete-filled steel tubular stub columns”, Npl,Rk1 characteristic value of the concrete filled

Thin-Walled Structures, Vol. 43, No. 8, pp. 1131–1142. sectional plastic resistance to compression

Liu, D.L., Gho, W.M. and Yuan, J. (2003). “Ultimate capacity of Npl,Rk2 characteristic value of the concrete filled

high-strength rectangular concrete-filled steel hollow section sectional plastic resistance with confinement

stub columns”, Journal of Constructional Steel Research, effect

Vol. 59, No. 12, pp. 1499–1515. Ntest,r testing values of the residual strength,

Lue, D.M., Liu, J.L. and Yen, T. (2007). “Experimental study on defined as the maximum load beyond the

rectangular CFT columns with high-strength concrete”, axial shortening limit, ϕlim

Journal of Constructional Steel Research, Vol. 63, No. 1, Ntest,u testing values of the ultim ate resistance

pp. 37–44. t thickness of steel tube

Saw, H.S. and Liew, J.Y.R. (2000). “Assessment of current methods urp the displacement in radial direction at the

for the design of composite columns in buildings”, Journal of point “P”

Constructional Steel Research, Vol. 53, No. 2, pp. 121–147. δ steel contribution ratio, the same as defined

Varma, A.H., Ricles, J.M., Sause, R. and Lu, L.W. (2002). in Eurocode 4

“Experimental behavior of high strength square concrete-filled ε rp , ε zp , εθp strains in radial, longitudinal and

steel tube beam-columns”, Journal of Structural Engineering, circumferential directions respectively at the

ASCE, Vol. 128, No. 3, pp. 309–318. point “P”

Varma, A.H., Ricles, J.M., Sause, R. and Lu, L.W. (2004). “Seismic ηa,ηc factors related to the confinement of concrete

−

behavior and design of high-strength square concrete-filled steel λ relative slenderness, the same as defined in

tube beam columns”, Journal of Structural Engineering, ASCE, Eurocode 4

Vol. 130, No. 2, pp. 169–179. νa,νc Poisson’s ratio of steel and concrete

Varma, A.H., Ricles, J.M., Sause, R. and Lu, L.W. (2002). “Seismic respectively

behavior and modeling of high-strength composite concrete-filled ϕlim a deformation limit on axial shortening

steel tube (CFT) beam-columns”, Journal of Constructional Steel displacement ratio

Research, Vol. 58, No. 5–8, pp. 725–758. HSC high strength concrete

Xiong, D.X. and Zha, X.X. (2007). “A numerical investigation on LVDT linear varying displacement transducer

the behaviour of concrete-filled steel tubular columns under NSC normal strength concrete

initial stresses”, Journal of Constructional Steel Research, SF steel fibre

Vol. 63, No. 5, pp. 599–611. UHSC ultra-high strength concrete

Advances in Structural Engineering Vol. 15 No. 9 2012 1503

You might also like

- U.S. - A Narrative History, Volume 1 - To 1865Document380 pagesU.S. - A Narrative History, Volume 1 - To 1865Phan Đào Hoàng Hiệp86% (7)

- US A Narrative History, Volume 2 Since 1865 by James West Davidson Et Al.Document433 pagesUS A Narrative History, Volume 2 Since 1865 by James West Davidson Et Al.Phan Đào Hoàng Hiệp100% (3)

- Proceedings of The 16th International Symposium For Tubular Structures (ISTS 2017) DecemDocument721 pagesProceedings of The 16th International Symposium For Tubular Structures (ISTS 2017) DecemPhan Đào Hoàng HiệpNo ratings yet

- Column DesignDocument36 pagesColumn DesignGaurav KashyapNo ratings yet

- (Chen Et Al., 2011) Seismic Behavior of Ductile Rectangular Composite Bridge PiersDocument14 pages(Chen Et Al., 2011) Seismic Behavior of Ductile Rectangular Composite Bridge PiersJose ManuelNo ratings yet

- Concrete-Filled Steel Tube Columns Encased With Thin Precast ConcreteDocument11 pagesConcrete-Filled Steel Tube Columns Encased With Thin Precast ConcretevardhangargNo ratings yet

- Analytical Model For Predicting Axial Capacity and Behavior of Concrete Encased Steel Composite Stub ColumnsDocument10 pagesAnalytical Model For Predicting Axial Capacity and Behavior of Concrete Encased Steel Composite Stub Columnsanon_47684961No ratings yet

- A Review On Concrete Filled Steel Tubes Column: December 2015Document7 pagesA Review On Concrete Filled Steel Tubes Column: December 2015Sushant WaghmareNo ratings yet

- LAI e HO (2012) - Behaviour of Uni Axially Loaded Concrete Filled Steel Tube Columns Confined byDocument24 pagesLAI e HO (2012) - Behaviour of Uni Axially Loaded Concrete Filled Steel Tube Columns Confined byRenata MartiniNo ratings yet

- Structural Design Tall Build - 2009 - Hong - Composite Beam Composed of Steel and Precast Concrete Modularized HybridDocument28 pagesStructural Design Tall Build - 2009 - Hong - Composite Beam Composed of Steel and Precast Concrete Modularized Hybridsherif IbrahimNo ratings yet

- Behaviour of Stiffened Concrete-Filled Steel Composite (CFSC) Stub ColumnsDocument29 pagesBehaviour of Stiffened Concrete-Filled Steel Composite (CFSC) Stub ColumnsJeno MscNo ratings yet

- 1.behavior of Eccentrically Loaded Circular Tubed Steel-Reinforced Concrete Short Columns Using High-Strength ConcreteDocument12 pages1.behavior of Eccentrically Loaded Circular Tubed Steel-Reinforced Concrete Short Columns Using High-Strength ConcreteSakib 31No ratings yet

- Vol16no4 4 PDFDocument7 pagesVol16no4 4 PDFDima OvsiiNo ratings yet

- Concrete Filled Steel Tube Columns: S.S.G.B.C.O.E.T., BHUSAWALDocument34 pagesConcrete Filled Steel Tube Columns: S.S.G.B.C.O.E.T., BHUSAWALTameem AnsariNo ratings yet

- Bearing Capacity of Embedded Channel-Shaped Steel Connections at Precast Concrete Beam EndDocument14 pagesBearing Capacity of Embedded Channel-Shaped Steel Connections at Precast Concrete Beam EndMohammad AkbarNo ratings yet

- Experimental Study On Behaviour of Composite Column CFTDocument7 pagesExperimental Study On Behaviour of Composite Column CFTnilkanthNo ratings yet

- Concrete-Filled Steel Tubular (CFST) Columns: Mayank Vyas and Ghanishth AgrawalDocument4 pagesConcrete-Filled Steel Tubular (CFST) Columns: Mayank Vyas and Ghanishth AgrawalK RaghuNo ratings yet

- Hai Han, Feng An (2013) - Performance of Concrete-Encased CFST Stub Columns Under Axial Compression, ElsevierDocument15 pagesHai Han, Feng An (2013) - Performance of Concrete-Encased CFST Stub Columns Under Axial Compression, ElsevierMODHUPOM CHOUDHURYNo ratings yet

- Ecc. Loaded Composite Column 2011Document13 pagesEcc. Loaded Composite Column 2011afzal taiNo ratings yet

- Sunder CFT Column ReportDocument33 pagesSunder CFT Column Reportsunder kumawatNo ratings yet

- Microsoft Word - 1555-2604-1-RV-1Document10 pagesMicrosoft Word - 1555-2604-1-RV-1Rahul KumarNo ratings yet

- Experimental Study of Concrete Filled Tubular Short ColumnsDocument7 pagesExperimental Study of Concrete Filled Tubular Short ColumnsAnonymous kw8Yrp0R5r100% (1)

- Journal of Constructional Steel Research: Piero Colajanni, Lidia La Mendola, Alessia MonacoDocument15 pagesJournal of Constructional Steel Research: Piero Colajanni, Lidia La Mendola, Alessia Monacosuran_qutbiNo ratings yet

- Study of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingDocument6 pagesStudy of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingAkshay DobleNo ratings yet

- Experimental Study On Shear Performance of Steel Shell-Concrete Composite Structure in Immersed TunnelDocument18 pagesExperimental Study On Shear Performance of Steel Shell-Concrete Composite Structure in Immersed Tunnel6607977fe509edbd42048a98No ratings yet

- Construction Techniques of Steel and Concrete Composite StructuresDocument8 pagesConstruction Techniques of Steel and Concrete Composite StructuresAvinash KommireddiNo ratings yet

- 1 s2.0 S0143974X19307886 MainDocument19 pages1 s2.0 S0143974X19307886 MainSiva GuruNo ratings yet

- Seismic Performance of Concrete Filled Steel Tubular Column Building - A Survey of LiteratureDocument5 pagesSeismic Performance of Concrete Filled Steel Tubular Column Building - A Survey of LiteratureKrishna MurariNo ratings yet

- Applied Sciences: Experimental Study of High-Strength Concrete-Steel Plate Composite Shear WallsDocument34 pagesApplied Sciences: Experimental Study of High-Strength Concrete-Steel Plate Composite Shear Wallsci_balaNo ratings yet

- A Unified Approach To Evaluate Axial Force-Moment Interaction Curves of Concrete Encased Steel Composite ColumnsDocument15 pagesA Unified Approach To Evaluate Axial Force-Moment Interaction Curves of Concrete Encased Steel Composite ColumnsKrishna MurariNo ratings yet

- 02-Cyclic Testing of a Composite Joint 2020Document18 pages02-Cyclic Testing of a Composite Joint 2020moustafa DawoodNo ratings yet

- 1 s2.0 S0263823112000602 MainDocument9 pages1 s2.0 S0263823112000602 MainrudynyambiNo ratings yet

- 1 s2.0 S0141029619340921 MainDocument13 pages1 s2.0 S0141029619340921 MainSiva GuruNo ratings yet

- Yuan & Bing, 2021, High-Strength Grout and Deformed Steel BarsDocument11 pagesYuan & Bing, 2021, High-Strength Grout and Deformed Steel BarsDingjian ZhangNo ratings yet

- A Review On Concrete Filled Steel Tubes Column: December 2015Document7 pagesA Review On Concrete Filled Steel Tubes Column: December 2015Dony DoanxNo ratings yet

- Steel-Concrete Composite Coupling Beams - Behavior and DesignDocument11 pagesSteel-Concrete Composite Coupling Beams - Behavior and DesignFrancisco Javier Torres AlvaradoNo ratings yet

- Comparison Between Experimental and Numerical Studies of Fully Encased Composite ColumnsDocument8 pagesComparison Between Experimental and Numerical Studies of Fully Encased Composite ColumnsAbdul BariNo ratings yet

- Seismic Performance of Emulative Precast Concrete Beam-Column Connections With Alternative Reinforcing DetailsDocument14 pagesSeismic Performance of Emulative Precast Concrete Beam-Column Connections With Alternative Reinforcing DetailsMălíķ ĂsfęnđýårNo ratings yet

- Concrete Filled Steel Tubular (CFST) Columns in Composite StructuresDocument8 pagesConcrete Filled Steel Tubular (CFST) Columns in Composite Structuresashish SindhuNo ratings yet

- Advantages CFSTDocument14 pagesAdvantages CFSTprajjwal patidarNo ratings yet

- Hou 2016Document12 pagesHou 2016Evonne LeeNo ratings yet

- Journal of Constructional Steel Research: Piero Colajanni, Lidia La Mendola, Alessia MonacoDocument15 pagesJournal of Constructional Steel Research: Piero Colajanni, Lidia La Mendola, Alessia MonacoRami Alraof AlaydiNo ratings yet

- Paper 033 CNDocument32 pagesPaper 033 CNLeroyNo ratings yet

- Engineering Structures: Yiyan Chen, Jucan Dong, Tianhua XuDocument9 pagesEngineering Structures: Yiyan Chen, Jucan Dong, Tianhua XuAbhishekNo ratings yet

- Composite Structure (31-38) PDFDocument48 pagesComposite Structure (31-38) PDFrajesh100% (1)

- Composite Steel JoistDocument10 pagesComposite Steel JoistMaher saltiNo ratings yet

- Engineering Structures: A A C A A BDocument14 pagesEngineering Structures: A A C A A BShashikant ChaturvediNo ratings yet

- Performance of Concrete-Encased CFST Box Stub Columns Under Axial Compression, 2015 (Yu-Feng An)Document16 pagesPerformance of Concrete-Encased CFST Box Stub Columns Under Axial Compression, 2015 (Yu-Feng An)Phan Đào Hoàng HiệpNo ratings yet

- Strength of Concrete Filled Tubular ColumnDocument10 pagesStrength of Concrete Filled Tubular ColumnJitendraNo ratings yet

- Finite Element Analysis: Axially Loaded Steel Fibre Reinforced Concrete Ribbed WallDocument11 pagesFinite Element Analysis: Axially Loaded Steel Fibre Reinforced Concrete Ribbed WallsweetqistNo ratings yet

- Eccentric Axial Load Test For High-Strength Composite Columns of Various Sectional ConfigurationsDocument14 pagesEccentric Axial Load Test For High-Strength Composite Columns of Various Sectional ConfigurationsvardhangargNo ratings yet

- 1 s2.0 S0141029622009907 MainDocument10 pages1 s2.0 S0141029622009907 MainMoiz TariqNo ratings yet

- Concrete Filled With High Strength Steel Box Column For Tall Building-Behavior & DesignDocument20 pagesConcrete Filled With High Strength Steel Box Column For Tall Building-Behavior & DesigntaosyeNo ratings yet

- Steel-Concrete Composite Coupling Beams - Behavior and DesignDocument11 pagesSteel-Concrete Composite Coupling Beams - Behavior and DesigncyrusnasiraiNo ratings yet

- Axial Stress-Strain Behavior of High-Strength Concrete Confined by Circular Thin-Walled Steel Tubes, 2018 (Jiepeng Liu)Document12 pagesAxial Stress-Strain Behavior of High-Strength Concrete Confined by Circular Thin-Walled Steel Tubes, 2018 (Jiepeng Liu)Phan Đào Hoàng HiệpNo ratings yet

- Materials 14 04839 v2Document23 pagesMaterials 14 04839 v2Sandy YansikuNo ratings yet

- Prestressed ConcreteDocument2 pagesPrestressed ConcreteJianne Cabugsa LitohonNo ratings yet

- Creep Modeling For Concrete-Filled Steel Tubes: Wassim Naguib, Amir MirmiranDocument18 pagesCreep Modeling For Concrete-Filled Steel Tubes: Wassim Naguib, Amir Mirmiransaber javidNo ratings yet

- Jounal Composite 4Document11 pagesJounal Composite 4barath kumarNo ratings yet

- 14 - 05 03 0004 PDFDocument6 pages14 - 05 03 0004 PDFAbdelkaderBenyoucefNo ratings yet

- The Blade Cellular Beam CasestudyDocument6 pagesThe Blade Cellular Beam CasestudyVAISHNAVI GHARGENo ratings yet

- Concrete Filled Steel TubesDocument24 pagesConcrete Filled Steel TubesSIJAN SHRESTHA100% (1)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- @constitutive Model For Confined Ultra-High Strength Concrete in Steel Tube, 2016Document11 pages@constitutive Model For Confined Ultra-High Strength Concrete in Steel Tube, 2016Phan Đào Hoàng HiệpNo ratings yet

- Linking Analysis ExampleDocument14 pagesLinking Analysis ExamplePhan Đào Hoàng HiệpNo ratings yet

- A One Hour Course On Nonlinear Modeling of Structures. Computational Framework For Earthquake SimulationDocument30 pagesA One Hour Course On Nonlinear Modeling of Structures. Computational Framework For Earthquake SimulationPhan Đào Hoàng HiệpNo ratings yet

- Elevated Temperature Material Properties of Cold-Formed Steel Hollow Sections, 2015 (Finian McCann)Document11 pagesElevated Temperature Material Properties of Cold-Formed Steel Hollow Sections, 2015 (Finian McCann)Phan Đào Hoàng HiệpNo ratings yet

- Using Reactions: Applying A Reaction - Structural Toolkit ModulesDocument11 pagesUsing Reactions: Applying A Reaction - Structural Toolkit ModulesPhan Đào Hoàng HiệpNo ratings yet

- Using A Custom Steel SectionDocument9 pagesUsing A Custom Steel SectionPhan Đào Hoàng HiệpNo ratings yet

- 2019 DSSIMULIA - Established - An Inelastic Constitutive Model For ConcreteDocument10 pages2019 DSSIMULIA - Established - An Inelastic Constitutive Model For ConcretePhan Đào Hoàng HiệpNo ratings yet

- 2019 DSSIMULIA - Established - Damaged Plasticity Model For Concrete and Other Quasi-Brittle MaterialsDocument11 pages2019 DSSIMULIA - Established - Damaged Plasticity Model For Concrete and Other Quasi-Brittle MaterialsPhan Đào Hoàng HiệpNo ratings yet

- 2019 DSSIMULIA - Established - Isotropic Elasto-PlasticityDocument6 pages2019 DSSIMULIA - Established - Isotropic Elasto-PlasticityPhan Đào Hoàng HiệpNo ratings yet

- 2019 DSSIMULIA - Established - A Cracking Model For Concrete and Other Brittle MaterialsDocument9 pages2019 DSSIMULIA - Established - A Cracking Model For Concrete and Other Brittle MaterialsPhan Đào Hoàng HiệpNo ratings yet

- 2019 DSSIMULIA - Established - Integration of Plasticity ModelsDocument3 pages2019 DSSIMULIA - Established - Integration of Plasticity ModelsPhan Đào Hoàng HiệpNo ratings yet

- 2019 DSSIMULIA - Established - About Plasticity ModelsDocument3 pages2019 DSSIMULIA - Established - About Plasticity ModelsPhan Đào Hoàng HiệpNo ratings yet

- Elections USA - in Brief Series - English - Hi ResDocument60 pagesElections USA - in Brief Series - English - Hi ResPhan Đào Hoàng HiệpNo ratings yet

- Democracy in Brief - in Brief Series - English - Hi ResDocument84 pagesDemocracy in Brief - in Brief Series - English - Hi ResPhan Đào Hoàng HiệpNo ratings yet

- Arcd 15Document1 pageArcd 15Suthari AmbikaNo ratings yet

- Introduction To Offshore Pipelines & Risers - Jaeyoung LeeDocument172 pagesIntroduction To Offshore Pipelines & Risers - Jaeyoung Leeafifahrashid89% (9)

- 5-Compressive Strength of Clay BricksDocument3 pages5-Compressive Strength of Clay BricksZhiwar oramari50% (2)

- Figure PG-53.3 Diagram For Determining Equivalent Longitudinal Efficiency of Diagonal Ligaments Between Openings in Cylindrical ShellsDocument6 pagesFigure PG-53.3 Diagram For Determining Equivalent Longitudinal Efficiency of Diagonal Ligaments Between Openings in Cylindrical ShellsaruntpeNo ratings yet

- Brazed Plate Heat ExchangerDocument2 pagesBrazed Plate Heat ExchangerAndone GigiNo ratings yet

- Reinforced Concrete Sections Under Moment and Axial LoadDocument5 pagesReinforced Concrete Sections Under Moment and Axial LoadAlberto CaínNo ratings yet

- JacketingDocument9 pagesJacketingsp thipathiNo ratings yet

- P6 3B Bernardo KathryneDocument4 pagesP6 3B Bernardo KathryneKATHRYNE BERNARDONo ratings yet

- Pom - Kocetal K300Document1 pagePom - Kocetal K300armandoNo ratings yet

- Plumbing Sanitary Permit Front and BackDocument2 pagesPlumbing Sanitary Permit Front and BackJohn MoralesNo ratings yet

- Notes On Numerical Fluid Mechanics and Multidisciplinary DesignDocument202 pagesNotes On Numerical Fluid Mechanics and Multidisciplinary DesignAnonymous uCYIu1No ratings yet