Professional Documents

Culture Documents

Planning Points - 070122

Planning Points - 070122

Uploaded by

ravitejatalatamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Planning Points - 070122

Planning Points - 070122

Uploaded by

ravitejatalatamCopyright:

Available Formats

CHENNAI PETROLEUM CORPORATION LIMITED

PRODUCTION PLANNING 07-Jan-22

CRUDE RECEIPT PLAN

TANKER GRADE QTY ( MT ) L/C CARGO START TIME STOP TIME

S'SINDHU RAV 55,000 105 107 ,119 , 08-Jan 08:OO 09-Jan 08:OO

MT TILOS BAH 1,40,500 119 109 ,111 ,113 ,112 , 09-Jan 20:OO 11-Jan 10:OO

S'GANGA BOM 55,000 112 118 ,107 , 11-Jan 20:OO 12-Jan 20:OO

S'GANGA NMN 30,000 107 116 15-Jan 06:OO 16-Jan 07:OO

FEEDING PLAN

REFINERY FEED SPIKE Rate/hr REMARKS START TIME STOP TIME

120 330 C/o as per indicative time 07-Jan 06:OO 10-Jan 10:OO

120 380 When 120 is low,c/o 10-Jan 10:OO 11-Jan 19:OO

CDU1 121 380 C/o as per indicative time 11-Jan 19:OO 12-Jan 18:OO

106 380 When 106 is low,c/o 12-Jan 18:OO 14-Jan 05:OO

121 380 14-Jan 05:OO 17-Jan 06:OO

HS LS 110 114 450 / 100 C/o as per indicative time 07-Jan 06:OO 10-Jan 10:OO

LS 107 500 When 107 is low,c/o 10-Jan 10:OO 12-Jan 20:OO

CDU2

LS 119 500 When 118 is ready,c/o 12-Jan 20:OO 13-Jan 10:OO

BH 118 500 13-Jan 10:OO 17-Jan 06:OO

HS LS 109 107 114 230 / 100 C/o as per indicative time 07-Jan 06:OO 07-Jan 14:OO

HS LS 112 107 300 / 150 When 107 is req for receipt,c/o 07-Jan 14:OO 08-Jan 06:OO

HS LS 116 112 150 / 300 When 116 is low,c/o 08-Jan 06:OO 10-Jan 01:OO

CDU3

HS LS 112 107 400 / 100 When 107 is low,c/o 10-Jan 01:OO 11-Jan 06:OO

HS LS 109 119 400 / 100 When 109 is low,c/o 11-Jan 06:OO 16-Jan 14:OO

HS LS 111 116 350 / 150 16-Jan 14:OO 19-Jan 04:OO

GENERAL

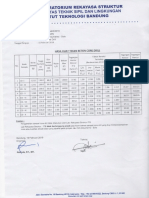

Crude Tank Composition

07-Jan High Sulphur Crude s Low Sulphur Crude s HS UNIT ETP Total

Dip VR VGO

TANK ARB DAS UPP BAM BAL BAH ARL % BOM RAV NMN ESC SAP AZE NKO % RCO SLOP SLOP %

T105 782 42 1 0 48 8 99 1 100

T106 498 13 1 0 12 52 77 1 1 2 19 100

T107 606 69 1 6 1 3 1 18 99 1 100

T108 205 84 1 0 15 100 100

T109 276 3 0 84 13 100 100

T110 1105 15 1 81 3 100 100

T111 240 1 15 15 66 98 2 100

T112 1047 1 0 18 81 100 100

T113 479 0 6 2 68 76 0 0 0 24 100

T114 438 9 7 4 20 9 10 62 100

T115 317 1 1 65 1 2 24 93 7 100

T116 314 6 1 73 0 1 0 16 97 3 100

T118 201 100 100 100

T119 260 1 69 0 2 0 22 95 5 100

T120 1430 3 0 92 3 99 0 1 100

T121 1508 14 1 85 100 100

Tank unde r M&I: 117

Production Planning 07-Jan-22

Lube Units - Plan Fri

Feed rate Ext/ Indicative Target

Plant Grade Feed tk R/D tk Remarks Dist Routing

m3/hr Wax time of c/o Visc

71 VR 70* Spindle DHDS 2.8

500N 55 305/309 323 330/331/ASP Next change 08-Jan 08:OO LN OHCU 5.1

LN 65 302 320 303/ASP Next change 10-Jan 16:OO IN OHCU 8.8

73

IN 68 311/304 321 303/ASP Next change 12-Jan 16:OO 500N 305/309 14.5-15

BN 52 308/310 306 307/ASP Next change 14-Jan 16:OO HN DCU 23.5

DAO 308/310 33-35

500N 35 323 324 Wax Next change 08-Jan 08:OO Wax Feed (KL) 2964

9

LN 50 320 341 Wax Next change 10-Jan 16:OO

IN 45 321 340 Wax Next change 12-Jan 16:OO Wax - feed

10

days

500N Match Pt-9 324 372/369 330/331/ASP Next change 08-Jan 08:OO

10

LN Match Pt-9 341 360 303/ASP Next change 10-Jan 16:OO

IN Match Pt-9 340 361/368 303/ASP Next change 12-Jan 16:OO

* PDA T'put is varied based on Asphalt ullage.

Product Tanker Plan

Tanker Name Product Laycan Quantity (TMT) Destination Remarks

MT Unique Infinity (Loading on) Naphtha (C: +22 / P: 55 % / FBP: 190°C) 06-08/01/22 35 +/- 10 % Export CPCL

TBN Naphtha (C: +22 / P: 55 % / FBP: 190°C) 15-17/01/22 35 +/- 10 % Export CPCL

TBN Naphtha (C: +22 / P: 60 % / FBP: 180°C) 01-03/02/22 35 +/- 10 % Export CPCL

CTMPL Plan (TKL) Stream Routing Plan

Date Product Quantity Remarks MS Raw Diesel

04-Jan-22 PCK 0.3 Over FCCU MS UCO (FBP < 200°C) Pt-1 / 15 / 201 (HS) DHDS / DHDT

04-Jan-22 ZSKO 0.4 Over Naphtha Pt-1 / 15 / 201 (LS) DHDT / DHDS

04-Jan-22 ATF 3.0 Over Pt-1 Hy Nap CCR / DHDT / DHDS DCU HCN / LCGO DHDS

05-Jan-22 ZSKO 0.2 Over Pt-15 Hy Nap DHDT / DHDS / CCR / HSD BS-VI FCCU TCO HSD BS-VI / DHDS / DHDT

05-Jan-22 PCK 0.3 Over Pt-201 Hy Nap DHDT / DHDS / CCR VGO

05-Jan-22 SKO 2.0 Over Pt-201 LSRG ISOM / HGU / LPN Pt- 15 / 201 VGO OHCU

05-Jan-22 PCK 0.3 Over Pt-1 Stab Nap ISOM / HGU / LPN LS VGO to FCCU -

05-Jan-22 MS 38.5 On Pt-201 LSRN CCR / LPN UCO to FCCU Maximum (140+)

09-Jan-22 PCK 0.3 Pt-15 Stab Nap HGU / CCR / ISOM / LPN Pt- 15 / 201 Slop Dist (LS) RFO / DCU / FO

09-Jan-22 HSD 60.0 Pt-74 Bal Nap Sp I Top - ISOM / Sp II Btm - CCR Pt- 15 /201 Slop Dist (HS) DCU / FO

15-Jan-22 PCK 0.3 207 Light Nap Pt-74 / ISOM / HGU DCU HCGO OHCU / FO

15-Jan-22 MS 35.7 207 Hy Nap CCR / HSD BS-VI / MS Lube Slop Tk- 312 / 313 / 325 / FO

19-Jan-22 PCK 0.3 DHDS Syn Nap CCR / MS / FCCU / LPN OHCU Conversion Maximum (64%)

CBPL Plan (TKL) DHDT Syn Nap CCR / MS / FCCU / LPN 207 Filter Backwash Tk- 312 / 313 / 325

Date Product Quantity Remarks 206 NHT LN Pt-74 / ISOM Pt- 15 / 201 HS EGO DHDS

27-Dec-21 HSD 65.0 Over 212 NHDT C7+ CCR / HGU Pt- 15 / 201 LS EGO DHDT

05-Jan-22 PCK 0.2 Over 212 NHDT C5- MS / HGU VBU VGO -

05-Jan-22 MS 6.5 (IOC) Over 212 DIH Recycle Pt-74 (8 m3/hr) VR

06-Jan-22 LSATF 0.4 Over DCU LCN ISOM / DHDS Pt-1 PDA / ABB / DCU / FO

06-Jan-22 ATF 14.5 On VBU Naphtha - Pt- 15 / 201 (HS) DCU / ABB / PDA / FO

08-Jan-22 LSATF 0.3 ATF MODE Pt- 15 / 201 (LS) RFO / DCU / FO

08-Jan-22 HSD 25.0 Pt-1 TPL SK VBU Tar -

12-Jan-22 PCK 0.2 Pt-15 Pt-17 (40 m3/hr), balance to TPL SK Extracts Bitumen / DCU / FO

12-Jan-22 MS 21.0 (IOC) Pt-201 Pt-203 (40 m3/hr), balance to TPL SK Pitch Bitumen / DCU

14-Jan-22 LSATF 0.4 OHCU ATF Slop to DCU 30 m3/hr

14-Jan-22 ATF 13.5 Pt-4 TPL Return SK only Slop to CDU-1 / CDU-2 30 m3/hr

16-Jan-22 LSATF 0.3 HSD Recovery Target (at 360°C)

16-Jan-22 HSD 49.0 CDU 1 15 Atm 15 Vac 201 Atm 201 Vac DCU LCGO OHCU

22-Jan-22 PCK 0.2 90 98 98 98 98 90 90

22-Jan-22 MS 21.0 (IOC) Unit Tput Target (m3/hr)

24-Jan-22 LSATF 0.4 Pt-4 DHDS DHDT OHCU FCCU ISOM CCRU Pt-74 Pt-14 DCU PDA VBU

24-Jan-22 ATF 13.5 60 300 300 300 140 50 70 20 14 250 70 -

Standing Instructions: Sulphur Target (ppm)

1) FCCU to be operated in MS maximisation mode (Cracked Gasoline FBP to be targeted at 200°C). DHDS 4

2) Heavy Naphthas to be fully absorbed in Diesel pool, routing to naphtha pool to be avoided. DHDT 4

3) To maximise MS production, FCCU / CCRU / ISOM Tputs and Octane Tonnage to be maximised to the extent possible. OHCU HSD 10

4) Value added products: Propylene / PCFS / Hexane / MTO / LOBS / Wax production to be maximised LCO 50

5) Absorption of HS Raw Diesel and DCU streams to be prioritised to DHDS for hydrogen saving. HCO 100

6) LCO and HCO to be absorbed in HSD BS-VI header based on sulphur and recovery. Cr Gasoline 13

7) Excess pitch to be absorbed in DCU and PDA Tput to be altered based on bitumen ullage and pitch absorption in DCU. Naphtha Pool FBP (°C)

8) ISOM C5- to be kept routed to MS pool based on header RVP. Hy Naphtha 180

9) All CDUs SK flash to be maintained at 45°C min for TPL SK flash increase (TPL Return SK trial in Pt-17 merox unit). Syn Naphtha 180

Today's Instructions: Operating Mode

1) DCU Throughput to be increased to 250 m3/hr FCCU MS

2) TPL return SK pumping to Plant-4 to be maximized

3) OHCU conversion to be maximized to enable UCO depletion

4) FO Batch (180) needs to be prepared urgently for meeting market requirement

5) DHDT Throughput to be maintained at 300 m3/hr in view of low rawdiesel stocks.

CM (PP) 07-01-2022

You might also like

- Well Intervention IntroductionDocument43 pagesWell Intervention Introductionmissaoui100% (4)

- Stihl 08S ManualDocument51 pagesStihl 08S ManualSMWilsonNo ratings yet

- Planning Points 11.03.22Document2 pagesPlanning Points 11.03.22ravitejatalatamNo ratings yet

- Adhe PPMDocument15 pagesAdhe PPMAdhe R ebeka PardosiNo ratings yet

- DSMC Quan Tum Miramar01132a201702061109Document2 pagesDSMC Quan Tum Miramar01132a201702061109Jorge IbacetaNo ratings yet

- Rekap Absen Ds Siantarsidempuan Agustus 2017Document5 pagesRekap Absen Ds Siantarsidempuan Agustus 2017BillyNo ratings yet

- Hasil Test Core DrillDocument1 pageHasil Test Core DrillPanji Ardiansah WijayaNo ratings yet

- Status Sheet 02 11 10Document4 pagesStatus Sheet 02 11 10haaniaNo ratings yet

- Six Parameter TGL 13 April 2024Document1 pageSix Parameter TGL 13 April 2024edibagus401No ratings yet

- Turakhia Polymers Pvt. LTD.: DCA Cum CS of Indian Oil Corporation Ltd. For PP / HDPE / LLDPEDocument4 pagesTurakhia Polymers Pvt. LTD.: DCA Cum CS of Indian Oil Corporation Ltd. For PP / HDPE / LLDPEdiadam07No ratings yet

- 2021-07-02 - 13-09-31 - Soy Gluten 70.30 - B9r2r9qvme4rDocument5 pages2021-07-02 - 13-09-31 - Soy Gluten 70.30 - B9r2r9qvme4rGagan SvNo ratings yet

- Fisa Xbar R SDocument1 pageFisa Xbar R SCristi BragaNo ratings yet

- Hist StrukDocument1 pageHist Strukrazanah aulia marhanNo ratings yet

- Laporan Bulanan Malaria 2016Document174 pagesLaporan Bulanan Malaria 2016Krisandy WinandarNo ratings yet

- Personnel Number Name of Employee or Applicant Identity Number Cost Center Serial NumberDocument47 pagesPersonnel Number Name of Employee or Applicant Identity Number Cost Center Serial NumberMuhammad AliNo ratings yet

- KPI Target Band Kpis: I-AS-TZPR-ENB-0068 2300Document18 pagesKPI Target Band Kpis: I-AS-TZPR-ENB-0068 2300Aditya NaikNo ratings yet

- Amar Chand STFC Tata Magic CG 04 T 4713 NA 223000 223000 25-Apr-12 Installm Ent Amt Rcpt. No. Recd. Date RCPT Amount Delay DaysDocument3 pagesAmar Chand STFC Tata Magic CG 04 T 4713 NA 223000 223000 25-Apr-12 Installm Ent Amt Rcpt. No. Recd. Date RCPT Amount Delay DaysAlok_1984No ratings yet

- Comments For Shut WellsDocument6 pagesComments For Shut WellsarpitNo ratings yet

- Impedancias de Transformadores de Dos DevanadosDocument7 pagesImpedancias de Transformadores de Dos DevanadosEDUARDO SALINAS LOPEZNo ratings yet

- Cord Card Hut Tni Al.14.0 W2Document1 pageCord Card Hut Tni Al.14.0 W2YES99 99YESNo ratings yet

- JFB Metallized Polyester Film CapacitorDocument2 pagesJFB Metallized Polyester Film CapacitorJuan Manuel JorqueraNo ratings yet

- TBN TrendDocument8 pagesTBN TrendNaveed Ul Qamar MughalNo ratings yet

- Practica 3 PCPDocument5 pagesPractica 3 PCPHoolaNo ratings yet

- 02. Absensi Februari 2022Document8 pages02. Absensi Februari 2022PUTRIANA CARONA MANURUNGNo ratings yet

- 5th Nov 2020 1 IOCL PDFDocument4 pages5th Nov 2020 1 IOCL PDFTushar Prakash ChaudhariNo ratings yet

- Train 6 - WH6 & 8 Platform - Histograms - 20 Dec 07Document3 pagesTrain 6 - WH6 & 8 Platform - Histograms - 20 Dec 07MarkyNo ratings yet

- PMS & Shutdown Baseline ScheduleDocument2 pagesPMS & Shutdown Baseline ScheduleSteve UkohaNo ratings yet

- U UF FN Pin NK Le Ette Ers: R Rou Ute Su Upp Plem Me Nts SDocument45 pagesU UF FN Pin NK Le Ette Ers: R Rou Ute Su Upp Plem Me Nts SmtagossipNo ratings yet

- Job Order 2020Document415 pagesJob Order 2020Carwill TesdaNo ratings yet

- Delivery ChallanDocument3 pagesDelivery ChallanStructures ProductionNo ratings yet

- RIwayat Pembelian Argon TTC 2018-2021Document7 pagesRIwayat Pembelian Argon TTC 2018-2021Meita UtariNo ratings yet

- QC Chart - ICP-OES - FINALDocument62 pagesQC Chart - ICP-OES - FINALConsultant JerocasNo ratings yet

- Laporan Beban Hunting Cti Pltu Galang Batang Pebruari 2013: 0 7 P E B R U A R I 2 0 1 3Document12 pagesLaporan Beban Hunting Cti Pltu Galang Batang Pebruari 2013: 0 7 P E B R U A R I 2 0 1 3MArco 'NoNo ratings yet

- Pile Load Test: On Ruby To Hasanpur RoadDocument5 pagesPile Load Test: On Ruby To Hasanpur RoadNabajyoti KalitaNo ratings yet

- VIDAPANAKAL House Site ProformaDocument1 pageVIDAPANAKAL House Site ProformaVB665No ratings yet

- Tabela Tubos HidráulicosDocument1 pageTabela Tubos HidráulicosJPJFNo ratings yet

- Platou Dry 130710Document2 pagesPlatou Dry 130710Mustafa Ozkara100% (1)

- Van ZariDocument47 pagesVan Zariale559413No ratings yet

- Tubulão Oval - Junta ADocument4 pagesTubulão Oval - Junta ARomes Monteiro da silvaNo ratings yet

- Samoa 3-2-21Document3 pagesSamoa 3-2-21motayyab ahmedNo ratings yet

- FY10 ICD-9-CM Procedure Codes Linked To NHSN Operative Procedure CategoriesDocument22 pagesFY10 ICD-9-CM Procedure Codes Linked To NHSN Operative Procedure CategoriesYohan Julian Mega NandaNo ratings yet

- 8 INH Solid-July17Document1 page8 INH Solid-July17sridharNo ratings yet

- TDS Statement 07-08Document14 pagesTDS Statement 07-08kanchan_saha27No ratings yet

- JC011 T-Nagar Ring Details BackupDocument21 pagesJC011 T-Nagar Ring Details BackupAshok KumarNo ratings yet

- Chemistry Divya ManyaDocument9 pagesChemistry Divya ManyaDivyaNo ratings yet

- List of Type Tested TransformersDocument13 pagesList of Type Tested Transformersvikram_kakadiyaNo ratings yet

- Fase Acercam Carril Volumen So N FW FHV A 1316 1564 B 1398 2602 B 1509 1660Document3 pagesFase Acercam Carril Volumen So N FW FHV A 1316 1564 B 1398 2602 B 1509 1660Davila Yalli JhonNo ratings yet

- 1 StandardReportDocument9 pages1 StandardReportAgroNo ratings yet

- Employee'S Provident Fund Organisation: Electronic Challan Cum Return (Ecr)Document5 pagesEmployee'S Provident Fund Organisation: Electronic Challan Cum Return (Ecr)Mainak MitraNo ratings yet

- Truss 3Document164 pagesTruss 3balram12122000No ratings yet

- Harga Tbs Kirim Ke Pks GSPPDocument5 pagesHarga Tbs Kirim Ke Pks GSPPDwi Heri FitriansyahNo ratings yet

- Pasteles ProgramaDocument163 pagesPasteles ProgramaAngel GarciaNo ratings yet

- Form Mar 14, 2022Document1 pageForm Mar 14, 2022nicholasiraNo ratings yet

- Personal Sist 28X14Document10 pagesPersonal Sist 28X14Eduardo NoriegaNo ratings yet

- Analisis Estrucutral CMDocument50 pagesAnalisis Estrucutral CMAndreita OrTssNo ratings yet

- Sodexo Perú S.A - Contractor: Week 05-06Document4 pagesSodexo Perú S.A - Contractor: Week 05-06Juan SanjinezNo ratings yet

- NO Unit Number Daily Check Last Service Next Service Lose Time Date HM Date HM Date HM DateDocument20 pagesNO Unit Number Daily Check Last Service Next Service Lose Time Date HM Date HM Date HM Datesyamsuri samNo ratings yet

- b15-305 LedgerDocument10 pagesb15-305 LedgerMARY JERICA OCUPENo ratings yet

- HKH 1106 2022-07-22 SD 2022-07-28 8821Document16 pagesHKH 1106 2022-07-22 SD 2022-07-28 8821Nurcahyadin WorkNo ratings yet

- TS/PTT/18/0101494 : Delivery OrderDocument1 pageTS/PTT/18/0101494 : Delivery Orderkatta netNo ratings yet

- Practica Muni 1Document24 pagesPractica Muni 1davichoreategui94No ratings yet

- 02.03.2021 Ref 1MOMDocument41 pages02.03.2021 Ref 1MOMravitejatalatamNo ratings yet

- Internal Safety Audit - 2020: Job Not Completed Even Target Date Over: 1Document24 pagesInternal Safety Audit - 2020: Job Not Completed Even Target Date Over: 1ravitejatalatamNo ratings yet

- Internal Safety Audit - 2020: Job Not Completed Even Target Date Over: 1Document24 pagesInternal Safety Audit - 2020: Job Not Completed Even Target Date Over: 1ravitejatalatamNo ratings yet

- Planning Points 11.03.22Document2 pagesPlanning Points 11.03.22ravitejatalatamNo ratings yet

- ECD Scope of Work EditedDocument29 pagesECD Scope of Work EditedFikri Barry AlfianNo ratings yet

- Lecture 1 Introduction Fall 2023Document34 pagesLecture 1 Introduction Fall 2023MrHemFunNo ratings yet

- Indian Oil Corporation LTDDocument1 pageIndian Oil Corporation LTDAjay HariharanNo ratings yet

- Conc.n, ,. I T. No: 26 Wills' Mineral Processing TechnologyDocument5 pagesConc.n, ,. I T. No: 26 Wills' Mineral Processing TechnologyFABIAM EMILIO SUAREZ ESPITIANo ratings yet

- Namaste PDFDocument27 pagesNamaste PDFuma mishraNo ratings yet

- Peta Cekungan Air Tanah Yogyakarta Sleman (Yogyakarta Sleman Groundwater Basin)Document2 pagesPeta Cekungan Air Tanah Yogyakarta Sleman (Yogyakarta Sleman Groundwater Basin)Abu Rosyid AlMukhtaryNo ratings yet

- Specifications Guide: Americas Crude OilDocument21 pagesSpecifications Guide: Americas Crude OilAbdurahman JumaNo ratings yet

- 24 Jan - MCQ LPG SnapshotDocument26 pages24 Jan - MCQ LPG SnapshotmcqNo ratings yet

- Gas Production and Utilization Data (Provisional) April, 2023Document1 pageGas Production and Utilization Data (Provisional) April, 2023Rich WisdomNo ratings yet

- Paper Industry - IndiaDocument21 pagesPaper Industry - Indiaakj1992100% (1)

- Adnoc Hail and GashaDocument1 pageAdnoc Hail and GashaebrahimNo ratings yet

- 2018 Nogiar 1Document112 pages2018 Nogiar 1Dear Lakes AyoNo ratings yet

- 2010 Prod CostsDocument31 pages2010 Prod Costsricardov2009No ratings yet

- World Oil and Gas DataDocument4 pagesWorld Oil and Gas DataPaul AndrewNo ratings yet

- References BI - Oil and Gas InstallationsDocument1 pageReferences BI - Oil and Gas InstallationsAmine Ben salemNo ratings yet

- MINING True or FalseDocument2 pagesMINING True or FalseArriety KimNo ratings yet

- Company Address List TemplateDocument30 pagesCompany Address List TemplatenbvnvnvNo ratings yet

- Oil ReportDocument8 pagesOil Reportashish_20kNo ratings yet

- What We Know About EOR Today: I Was EOR Before EOR Was CoolDocument27 pagesWhat We Know About EOR Today: I Was EOR Before EOR Was CoolSheren Immanuella LoverdyNo ratings yet

- Turkey Mining SectorDocument1 pageTurkey Mining SectorGardo PrasetyoNo ratings yet

- Jorcandkcmicodes PDFDocument2 pagesJorcandkcmicodes PDFBisma SalimudinNo ratings yet

- SSDK Mine Basic InformationDocument2 pagesSSDK Mine Basic InformationAchmad Doanx100% (1)

- Longwall MiningDocument2 pagesLongwall MiningRiswan RiswanNo ratings yet

- QatarEnergy Annual Review 2020 - EnglishDocument174 pagesQatarEnergy Annual Review 2020 - Englishnunya businessNo ratings yet

- 2021 Oil &gas Storage and TransportationDocument3 pages2021 Oil &gas Storage and TransportationSyed Mohd Raza TaqviNo ratings yet

- Extraction (L)Document45 pagesExtraction (L)Praveen yadavNo ratings yet

- Para Oficina de Oir 04-Noviembre-2019: Marca Modelo Serie B.H.P. Combustible Tipo Fecha DE Fabricacion InstalacionDocument49 pagesPara Oficina de Oir 04-Noviembre-2019: Marca Modelo Serie B.H.P. Combustible Tipo Fecha DE Fabricacion InstalacionLuis FinquinNo ratings yet

- Ministry of OIl & Gas India Statistics 1617Document222 pagesMinistry of OIl & Gas India Statistics 1617R LNNo ratings yet