Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

16 viewsTermodinamika Chapter 8 Ed 7

Termodinamika Chapter 8 Ed 7

Uploaded by

mutiara eva syehrinaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Desain Penutup Dibawah Tekanan Luar (External Pressure)Document14 pagesDesain Penutup Dibawah Tekanan Luar (External Pressure)mutiara eva syehrinaNo ratings yet

- Moduli of Elasticity of Carbon Steel Million PsiDocument1 pageModuli of Elasticity of Carbon Steel Million Psimutiara eva syehrinaNo ratings yet

- Intro To Water TreatmentDocument30 pagesIntro To Water Treatmentmutiara eva syehrinaNo ratings yet

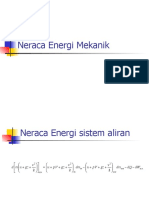

- Neraca Energi MekanikDocument9 pagesNeraca Energi Mekanikmutiara eva syehrinaNo ratings yet

Termodinamika Chapter 8 Ed 7

Termodinamika Chapter 8 Ed 7

Uploaded by

mutiara eva syehrina0 ratings0% found this document useful (0 votes)

16 views13 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

16 views13 pagesTermodinamika Chapter 8 Ed 7

Termodinamika Chapter 8 Ed 7

Uploaded by

mutiara eva syehrinaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 13

chapter 8

chapter” —

Production of Power from Heat

he mechanical energy us

Jear power, the sun is the ultimate soure Of fa im the sun is faage it

Except for nuclear power: the 9 A TT reaches the earth fro! s 2, but

by mankind. The total rate aetface is small. Energy gathered over a lage

rf

t which it falls on a square meter o! ¢ sutarees

Sere required to make practical its use in any large-scale production of Kk Neveteles,

solar photovoltaic cells are used for electric power in small-scale special app! Solar

sotatron alco finds direct application for heating water and buildings, for generation of high

temperatures in metallurgical applications (solar furnaces), and for evaporating water in the

production of salt |

The kinetic energy associated with atmospheric winds is increasingly used in favorable

locations to produce power by large windmills. The potential energy of tides is another possible

source of power, but production from these sources remains small in comparison with world

demands for energy. Eventually, such alternatives will become essential.

Significant hydroelectric power is generated by conversion of the potential energy of

ear eas ia ae Principle be accomplished with an efficiency of 100%.

tc and ar cy a ee ame the chemical molec) ene

"i lations for this purpose depend on the evolution

— .. a battery. Ae

; 5 ‘ontinuous!; trodes.

resul Acts With o) y to the elect

ting effic *YBEN 0 produce water through elect?

chemical conversion, The

ment over processes

iency

anes 4, 8 that first

applicati convert chem, AS pre: r h ‘

inSee. 13.10. Pomation, and ay ea cnergy ine i 85%, aconsiderable improve

° ind other y, . This technology has pote”

SES. Its

theoretical basis is consider

290

1, The Steam Power Plant mn

In a conventional power plant the molecular energy of fuel is released by a combustion

‘ocess. The function of the work-producing device is to convert part of the heat of com-

pian into mechanical energy. In a nuclear power plant the fission process releases energy

wae nucleus of the atom as heat, which is then partially converted into work. Thus, the

thermodynamic analysis of heat engines, as presented in this chapter, applies equally well to

“omventional (fossil-fuel) and nuclear power plants.

‘The steam power plant is a large-scale heat engine in which the working fluid (H20) is in

sieady-state flow successively through a pump, a boiler, a turbine, and a condenser in a cyclic

recess (SCC. 5.2). The working fluid is separated from the heat source, and heat is transferred

ross a physical boundary. In a fossil-fuel-fired plant the combustion gases are separated from

the steam by boiler-tube walls.

The internal-combustion engine is another form of heat engine, wherein high tempera-

tures are attained by conversion of the chemical energy of a fuel directly into internal energy

within the work-producing device. Examples are Otto and Diesel engines and the gas turbine.!

This chapter is devoted to the analysis of several common heat-engine cycles.

Gy

Boiler

WW, (turbine)

Turbine

Figure 8.1: Simple

steam power plant.

Condenser

81 THE STEAM POWER PLANT

The Camot-engine cycle, described in Sec. 5.2, operates reversibly and consists of two isother-

al Seps connected by two adiabatic steps. In the isothermal step at higher temperature Try,

IQ 1 is absorbed by the working fluid of the engine, and in the isothermal step at lower

1

wept of steam power plants and internal-comt

Combs ammers, ‘Steam Plant Operation, 6th ed..

” Engine in Theory and Practice: Thermodynamics,

bastion engines can be found in E. B. Woodruff, H. B. Lammers,

"McGraw-Hill, New York, 1992; and C. F. Taylor, The Internal

Fluid Flow. Performance, MIT Press. Boston, 1984,

|APTER 8. Production of Power from 1. Heat

CH:

292

.3: The Rankine cycle,

Figure 8.2: Camot eyele on a 75 diagram. Figure 8.3: Th cycle.

‘The work produced is |W] = |Qul—|Qcl,

temperature Tc, heat |Qcl is discarded by the fu

and the thermal efficiency of the Carnot engine is:

wt Te (5.8)

lQal Tu

Clearly, 9 increases as Ty increases and as Te decreases. Although the efficiencies of practical

heat engines are lowered by irreversibilities, it is still true that their efficiencies are increased

when the average temperature at which heat is absorbed is increased and when the average

temperature at which heat is rejected is decreased.

re 8.1 shows a simple steady-state steady-flow process in which steam generated in

a boiler is expanded in an adiabatic turbine to produce work. The discharge stream from the

turbine passes to a condenser from which it is pumped adiabatically back to the boiler. The

power produced by the turbine is much greater than the pump requirement, and the net power

‘output is equal to the difference between the rate of heat input i iler 10

e , the rate

of heat rejection in the condenser |Oc|. mecca Hace

‘The processes that occur as the workin,

represented by lines on the TS diagram of Fi

1

ig fluid flows around the cycle of Fig. 8.1 a

. 8.2. The i =

represented ass Fig. sequence of lines shown con

sanwaled ligald wate” abeonbe rare the sition process taking place in the boiler, whet

ees ort 5 ye constant temperature Ty, and produces satural

Is a reversible, adiabatic expansion of saturated apoE Ia the two-phis

and vay is i ; jon is

23 oy gall and vapor at Tc. This isentropic expansion

Y of the Camot cycle j

ycle just described j :

aS a standard of Sescribed is given reversible

lies attend ty bel comparison for Saal ate by Eq. a) tel a ower

that take nt Operation of equipmen yam Power plants. HE, 3

in saturated steamy ctuPMent intended to carry out steps?

Produce an exhaust with high liquid O™

cycle, it could serve

rbines

ge Steam Power Plant 293

h eauses severe erosion problems?

whic! Even more difficult is the design of a pump that takes

jna mixture of liquid and vapor (point 4) and discharges a saturated liquid (point 1). For these

iysons, a altemative model cycle js taken as the standard, at least for fossil-fuel-burning

“ver plants. It is called the Rankine cycle, and differs from the cycle of Fig. 8.2 in two major

Mipects. First, the heating step | ~» 2 is carried well beyond vaporization, so as to produce a

superheated Vapor. and second, the cooling step 3 + 4 brings about complete condensation,

‘eling saturated liquid to be pumped to the boiler. The Rankine cycle therefore consists of

jhe four steps shown by Fig. 8.3, and described as follows

2 1 + 2 A constant-pressure heating, process in a boiler. The step lies along an isobar

(the pressure of the boiler), and consists of three sections: heating of subcooled liquid

water (o its saturation temperature, vaporization at constant temperature and pressure,

and superheating of the vapor to a temperature well above its saturation temperature.

«2+ 3 Reversible, adiabatic (isentropic) expansion of vapor in a turbine to the pressure

of the condenser. The step normally crosses the saturation curve, producing a wet ex-

haust. However, the superheating accomplished in step | —> 2 shifts the vertical line far

enough to the right on Fig. 8.3 that the moisture content is not too large.

#3 4 A constant-pressure, constant-temperature process in a condenser to produce

saturated liquid at point 4.

4-41 Reversible, adiabatic (isentropic) pumping of the saturated liquid to the pressure

of the boiler, producing compressed (subcooled) liquid. The vertical line (whose length

is exaggerated in Fig. 8.3) is very short, because the temperature rise associated with

compression of a liquid is small.

Figure 8.4: Simple

practical power cycle.

Power plants can be built to operate on a cycle that departs from the Rankine cycle solely

because of the imeversibilities of the work-producing and work-requiring steps. Figure 8.4

|g Nevenbcess, present-day nuclear power plants generate saturated steam and operate with turbines designed to

| Saud wt various stages of expansion,

Production of Power fom

7

CHAPTER 8.

vod _+ Zand 4 — 1. The lines

cea ‘The turbine exhaust is toma

ethan about 10%, erosion Problems ap

e condenser may Occur, but the fect

bilities OF S

f increasint

intent is les:

re in the

irreve!

illustrates the effects of these inetion 7

Tonger vertical, but tend in the ee

still wet, but as long as the m the condensat

not serious. Slight subcooling ©

inconsequential.

‘The boiler serves (©

cycle, and the condenser trans

and potential-energy changes Te

case to:

lear react

ing fuel (or from a nuc 01) to

aycle «the surroundings. Neglecting kine

transfer heat from

relations, Eqs. (2.31) and (2.32), in eige

fers heat from t

.duces the energy

Q=4H (8.2)

ganan | BD

ir il it . 7.2 and 7.3.

‘Turbine and pump calculations are treated in detail in Secs.

-Example 8.1

Steam generated in a power plant at a pressure of 8,600 kPa and a temperature of

500°C is fed to a turbine. Exhaust from the turbine enters a condenser at 10 kPa,

where it is condensed to saturated liquid, which is then pumped to the boiler,

(a) What is the thermal efficiency of a Rankine cycle operating at these condi-

tions?

(6) What is the thermal efficiency of a Practical cycle operating at these conditions

ithe turbine efficiency and pump efficiency are both 0.757

(c) t ane a Of the power cycle of part (6) is 80,000 kW, what is the steam rate

‘anet are the heat-transter rates in the boiler and condencors

Solution 8.1

(Ms =~1.2742 44 ke~!

Ws isenteopi

Mo. (isentropic) — (AH)s = _} 20.

"eover, the enthalpy atthe en 274.2 ki kg-l

tof ;

of isentropic ©Xpansion, H/

acer |

Thus

, in Ex. 7.6, is here:

B= 74g kgo!

= 45.83°C) js:

191.8 kd kgt

Plant

4. The Steam Power 295

‘thus by Bq. (8.2) applied to the condenser,

Q(condenser) = Hg — H3 = 191.8~ 2,117.4 — 1,925.6 I ko!

where the minus sign signifies that heat flows out of the system

The pump operates under essentially the same conditions as the pump of

Ex. 7.10, where:

W, (isentropic) = (AH)s = 8.7 kgo!

Whence, = Hy = Ha + (AH)s = 191.8 4.8.7 = 200.5 kg!

The enthalpy of superheated steam at 8,600 kPa and 500°C is:

Hy = 3,391.6 kJ kgé!

By Eq. (8.2) applied to the boiler,

Q(boiler) = H — H, = 3,391.6 — 200.5 = 3,191.1 ki kg!

‘The net work of the Rankine cycle is the sum-of the turbine work-and the pump

work:

W, (Rankine) = —1,274.248.7 = —1,265.5 kJ kg!

This result is of course also:

W, (Rankine) = —Q(boiler) — Q(condenser)

= —3,191.1 + 1,925.6 = ~1,265.5 KJ kg-!

‘The thermal efficiency of the cycle is:

1W,(Rankine)| _ 1,265.5

Qboiler) 3191.1

= 0.3966

(®) With a turbine efficiency of 0.75, then also from Ex. 7.6:

W, (turbine) = AH = —955.6 kJ kg~!

Whence Hy = Hy + AH = 3,391.6 — 955.6 = 2,436.0 I kg!

For the condenser,

1

Q(condenser) = Hy — Hs = 191.8 — 2,436.0 = —2,244.2 kd kg

BY Ex. 7.10 for the pump,

W, (pump) = AH = 11.6 KJ kg~!

‘The net work of the cycle is therefore:

—

W, (net) = —955.6 + 11.6 = —944.0 kJ kg”

prER 8. Production of Powe;

on . PEE OM Hey

296 :

296 _

Hy = Hi: pan 198+ 16 = 203 4

id 2 Hs

: -Hi = 3,391.6 — 203.4 = 3,188.2 kJ kg!

1 = 3,391.

Then boiler) = #2

cy of te eyele is therefore:

“The thermal efficie

[We(net)| 944.0 _ 9.2961

1= Qcpoiler) 3,188.

B

which may be compared with the result of part (a).

(c) For a power rating of 80,000 kW:

W,(net) = rit W, (net)

. _ We(net) _ —80,000 kJ

m= Welnet) 944.0 J kg

red

or 84.75 kg s

‘Then by Eq. (8.1),

Oboiler) = (84.75)(3,188.2) = 270.2 x 10° kJ s~!

G(condenser) = (84.75)(—2,244,2)

190.2 x 10° kJ s-!

Note that Orboiler) + O(condenser) = — Ww, (net)

—————___

The Regenerative Cycle

‘The thermal efficiency of a st reased

herm a steam power cycle is j

as ‘amperature in the boiler is raised, tt isalse irene increased a wet

these same condi ler pressures and t igh of ss Howe

sae conditions ete gee ae sia bigh prea

“ause they require

Westment in

Severe conditions are impose ou Moreover, these costs increase ever

i 000 kPa ~ Thus, in practice power plants seldom

Power plant increases as the press Peratures much above pans The

ensation temperature ene the temperature in the condesst

the cooling medi

ium, usu; must be higher than the temperature

b ture

Se°graphy. Power plants univers 2% this is con

ith

mod niversall trolled b i eral

oe Pow y y local

Tates feedwater : " ‘er plants o, -ondenser a of cla

the boiler, is first he ‘ater from the & Modification fe ee i a mm i

stages, with stea Y Steam ; Rankine faa

rangement eae taken From the ned from the pi, ae being pumped directly bark

on this Get four feedwater rei at turbine. This is y done in cr

BUTE and described jee is normally done in 5

town in Fig 8 gue States of expansion. *

8 paragraphs Le OPerating conditions indict

oe

illustrative calculations of man a

2. St typical, and are the basis 0°

P= 2,900 kPa

P= 1,150 kPa

Condenser

Feedwater heaters

Figure 8.5: Steam power plant with feedwater heating.

Ss aed of steam generation in the boiler are the same as in Ex. 8.1: 8,600 kPa

ee eieed erie ‘of the turbine, 10 KPa, is also the same. The saturation

teemndenan e exhaust steam is therefore 45.83°C. Allowing for slight subcooling of

fedvater purnp, wi fix the temperature of the liquid water from the condenses a 45°C. The

Hemperature P, Which operates under exactly the conditions of the pump in Ex. 7.10, causes

‘theaters engarnn of about 1°C, making the temperature of the feedwater entering the series

Th equal to 46°C.

te oe temperature of steam at

ature ig ae ‘to which the feedwater can be

be ncesign variable, whichis ultimately fixed by ecot

Must be chosen before any thermodynamic calculations ct tbe made. We have therefore

marly specified a temperature of 226°C for the feedwatet stream entering the boiler. We

ial specified that all four feedwater heaters accomplish the same temperature rise. Thus,

sacl temperature rise of 226 — 46 = 180°C is vided into four 45°C increments. This

tures atthe values shown on FB: 8.5.

ssure high enough that its

i ata pres

ayn” temperature is above that of the ving the ate, We have Hee

St minimum temperature difference £0 heat transfer of ;

leas un steam pressures such that

Breater than the exit temperatures °

the boiler pressure of 8,600 kPa is 300.06°C, and

raised in the heaters is certainly less. This tem-

nomic considerations. However, a

rhea os shown inthe feedwater heaters 0

ed the feedwater streams. THE condensate from

CHAPTER 8. Production of Power fron .

Sy

298 _—— .

“i ie valve to the barat at : e ioe lower 34

eri fh i series is flashed into the condense,

each feedwater heatets ne eral hes sia io en < :

collected condens! .

and the colle s from the condens He are false the average as

allsondensate Fetus ram 1 6 ay,

ete esd to Fn the boiler. This ine he his

at which heat is added ier.

said to operate on a regenerative evel

Ee

a throttl

eases tl

Example 8.2 — /

Determine the thermal efficiency of the power plant aN eee cen te

bine and pump efficiencies of 0.75. If its power rating is Dr i iat is the

rate from the boiler and what are the heat-transfer rates in the boiler and Condenser

Solution 8.2

Initial calculations are made on the basis of 1 kg of steam entering the turbine

from the boiler. The turbine is in effect divided into five sections, as indicated in

Fig. 8.5. Because steam is extracted at the end of each section, the flow rate in the

\¢ decreases from one section to the next. The amounts of steam extracted

from the first four sections are determined by energy balances.

‘This requires enthalpies of the compressed feedwater streams. The effect of

pressure at constant temperature on a liquid is given by Eq. (7.25):

ASH=V(1-BT)AP (const T)

For saturated liquid water at 226°C (499.15 K), the steam tables provide:

PM =2598.2kPa HH =9TLSK ke! v= 1,201 em? kee!

In addition, at this temperature,

B = 1.582 x 10-3 K-!

‘Thus, for a pressure change from the Saturation pressure to 8,600 kPa:

Skike!

AH = 1.201{1 ~ (1.528 x 10-499, 15)}{8:600 ~ 2,598.2)

105

and _ .

me H = H(sat. liq.) + AH = 971.5 +15 = 973.0 kd kg!

Sint Calculations yield the enthalpies of the feedwat ~~

ent values are given inthe following table,” St tet “o™P™

17°C

26 181

HIS kg" for water at ca =

and P= 8,600 kPa 9

73.0 7713 57.4 3875 2000

‘The Steam Power Plant

1

a ”

rhooted .

Tio sue - ——

rom boil :

re

12 5006

"Same Pr

Stoam food to

section Il

P= 2,900 Pe Figure 8.6

W 3,151.2 :

“a = 363.68°C Section Lof

whe0 ‘Vkg fiquid 5 = 6.8150 turbine and first

ime aes feedwater beater.

1= 226°C ot ee

H= 9730 r= ere

H=™M3

mkg condensate

Soturated ii

t 2,900 Pa

2 23197°C

H= 9995

Consider the first section of the turbine and the first feedwater heater, as shown

by Fig. 8.6. The enthalpy and entropy of the steam entering the turbine are found

from the tables for superheated steam. The assumption of isentropic expansion of

steam in section I of the turbine to 2,900 kPa leads to the result:

(AH)s = ~320.5 1d kg™!

If we assume that the turbine efficiency is independent of the pressure to which

the steam expands, then Eq. (7.16) gives:

AH = n(AH)s = (0.15)(-320.5) = —240.4 kg"!

AH =-240.415

By Eq. (7.14), woo

Inaddition, the enthalpy of steam discharged from this section of the turbine is:

H = 3,391.6 — 240.4 = 3,151.2 KI ke!

water heater results from the assump-

a Oe aay a te and from the assign-

tion that kinetic- and ial: changes are negligib!

} potential-energy ;

™ents, @ = —W, = 0. Equation (2.30) then reduces to:

AnH ts = 0

Cm —*

300 Enthalpy: ki kg-1

Entropy: kd kg-1K-1

Steam feed to

section I

P= 1,150KPe

‘H = 2,987.

Figure 8.7: Section I! 2.9878

of turbine and second

feedwater heater.

1 kg water

n= SITs

H=™3

{0.09374 + m) kg

condensate

ee ‘Saturated liquid

one sraiso KPa

1 = 186,05°C

n= 7889

oo

‘This equation gives mathematical expression to the requirement that the total en-

thalpy change for the process be zero, Thus on the basis of 1 kg of steam entering

the turbine (Fig. 8.6):

m(999.5 — 3,151.2) + (1)(973.0 — 771.3) = 0

Whence, sm = 0.09374 kg

On the basis of 1 kg of steam entering the turbi

teri _ es

flowing into section ofthe turbine, Sines ¢ —m is the mass of sea

Section II of the turbine and th

In doing the same eaclaions as for sention ana ae shown in ni

steam leaving section II

and 1 —m = 0.90626 kg

H = 2987813 kp~

987.8 KI kgé!

‘Then on the basis of | k,

BOF Steam enterin,

8 the turbi

We) = oo

(2,987.8 —

8 3.151.2)(0,90626) = ~148.08 kJ

Pers

aqeam Powes Plant

301

tm

soergy balance O7 the feedwater heater (Fig. 8.7) gives:

arenes :

(0.09374 + m)(789.9) — (0.09374)(999.5)

— m(2,987.8) + (1)(771.3 — 577.4) =0

whence m = 0.07971 kg

ve tat toting the condensate stream does not change its enthalpy.

ts and those of similar calculations for the remaining sections of

* qhese results ane .

ihe turbine are listed in the accompanying table. From the results shown,

> Ws = 804.010 and Yim = 0.3055 kg

Nee ey Tanner ara

Hik} kg"! Ws/k3 PCat mikg of

at section for section section steam

exit exit State extracted

Seal 3151.2 240.40 363.65. Superheated 0.09374

vapor

Sec. 2,987.8 148.08 272.48 Superheated 0.07928

vapor

Sec. II 2,827.4 132.65 183.84 Superheated 0.06993

vapor

Sec.1V 2,651.3 — 133.32 96.00 Wet vapor 0.06257

x = 0.9919

Sec.V 2,435.9 149.59 45.83 Wet vapot

x = 0.9378

Thus for every kilogram of steam entering the turbine, the work produced is

8040 k5, and 0.3055 kg of steam is extracted from the turbine for the feedwater

heaters, The work required by the pump is exactly the work calculated for the

pamp in Ex. 7.10, that is, 11.6 kJ. The net work ‘of the cycle on the basis of 1 KE

of steam generated in the boiler is therefore:

W, (net) = —804.0 + 11.6 = 792.4 KS

On the same basis, the heat added in the boiler is:

QO(boiler) = 4H = 3,391.6 — 973.0 = 2,418.6 KI

The thermal efficiency of the cycle is therefore:

iwy(ned _ 7924 — 03276

1= Qqpoilen) ZAl8.6

8 significant improvement over the value

Che

30,000 5°

et) =

3

se Wat _

Because 90,000 __ 100,96 ke 7!

x92

0 calculate the he

We (ned) _

W, (net)

eat-transfer rate in the

turbine, used |

This is the steam rate (0 the

boiler: :

Otboile = 7 AH= (100.96)(2.418.6) = 244.2 x 10° KI s

iter) =

The heat-transfer rate (0 the cooling water in the condenser IS:

Ne heat

— Qrboiler) - Ws(net)

O(condenser) =

— (-80.0 x 10°) = 164.2 x 10° kJ s“!

= -244.2 x 10°

rate is higher than was found in Ex. 8.1, the heat-

Although the steam generation

because their func-

transfer rates in the boiler and condenser are appreciably less,

tions are partly taken over by the feedwater heaters.

__

‘8.2 .INTERNAL-COMBUSTION ENGINES

In a steam power

plant, the steam is an i

i 3 an i ,

baring fuel or from a nuclear reactor Tee esa (© Which heat is transferred for

: Ii

surfaces: (1) for the absorption of heat b is therefore characterized by large heat-transfet

Ie wall: i

Of heat ae” withstand high temperatures and pres

feat absorpti "

thin the engi 2 82 internal-combustion engine,

example on and the combustion products

imposes a limit on the t

temperat

te ater hand, a fuel is bared

working medium, acting for

internal, and do not in

; Wwolve heat- a piston j :

Pea Moteover, fuel and air fow stexqy en eestiOn engi

in low steadily out of en te SALY into an intense cOmPlicat amic

&@ steam power Of it; no Work: an internal. tes thermodyn ‘ot

i * plant. However, povine Medium und bust

i for mi nde

king Ai ae 7 et

engines. In addition, ee tha ‘aking simple Pie! a cyclic process, as does 5°

thal are equivalene ee analyses, one imagines cyclic em,

In what fol A in performance 1 imagines cyclic cris

to actual internal-com!

- ‘at

lt

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Desain Penutup Dibawah Tekanan Luar (External Pressure)Document14 pagesDesain Penutup Dibawah Tekanan Luar (External Pressure)mutiara eva syehrinaNo ratings yet

- Moduli of Elasticity of Carbon Steel Million PsiDocument1 pageModuli of Elasticity of Carbon Steel Million Psimutiara eva syehrinaNo ratings yet

- Intro To Water TreatmentDocument30 pagesIntro To Water Treatmentmutiara eva syehrinaNo ratings yet

- Neraca Energi MekanikDocument9 pagesNeraca Energi Mekanikmutiara eva syehrinaNo ratings yet