Professional Documents

Culture Documents

Suspended Grease Interciptor

Suspended Grease Interciptor

Uploaded by

AHMED ATIFOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Suspended Grease Interciptor

Suspended Grease Interciptor

Uploaded by

AHMED ATIFCopyright:

Available Formats

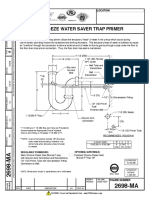

SMITH ® JAY R.

LOCATION

SMITH MFG. CO.®

L

NITARY

ASPE

® SA

MEMBER OF MORRIS GROUP INTERNATIONAL

POST OFFICE BOX 3237

MONTGOMERY, ALABAMA 36109-0237 (USA)

TEL: 334-277-8520 FAX: 334-272-7396 www.jrsmith.com

EN e

G IN

G

® I

nti N E E R Cu

ve

MEMBER OF:

P

CUSTOMER

re

r

on R n

DRIVEN ather Tha

SINCE 1926

GREASE INTERCEPTORS

S8200 SERIES

DRAWING NUMBER

GREASE INTERCEPTORS WITH EXTENSION

WE CAN ASSUME NO RESPONSIBILITY FOR USE OF SUPERSEDED OR VOID DATA

FUNCTION: Used in kitchens, restaurants, institutions and all types of food processing areas where waste water contains

grease, fats and oils which must be intercepted and collected before entering the drainage system. Interceptors with extensions

are installed recessed in the floor with cover flush with finished floor. Extension provides additional roughing depth from top of

interceptor to center line of inlet and outlet. Extension should not be used as a means for supporting the assembly. The entire

interceptor body and extension must rest on solid ground or suitable support hangers.

SIZE

ING A N D D R B AI

Non-Skid Cover UM NA

Cleanout

PL

GE

Lock and Lift Ring CER T IF IED

F-Body Width G

®

IN S T TE

2 1/2(64) IT U

NONE

NOTE: 4"(100) WHEN ORDERING, SPECIFY HEIGHT

MIN Always Specify Figs. 8210 thru 8250 carry the

Gasket REQUIRED FROM TOP OF INTERCEPTOR

SCALE:

Extension Height Anchor Flange Plumbing and Drainage

TO TOP OF EXTENSION USING SUFFIX

Required (When Specified) Institute Certification Seal

NUMBER FOR EXTENSION HEIGHT. Certifying conformance to

Outlet EXAMPLE: FIG. 8225 WITH 6"(150) Grease Interceptor Standard

C EXTENSION -SPECIFY FIG. 8225 (-E06) PDI-G101.

Inlet A A

4-24-85

Air Relief Inlet Dimensions

E Static PCN/ GPM Grease and C.O.

Fig. Flow Cap Outlet Roughing Body Plug

B Water Line B

No. Rate Lbs. Size Dimensions Height Width Size

DATE:

Removable A* B C D E F G

Baffles 8210 10 20 02(50) 9 1/2(240) 3 3/4(95) 21 1/4(540) 13 1/4(335) 11 1/2(290) 2(51)

8215 15 30 02(50) 12(305) 3 1/2(89) 25(635) 15 1/2(395) 13 1/2(345) 2(51)

8220 20 40 03(75) 13(330) 4(100) 28 1/2(725) 17(430) 15 3/4(400) 2(51)

APPROVED BY:

D

8225 25 50 03(75) 15 1/4(390) 4 1/2(115) 30(760) 19 3/4(500) 16 3/4(425) 2(51)

03(75) 16(405)

KG

8235 35 70 5(125) 32 1/2(825) 21(535) 18 1/4(465) 2(51)

8250 50 100 03(75) 17 1/2(445) 6 3/4(170) 35 1/2(900) 24 1/4(615) 20 3/4(525) 2(51)

*Available with larger inlet and outlet when specified.

DIMENSIONS ARE SUBJECT TO MANUFACTURERS TOLERANCE AND CHANGE WITHOUT NOTICE

REGULARLY FURNISHED: VARIATIONS: OPTIONAL MATERIALS:

Steel Interceptor and Extension with Anchor Flange -F Acid Resistant Coating Inside - ARI

Gray Duco Coating Inside and Cover Recessed for Terrazzo Acid Resistant Coating Outside - ARO

CHECKED BY:

Outside and Flow Control Fitting. Ceramic or Quarry Tile -QC Acid Resistant Coating Inside and

CR

Cover Recessed for Vinyl or Outside - ARIO

NOTE: 2"(51) must be added to dimension D Asphalt Tile -TC Aluminum Cover -AC

and F for clearance of extension clamps. Flange and Flashing Clamp -F-C

Lift Out Sediment Bucket -B NOTE: It is the responsibility of the

NOTE: Dimensions shown in parentheses NO-HUB Adaptor (2) Req'd installer to check all parts (internal and

are in millimeters. (Specify Fig. 2646Y) external) to verify they are in their proper

operating order and location.

VGD

DRAWN BY:

Traffic Rated Cover-H20

INSTALLATION NOTE

Flashing Flashing The Steel Extension supplied with the 8200 Series Interceptor is designed to

Clamp increase the roughing dimension from the Inlet-Outlet centerline to the

finished floor. The Extension and Anchoring Flange should not be used to

(Optional) support the unit. When installed in ground floor locations, the Interceptor

8200 SERIES

must rest on solid ground or on some suitable concrete pad. If the 8200

Anchor Flange Series Interceptor is installed in an upper floor (suspended in the ceiling

(Optional) below), a suitable method of supporting the entire unit must be provided and

meet the approval of the structural engineer and architect. The installation

sketch shows a typical Interceptor with Extension and one method of

Steel Rod supporting the entire weight. Support of an interceptor, whether supplied

(By Others) with a cradle or independently, is essential for safety and functional integrity

of the installation. Upon request, Jay R. Smith Mfg. Co. will provide the

weight of the specific unit. Additional weight must be added to compensate

for the weight of the liquid/grease when full and in the flowing mode of

Pipe, Angle Iron or Steel Plate operation. Also shown are the "When Specified" options of an Anchor Flange

(By Others) and Flashing Clamp.

L 1-22-18 Revised Callout TBW CL

K 1-19-18 Revised Variations, Removed Note TBW CL WEIGHT VOLUME FIGURE NUMBER

J 2-3-05 Revised Variations RN CL POUNDS CUBIC FEET

8200 SERIES

NUMBER

H 8-13-02 Revised "F Dim." in Chart RN CL

FIGURE

G 12-10-98 Added Notes CMD J Mc

REV. DATE DESCRIPTION BY CKD. BY

WARNING: THIS PRODUCT CAN EXPOSE YOU TO CHEMICALS INCLUDING PHTHALATES OR SELENIUM WHICH ARE KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER OR REPRODUCTIVE HARM.

FOR MORE INFORMATION VISIT: www.P65Warnings.ca.gov

You might also like

- Saudi Energy Conservation Code - Commercial (SBC 601) - UnlockedDocument105 pagesSaudi Energy Conservation Code - Commercial (SBC 601) - UnlockedAHMED ATIF83% (6)

- tlc9803 EN2008.08.27Document37 pagestlc9803 EN2008.08.27Zuleica Ocón20% (5)

- Practicale Plumbing Design Guide-P1Document100 pagesPracticale Plumbing Design Guide-P1AHMED ATIFNo ratings yet

- Engineered Plumbing Design II (ASPE)Document153 pagesEngineered Plumbing Design II (ASPE)AHMED ATIFNo ratings yet

- Grammar Practice Worksheets - Simple Present - FromDocument1 pageGrammar Practice Worksheets - Simple Present - FromLeonel Agsgdf100% (7)

- Screening Test - Grade 7Document5 pagesScreening Test - Grade 7Hosain Said Usman Jr.100% (17)

- Markvie TagsDocument28 pagesMarkvie Tagssrinivas100% (2)

- IndiaHikes PDFDocument5 pagesIndiaHikes PDFAAMOD KHARB PGP 2018-20 BatchNo ratings yet

- Balcony DrainDocument1 pageBalcony DrainraghuragooNo ratings yet

- Special Purpose Combo Roof Drain: SmithDocument1 pageSpecial Purpose Combo Roof Drain: SmithSoojaelimNo ratings yet

- 2698 - MA - Trap PrimerDocument1 page2698 - MA - Trap PrimerkuraimundNo ratings yet

- J.R. Smith 1015 Roof DrainDocument2 pagesJ.R. Smith 1015 Roof DrainDarl Anthony VelosoNo ratings yet

- J.R. Smith 1830 Roof Drain, SecondaryDocument1 pageJ.R. Smith 1830 Roof Drain, SecondaryDarl Anthony VelosoNo ratings yet

- D 8-910Document1 pageD 8-910ibnrafeeqNo ratings yet

- d1010 RDPDocument1 paged1010 RDPFernando CardosoNo ratings yet

- Quad Close Trap Seal Submittal (Fig. 2692)Document2 pagesQuad Close Trap Seal Submittal (Fig. 2692)kuraimundNo ratings yet

- Catalogue 2016 ToshibaDocument36 pagesCatalogue 2016 ToshibaMastArchNo ratings yet

- South Kensington: Prince Consort RoadDocument1 pageSouth Kensington: Prince Consort RoadA MamgNo ratings yet

- Polyenone Green ECO YarnDocument8 pagesPolyenone Green ECO Yarnzafar87333No ratings yet

- Pol808 3Document4 pagesPol808 3robert.leon007No ratings yet

- General Notes: Bridge Site Location PlanDocument1 pageGeneral Notes: Bridge Site Location PlanCarl Lou BaclayonNo ratings yet

- Example Part B Plans - 1 BoxDocument7 pagesExample Part B Plans - 1 Boxapi-255636511No ratings yet

- Ina Market Site PlanDocument1 pageIna Market Site Planjaidev vermaNo ratings yet

- Becoming MDVTI-MDETTE Study CentreDocument3 pagesBecoming MDVTI-MDETTE Study Centreभृगुवंशी आयुष त्रिवेदीNo ratings yet

- Management Services Division Management Services DivisionDocument130 pagesManagement Services Division Management Services DivisionVictor Viceor100% (6)

- South Kensington CampusDocument1 pageSouth Kensington Campuskeke renNo ratings yet

- 1 in 1 Out Acdb PanelDocument5 pages1 in 1 Out Acdb PanelDesign TeamNo ratings yet

- CheckbackDocument1 pageCheckbackSadish MaharjanNo ratings yet

- Item 13 D - 2020-23c - Shingles - Weathered Wood GAF Timerbline Shingles and SpecsDocument23 pagesItem 13 D - 2020-23c - Shingles - Weathered Wood GAF Timerbline Shingles and SpecsoswaldoNo ratings yet

- Saeed Hamad Alrashdi - Schematic Diagram ApprovedDocument1 pageSaeed Hamad Alrashdi - Schematic Diagram ApprovedHoran HoranNo ratings yet

- Table of SpecificationDocument10 pagesTable of SpecificationRolando ValdezNo ratings yet

- Water Entry Connection Point Layout ApprovedDocument1 pageWater Entry Connection Point Layout ApprovedHoran HoranNo ratings yet

- MUK-61-2-0650-ERC-0001 Rev 3Document1 pageMUK-61-2-0650-ERC-0001 Rev 3Suresh MahalingamNo ratings yet

- Foundation Drawing 01Document1 pageFoundation Drawing 01Pawan ShettyNo ratings yet

- Flow Rate Monitoring - RFO Type: 4.5 To 24 VDC Pulsed OutputDocument2 pagesFlow Rate Monitoring - RFO Type: 4.5 To 24 VDC Pulsed OutputReza Pratama NugrahaNo ratings yet

- m4.0 - Mechanical Typical Guestroom PlanDocument1 pagem4.0 - Mechanical Typical Guestroom PlanVinh Nguyễn QuangNo ratings yet

- GA Drawing SO2 Scrubber - R1-To SadiartoDocument1 pageGA Drawing SO2 Scrubber - R1-To SadiartoAyahKenzieNo ratings yet

- GA Drawing SO2 Scrubber - R1Document1 pageGA Drawing SO2 Scrubber - R1AyahKenzieNo ratings yet

- De 04Document1 pageDe 04Sachin SharmaNo ratings yet

- S1Document1 pageS1Tyrone PaulinoNo ratings yet

- H O M E Stan DAR DS Proj Ects MEE Ting S Refe Renc E Libr ARY NEW S & Medi A Abou TUS Stay CON Nect EDDocument5 pagesH O M E Stan DAR DS Proj Ects MEE Ting S Refe Renc E Libr ARY NEW S & Medi A Abou TUS Stay CON Nect EDBASANTA KUMAR SAHUNo ratings yet

- Marjan Increment Program Jubail Area-Pipeline Projact PKG#18 Electrical Equipment Sizing CalculationDocument22 pagesMarjan Increment Program Jubail Area-Pipeline Projact PKG#18 Electrical Equipment Sizing CalculationAfzal AsifNo ratings yet

- E SE NE: Residence ResidenceDocument1 pageE SE NE: Residence ResidenceManvi SharmaNo ratings yet

- Roof Plan - Lightning Protection: Construction DrawingDocument1 pageRoof Plan - Lightning Protection: Construction DrawingrajavelNo ratings yet

- Misc RW 001Document1 pageMisc RW 001Tanveer IqbalNo ratings yet

- TECHNICAL PLANS For The Procurement of The Construction of Dormitory Building III MaleDocument58 pagesTECHNICAL PLANS For The Procurement of The Construction of Dormitory Building III Malekayjas70No ratings yet

- Architectural PlanDocument15 pagesArchitectural Plankayjas70No ratings yet

- Architectural PlanDocument15 pagesArchitectural Plankayjas70No ratings yet

- Centro Colan 2 13-06 Esc 1 en 125Document1 pageCentro Colan 2 13-06 Esc 1 en 125claudia valdiviezoNo ratings yet

- DWG - Additional Fat Trap Fly Ash SiloDocument3 pagesDWG - Additional Fat Trap Fly Ash SiloadribmutNo ratings yet

- The Reward and Remuneration Series Handbook PDFDocument320 pagesThe Reward and Remuneration Series Handbook PDFOdhis KanayoNo ratings yet

- Rompa International 2023Document220 pagesRompa International 2023AnAs Al ArjanNo ratings yet

- BLUE POLYNESIA TRUSES-ModelDocument1 pageBLUE POLYNESIA TRUSES-ModelXixi XuNo ratings yet

- Personnel Master File MAYBUBON IsDocument2 pagesPersonnel Master File MAYBUBON IsMark James VallejosNo ratings yet

- Wellingtonpark BikemapaeastDocument1 pageWellingtonpark BikemapaeastsamdmcscribdNo ratings yet

- CrisiDocument11 pagesCrisiiGiorgosNo ratings yet

- REMOTE BOX-ModelDocument1 pageREMOTE BOX-ModelAndreas OktoraNo ratings yet

- Full Campus PlanDocument1 pageFull Campus PlanMaine Trust For Local NewsNo ratings yet

- Reference Center Line PlanDocument1 pageReference Center Line PlanAnand KasaudhanNo ratings yet

- Daftar Nilai Siswa SMP Dr. Soetomo: Nama Siswa Nama SiswaDocument1 pageDaftar Nilai Siswa SMP Dr. Soetomo: Nama Siswa Nama Siswapkks penilaian2019No ratings yet

- SouthsudanDocument1 pageSouthsudanBior DanielNo ratings yet

- Nuydeup - 1: STR STR CON CON DEX DEX INT INT WIS WIS CHA CHADocument9 pagesNuydeup - 1: STR STR CON CON DEX DEX INT INT WIS WIS CHA CHADylan VeraartNo ratings yet

- S-23-01 Saraswati Singh TKDocument3 pagesS-23-01 Saraswati Singh TKTanweer KhanNo ratings yet

- Vegan Leathers Comparisons - Cleaned - CopieDocument23 pagesVegan Leathers Comparisons - Cleaned - CopieAhmad IbrahimNo ratings yet

- One Flow Anti Scale SolutionDocument6 pagesOne Flow Anti Scale SolutionAHMED ATIFNo ratings yet

- Appendix 2 93M-0501-B13-6O000-DGM-00003 - 6OC TMainline Traction Power Sectioning Diagram (FDR)Document11 pagesAppendix 2 93M-0501-B13-6O000-DGM-00003 - 6OC TMainline Traction Power Sectioning Diagram (FDR)AHMED ATIFNo ratings yet

- Appendix 1 93M-0501-B13-NC000-DGM-00003 NCC Mainline Power Sectioning Diagram (FDR)Document15 pagesAppendix 1 93M-0501-B13-NC000-DGM-00003 NCC Mainline Power Sectioning Diagram (FDR)AHMED ATIFNo ratings yet

- Catalog DDocument268 pagesCatalog DAHMED ATIFNo ratings yet

- C - Perforated DiffusersDocument31 pagesC - Perforated DiffusersAHMED ATIFNo ratings yet

- 010 773 (KESSEL Catalogue 3.2Document326 pages010 773 (KESSEL Catalogue 3.2AHMED ATIFNo ratings yet

- Subject: AHU& FCU Connection Details Project: NHJH AHU Connection and Access Side Based On Below Picture For ReferencesDocument3 pagesSubject: AHU& FCU Connection Details Project: NHJH AHU Connection and Access Side Based On Below Picture For ReferencesAHMED ATIFNo ratings yet

- FCUDocument4 pagesFCUAHMED ATIFNo ratings yet

- INFRA Report Final 2-2-2017Document29 pagesINFRA Report Final 2-2-2017AHMED ATIFNo ratings yet

- All About Desert LifeDocument26 pagesAll About Desert Lifejinky baldespiñosaNo ratings yet

- Engineering Recommendation P28 - Issue 2 2018 - ENADocument83 pagesEngineering Recommendation P28 - Issue 2 2018 - ENACalum MartinNo ratings yet

- Plasticization Effect of Triacetin On Structure and Properties of Starch Ester FilmDocument8 pagesPlasticization Effect of Triacetin On Structure and Properties of Starch Ester FilmNanik HendrawatiNo ratings yet

- 50 Largest Hedge Fund Managers in EuropeDocument12 pages50 Largest Hedge Fund Managers in Europehttp://besthedgefund.blogspot.comNo ratings yet

- Defect Behavior in BF2 Implants For SD Applications As A Function of Ion Beam CharacteristicsDocument4 pagesDefect Behavior in BF2 Implants For SD Applications As A Function of Ion Beam CharacteristicsMustafa BaşakNo ratings yet

- Touch HD Android EngDocument2 pagesTouch HD Android Engvaitheeswaran kumaravelNo ratings yet

- Basic Tools and Equipment Used in Meal PreparationDocument37 pagesBasic Tools and Equipment Used in Meal Preparationhersal fae gerardo100% (2)

- Policies Regarding Water Conservation in India (Conserve Water, Conserve Life, Save Water, and It Will Save You)Document11 pagesPolicies Regarding Water Conservation in India (Conserve Water, Conserve Life, Save Water, and It Will Save You)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Primary Survey AssessmentDocument52 pagesPrimary Survey Assessmentlapkas donjuanNo ratings yet

- ThesisDocument11 pagesThesismae santosNo ratings yet

- Astmd7622 10Document5 pagesAstmd7622 10moh_ichwanuddinNo ratings yet

- Quarter 2 W1-W6Document46 pagesQuarter 2 W1-W6jeric m. gutierrez100% (1)

- Cosmetic Product Usage and Self-Confidence Among HUMSS Students of BayambangDocument39 pagesCosmetic Product Usage and Self-Confidence Among HUMSS Students of BayambangLoraine DiazonNo ratings yet

- Chemistry FileDocument36 pagesChemistry FilepathisharmaNo ratings yet

- Clean Agent Fire Protection SystemDocument9 pagesClean Agent Fire Protection Systemjkhan_724384No ratings yet

- Jurnal Gingivitis Vivian 190631174Document5 pagesJurnal Gingivitis Vivian 190631174VivianNo ratings yet

- Cv. Thomas Fajar Sulaksono: Application For EmploymentDocument5 pagesCv. Thomas Fajar Sulaksono: Application For Employmentrajawali fotocopyNo ratings yet

- Inhibition of in Vitro Cell Adherence of Clostridium Difficile by Saccharomyces BoulardiiDocument7 pagesInhibition of in Vitro Cell Adherence of Clostridium Difficile by Saccharomyces BoulardiiSatyajit LenkaNo ratings yet

- Cervicogenic Headache Diagnosis and Treatment BogdukDocument10 pagesCervicogenic Headache Diagnosis and Treatment BogdukYoan PereiraNo ratings yet

- Principles of Fluid ManagementDocument17 pagesPrinciples of Fluid ManagementBrainy-Paykiesaurus LuminirexNo ratings yet

- Well Control - Kill Sheet Pre-Recorded Information Pump Strokes RequiredDocument1 pageWell Control - Kill Sheet Pre-Recorded Information Pump Strokes RequiredscrbdgharaviNo ratings yet

- Synthesis EssayDocument4 pagesSynthesis Essayapi-284842143No ratings yet

- Specification For Fire Water HydrantDocument5 pagesSpecification For Fire Water HydrantThiru AnanthNo ratings yet

- Kathrein 80010454 (KRE1012056)Document2 pagesKathrein 80010454 (KRE1012056)Mani_3ipNo ratings yet

- Chapter 23 - SensorsDocument18 pagesChapter 23 - SensorsnikolasthermosolutionsNo ratings yet