Professional Documents

Culture Documents

Thiobacillus Ferrooxidans: Particle Size Effects in The Microbiological Eaching Sulfide Concentrates by

Thiobacillus Ferrooxidans: Particle Size Effects in The Microbiological Eaching Sulfide Concentrates by

Uploaded by

W ZuoCopyright:

Available Formats

You might also like

- Case 2290 PDFDocument90 pagesCase 2290 PDFDarioNo ratings yet

- Mini ProjectDocument79 pagesMini ProjectadzhamNo ratings yet

- Water DesalinationDocument142 pagesWater DesalinationKhaleel Jaberov100% (1)

- Determination of Small Amounts of Water in Organic Solvents by Spectrophotometric AnalysisDocument13 pagesDetermination of Small Amounts of Water in Organic Solvents by Spectrophotometric AnalysisLUIS XVNo ratings yet

- Determination of The Mark-HouwinkDocument5 pagesDetermination of The Mark-HouwinkMariane AlcântaraNo ratings yet

- 무게분석 관련논문Document2 pages무게분석 관련논문간다고No ratings yet

- Synthesis, Characterization, and Use of A Cobalt (l1) Complex As An NMR Shift ReagentDocument2 pagesSynthesis, Characterization, and Use of A Cobalt (l1) Complex As An NMR Shift ReagentAliceNo ratings yet

- Teju Rs 3Document6 pagesTeju Rs 3chemicalcommunicationsocietyNo ratings yet

- Some Measure, Ments of Diffusion I N Liquids: Division UniversityDocument5 pagesSome Measure, Ments of Diffusion I N Liquids: Division Universityvan6_04No ratings yet

- 1955 The System Ba (NO3) 2-KNO3Document3 pages1955 The System Ba (NO3) 2-KNO3Adrian CaraballoNo ratings yet

- Exemplar For IA AaaDocument15 pagesExemplar For IA Aaagaylord gaysonNo ratings yet

- Hill's ReactionDocument11 pagesHill's ReactionTiyah TimothyNo ratings yet

- Cape Manual Unit 1 2015Document25 pagesCape Manual Unit 1 2015Orlanda EllisNo ratings yet

- Chemistry ProjectDocument11 pagesChemistry ProjectSarnendu ChattopadhyayNo ratings yet

- From The Kerckhoff Laboratories of Biology, California Institute of Technology, PasadenaDocument15 pagesFrom The Kerckhoff Laboratories of Biology, California Institute of Technology, Pasadenaمحمد عامر الحكيميNo ratings yet

- Anatase Photo MB PHDocument5 pagesAnatase Photo MB PHNahed YacoubNo ratings yet

- Determination of Mercury (II) in Dithizone-ImpregnatedDocument4 pagesDetermination of Mercury (II) in Dithizone-ImpregnatedDiễn Đàn Hóa HọcNo ratings yet

- Spectrophotometric Determination of Hydrogen Sulfide PDFDocument3 pagesSpectrophotometric Determination of Hydrogen Sulfide PDFVictor HugoNo ratings yet

- Mo JAEDocument4 pagesMo JAEThanhThao TranNo ratings yet

- 2003-The Christiansen Effect of Brightly Colored Colloidal Dispersion With An Amphiphilic PolymerDocument5 pages2003-The Christiansen Effect of Brightly Colored Colloidal Dispersion With An Amphiphilic PolymerAndrés Oswaldo Rivera HérnandezNo ratings yet

- Solid State NMR For Determination of Degree of Acetylation ofDocument6 pagesSolid State NMR For Determination of Degree of Acetylation ofيحيى بورغدةNo ratings yet

- 202016684, A.Mtonga Prac 4Document8 pages202016684, A.Mtonga Prac 4AlindileNo ratings yet

- Characterization of Chitosan. Influence of Ionic Strength and Degree of AcetylatiDocument5 pagesCharacterization of Chitosan. Influence of Ionic Strength and Degree of AcetylatiAlejandra Rojas-OlivosNo ratings yet

- The Nature of Laponite and Its Aqueous DispersionsDocument8 pagesThe Nature of Laponite and Its Aqueous DispersionsCleanne LimaNo ratings yet

- Note 149243671Document6 pagesNote 149243671RamyaNo ratings yet

- Nikel Icp-Aes2Document4 pagesNikel Icp-Aes2Fatah-Tata NabellaNo ratings yet

- Plntphys00607 0084Document5 pagesPlntphys00607 0084tito cuadrosNo ratings yet

- Chemistry ProjectDocument15 pagesChemistry ProjectArjun Chauhan50% (2)

- About The Solubility of Reduced SWCNT in Dmso: Home Search Collections Journals About Contact Us My IopscienceDocument7 pagesAbout The Solubility of Reduced SWCNT in Dmso: Home Search Collections Journals About Contact Us My IopscienceajaysingodiyaNo ratings yet

- Binary Phase Diagram of WaterDocument10 pagesBinary Phase Diagram of WaterkmkmNo ratings yet

- Laboratory Experiment To Measure The Relative Redox Activity of Laboratory EnrichedDocument9 pagesLaboratory Experiment To Measure The Relative Redox Activity of Laboratory EnrichedBrian AlalaNo ratings yet

- Chemistry Manual 2019Document65 pagesChemistry Manual 2019yusuphsaida36No ratings yet

- Limitations in CelluloseDocument6 pagesLimitations in CelluloseShofiaNo ratings yet

- SI Catalytic N2 to-NH3 Conversion by Fe at Lower Driving ForceDocument29 pagesSI Catalytic N2 to-NH3 Conversion by Fe at Lower Driving ForceJoseph KfouryNo ratings yet

- 1 s2.0 0013468673800313 MainDocument7 pages1 s2.0 0013468673800313 MainbrianNo ratings yet

- Separation of Carbon Quantum Dots On A C18 ColumnDocument15 pagesSeparation of Carbon Quantum Dots On A C18 ColumnnazarNo ratings yet

- Atomic SpectrosDocument4 pagesAtomic SpectrosEdna Lip AnerNo ratings yet

- Preparations Observation ChemDocument17 pagesPreparations Observation ChemShailendri AishuNo ratings yet

- Treatment-Oriented Characterization of Dry Scrubber Residue From Municipal Solid Waste IncinerationDocument10 pagesTreatment-Oriented Characterization of Dry Scrubber Residue From Municipal Solid Waste IncinerationMesin 1ic04No ratings yet

- Environmental Engineering LabmanualDocument32 pagesEnvironmental Engineering LabmanualrupenderNo ratings yet

- Spectrochimica Acta Part A: Molecular and Biomolecular SpectrosDocument8 pagesSpectrochimica Acta Part A: Molecular and Biomolecular SpectrosHassan TalebiNo ratings yet

- Environmental Engineering LabDocument31 pagesEnvironmental Engineering LabShaikKhan100% (2)

- DNA Isolation, Restriction Digest, and ElectrophoresisDocument11 pagesDNA Isolation, Restriction Digest, and ElectrophoresisRosemarie Dawn Tagare100% (2)

- Determination of Total Ion Concentration Using Ion Exchange Chromatography - Ace de La SernaDocument6 pagesDetermination of Total Ion Concentration Using Ion Exchange Chromatography - Ace de La Sernaaodelaserna100% (1)

- Quantification of Iron in A Given Sample by Using Single Beam SpectrophotometerDocument6 pagesQuantification of Iron in A Given Sample by Using Single Beam SpectrophotometerUshna Asif BSCHE-ENo ratings yet

- Rooney 1991 Molecular Environment Intracellular 23naDocument19 pagesRooney 1991 Molecular Environment Intracellular 23naAlfonso LemaNo ratings yet

- Yang 2002Document4 pagesYang 2002A Regular PandaNo ratings yet

- Determination of KSP For A Sparingly Soluble SaltDocument2 pagesDetermination of KSP For A Sparingly Soluble Saltmosoil0% (2)

- AP Chemistry - Kinetics of A Reaction LabDocument8 pagesAP Chemistry - Kinetics of A Reaction LabJonathan Chen50% (2)

- CPC CMC Value3Document7 pagesCPC CMC Value3SHASHI SHEKHARNo ratings yet

- Photocatalytic Inactivation of Bacteria by Tio2-Based Compounds Under Simulated Sunlight IrradiationDocument4 pagesPhotocatalytic Inactivation of Bacteria by Tio2-Based Compounds Under Simulated Sunlight IrradiationSEP-PublisherNo ratings yet

- HT - Efect Memorie - 2004Document5 pagesHT - Efect Memorie - 2004seby_antalNo ratings yet

- Spectrophotometric Determination of IronDocument4 pagesSpectrophotometric Determination of IronUmadevi RamakrishnanNo ratings yet

- thay đổi PH đến Quang xúc tácDocument3 pagesthay đổi PH đến Quang xúc táckẻ khờ khạoNo ratings yet

- Lab Protocal I Revised PDFDocument40 pagesLab Protocal I Revised PDFAswathyNo ratings yet

- Cong - Degradation of HNBR in Aqueous Solutions of H2S or HCL, 2013Document5 pagesCong - Degradation of HNBR in Aqueous Solutions of H2S or HCL, 2013oreamigNo ratings yet

- Experiment 4: Water Analysis Solids Gallardo, Hans Tristan MDocument7 pagesExperiment 4: Water Analysis Solids Gallardo, Hans Tristan Mjamila milanoNo ratings yet

- Exp. # 8 Polymers, Polymerization, and AnalysisDocument14 pagesExp. # 8 Polymers, Polymerization, and AnalysisAlyssa FerenceNo ratings yet

- Experimental Procedure of QdsDocument7 pagesExperimental Procedure of QdsAyesha ZakirNo ratings yet

- Facile Synthesis and Characterization of Acetate Intercalated Co-LaDocument6 pagesFacile Synthesis and Characterization of Acetate Intercalated Co-LaAlexa RiveraNo ratings yet

- Dav School (Affiliated To CBSE New Delhi) Sree Nandeeswarar Campus - Adambakkam Xii STD Chemistry Practical ManualDocument54 pagesDav School (Affiliated To CBSE New Delhi) Sree Nandeeswarar Campus - Adambakkam Xii STD Chemistry Practical ManualSivaRamaKrishnan R.No ratings yet

- Ijct 9 (6) 540-542Document3 pagesIjct 9 (6) 540-542AssyakurNo ratings yet

- Evaluating The Effect of Feed Particles Size and Their Hardness On The Particle Size Distribution of Semi Autogenous SAG Mill S ProductDocument22 pagesEvaluating The Effect of Feed Particles Size and Their Hardness On The Particle Size Distribution of Semi Autogenous SAG Mill S ProductW ZuoNo ratings yet

- 3rd International Geometallurgy Conference 2016 Paper Number (PDFDrive)Document22 pages3rd International Geometallurgy Conference 2016 Paper Number (PDFDrive)W ZuoNo ratings yet

- Estimation of Rock Comminution Characteristics by Using Drill Penetration RatesDocument166 pagesEstimation of Rock Comminution Characteristics by Using Drill Penetration RatesW ZuoNo ratings yet

- Eighth Mill Operators' Conference Proceedings 2003 - Evolution and Survival in The Minerals Industry (PDFDrive)Document233 pagesEighth Mill Operators' Conference Proceedings 2003 - Evolution and Survival in The Minerals Industry (PDFDrive)W ZuoNo ratings yet

- Ninth Mill Operators' Conference Proceedings 2007 (PDFDrive)Document231 pagesNinth Mill Operators' Conference Proceedings 2007 (PDFDrive)W ZuoNo ratings yet

- A More Holistic View of Mill Liner ManagDocument10 pagesA More Holistic View of Mill Liner ManagW ZuoNo ratings yet

- Comminution Circuit DesignDocument17 pagesComminution Circuit DesignW ZuoNo ratings yet

- Geometallurgy What Why and HowDocument46 pagesGeometallurgy What Why and HowW ZuoNo ratings yet

- The Arrium IsaMill From Design Through Commissioning and OptimisationDocument11 pagesThe Arrium IsaMill From Design Through Commissioning and OptimisationW ZuoNo ratings yet

- Development of An AG - SAG Mill Batch Test Methodology (PDFDrive)Document117 pagesDevelopment of An AG - SAG Mill Batch Test Methodology (PDFDrive)W ZuoNo ratings yet

- Geometallurgical Modeling at Olympic DamDocument22 pagesGeometallurgical Modeling at Olympic DamW ZuoNo ratings yet

- Simulation of Layout Rearrangement in The Grinding - Classification Process - For Increasing Throughput of Industrial Gold Ore PlantDocument13 pagesSimulation of Layout Rearrangement in The Grinding - Classification Process - For Increasing Throughput of Industrial Gold Ore PlantW ZuoNo ratings yet

- 2010 Aug Bulletin 038advanced Comminution Circuit DesignDocument5 pages2010 Aug Bulletin 038advanced Comminution Circuit DesignW ZuoNo ratings yet

- Importance of Oxidation During Regrinding of Rougher Flotation Concentrates With A High Content of Sulfides 2014 Minerals EngineeringDocument8 pagesImportance of Oxidation During Regrinding of Rougher Flotation Concentrates With A High Content of Sulfides 2014 Minerals EngineeringW ZuoNo ratings yet

- The Influence of Liner Wear On Milling EfficiencyDocument21 pagesThe Influence of Liner Wear On Milling EfficiencyW ZuoNo ratings yet

- Repurposing Legacy Metallurgical Data Part IDocument11 pagesRepurposing Legacy Metallurgical Data Part IW ZuoNo ratings yet

- Pre-Process To Increase Capacity of SAG-case StudyDocument12 pagesPre-Process To Increase Capacity of SAG-case StudyW ZuoNo ratings yet

- Effect of Regrinding Conditions On Pyrite Flotation in The Presence of Copper Ions 2013 International Journal of Mineral ProcessingDocument8 pagesEffect of Regrinding Conditions On Pyrite Flotation in The Presence of Copper Ions 2013 International Journal of Mineral ProcessingW ZuoNo ratings yet

- The Separation of Kyanite From Quartz by Flotation at Acidic PH 2016 Minerals EngineeringDocument8 pagesThe Separation of Kyanite From Quartz by Flotation at Acidic PH 2016 Minerals EngineeringW ZuoNo ratings yet

- The Separation of Chalcopyrite and Chalcocite From Pyrite in Cleaner Flotation After Regrinding 2014 Minerals EngineeringDocument9 pagesThe Separation of Chalcopyrite and Chalcocite From Pyrite in Cleaner Flotation After Regrinding 2014 Minerals EngineeringW ZuoNo ratings yet

- The Flotation of Aluminosilicate Polymorphic Minerals With Anionic and Cationic Collectors 2016 Minerals EngineeringDocument10 pagesThe Flotation of Aluminosilicate Polymorphic Minerals With Anionic and Cationic Collectors 2016 Minerals EngineeringW ZuoNo ratings yet

- The Effect of Regrind Mills On The Separation of Chalcopyrite From Pyrite in Cleaner Flotation 2015 Minerals EngineeringDocument11 pagesThe Effect of Regrind Mills On The Separation of Chalcopyrite From Pyrite in Cleaner Flotation 2015 Minerals EngineeringW ZuoNo ratings yet

- The Effect of Particle Breakage Mechanisms During Regrinding On The Subsequent Cleaner Flotation 2014 Minerals EngineeringDocument8 pagesThe Effect of Particle Breakage Mechanisms During Regrinding On The Subsequent Cleaner Flotation 2014 Minerals EngineeringW ZuoNo ratings yet

- A Review of The Effects of Grinding Media and Chemical Conditions On The Flotation of Pyrite in Refractory Gold OperationsDocument8 pagesA Review of The Effects of Grinding Media and Chemical Conditions On The Flotation of Pyrite in Refractory Gold OperationsW ZuoNo ratings yet

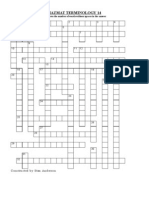

- Hazmat Terminology 14: in Clues, The Following ( - Words) Indicates The Number of Words Without Spaces in The AnswerDocument5 pagesHazmat Terminology 14: in Clues, The Following ( - Words) Indicates The Number of Words Without Spaces in The AnswerFire LibraryNo ratings yet

- Film Developing ProcessDocument10 pagesFilm Developing ProcessEFREN RAFFY N. PEPITONo ratings yet

- Applied Source Rock GeochemistryDocument28 pagesApplied Source Rock GeochemistryHuber Alberto Rivera Rosado100% (1)

- Effects of Processing Methods and Packaging MateriDocument11 pagesEffects of Processing Methods and Packaging MateriShaza DaweyNo ratings yet

- Weekly Workout 2023-24Document19 pagesWeekly Workout 2023-24Mihir DhankarNo ratings yet

- Abstracts IschiaDocument81 pagesAbstracts IschiapplotticiNo ratings yet

- Comparative Performance Analysis of Various Pre-Combustion CO Capture TechniquesDocument26 pagesComparative Performance Analysis of Various Pre-Combustion CO Capture TechniquesUsama ShakilNo ratings yet

- X Rbse Science-2 Free Notes: Carbon and Important Compounds of CarbonDocument9 pagesX Rbse Science-2 Free Notes: Carbon and Important Compounds of CarbonBhaveshNo ratings yet

- Target 1 - Level 2 - Chapter 2 PDFDocument26 pagesTarget 1 - Level 2 - Chapter 2 PDFRohan ArekatlaNo ratings yet

- German ATV DVWK A 168E Corrosion of Wastewater Systems Wastewater 1998 PDFDocument51 pagesGerman ATV DVWK A 168E Corrosion of Wastewater Systems Wastewater 1998 PDFJosip Medved100% (1)

- Installation Guidelines For Flygt Pumps: Pump Anchoring RecommendationsDocument6 pagesInstallation Guidelines For Flygt Pumps: Pump Anchoring RecommendationsراموندولدولاوNo ratings yet

- Parametros Del Proceso de Optimizacion para El Proceso de Aglomeracion Carbón Aceite Usando Aceites RecolectadosDocument10 pagesParametros Del Proceso de Optimizacion para El Proceso de Aglomeracion Carbón Aceite Usando Aceites RecolectadosGema EscobedoNo ratings yet

- BHT MSDSDocument5 pagesBHT MSDSChanpreet SinghNo ratings yet

- Uv Method Plus Program PostersDocument15 pagesUv Method Plus Program PosterssacrificiuNo ratings yet

- PFH13232 enDocument4 pagesPFH13232 envoodoo709No ratings yet

- Desalter EfficiencyDocument3 pagesDesalter Efficiencykronos39zeusNo ratings yet

- Benzoic Acid and Sodium Benzoate - SafetyDocument105 pagesBenzoic Acid and Sodium Benzoate - SafetyIgnacio Real BuffelliNo ratings yet

- (Ebook) - DIY - How To Build Your Own CNC Machine - O'BrienDocument1 page(Ebook) - DIY - How To Build Your Own CNC Machine - O'Brieniron109No ratings yet

- Soil Description and Classification PDFDocument33 pagesSoil Description and Classification PDFPrasobh ShamohanNo ratings yet

- Sample QuizDocument4 pagesSample QuizJohn Mark CabicunganNo ratings yet

- EM - 10th Science Notes 2018-19-1Document153 pagesEM - 10th Science Notes 2018-19-1Nagesh EinsteinNo ratings yet

- Vertical Drain: by Sanchari HalderDocument62 pagesVertical Drain: by Sanchari HalderwillypraviantoNo ratings yet

- An Arduino-Based EIS With A Logarithmic Amplifier For Corrosion MonitoringDocument6 pagesAn Arduino-Based EIS With A Logarithmic Amplifier For Corrosion MonitoringRoger RozarioNo ratings yet

- Data Storage On Fingure NailDocument17 pagesData Storage On Fingure NailpallavinooluNo ratings yet

- Topic of Entrance ExaminationDocument3 pagesTopic of Entrance ExaminationNguyễnHuânNo ratings yet

- The Kinetics of A Bleach ReactionDocument4 pagesThe Kinetics of A Bleach ReactionJelena ZdravkovicNo ratings yet

Thiobacillus Ferrooxidans: Particle Size Effects in The Microbiological Eaching Sulfide Concentrates by

Thiobacillus Ferrooxidans: Particle Size Effects in The Microbiological Eaching Sulfide Concentrates by

Uploaded by

W ZuoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thiobacillus Ferrooxidans: Particle Size Effects in The Microbiological Eaching Sulfide Concentrates by

Thiobacillus Ferrooxidans: Particle Size Effects in The Microbiological Eaching Sulfide Concentrates by

Uploaded by

W ZuoCopyright:

Available Formats

Particle Size Effects in the Microbiological

f eaching of Sulfide Concentrates by

Thiobacillus Ferrooxidans

M. A. Blancarte-Zurita and R. M. R. Branion

Department of Chemical Engineering, University of British Columbia,

Vancouver, British Columbia, Canada V6T 1W5

R. W. Lawrence

B. C. Research, 3650 Wesbrook Mall, Vancouver, British Columbia,

Canada V6S 2L2

Accepted for publication July 9, 1985

INTRODUCTION for 1 h to give 91.8% smaller than 400 Tyler mesh. It

was then recovered by filtration and dried at 60°C. The

The microbiological leaching of metals from sulfide

elemental analysis of the concentrate was 27.8% cop-

minerals has attracted much attention from researchers

per, 28.0% iron, 31.1% sulfur, and 5.5% insoluble.

and metal producers. An excellent critical review of

this topic has been published by Brierley.' One of the

foci of such research is the leaching of sulfide mineral

concentrates, which is the concern of the present work. Culture Technique

Specifically, this communication deals with the effects All experiments were carried out in 250-mL bottom-

of leaching on particle size when Cu and Fe are leached baffled Erlenmeyer flasks containing 7.5 g of concen-

from a chalcopyrite concentrate and Zn is leached from trate and 70 mL of the iron-free 9 K medium of Sil-

a ZnS concentrate by Thiobucillus ferrooxiduns. verman and L ~ n d g r e n The

. ~ pH was adjusted to 2.0

with IN HZS04.The flasks were loosely stoppered with

a cotton plug and mounted on a gyratory shaker. The

MATERIALS AND METHODS shaker was located in a dark room, maintained at 35°C

with a C0,-enriched atmosphere.

Microorganism Before inoculation, but after the adjustment of pH

to 2, the flasks were held for 24 h to allow for acid

The microorganism used in this study was originally consumption by alkaline gangue present in the con-

isolated by Razzell and Trussel12 from a copper mine centrate. After this the pH was readjusted to 2.0 and

located at Britannia, B.C. It has been routinely main- the flasks inoculated with 5 mL of T . ferrooxiduns

tained on copper concentrate suspended in the 9 K suspension.

medium, but without the iron described by Silverman Evaporative water losses were made up periodically

and L ~ n d g r e n . ~ by adding distilled water. In the sterile control flasks

It was determined4 that to minimize the time taken 1 mL of 1 :70 v/v phenol solution was added instead

to reach maximum copper concentration and to max- of inoculum.

imize the rate of copper extraction an inoculum age of

8 days was optimal. Thus transfers to new media were

made every 8 days.

Analyses

The copper and iron contents of the medium were

Substrate

determined at various times by stopping the shaker,

The chalcopyrite concentrate used in this study was allowing the solids to settle for 10-15 min, then with-

a commercial flotation concentrate supplied by New- drawing a 1-mL sample of the supernatant. The metal

mont Mines Ltd., Similkameen Div., Princeton, B.C. analyses were done using an atomic absorption

This concentrate was wet ball milled at 55% solids spectrophotometer.

Biotechnology a n d Bioengineering, Vol. XXVI11, Pp. 751-755 (1986)

0 1986 J o h n Wiley & Sons, Inc. CCC 0006-3592/86/050751-05$04.00

Concentrate Size Fractionation assuming that the particle shape factor is constant gives

for the change in particle mass

In some of our studies we wanted to follow the ef-

fects of leaching on particle size and vice versa; thus dN -

-- d dP

- - 3 p a dp2 __ (3)

we needed to get fractions of chalcopyrite having dif- dt dt

ferent particle sizes. The beaker decantation method5 The rate of appearance of Cu in solution can be

is a simple way of doing this. Concentrate is added to measured; call this rate r which is expressed in terms

water in a large beaker or any other suitable container. of mass x volume-' x time-'. To convert the rate

The slurry is stirred to mix it well then allowed to settle of Cu dissolution to a rate of particle dissolution we

for a predetermined time. The larger particles settle must divide r by the weight fraction f of Cu in the

while the smaller ones remain in suspension. The su- concentrate. Thus the rate of particle dissolution is r/f.

pernatant suspension is carefully poured off into an- The term - 3a dp2 (d dpldt) represents the dissolution

other beaker and the process repeated using a longer rate of a single particle. The measurement of r is made

settling time, etc. in a suspension containing many particles per unit vol-

This fractionation procedure requires the use of a ume. Let n be the number of particles per unit volume.

deffoculatingagent to obtain uniform dispersions. Tween Assume that no particles disappear during leaching;

40 (polyoxyethylene sorbitan monopalmitate) was used. then n is a constant and is equal to Cdpa dpO3,where

It was subsequently removed from the fractionated C, is the initial mass of concentrate per unit volume

particles by solvent extraction with isopropanol in the in the leach system and dpo is the initial particle diameter.

presence of K2C03.6Tween 40 inhibited leaching but Then

after removal by the solvent extraction technique no

such inhibition was observed. 99% removal of the dis-

persant could be a ~ h i e v e d . ~

which reduces to

Particle Size Analysis -3C0 dp2 -d = dp- r

(5)

Dilute suspensions of the various fractions were made dpO3 dt f

in 10 mL of ethanol using 0.1% aerosol GPG (sodium r, f , and dp, can be measured, and C, can be set by

dioctyl sulfosuccinate in ethanol and water) as a dis- the experimenter; thus eq. ( 5 ) can be integrated to give

persant in an ultrasonic bath. Microscope slides were particle diameter as a function of time.

prepared from these suspensions and size distributions If necessary the assumption of no total disappear-

were measured using an eyepiece micrometer in a mi- ance of particles during leaching can be relaxed but

croscope to measure the Martin's diameters of 100 then the integration must be done numerically; r is a

particles~

function of the amount of mineral surface per unit vol-

After the leaching phase of this study was completed ume available to the organism and thus a function of

use of a Leitz image analyzer became possible so the dp since surface area is proportional to dp2. For batch

unleached fractions were reanalyzed using this instru- leaches r is also a function of time.

ment counting at least 1000 particles.

RESULTS AND DISCUSSION

THEORETICAL

Table I provides data about the initial sizes of the

The following shrinking particle model is proposed various fractions used in the leaching experiments as

to describe the leaching behavior. Since material is well as the mean size of the unfractionated concentrate.

being solubilized from the particles the particle mass

decreases and it is assumed that as leaching occurs the

particles get smaller. The rate of particle size decrease Table I. Properties of particle size fractions.

is given by - dN/dt, where N is the particle mass and Mean particle diameter (pm)

t is time. Assuming that the particles have a constant

density p, we have Fraction Image

number Microscope analyzer

dN -

-- dV

- -P-& (1) 1 0.38 0.20

dt

2 1.81 2.68

where V is particle volume, which can be represented 3 1.67 2.76

by 4 3.10 3.53

5 5.64 5.98

V = a dp3 (2) 6 6.74 6.45

Unfractionated 1.86 2.86

where dp is the particle diameter and a the particle concentrate

shape factor. Now substituting eq. (2) into eq. ( 1 ) and

752 BIOTECHNOLOGY AND BIOENGINEERING, VOL. 28, MAY 1986

,

I

O h 181urn 72h 184um 24h 228um

7 -1 -1

240h 141um 10

330 h 1.42 urn

E I0

Lnr ' m

6 0

0 0

0 00 I I6 I 20 I 30 4 8

SIZE i m c ~ w l o f ~ l

Figure 1. Particle size distribution as a function of leach time for fraction 2.

>-

0

11 -

r.

6 1

10- ,--A

&fraction 1

v

z 9- / nfraction 2

x fraction 3

fraction 4

p: 7- Xfraction 5 0 I

0

b

z; 6-

I LEGEND I

z 5-

"p:

0

4-

w 3-

a

3

" 2-

1-

0 50 100 150 200 250 300 350 400 450 0 50 100 I50 200 250 300 350 400 450

TIME (h) TIME (hours)

Figure 2. Copper concentration solution as a function of leach time Figure 3. Particle size vs leach time for fractions 2, 3, and 5. The

for various particle sizes. lines are calculated using eq. (9). The points are experimental mea-

surements using a microscope.

Figure 1 shows a typical size distribution as a func-

tion of leach time (for fraction 2 ) , indicating that par-

ticle size does decrease with time but not, for this Figure 3 and 4 show that the predictions of the model

particular concentrate, by very much. are not in disagreement with the measured data and

Figure 2 plots copper concentration as a function of thus the model has some credibility. On the other hand,

leach time for the various concentrate fractions. Figure there is a great deal of scatter in the measured data.

2 shows that the rate of Cu dissolution r is a function Moreover, the concentrate used did not leach very well

of dp and of time. However, since this concentrate did and thus did not provide an ideal test of the model for

not leach very well, i.e., the Cu extraction was typi- particle shrinkage.

cally of the order of 26%, we assumed the r would not Torma et a].' measured particle size distributions

change much as a result of particle size changes during initially and at various intervals during the leaching of

leaching; however, r was treated as a function of leach a ZnS concentrate. They and Sanmugasunderam8 also

time t. Curves of the form published data from which the rate of Zn dissolution

can be calculated. In these ZnS leaching studies much

[CU]

atb = (6) higher levels of Zn extraction were observed (80 + %);

where a and b are constants and [Cu] is copper con- thus the particles would become much smaller or, in

centration were fitted to the data of Figure 2 for each the case of the smaller ones, disappear.

particle size fraction. From (6)

Introducing (7) into ( 5 ) leads to

(7)

h

m

6u

5-

- dp2 d dp = -

ab

f

I: tb-' dt (8)

I.

u

c

i

2

4-

4

which integrates to .I

1/3

9 3-

(9)

dP0

Plots of dp vs. c for fractions 2 , 3, and 5 of Table I

as calculated by eq. (9) are shown in Figure 3. Also

shown are the measured values taken from Figure 1

and others like it (not shown). These values are those

ol

measured using the microscope. 0 50 100 150 200 250

Later a test was run using the unfractionated con- TIME (hours)

centrate and analyzing particle size distribution with Figure 4. Particle size vs. leach time for the unfractionated con-

the image analyzer. These results are presented in Fig- centrate. The line is calculated using eq. (9). The points are exper-

ure 4. imental measurements using an image analyzer.

754 BJOTECHNOLOGY AND BIOENGINEERING, VOL. 28, MAY 1986

and Engineering Research Council of Canada, and El Consejo Na-

; o o * l 90

cional d e Ciencia y Tecnologia (MCxico).

NOMENCLATURE

Constants

Initial mass of concentrate per unit volume (g/L)

Particle diameter (cm)

Initial particle diameter (cm)

Weight fraction of copper in concentrate

Particle mass (g)

Number of particles per unit volume (L-’)

Time (h)

Leaching rate (g/L h)

Particle volume (cm’)

“ T - - i - -

7 7- 1

Particle shape factor

0 5 10 15 10 25 30 35 40 Density of concentrate (g/cm3)

PARTICLE DIAMETER (urn)

Figure 5. Cumulative particle size (mass basis) distribution of a

ZnS concentrate after 212 h of leaching. The line is calculated using References

a program based on eq. (5). The points represent the experimental

data of Torma et a].’ 1. C. L. Bnerly, “Bacterial leaching,” CRC Crir. Rev. Microbiol.,

207 (1978).

2. W. E. Razzel and P. C. Trussel, J. Bacteriol., 85, 595 (1963).

A computer program based on the model presented 3. M. P. Silverman and D. G. Lundgren, J. Bacteriol., 77,642 (1959).

4. M. A. Blancarte-Zurita, “Effect of particle size on the kinetics

in this work was written to predict the size distributions

of microbiological leaching of chalcopyrite,” M.A.Sc. Thesis,

measured by Torma et al.’ A more detailed description University of British Columbia, (1983).

is given in ref. 9. This program integrated eq. ( 5 ) using 5. E. J. Pryor, Mineraf Processing (Elsevier, Amsterdam, 1965).

equations fitted to Torma’s and Sanmugasunderam’s 6. Organization for Economic Co-operation and Development

data to give r as a function of dp. It also allowed for (OECD), Proposed method for the determination of the biode-

gradability of surfactants used in synthetic detergents, Paris, 1974.

the disappearance of particles before completion of the

7. A. E. Torma, C. C. Walden, and R. M. R. Branion, Biorechnoi.

leach. Figure 5 plots the cumulative mass-based par- Bioeng., 12, 500 (1970).

ticle size distributions as calculated by the program 8. V. Sanmugasunderam, “Kinetic studies on the biological leaching

and as measured by Torma et al.’ Agreement is good, of ZnS concentrate in 2 stage, continuous, stirred tank reactors,”

thus lending further credibility to this model. Ph.D. Thesis, University of British Columbia (1981).

9. M. A. Blancarte-Zunta, R. M. R. Branion, and R. W. Lawrence,

Financial assistance for this project has been provided by B.C. Re- Preprints, International Symposium on Biohydrometallurgy,

search, The University of British Columbia, The Natural Sciences Vancouver, 1985.

COMMUNICATION TO THE EDITOR 755

You might also like

- Case 2290 PDFDocument90 pagesCase 2290 PDFDarioNo ratings yet

- Mini ProjectDocument79 pagesMini ProjectadzhamNo ratings yet

- Water DesalinationDocument142 pagesWater DesalinationKhaleel Jaberov100% (1)

- Determination of Small Amounts of Water in Organic Solvents by Spectrophotometric AnalysisDocument13 pagesDetermination of Small Amounts of Water in Organic Solvents by Spectrophotometric AnalysisLUIS XVNo ratings yet

- Determination of The Mark-HouwinkDocument5 pagesDetermination of The Mark-HouwinkMariane AlcântaraNo ratings yet

- 무게분석 관련논문Document2 pages무게분석 관련논문간다고No ratings yet

- Synthesis, Characterization, and Use of A Cobalt (l1) Complex As An NMR Shift ReagentDocument2 pagesSynthesis, Characterization, and Use of A Cobalt (l1) Complex As An NMR Shift ReagentAliceNo ratings yet

- Teju Rs 3Document6 pagesTeju Rs 3chemicalcommunicationsocietyNo ratings yet

- Some Measure, Ments of Diffusion I N Liquids: Division UniversityDocument5 pagesSome Measure, Ments of Diffusion I N Liquids: Division Universityvan6_04No ratings yet

- 1955 The System Ba (NO3) 2-KNO3Document3 pages1955 The System Ba (NO3) 2-KNO3Adrian CaraballoNo ratings yet

- Exemplar For IA AaaDocument15 pagesExemplar For IA Aaagaylord gaysonNo ratings yet

- Hill's ReactionDocument11 pagesHill's ReactionTiyah TimothyNo ratings yet

- Cape Manual Unit 1 2015Document25 pagesCape Manual Unit 1 2015Orlanda EllisNo ratings yet

- Chemistry ProjectDocument11 pagesChemistry ProjectSarnendu ChattopadhyayNo ratings yet

- From The Kerckhoff Laboratories of Biology, California Institute of Technology, PasadenaDocument15 pagesFrom The Kerckhoff Laboratories of Biology, California Institute of Technology, Pasadenaمحمد عامر الحكيميNo ratings yet

- Anatase Photo MB PHDocument5 pagesAnatase Photo MB PHNahed YacoubNo ratings yet

- Determination of Mercury (II) in Dithizone-ImpregnatedDocument4 pagesDetermination of Mercury (II) in Dithizone-ImpregnatedDiễn Đàn Hóa HọcNo ratings yet

- Spectrophotometric Determination of Hydrogen Sulfide PDFDocument3 pagesSpectrophotometric Determination of Hydrogen Sulfide PDFVictor HugoNo ratings yet

- Mo JAEDocument4 pagesMo JAEThanhThao TranNo ratings yet

- 2003-The Christiansen Effect of Brightly Colored Colloidal Dispersion With An Amphiphilic PolymerDocument5 pages2003-The Christiansen Effect of Brightly Colored Colloidal Dispersion With An Amphiphilic PolymerAndrés Oswaldo Rivera HérnandezNo ratings yet

- Solid State NMR For Determination of Degree of Acetylation ofDocument6 pagesSolid State NMR For Determination of Degree of Acetylation ofيحيى بورغدةNo ratings yet

- 202016684, A.Mtonga Prac 4Document8 pages202016684, A.Mtonga Prac 4AlindileNo ratings yet

- Characterization of Chitosan. Influence of Ionic Strength and Degree of AcetylatiDocument5 pagesCharacterization of Chitosan. Influence of Ionic Strength and Degree of AcetylatiAlejandra Rojas-OlivosNo ratings yet

- The Nature of Laponite and Its Aqueous DispersionsDocument8 pagesThe Nature of Laponite and Its Aqueous DispersionsCleanne LimaNo ratings yet

- Note 149243671Document6 pagesNote 149243671RamyaNo ratings yet

- Nikel Icp-Aes2Document4 pagesNikel Icp-Aes2Fatah-Tata NabellaNo ratings yet

- Plntphys00607 0084Document5 pagesPlntphys00607 0084tito cuadrosNo ratings yet

- Chemistry ProjectDocument15 pagesChemistry ProjectArjun Chauhan50% (2)

- About The Solubility of Reduced SWCNT in Dmso: Home Search Collections Journals About Contact Us My IopscienceDocument7 pagesAbout The Solubility of Reduced SWCNT in Dmso: Home Search Collections Journals About Contact Us My IopscienceajaysingodiyaNo ratings yet

- Binary Phase Diagram of WaterDocument10 pagesBinary Phase Diagram of WaterkmkmNo ratings yet

- Laboratory Experiment To Measure The Relative Redox Activity of Laboratory EnrichedDocument9 pagesLaboratory Experiment To Measure The Relative Redox Activity of Laboratory EnrichedBrian AlalaNo ratings yet

- Chemistry Manual 2019Document65 pagesChemistry Manual 2019yusuphsaida36No ratings yet

- Limitations in CelluloseDocument6 pagesLimitations in CelluloseShofiaNo ratings yet

- SI Catalytic N2 to-NH3 Conversion by Fe at Lower Driving ForceDocument29 pagesSI Catalytic N2 to-NH3 Conversion by Fe at Lower Driving ForceJoseph KfouryNo ratings yet

- 1 s2.0 0013468673800313 MainDocument7 pages1 s2.0 0013468673800313 MainbrianNo ratings yet

- Separation of Carbon Quantum Dots On A C18 ColumnDocument15 pagesSeparation of Carbon Quantum Dots On A C18 ColumnnazarNo ratings yet

- Atomic SpectrosDocument4 pagesAtomic SpectrosEdna Lip AnerNo ratings yet

- Preparations Observation ChemDocument17 pagesPreparations Observation ChemShailendri AishuNo ratings yet

- Treatment-Oriented Characterization of Dry Scrubber Residue From Municipal Solid Waste IncinerationDocument10 pagesTreatment-Oriented Characterization of Dry Scrubber Residue From Municipal Solid Waste IncinerationMesin 1ic04No ratings yet

- Environmental Engineering LabmanualDocument32 pagesEnvironmental Engineering LabmanualrupenderNo ratings yet

- Spectrochimica Acta Part A: Molecular and Biomolecular SpectrosDocument8 pagesSpectrochimica Acta Part A: Molecular and Biomolecular SpectrosHassan TalebiNo ratings yet

- Environmental Engineering LabDocument31 pagesEnvironmental Engineering LabShaikKhan100% (2)

- DNA Isolation, Restriction Digest, and ElectrophoresisDocument11 pagesDNA Isolation, Restriction Digest, and ElectrophoresisRosemarie Dawn Tagare100% (2)

- Determination of Total Ion Concentration Using Ion Exchange Chromatography - Ace de La SernaDocument6 pagesDetermination of Total Ion Concentration Using Ion Exchange Chromatography - Ace de La Sernaaodelaserna100% (1)

- Quantification of Iron in A Given Sample by Using Single Beam SpectrophotometerDocument6 pagesQuantification of Iron in A Given Sample by Using Single Beam SpectrophotometerUshna Asif BSCHE-ENo ratings yet

- Rooney 1991 Molecular Environment Intracellular 23naDocument19 pagesRooney 1991 Molecular Environment Intracellular 23naAlfonso LemaNo ratings yet

- Yang 2002Document4 pagesYang 2002A Regular PandaNo ratings yet

- Determination of KSP For A Sparingly Soluble SaltDocument2 pagesDetermination of KSP For A Sparingly Soluble Saltmosoil0% (2)

- AP Chemistry - Kinetics of A Reaction LabDocument8 pagesAP Chemistry - Kinetics of A Reaction LabJonathan Chen50% (2)

- CPC CMC Value3Document7 pagesCPC CMC Value3SHASHI SHEKHARNo ratings yet

- Photocatalytic Inactivation of Bacteria by Tio2-Based Compounds Under Simulated Sunlight IrradiationDocument4 pagesPhotocatalytic Inactivation of Bacteria by Tio2-Based Compounds Under Simulated Sunlight IrradiationSEP-PublisherNo ratings yet

- HT - Efect Memorie - 2004Document5 pagesHT - Efect Memorie - 2004seby_antalNo ratings yet

- Spectrophotometric Determination of IronDocument4 pagesSpectrophotometric Determination of IronUmadevi RamakrishnanNo ratings yet

- thay đổi PH đến Quang xúc tácDocument3 pagesthay đổi PH đến Quang xúc táckẻ khờ khạoNo ratings yet

- Lab Protocal I Revised PDFDocument40 pagesLab Protocal I Revised PDFAswathyNo ratings yet

- Cong - Degradation of HNBR in Aqueous Solutions of H2S or HCL, 2013Document5 pagesCong - Degradation of HNBR in Aqueous Solutions of H2S or HCL, 2013oreamigNo ratings yet

- Experiment 4: Water Analysis Solids Gallardo, Hans Tristan MDocument7 pagesExperiment 4: Water Analysis Solids Gallardo, Hans Tristan Mjamila milanoNo ratings yet

- Exp. # 8 Polymers, Polymerization, and AnalysisDocument14 pagesExp. # 8 Polymers, Polymerization, and AnalysisAlyssa FerenceNo ratings yet

- Experimental Procedure of QdsDocument7 pagesExperimental Procedure of QdsAyesha ZakirNo ratings yet

- Facile Synthesis and Characterization of Acetate Intercalated Co-LaDocument6 pagesFacile Synthesis and Characterization of Acetate Intercalated Co-LaAlexa RiveraNo ratings yet

- Dav School (Affiliated To CBSE New Delhi) Sree Nandeeswarar Campus - Adambakkam Xii STD Chemistry Practical ManualDocument54 pagesDav School (Affiliated To CBSE New Delhi) Sree Nandeeswarar Campus - Adambakkam Xii STD Chemistry Practical ManualSivaRamaKrishnan R.No ratings yet

- Ijct 9 (6) 540-542Document3 pagesIjct 9 (6) 540-542AssyakurNo ratings yet

- Evaluating The Effect of Feed Particles Size and Their Hardness On The Particle Size Distribution of Semi Autogenous SAG Mill S ProductDocument22 pagesEvaluating The Effect of Feed Particles Size and Their Hardness On The Particle Size Distribution of Semi Autogenous SAG Mill S ProductW ZuoNo ratings yet

- 3rd International Geometallurgy Conference 2016 Paper Number (PDFDrive)Document22 pages3rd International Geometallurgy Conference 2016 Paper Number (PDFDrive)W ZuoNo ratings yet

- Estimation of Rock Comminution Characteristics by Using Drill Penetration RatesDocument166 pagesEstimation of Rock Comminution Characteristics by Using Drill Penetration RatesW ZuoNo ratings yet

- Eighth Mill Operators' Conference Proceedings 2003 - Evolution and Survival in The Minerals Industry (PDFDrive)Document233 pagesEighth Mill Operators' Conference Proceedings 2003 - Evolution and Survival in The Minerals Industry (PDFDrive)W ZuoNo ratings yet

- Ninth Mill Operators' Conference Proceedings 2007 (PDFDrive)Document231 pagesNinth Mill Operators' Conference Proceedings 2007 (PDFDrive)W ZuoNo ratings yet

- A More Holistic View of Mill Liner ManagDocument10 pagesA More Holistic View of Mill Liner ManagW ZuoNo ratings yet

- Comminution Circuit DesignDocument17 pagesComminution Circuit DesignW ZuoNo ratings yet

- Geometallurgy What Why and HowDocument46 pagesGeometallurgy What Why and HowW ZuoNo ratings yet

- The Arrium IsaMill From Design Through Commissioning and OptimisationDocument11 pagesThe Arrium IsaMill From Design Through Commissioning and OptimisationW ZuoNo ratings yet

- Development of An AG - SAG Mill Batch Test Methodology (PDFDrive)Document117 pagesDevelopment of An AG - SAG Mill Batch Test Methodology (PDFDrive)W ZuoNo ratings yet

- Geometallurgical Modeling at Olympic DamDocument22 pagesGeometallurgical Modeling at Olympic DamW ZuoNo ratings yet

- Simulation of Layout Rearrangement in The Grinding - Classification Process - For Increasing Throughput of Industrial Gold Ore PlantDocument13 pagesSimulation of Layout Rearrangement in The Grinding - Classification Process - For Increasing Throughput of Industrial Gold Ore PlantW ZuoNo ratings yet

- 2010 Aug Bulletin 038advanced Comminution Circuit DesignDocument5 pages2010 Aug Bulletin 038advanced Comminution Circuit DesignW ZuoNo ratings yet

- Importance of Oxidation During Regrinding of Rougher Flotation Concentrates With A High Content of Sulfides 2014 Minerals EngineeringDocument8 pagesImportance of Oxidation During Regrinding of Rougher Flotation Concentrates With A High Content of Sulfides 2014 Minerals EngineeringW ZuoNo ratings yet

- The Influence of Liner Wear On Milling EfficiencyDocument21 pagesThe Influence of Liner Wear On Milling EfficiencyW ZuoNo ratings yet

- Repurposing Legacy Metallurgical Data Part IDocument11 pagesRepurposing Legacy Metallurgical Data Part IW ZuoNo ratings yet

- Pre-Process To Increase Capacity of SAG-case StudyDocument12 pagesPre-Process To Increase Capacity of SAG-case StudyW ZuoNo ratings yet

- Effect of Regrinding Conditions On Pyrite Flotation in The Presence of Copper Ions 2013 International Journal of Mineral ProcessingDocument8 pagesEffect of Regrinding Conditions On Pyrite Flotation in The Presence of Copper Ions 2013 International Journal of Mineral ProcessingW ZuoNo ratings yet

- The Separation of Kyanite From Quartz by Flotation at Acidic PH 2016 Minerals EngineeringDocument8 pagesThe Separation of Kyanite From Quartz by Flotation at Acidic PH 2016 Minerals EngineeringW ZuoNo ratings yet

- The Separation of Chalcopyrite and Chalcocite From Pyrite in Cleaner Flotation After Regrinding 2014 Minerals EngineeringDocument9 pagesThe Separation of Chalcopyrite and Chalcocite From Pyrite in Cleaner Flotation After Regrinding 2014 Minerals EngineeringW ZuoNo ratings yet

- The Flotation of Aluminosilicate Polymorphic Minerals With Anionic and Cationic Collectors 2016 Minerals EngineeringDocument10 pagesThe Flotation of Aluminosilicate Polymorphic Minerals With Anionic and Cationic Collectors 2016 Minerals EngineeringW ZuoNo ratings yet

- The Effect of Regrind Mills On The Separation of Chalcopyrite From Pyrite in Cleaner Flotation 2015 Minerals EngineeringDocument11 pagesThe Effect of Regrind Mills On The Separation of Chalcopyrite From Pyrite in Cleaner Flotation 2015 Minerals EngineeringW ZuoNo ratings yet

- The Effect of Particle Breakage Mechanisms During Regrinding On The Subsequent Cleaner Flotation 2014 Minerals EngineeringDocument8 pagesThe Effect of Particle Breakage Mechanisms During Regrinding On The Subsequent Cleaner Flotation 2014 Minerals EngineeringW ZuoNo ratings yet

- A Review of The Effects of Grinding Media and Chemical Conditions On The Flotation of Pyrite in Refractory Gold OperationsDocument8 pagesA Review of The Effects of Grinding Media and Chemical Conditions On The Flotation of Pyrite in Refractory Gold OperationsW ZuoNo ratings yet

- Hazmat Terminology 14: in Clues, The Following ( - Words) Indicates The Number of Words Without Spaces in The AnswerDocument5 pagesHazmat Terminology 14: in Clues, The Following ( - Words) Indicates The Number of Words Without Spaces in The AnswerFire LibraryNo ratings yet

- Film Developing ProcessDocument10 pagesFilm Developing ProcessEFREN RAFFY N. PEPITONo ratings yet

- Applied Source Rock GeochemistryDocument28 pagesApplied Source Rock GeochemistryHuber Alberto Rivera Rosado100% (1)

- Effects of Processing Methods and Packaging MateriDocument11 pagesEffects of Processing Methods and Packaging MateriShaza DaweyNo ratings yet

- Weekly Workout 2023-24Document19 pagesWeekly Workout 2023-24Mihir DhankarNo ratings yet

- Abstracts IschiaDocument81 pagesAbstracts IschiapplotticiNo ratings yet

- Comparative Performance Analysis of Various Pre-Combustion CO Capture TechniquesDocument26 pagesComparative Performance Analysis of Various Pre-Combustion CO Capture TechniquesUsama ShakilNo ratings yet

- X Rbse Science-2 Free Notes: Carbon and Important Compounds of CarbonDocument9 pagesX Rbse Science-2 Free Notes: Carbon and Important Compounds of CarbonBhaveshNo ratings yet

- Target 1 - Level 2 - Chapter 2 PDFDocument26 pagesTarget 1 - Level 2 - Chapter 2 PDFRohan ArekatlaNo ratings yet

- German ATV DVWK A 168E Corrosion of Wastewater Systems Wastewater 1998 PDFDocument51 pagesGerman ATV DVWK A 168E Corrosion of Wastewater Systems Wastewater 1998 PDFJosip Medved100% (1)

- Installation Guidelines For Flygt Pumps: Pump Anchoring RecommendationsDocument6 pagesInstallation Guidelines For Flygt Pumps: Pump Anchoring RecommendationsراموندولدولاوNo ratings yet

- Parametros Del Proceso de Optimizacion para El Proceso de Aglomeracion Carbón Aceite Usando Aceites RecolectadosDocument10 pagesParametros Del Proceso de Optimizacion para El Proceso de Aglomeracion Carbón Aceite Usando Aceites RecolectadosGema EscobedoNo ratings yet

- BHT MSDSDocument5 pagesBHT MSDSChanpreet SinghNo ratings yet

- Uv Method Plus Program PostersDocument15 pagesUv Method Plus Program PosterssacrificiuNo ratings yet

- PFH13232 enDocument4 pagesPFH13232 envoodoo709No ratings yet

- Desalter EfficiencyDocument3 pagesDesalter Efficiencykronos39zeusNo ratings yet

- Benzoic Acid and Sodium Benzoate - SafetyDocument105 pagesBenzoic Acid and Sodium Benzoate - SafetyIgnacio Real BuffelliNo ratings yet

- (Ebook) - DIY - How To Build Your Own CNC Machine - O'BrienDocument1 page(Ebook) - DIY - How To Build Your Own CNC Machine - O'Brieniron109No ratings yet

- Soil Description and Classification PDFDocument33 pagesSoil Description and Classification PDFPrasobh ShamohanNo ratings yet

- Sample QuizDocument4 pagesSample QuizJohn Mark CabicunganNo ratings yet

- EM - 10th Science Notes 2018-19-1Document153 pagesEM - 10th Science Notes 2018-19-1Nagesh EinsteinNo ratings yet

- Vertical Drain: by Sanchari HalderDocument62 pagesVertical Drain: by Sanchari HalderwillypraviantoNo ratings yet

- An Arduino-Based EIS With A Logarithmic Amplifier For Corrosion MonitoringDocument6 pagesAn Arduino-Based EIS With A Logarithmic Amplifier For Corrosion MonitoringRoger RozarioNo ratings yet

- Data Storage On Fingure NailDocument17 pagesData Storage On Fingure NailpallavinooluNo ratings yet

- Topic of Entrance ExaminationDocument3 pagesTopic of Entrance ExaminationNguyễnHuânNo ratings yet

- The Kinetics of A Bleach ReactionDocument4 pagesThe Kinetics of A Bleach ReactionJelena ZdravkovicNo ratings yet