Professional Documents

Culture Documents

Injection Pump Test Specifications

Injection Pump Test Specifications

Uploaded by

admin tigasaudaraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Injection Pump Test Specifications

Injection Pump Test Specifications

Uploaded by

admin tigasaudaraCopyright:

Available Formats

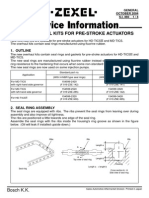

INJECTION PUMP TEST SPECIFICATIONS 096000-8990

096000-899# MANU-

INJECTION PUMP (VE6/10F2000RND899) TOYOTA

FACTURER

ENGINE

Governor Type All speed 1HZ

TYPE

VEHICLE

Rated Voltage 12V LAND CRUISER

MODEL

Rotation Clockwise viewed from drive side Dimension (mm) MS : 0.28 – 0.30

Injection Order A–B–C–D–E–F Dimension (mm) K : 3.20 – 3.40

Injection Interval 60° ±30' Dimension (mm) KF : 5.80 – 6.00

1. TEST CONDITIONS

1) Nozzle : 093400-0540 4) Feed Pressure : 0.2 kgf/cm 2

(DN12SD12A)

2) Nozzle Opening : 145 – 155 kgf/cm 2 5) High Pressure Pipe : ø2 x ø6 x 840 mm

Pressure

3) Test Oil : SAE J967 (ISO4113) 6) Fuel Temperature : 40 – 45°C

(104 – 113°F)

NOTE: Apply 6 volts DC across the fuel cut solenoid during adjustment.

2. PRE-ADJUSTMENT (at full lever position)

Fuel Delivery

Pump Speed (rpm) Remarks

(cc/200st. 1cyl.)

Full Load 1200 10.96 – 11.56 By full load setting screw

High Speed 2300 3.40 – 5.00 By max. speed setting screw

Load Sensing Timer: Adjust the governor shaft so that the dimension "L" between the housing flange and the end of the governor

shaft is about 2.5 mm.

3. ADJUSTMENT OF PUMP INTERNAL PRESSURE (at full lever position)

Pump Speed (rpm) Internal Pressure (kgf/cm 2) Remarks

500 3.0 – 3.6 By the regulating valve

2000 7.6 – 8.2

4. OVERFLOW QUANTITY CHECK (at full lever position)

Pump Speed (rpm) Overflow Quantity (cc/1000st) Remarks

The overflow valve belonging to the pump should

2000 183.0 – 400.0

be used for checking.

5. ADJUSTMENT OF TIMER (at full lever position)

Pump Speed (rpm) 800 1200 1600 2000

Piston Travel (mm) 1.1 – 1.9 2.93 – 3.73 4.79 – 5.59 6.6 – 7.4

NOTE: Hysteresis at each pump speed is less than 0.3 mm.

096000-8990

6. ADJUSTMENT OF FUEL DELIVERY

Lever Pump speed Fuel Delivery Max. Spread Boost

Position (rpm) (cc/200st, 1cyl) In Delivery Pressure Remarks

(cc) Absolute

Pressure

(mmHg)

FULL 1200 11.16 – 11.36 0.4 — By full load setting screw

2300 3.60 – 4.80 — — By max. speed setting screw

2200 7.70 – 9.30 — —

2400 Less than 0.20 — —

100 10.00 – 14.00 1.4 — By governor sleeve plug

500 9.12 – 10.13 0.6 —

2000 10.26 – 11.26 0.6 —

— — — —

7. SETTING OF LOAD SENSING TIMER (at full lever position)

Pump Speed Fuel Delivery (cc/200st, 1cyl) Remarks

(rpm)

Start of Load Sensing 1600 Full-load delivery – (1.0 – 1.8) By governor shaft

End of Pressure Drop 1600 More than 7.68 Check

CHECK POINTS 1. Piston Travel at End of Pressure Drop : 2.83 – 3.63 mm (pump speed 1600 rpm)

2. Dimension of Governor Shaft : L = 0.3 – 2.0 mm

8. SETTING OF ADJUSTING LEVER AT LOW SPEED

Lever Pump Speed Fuel Delivery Max. Spread

Position (rpm) (cc/500st, 1cyl) In Delivery Remarks

(cc)

IDLE 325 7.0 – 8.5 2.25 By idle setting screw

350 More than (Q + 1.25) —

375 6.25 – 7.75 — Presetting

450 Q – (3.0 – 5.5) —

9. ADJUSTMENT OF BOOST COMPENSATOR N.A. : Not Applicable

Pump Speed Boost Pressure Fuel Delivery Remarks

(rpm) (mmHg) (cc/1000st, 1cyl)

N.A. N.A. N.A.

10. ADJUSTMENT OF T.C.V. N.A. : Not Applicable

Pump Speed Boost Pressure Piston Stroke

(rpm) (mmHg) (mm)

N.A. N.A. N.A.

INJECTION PUMP TEST SPECIFICATIONS 096000-8990

11. ADJUSTMENT OF THROTTLE POSITION SENSOR N.A. : Not Applicable

Pump Speed (rpm) Condition Sensor Output Voltage

Set point N.A. N.A. N.A.

Check point N.A. N.A. N.A.

12. CHARACTERISTIC OF A.C.S.D. N.A. : Not Applicable

Lever Pump Speed Fuel Temperature

Measuring Value Remarks

Position (rpm) (°C)

IDLE N.A. N.A. N.A.

N.A. N.A. N.A.

13. ADJUSTMENT OF POWER CONTROL N.A. : Not Applicable

Boost

Lever Pump Speed Fuel Delivery

Pressure Remarks

Position (rpm) (cc/200st. 1cyl)

(mmHg)

FULL N.A. N.A. N.A.

14. ADJUSTMENT OF DASH POT N.A. : Not Applicable

Pump Speed Boost Pressure Fuel Delivery Remarks

(rpm) (mmHg) (cc/500st)

N.A. N.A. N.A.

15. FINAL CHECK AFTER ADJUSTMENT

(1) Range of lever angle between idle and full lever position is 43° ±5°.

(2) Resistance of pick-up tachometer must be 650 – 970 ohms.

(3) Q is measured fuel delivery quantity (cc/500st) at 375 rpm.

You might also like

- D155AX-6 Shop ManualDocument1,569 pagesD155AX-6 Shop ManualJorge Calderon Rojas100% (8)

- Detroit DDEC VIDocument19 pagesDetroit DDEC VIGeraldin PuertoNo ratings yet

- Repair Denso Pumps PDFDocument77 pagesRepair Denso Pumps PDFRodolfoArayaCarvajalNo ratings yet

- CFM56-3 Familiarization Training Manual MTU Maintenance Zhuhai Co. LTDDocument59 pagesCFM56-3 Familiarization Training Manual MTU Maintenance Zhuhai Co. LTDrenjithaero100% (4)

- Pump Test Specifications: InjectionDocument3 pagesPump Test Specifications: InjectionJaqueline S. S. Maicá100% (1)

- Si460 PDFDocument4 pagesSi460 PDFFranky Fernandez100% (1)

- Inj. Pump Calibration Data: 1. Test ConditionsDocument6 pagesInj. Pump Calibration Data: 1. Test ConditionsMiguel RojasNo ratings yet

- lt1000d6 PDFDocument3 pageslt1000d6 PDFJo Ferry50% (2)

- Student Text - MechanicalRailway Diesel Shed Training NotesDocument222 pagesStudent Text - MechanicalRailway Diesel Shed Training NotesPrachir Shrivastava89% (9)

- Doosan D12T and P126ti Workshop Manual PDFDocument186 pagesDoosan D12T and P126ti Workshop Manual PDFMuhammad rizki100% (4)

- Injection P Ump Test Specifications 196000-327#Document4 pagesInjection P Ump Test Specifications 196000-327#Manuel João JoãoNo ratings yet

- 093400-5350 Mitsubishi PDFDocument2 pages093400-5350 Mitsubishi PDFBaytolgaNo ratings yet

- EE4760Document2 pagesEE4760OFFICE DANACNo ratings yet

- 4720Document3 pages4720Junior IungNo ratings yet

- Injection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxDocument3 pagesInjection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxBaytolga100% (3)

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelJunior IungNo ratings yet

- 096000-4860 Toyata Hilux-4 Runner PDFDocument4 pages096000-4860 Toyata Hilux-4 Runner PDFBaytolgaNo ratings yet

- 093000-1613 Hi̇no PDFDocument2 pages093000-1613 Hi̇no PDFBaytolgaNo ratings yet

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsMartin Miguel Gomez SalviNo ratings yet

- 02EN1630Document2 pages02EN1630Edinson Ariel Chavarro QuinteroNo ratings yet

- Injection Pump Calibration Data: 1. Test ConditionsDocument3 pagesInjection Pump Calibration Data: 1. Test ConditionsElson DorigonNo ratings yet

- Bk2q-9k546-Ag 20190701 112041 PDFDocument2 pagesBk2q-9k546-Ag 20190701 112041 PDFคุณชายธวัชชัย เจริญสุขNo ratings yet

- Inj - P Ump Cal Ibration DataDocument3 pagesInj - P Ump Cal Ibration DataСергей ВладимировичNo ratings yet

- Injection Pump Test SpecificationsDocument2 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- (Oto-Hui - Com) Edc Hino s05Document2 pages(Oto-Hui - Com) Edc Hino s05ahmed_eng_1500No ratings yet

- Nozzles and Spare Parts For: Denso Common Rail InjectorsDocument6 pagesNozzles and Spare Parts For: Denso Common Rail InjectorsBalariniRetífica100% (1)

- Modifikacii HP 3Document5 pagesModifikacii HP 3pankituna5487No ratings yet

- 740 4010Document6 pages740 4010Miguel ChaconNo ratings yet

- Test SheetDocument3 pagesTest SheetNemo NeoNo ratings yet

- Denso Control Valve & Rod 2016Document4 pagesDenso Control Valve & Rod 2016Екатерина КалашниковаNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration Datamurillo_rodriguez8382No ratings yet

- CRS (ECD-U2P) For Land CruiserDocument45 pagesCRS (ECD-U2P) For Land CruiserВячеслав ГлушакNo ratings yet

- Injection Pump Test Specifications 093000-677#Document3 pagesInjection Pump Test Specifications 093000-677#Pedro Abellan100% (1)

- Service Bulletin: Fuel Injection PumpDocument6 pagesService Bulletin: Fuel Injection PumpAnonymous wpUyixsj100% (2)

- DATODocument1 pageDATOMiguel RojasNo ratings yet

- 4JB1 Calibration Data PDFDocument2 pages4JB1 Calibration Data PDFHendrian ArdyNo ratings yet

- VI - O55 - 6b - MotorDocument26 pagesVI - O55 - 6b - MotorDJJ ManutençãoNo ratings yet

- Test Plan Delphi TechnologiesDocument2 pagesTest Plan Delphi TechnologiesFRANCISCONo ratings yet

- Denso CodeDocument5 pagesDenso CodeTamer MoustafaNo ratings yet

- Methodology For The Repair of Denso CRIDocument6 pagesMethodology For The Repair of Denso CRIFaraz Haider100% (2)

- 1458718041Document24 pages1458718041Jose Camacho HernandezNo ratings yet

- Fuel Injection Equipment For M&M 245 DI Engine: SSE-I-MML/138 12.2003Document2 pagesFuel Injection Equipment For M&M 245 DI Engine: SSE-I-MML/138 12.2003Ravikant Saini100% (1)

- Nantai Catalog NewDocument30 pagesNantai Catalog Newspalomos100% (1)

- 101401-9271 Calibration DataDocument5 pages101401-9271 Calibration Datamurillo_rodriguez83820% (1)

- 606 9460Document2 pages606 9460Alex PakitoNo ratings yet

- Unidades HeuiDocument50 pagesUnidades HeuiagnaldoNo ratings yet

- Test Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorDocument2 pagesTest Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorJam B100% (3)

- Ricambi DensoDocument10 pagesRicambi DensoSprinter Transit Van100% (1)

- EDocument34 pagesEEdinson Ariel Chavarro Quintero100% (1)

- Dpico: Inj. Pump Calibration DataDocument6 pagesDpico: Inj. Pump Calibration DataGiovaniBalzaniNo ratings yet

- Diesel Segment Brosch Re enDocument32 pagesDiesel Segment Brosch Re enMohamed JawishNo ratings yet

- F 002 A0z 755 Spare PartsDocument17 pagesF 002 A0z 755 Spare PartsGowtham100% (1)

- 02EN0160Document2 pages02EN0160Miguel RojasNo ratings yet

- Temp 753Document2 pagesTemp 753Neelakandan Krishnan100% (1)

- Dpico: Inj. Pump Calibration DataDocument4 pagesDpico: Inj. Pump Calibration DataGiovaniBalzaniNo ratings yet

- 403 9140Document6 pages403 9140Edinson Ariel Chavarro Quintero100% (1)

- Ee6790 PDFDocument3 pagesEe6790 PDFEdinson Ariel Chavarro Quintero100% (1)

- ERIKC CatalogueDocument62 pagesERIKC CatalogueЕкатерина КалашниковаNo ratings yet

- Injection Pump Test Specifications 092000-512#Document3 pagesInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- Manual 0602N Eng PDFDocument27 pagesManual 0602N Eng PDFMohamedBenMansour100% (1)

- DENSO X2 Instruction PDFDocument13 pagesDENSO X2 Instruction PDFQuy MingNo ratings yet

- Test Plan 8523a320Document2 pagesTest Plan 8523a320taniaNo ratings yet

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsJunior IungNo ratings yet

- Injection Pump Test Specifications 196000-264#: (Full)Document4 pagesInjection Pump Test Specifications 196000-264#: (Full)ficoscha100% (1)

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©admin tigasaudaraNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©admin tigasaudaraNo ratings yet

- Rhino 196000-0601Document5 pagesRhino 196000-0601admin tigasaudaraNo ratings yet

- S M Illust - No. Part Name Denso P/N Manu. P/N QTY I/C Start End RemarksDocument4 pagesS M Illust - No. Part Name Denso P/N Manu. P/N QTY I/C Start End Remarksadmin tigasaudaraNo ratings yet

- Briggs 100602 and Other OHV Repair ManualDocument76 pagesBriggs 100602 and Other OHV Repair ManualpaulschweikardtNo ratings yet

- Evolution, Trends and Applications of Endoscopy in Internal Combustion EnginesDocument11 pagesEvolution, Trends and Applications of Endoscopy in Internal Combustion Enginesznadeem2No ratings yet

- General: Technical Data TAD722GEDocument8 pagesGeneral: Technical Data TAD722GEbaljeetjatNo ratings yet

- DK-20 Instrauction Manual (Operation)Document112 pagesDK-20 Instrauction Manual (Operation)Abhi ChaudhuriNo ratings yet

- Cat 308Document5 pagesCat 308George PlishkoNo ratings yet

- 02 EC-10004-5A Hydraulic Equipment PDFDocument32 pages02 EC-10004-5A Hydraulic Equipment PDFtai.nguyensvhcmutNo ratings yet

- Ir SS800 PDFDocument8 pagesIr SS800 PDFJuan Asarcado0% (1)

- Yamaha MotorcycleDocument60 pagesYamaha MotorcycleGoutam BiswasNo ratings yet

- HALE Portable ProspektDocument24 pagesHALE Portable ProspektKatie LawrenceNo ratings yet

- Me6016 Question BankDocument28 pagesMe6016 Question BankRandy VidsNo ratings yet

- Types of Ac 3 Phase Motor ThreeDocument41 pagesTypes of Ac 3 Phase Motor ThreeNurFatin ShahiraNo ratings yet

- Detroit Engine Service Manual DD S V 71 SerDocument12 pagesDetroit Engine Service Manual DD S V 71 SerAndrey PomazanovNo ratings yet

- XA-Series-ENGINE AND ACCESSORIESDocument2 pagesXA-Series-ENGINE AND ACCESSORIESRICHARD0% (1)

- Johnson RPM Chart Evinrude E-Tec RPM Chart Mercury 4-Stroke RPM ChartDocument2 pagesJohnson RPM Chart Evinrude E-Tec RPM Chart Mercury 4-Stroke RPM ChartUlf NymanNo ratings yet

- ARTICULATED DUMP TRUCK Pre InspectionDocument3 pagesARTICULATED DUMP TRUCK Pre InspectionkrisnantoNo ratings yet

- Scotck Yoke PPT Veltech 2016Document29 pagesScotck Yoke PPT Veltech 2016Chockalingam Athilingam50% (2)

- 4-Stroke Table of Content Temp PDFDocument11 pages4-Stroke Table of Content Temp PDFlavkeshNo ratings yet

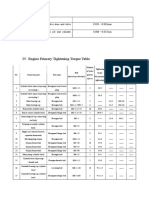

- IV. Engine Primary Tightening Torque TableDocument5 pagesIV. Engine Primary Tightening Torque TablerectificamosNo ratings yet

- 657g GearDocument2 pages657g GearANo ratings yet

- Hydraulic Dynamometers For Load Testing Prime Movers: AerospaceDocument1 pageHydraulic Dynamometers For Load Testing Prime Movers: Aerospace唐波No ratings yet

- 1606A-E93Tag4 Electropak: SeriesDocument10 pages1606A-E93Tag4 Electropak: Seriesubaldo caraballoNo ratings yet

- Model Tuning Tips YamahaDocument15 pagesModel Tuning Tips YamahaTwinFlatfourNo ratings yet

- Deutz Engine Model Serial NumberDocument28 pagesDeutz Engine Model Serial NumberanggieNo ratings yet

- Kymko Xciting 250-500 Service Manual 2005 Motowiki - byDocument393 pagesKymko Xciting 250-500 Service Manual 2005 Motowiki - byJorjNo ratings yet

- 63H34E05Document24 pages63H34E05Lo Shun Fat100% (1)