Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

12 viewsEquilibrium Flash Calculation

Equilibrium Flash Calculation

Uploaded by

Aatish ChandrawarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 02.understanding Process Equipment For Operators & Engineers-66Document5 pages02.understanding Process Equipment For Operators & Engineers-66Aatish ChandrawarNo ratings yet

- 07.troubleshooting Vacuum Systems-79Document3 pages07.troubleshooting Vacuum Systems-79Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-53Document5 pages02.understanding Process Equipment For Operators & Engineers-53Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-49Document5 pages02.understanding Process Equipment For Operators & Engineers-49Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-67Document5 pages02.understanding Process Equipment For Operators & Engineers-67Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-54Document5 pages02.understanding Process Equipment For Operators & Engineers-54Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-40Document5 pages02.understanding Process Equipment For Operators & Engineers-40Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-37Document5 pages02.understanding Process Equipment For Operators & Engineers-37Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-38Document5 pages02.understanding Process Equipment For Operators & Engineers-38Aatish ChandrawarNo ratings yet

- Thermosyphon Vs Kettle Reboiler - Process Heat TraDocument7 pagesThermosyphon Vs Kettle Reboiler - Process Heat TraAatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-65Document5 pages02.understanding Process Equipment For Operators & Engineers-65Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-64Document5 pages02.understanding Process Equipment For Operators & Engineers-64Aatish ChandrawarNo ratings yet

- Refinery and Petrochemical Line Sizing CriteriaDocument9 pagesRefinery and Petrochemical Line Sizing CriteriaAatish ChandrawarNo ratings yet

- Zero Velocity Valves For Water Hammer Prevention (PDF) - What Is PipingDocument4 pagesZero Velocity Valves For Water Hammer Prevention (PDF) - What Is PipingAatish ChandrawarNo ratings yet

- Select The Right Reboiler - Chemical Processing: "Reboiler Selection Requires Several Critical Choices."Document7 pagesSelect The Right Reboiler - Chemical Processing: "Reboiler Selection Requires Several Critical Choices."Aatish ChandrawarNo ratings yet

- Flame Detector SelectionDocument9 pagesFlame Detector SelectionAatish ChandrawarNo ratings yet

- Proper Valve SelectionDocument3 pagesProper Valve SelectionAatish ChandrawarNo ratings yet

- Guidelines For Slurry PipingDocument6 pagesGuidelines For Slurry PipingAatish ChandrawarNo ratings yet

- Rotameters-Variable Area Flow Meters Tech Info From MasterflexDocument4 pagesRotameters-Variable Area Flow Meters Tech Info From MasterflexAatish ChandrawarNo ratings yet

- When To Choose Variable-Area Flow Meters From MasterflexDocument4 pagesWhen To Choose Variable-Area Flow Meters From MasterflexAatish ChandrawarNo ratings yet

- EXAMPLE-Air and Flue Gas PropertiesDocument2 pagesEXAMPLE-Air and Flue Gas PropertiesAatish ChandrawarNo ratings yet

- Facts at Your Fingertips-48-60Document13 pagesFacts at Your Fingertips-48-60Aatish ChandrawarNo ratings yet

- Compressor Power Calculator: Fluid CharacteristicsDocument2 pagesCompressor Power Calculator: Fluid CharacteristicsAatish ChandrawarNo ratings yet

Equilibrium Flash Calculation

Equilibrium Flash Calculation

Uploaded by

Aatish Chandrawar0 ratings0% found this document useful (0 votes)

12 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

12 views4 pagesEquilibrium Flash Calculation

Equilibrium Flash Calculation

Uploaded by

Aatish ChandrawarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

seni OeNA

Equilibrium flash calculations

quickly computed on PC

A. K. Coker | Results are obtained much | which are time consuming,

Davy Energy & | faster than with provicusly | tedious, and subject to errorit

Environmental Lid. | published programs.’ performed manually. Previ-

Cleveland, UK. | "Flash vaporization calcula- | ous calculation procedures,

tions involving mulicompon- | invalved the use of program

Equlixium flash calcula- | ent mixtures are essenial to | mable calculators which, with

tions can be computed quick: | the design and successful | the growing use of personal

ly by an Interactve Fortran | operation of many processes. | compulers, are becoming ob-

program developed for per- | These calculations are often | solete

Sonal computers. The pro | required to determine the | — Mulicomponent flash (iso-

{gram determines the equili- | condition of the feed to a | thermal and adiabatic) com-

lum separation of a stream | ‘factionation column or to de~ | putations are incorporated as

for multcomponent mixtures | termine the flow of vapor | part of overall process simu-

in ol ga8, and chemical pro: | from a rebiler or condenser. | lation and equipment design.

cesses, resulting ina liqud- | Flash calculations often in- | However, single-stage flash

\apor equillrium mizure. | volve taand-eror solutions | fractionation processes are

also employed to. ablain a

0.1 | separation of the ight com

5 ge ners in @ feed and as a

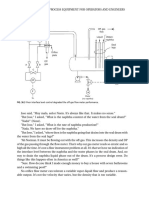

Continuous equilibrium flash fractionation eeiinary step before a

Mutticomponent fractionation

column, such as crude dist-

lation.

Table 1 lists ways of pro-

ducing two-phase mixes

from 2 single phase at appro-

priate conditone. Tho. ast

Process in the table typifies

the wellhead separation that

takes place in anol fed, tis

termed @ flash process be-

‘cause vapor forms as aresult

of rapidly dropping the pres-

sure.

Int tigi flow at, F, moter

Moe fraston,m,

Hester o produce

ear stated id

Fundamentals

To carry out an appropriate

flash cakulation, the pres-

sure, P, and the temperature,

T, must be known. I the val-

as of P and Tin the separat-

ing vessel are fixed, the value

Nomenclature of P must not be so high that

two phases cannot exist at

guid rato, 1, molest

EF = Congas ‘any value of T.

K° = iol fash constant foreach conponert nro fod arean | Hoa Tie outside of

‘a ell et ernps' i eta pace

E = Toi ies of au pe nce tho bubble point and. dow

TN’ = Ne facton of conponen th fou seam point range corresponding to

21 NoRootrZomeorent ine ood even P. For a valid two-phase

B= Ligure (Uv rato (taut vabe of = 10) qulrium calculation, the

= $5ih ie ec nent atone following relationship must be

Y= [Bil rls of pmponen inte vapor pase satisied:

YS 1G Petey Psat ne Nu nase

3) Ns fasten o compere in he weber anese

Top < Ta < Top

Table 1

Ways to produce

two-phase mixture

‘etion to proses two-phase mics

‘ck, possi ate inal comprossion

Exe tough a ah or anengn

Het to actiove parte vapor

eshte fesse trough ave, ose

‘where: Tap is the bubble point .

temperature, T, is the speci- f= 2 Km (1)

fied temperature, and Tuy is o

the dew point temperature.

The existence of a valid | Dew point

two-phase flash can be veri- el

fied with the design equa- | {, - % Yk, @

tions for the bubble

dew point, and equilbrium | Table 2 illustrates the

ata calcuiated at the speci- | phase condition using the liq-

fied pressure and tempora- | uid-vapor data associated

ture.

with the specified pressure

The design equations for | and temperature.

the bubble and dew points | From Table 2, the condi-

are:

Bubble point:

Nine-component mixture (Example 1)

outpet

tion for a valid two-phase

‘equilibrium flash is (see box

for nomenclature)

Fold sream data

Equilibrium flash

‘Table 2

criteria

h= & Kn>10 @)

fe

= mK > 1.0 (4)

Feed analyses in terms of

‘component concentrations

are normally not available for

‘complex hydrocarbon. mix-

tures with a final boing point

‘more than about 38°C. (e.g.,

‘n-pentane) unless such a

feed is broken down into

| pseudo components (narrow

Table 9

‘Component

Number smolesie cone

4 aie

2 ies

3 2318

i ‘Se

5 ane

é tre

E 26

3 a

: 4

Inout

but fash temperate, “7 ~

Input fash prose, pa? yo

Input number of coranonts?

feed and tgatonum ofeach component? 27520 7.2.

inpa 1

Nullconpenontequltrum fash caouaon at 90.0" F. and 370.0 psi

Totals

o Nes

Feed, auis

Molesiir Mole ac. _Meles/iv Mole frac. _Molosr

2ysa000 0278 «3883590072

fosso0 Ges aang Oa

2b1e000 Game aenaer © O70

Soro osa “agar Game

17igo00 O72 saabaet Ora

‘treo ots “4eh0e1 8600

216.000 Gee © 2osaes © 0 os

‘rom 008 “Agate «Boas

“000.000 ‘Ser Oo!

10900.000 1.000 5,418.00 1.000

1p yeu want orminate the program? Yes

| boiling fractions). This en-

ables the mole traction and

equilibrium constant, K, to be

estimated and, consequently,

flash calculation of the mix:

ture can be carried out A

continuous equilbrium flash

fractionation process is,

shown in Fig. 1.

Effient techriques for the

solution of the trial-and-error

calculations necessary in

‘mutticomponent flash compu:

tations are given by Smith,

Hengscbook, King, and Of

5. However, the iterate

Convergonce. method Test

suggested by Olver, and lat-

fer modifed by Kostecke, is

employed in the program.’ 2

Flash calculation equations

The equations used in the

program for multicomponent

librium flash calculations

& nik <1 all iquig(5)

nik <1 all vapor(6)

C= IM(K—1)(R+ TY

(K+R) ”

where: Rl = the liquid-vapor

(UN) ratio.

The now LIV ratio for each

iterative calculation, F’, is de-

termined from:

= (FR ~ EIR + 1)

+ ER + 1) ®)

Where the constants E and F

are determined from:

E=-26 ®

F= % (ym (10)

‘The computation then de-

termines_whether |E|_ «

0.001. I Elis not less than sabe

0.001, R is set equal to R’ je ic

and tle cacuistons of Equa | GAS liquefaction (Example 2)

tions 7,8, 9, and 10 are as a

repeated until |E) ~ 0.001. Eecerd

Once || < 0.001, the cal- umber snot ation _ Sona K

culation proceeds to Equa- : ages a oa

tions 11 and 12: 2 baer B70

: Baier Bae

L=MANK +R) (1) | 2 Soe S38

é Sour ae

MeM—b (12) é Som = Sam

3 ones = So007

‘The mole fractions of com-

ponents in tho food and the top 3

liquid and vapor phases are Ip ash temperate?

evaluated as follows: Ut weber cis =

Input fod and eal K of each component? 1.2. 0.90,

a Bar Sh

nom SM (13) ia 0

8 oom

£7 ose

i 38 bors

af aoe

wt & (14) 24 0.0007

utput

Miatlsomponertaquitism fash calculation at 200" F, 2nd 6000 pst

va

f

i

i

f

Bvt (16)

The program | eer

‘The Fortran program de- | rome sooo 1000 sonst 1000

veloped forthe fash caloula-

veloped! forthe Hash calOU | po you wal o emirate he pga? Yeuio

can bo run on IBM or IBM

Compatible personal comput- | program, and the program | The first example is a 9- | misturo at equloqum conci-

fre wih the MS DOS operal- | Gan be operated ether rom a | component stil product accs- | tons of 100 psia and. 160°

ing system. The program is | floppy diskette or it can be | mulator stream that is com- | F.”° Table 6 gives the feed

bavod. on the vapor-iquid | loaded onto a hard disk. | pressed. to 370. psia and | stream Gata and results.

‘equilibrium relationships giv- To operate the program, | cooled to 90° F.* The pro-

fn in handbooks avaiable | simply log onto the appropr- | gram is used to determine | Edltor’s note: OGY sub-

ffom the Ges Provessors | ate’ rive and type “FLA. | the amount of fquid and va- | scrbers may obtain a ee

Supplors Associaton, Tulsa, | SH.EXE” or “FLASH”. If | por produced at these cond | copy ofthe complete operat.

and other literature. printed results are required, | tions. Feed stream data and | ing program on diskette by

The program will handle | simply press the PriSc key on | the program's results are | sending a blank, 6% in. Hop-

‘ash calculations with feed | the keyboard. shown in Table 3. py diskette, iormatted to MS

streams containing up 10 15 | The program is not appi- | The second example | DOS, and a self~addressed,

‘components. As an added | cable to an adiabatic flash | flashes a feed stream to a | postage-paid or stamped re-

feature, the calculation will | process when the feed | natural gas liquotaction plant. | tum diskette mailer to: Refin-

check the feed composition | stream is at a higher pres- | The feed is flashed at 600 | ing/Petrochemical Editor, Oil

at fiash conditions for dew | sure than the flash pressure, | psia and 20°F The program | & Gas Joumal, P.O. Box

point and bubble point (i.e., | and the heat for vaporization | determines the flow rates of | 7947, Houston, TX, U.S.A,

Whether the feed is elther all | is provided by the enthalpy of | the liquid and vapor streams | 77257.

vapor or all liquid), the feed. In this situation, the | at a feed flowrate of 1,000 | Subscribers outside of the

These checks are per- | flash temperature will be un- | moles/h. US. send the diskette and

formed before the flash cal- | known and must be obtained | Feed stream data and the | return mailer without return

culations are started. If the | by tial and error. pprogram’s results are shown | postage to the same ad-

feed is above the dew point | A temperature must be | in Table 4. dress. This offer will expire

fr below the bubble point, an | found at which both the mate- | 12-component mixture is | Mar. 31, 199.

‘appropriate message is dis- | rial and energy balances are | flashed at 860 psia and —65"

played on the screen. A de- | satisfied. F. for the third example. Acknowledgment

‘aull value for R (LV ratio) Feed stream data and results | _ The author thanks Dr. C. J

1 is incorporated in the pro Examples | are shown in Table 5. Mumford, senior lecturer, AS-

gram to start the iterative | Fourexamples demonstrate | — Finally, the fourth example | ton University, UK. for the

process. Report-quelity out: | the use of the program and | determines the equilibrium | review of this work, and the

puts are generated by the | the results computed by ‘separation of a S-component | management of H&G Engi-

Twelve-component mixture (Example 3)

Feed sroam data

Table 6

Food Equitbeum

umber ‘Name __moloshr __coatant S

1 N 12g 2are a

2 caton dinite 120 Ota

§ Mebane 43962449

i inane ise (Oa

5 oe = O18

8 ‘Sobutane (ase

z neutne ears

8 opontano (Dos

3 ingen 13 os

to here Meets

it rep 8 ocor95

2 reeene 30 (Gages

out

Input fash temoeatue, 7 5

Input sah prose, pa? aso

Input number of compan? i

Ip food and eauttxum K ofeach componant? 1201.0 2674

200 sis

4.3020 440

Sigeo 0948

20860 Oe

200 aso

00 Gara

220 O0173

ia 80183

1120 9.0815,

a0” oeras

ee sn9 Gocose

Tutiecrnponent aquirium fash ealsuton st —65.0°F. and 8500 ia

cer see te SS Sui wage

om Kevalue __Molestiy Mole frac. _Melosinr Mole rac. Molesihr Mole fra.

3 2am 4201000 021 t2se28 ooo 1076178 oes

2 ots = “"230e0 © S000 S319 000 ‘aes 000

3 i gasoo0 © asi gowsors © Geet systauze © 9.00

4 aie —Sfovood © Ones Iom © Ore “Beant; © 9.000

3 Gite — Zogpoo —OuagTeatmns © tos ary Ba

é uss © “zane © ome “anees§= cars «anaes © oot

5 Sosr Geto oonr Saaee>cat Seaie Sone

8 017 —Yaso0e © ane tazse5 ous Bast 2.00

§ Soi —thso00 ous fasaes Gene 7am Smo

10 Goo = tigen © bone THozen coe [7s 9000

" Gon —“gaooa © oor “exe59 aus 2401 9.000

2 Got = Soc tot sas ae bor 800

Totala 58204000 4.000 14556559 1.000 49687492 4.000

Bo you want to terminate the proaram? YesNa

‘Tobie 6

Equilibrium separation (Example 4)

Food stream cata

‘Component

a

in Name _mow scion Sahat

i & 2 329

3 rah aise 7B

a eis s 13

i ee 8 pg

3 oh 8 oa

tno,

BS son tempore 2 1

Inc tach per, pon? 8

Inpro comsoneri?

IER gs aa mort Son 29

23 18

Bie

ret aren en 80 Fat 1200p

aad ee eee

= HOR RG, _Meahr Note.

i a ci 38

; is Es Be

i oe oe 33

fate 3s 28s

Do yeu want t trminate the program? YoeNo

The author. .

cater

‘4K. Colar is a process en

ter th Day Enea &

Imeal Lid) Suen on Tes,

Dead, UK He prevousiy

‘naw HEG ening ie

Bsgam, Uk

T1987 e186, caer ha

postdoctoral assijamen ih

‘hal Pealour Develo,

of igi Li and ha wid 2

{iacmiogsinte RED aepat

tmbet tive Cree Indust i

ek

(Cor reste BBs, Mo, and

ab dyes noua eng

eng for Aston User,

Brnghr, UX, He ep

fate maner of he neta 6

tity at Chama Enger, &

rember of ACN, ang 2 erp

fate manter of the rss

fen af Chemica Err

neering, Glasgow, U.K., tor

ppormission to publish this ar-

file.

References

Owen TH, “Hen caleulator gro-

‘am spcccn fash ealeuatens,

Gai, Mara, 1880, 130.

2.Rostete, ST, “Spood of hand

‘alelator poorams can De ir

proved,” OG, Aug 11, 1980,

‘or

3. Mansour, 5. “Flash Compute

‘vers ‘Cheinea Engineering,

Aes, 27, 1978

4. Blasiwell, WW, Chemical Proo-

‘eee Design on’ © Progamnable

acai, MeGra i ne, Now

York, 1908.

5, Pen, FLH, ad Green, D., Chem

cel" Engineers” Nencbook,

Mocraw Hil In., Now York,

‘ea

6. Sith, 8D, Design of Eqslstum

‘Stage Procossea, MaGrow ll

Ing, Now York, 1963.

7. Hongelabeck, FJ. Diettaion:

naples and Design Proce:

lures, Revolt Pabising. Co.

{001

£8. King, Ca, Saparaton Proceases,

Grau’ Hil Ino, Now: Yor,

san

9. Olver, EO, Ditsionl Separation

Proresses, John Wey & Sone,

4088,

10. Schacter, PLA, Handbook of

‘Separation Tocneiques or Cham

kel Engrows, MoGran Hin,

New York, 2nd Econ. 1088,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 02.understanding Process Equipment For Operators & Engineers-66Document5 pages02.understanding Process Equipment For Operators & Engineers-66Aatish ChandrawarNo ratings yet

- 07.troubleshooting Vacuum Systems-79Document3 pages07.troubleshooting Vacuum Systems-79Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-53Document5 pages02.understanding Process Equipment For Operators & Engineers-53Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-49Document5 pages02.understanding Process Equipment For Operators & Engineers-49Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-67Document5 pages02.understanding Process Equipment For Operators & Engineers-67Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-54Document5 pages02.understanding Process Equipment For Operators & Engineers-54Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-40Document5 pages02.understanding Process Equipment For Operators & Engineers-40Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-37Document5 pages02.understanding Process Equipment For Operators & Engineers-37Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-38Document5 pages02.understanding Process Equipment For Operators & Engineers-38Aatish ChandrawarNo ratings yet

- Thermosyphon Vs Kettle Reboiler - Process Heat TraDocument7 pagesThermosyphon Vs Kettle Reboiler - Process Heat TraAatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-65Document5 pages02.understanding Process Equipment For Operators & Engineers-65Aatish ChandrawarNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-64Document5 pages02.understanding Process Equipment For Operators & Engineers-64Aatish ChandrawarNo ratings yet

- Refinery and Petrochemical Line Sizing CriteriaDocument9 pagesRefinery and Petrochemical Line Sizing CriteriaAatish ChandrawarNo ratings yet

- Zero Velocity Valves For Water Hammer Prevention (PDF) - What Is PipingDocument4 pagesZero Velocity Valves For Water Hammer Prevention (PDF) - What Is PipingAatish ChandrawarNo ratings yet

- Select The Right Reboiler - Chemical Processing: "Reboiler Selection Requires Several Critical Choices."Document7 pagesSelect The Right Reboiler - Chemical Processing: "Reboiler Selection Requires Several Critical Choices."Aatish ChandrawarNo ratings yet

- Flame Detector SelectionDocument9 pagesFlame Detector SelectionAatish ChandrawarNo ratings yet

- Proper Valve SelectionDocument3 pagesProper Valve SelectionAatish ChandrawarNo ratings yet

- Guidelines For Slurry PipingDocument6 pagesGuidelines For Slurry PipingAatish ChandrawarNo ratings yet

- Rotameters-Variable Area Flow Meters Tech Info From MasterflexDocument4 pagesRotameters-Variable Area Flow Meters Tech Info From MasterflexAatish ChandrawarNo ratings yet

- When To Choose Variable-Area Flow Meters From MasterflexDocument4 pagesWhen To Choose Variable-Area Flow Meters From MasterflexAatish ChandrawarNo ratings yet

- EXAMPLE-Air and Flue Gas PropertiesDocument2 pagesEXAMPLE-Air and Flue Gas PropertiesAatish ChandrawarNo ratings yet

- Facts at Your Fingertips-48-60Document13 pagesFacts at Your Fingertips-48-60Aatish ChandrawarNo ratings yet

- Compressor Power Calculator: Fluid CharacteristicsDocument2 pagesCompressor Power Calculator: Fluid CharacteristicsAatish ChandrawarNo ratings yet