Professional Documents

Culture Documents

03 Consumo Energía Bond + Thoughput UNSMS

03 Consumo Energía Bond + Thoughput UNSMS

Uploaded by

Joan Puris CondorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03 Consumo Energía Bond + Thoughput UNSMS

03 Consumo Energía Bond + Thoughput UNSMS

Uploaded by

Joan Puris CondorCopyright:

Available Formats

Moly-Cop Tools, Version 3.

0

About the Bond_Op. Work Index Spreadsheet ...

Scope :

The Bond_Op. Work Index spreadsheet was designed to estimate the Operational Work Index of a given

grinding installation of known dimensions and operating conditions, based on the traditional Bond's Law and the

Hogg & Fuersteneau Power Model (see Mill Power_Ball Mills spreadsheet for further details on such model).

Theoretical Framework :

Undoubtedly, the extensive work of Fred C. Bond ("The Third Theory of Comminution", AIME Trans.,Vol. 193, p.

484, 1952. Also in Mining Engineering, May 1952) has been widely recognized as a very significant contribution

to a first understanding of the operational response of conventional ball mills in various grinding circuits. His

Third Theory or "Law" of Comminution has become the most traditionally accepted framework for the

evaluation of existing grinding operations as well as the design of new installations :

E = 10 Wi (1/P801/2 – 1/F801/2)

where :

E = Specific Energy Consumption, kWh/ton ground.

F80 = 80% passing size in the Fresh Ore Feed Stream, microns.

P80 = 80% passing size in the Final Ground Product, microns.

Wi = Bond's Work Index, indicative of the hardness of the ore, kWh/ton.

The Bond's Law so allows, as a first approach, to estimate the energy demand (kWh) required to grind each ton

of ore. Such Specific Energy Consumption determines in turns the Capacity of the grinding section, by the

expression :

M = P/E

where :

M = Fresh Ore Throughput (not including Circulating Load), ton/hr.

P = Net Mill Power Demand, kW.

Bond's Work Index may be estimated directly from operational data (whenever available) from back-calculation

of the first equation above. In such case is denoted as the Operational Work Index :

Wio = E / 10 (1/P801/2 – 1/F801/2)

Data Input :

All data required by the calculation routine must be defined in each corresponding unprotected white

background cell of the here attached Data File worksheet. Gray background cells contain the results of the

corresponding formulas there defined and are protected to avoid any accidental editing.

Moly-Cop Tools / 582975899.xlsx 03/17/2022 / 04:52:54

Moly-Cop Tools / 582975899.xlsx 03/17/2022 / 04:52:54

Moly-Cop Tools TM

(Version 3.0)

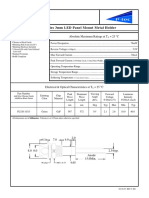

BOND'S LAW APPLICATION

Estimation of the Operating Work Index from Plant Data

Remarks Base Case Example

GRINDING TASK :

Ore Work Index, kWh/ton (metric) 12.71 Specific Energy, kWh/ton 8.37

Feed Size, F80, microns 4000 x Net Power Available, kW 3348

Product Size, P80, microns 150.0 y Number of Mills for the Task 1

Total Plant Throughput, ton/hr 400.00 Net kW / Mill 3348

Mill

MILL DIMENSIONS AND OPERATING CONDITIONS : Power, kW

2886 Balls

Eff. Diameter Eff. Length Mill Speed Charge Balls Interstitial Lift 0 Overfilling

ft ft % Critical Filling,% Filling,% Slurry Filling,% Angle, (°) 462 Slurry

18.20 29.00 50.00 38.00 38.00 100.00 34.23 3348 Net Total

L/D rpm 10.0 % Losses

1.593 8.98 3720 Gross Total

% Solids in the Mill 72.00 Charge Mill Charge Weight, tons Apparent

Ore Density, ton/m3 2.80 Volume, Ball Slurry Density

Slurry Density, ton/m3 1.86 m3 Charge Interstitial above Balls ton/m3

Balls Density, ton/m3 7.75 81.34 378.24 60.57 0.00 5.395

Moly-Cop Tools / 582975899.xlsx 03/17/2022 / 04:52:54

Utilice la información de proveedor

https://www.metso.com/cl/productos/molinos/molinos-de-bolas/

Utilice los siguientes

Molinos

Diametro Longitud

10 15

15.5 19

18 29

Moly-Cop Tools / 582975899.xlsx 03/17/2022 / 04:52:54

Moly-Cop Tools / 582975899.xlsx 03/17/2022 / 04:52:54

f80

12.71 9000 8500 8000 7500 7000 6500 6000 5500 5000 4500 4000 3500 3000

600

550

500

450

400

p80 350

300

250

200

150

100

Toma de decision

x 3

y 4

Prod 12

X

12 1 2 3 4 5 6 7 8 9 10 11 12 13

Moly-Cop Tools / 582975899.xlsx 03/17/2022 / 04:52:54

1 1 2 3 4 5 6 7 8 9 10 11 12 13

3 3 6 9 12 15 18 21 24 27 30 33 36 39

6 6 12 18 24 30 36 42 48 54 60 66 72 78

9 9 18 27 36 45 54 63 72 81 90 99 108 117

y 12 12 24 36 48 60 72 84 96 108 120 132 144 156

15 15 30 45 60 75 90 105 120 135 150 165 180 195

18 18 36 54 72 90 108 126 144 162 180 198 216 234

21 21 42 63 84 105 126 147 168 189 210 231 252 273

24 24 48 72 96 120 144 168 192 216 240 264 288 312

Moly-Cop Tools / 582975899.xlsx 03/17/2022 / 04:52:54

Moly-Cop Tools / 582975899.xlsx 03/17/2022 / 04:52:54

12.00

10.00

2500 2000 1500 1000

8.00

6.00

4.00

2.00

0.00

0 100 200 300 400 500 600 700

X

14 15 16 17 18 19 20 21 22 23 24 25

Moly-Cop Tools / 582975899.xlsx 03/17/2022 / 04:52:54

14 15 16 17 18 19 20 21 22 23 24 25

42 45 48 51 54 57 60 63 66 69 72 75

84 90 96 102 108 114 120 126 132 138 144 150

126 135 144 153 162 171 180 189 198 207 216 225

168 180 192 204 216 228 240 252 264 276 288 300

210 225 240 255 270 285 300 315 330 345 360 375

252 270 288 306 324 342 360 378 396 414 432 450

294 315 336 357 378 399 420 441 462 483 504 525

336 360 384 408 432 456 480 504 528 552 576 600

Moly-Cop Tools / 582975899.xlsx 03/17/2022 / 04:52:54

Moly-Cop Tools TM

(Version 2.0)

BOND'S LAW APPLICATION

Estimation of a Conventional Ball Mill Grinding Capacity

Remarks Base Case Example

GRINDING TASK :

Ore Work Index, kWh (net)/metric ton 11.00 Specific Energy, kWh/ton 6.14

Feed Size, F80, microns 4500 x Net Power Available, kW 4124

Product Size, P80, microns 200.0 y Number of Mills for the Task 1

Total Plant Throughput, ton/hr 671.91 Net kW / Mill 4124

Mill

MILL DIMENSIONS AND OPERATING CONDITIONS : Power, kW

3555 Balls

Eff. Diameter Eff. Length Mill Speed Charge Balls Interstitial Lift 0 Overfilling

ft ft % Critical Filling,% Filling,% Slurry Filling,% Angle, (°) 569 Slurry

18.20 21.90 80.00 38.00 38.00 100.00 35.00 4124 Net Total

L/D rpm 10.0 % Losses

1.203 14.36 4583 Gross Total

% Solids in the Mill 72.00 Charge Mill Charge Weight, tons Apparent

Ore Density, ton/m3 2.80 Volume, Ball Slurry Density

Slurry Density, ton/m3 1.86 m3 Charge Interstitial above Balls ton/m3

Balls Density, ton/m3 7.75 61.43 285.64 45.74 0.00 5.395

You might also like

- USIM PAC 31 Starting GuideDocument32 pagesUSIM PAC 31 Starting GuideDirceu Nascimento100% (1)

- Appendix B-1 Bond Work Index Test Procedure For Determination of The Bond Ball Mill Work Index PDFDocument3 pagesAppendix B-1 Bond Work Index Test Procedure For Determination of The Bond Ball Mill Work Index PDFLuis Argüelles SaenzNo ratings yet

- A Mini Project Report ON Web Based College Admission System: Bachelor of Computer ApplicationsDocument48 pagesA Mini Project Report ON Web Based College Admission System: Bachelor of Computer ApplicationsAbhimanyu Pandey100% (1)

- HRM - Thomas CookDocument52 pagesHRM - Thomas CookSabrish Nair50% (2)

- Bond Mill Throughput10X10Document5 pagesBond Mill Throughput10X10Flia Diaz Zuniga100% (1)

- Scope:: About The Mill Power - SAG Mills Spreadsheet ..Document4 pagesScope:: About The Mill Power - SAG Mills Spreadsheet ..percyNo ratings yet

- Mill Power - Rod MillsDocument4 pagesMill Power - Rod MillsFredy PeñaNo ratings yet

- Bond Mill ThroughputDocument5 pagesBond Mill ThroughputAnonymous TsKN7XZBNo ratings yet

- Bond Mill SizingDocument3 pagesBond Mill SizingDidi Paul Huilca RodriguezNo ratings yet

- Media Charge Dynamics Ball MillsDocument31 pagesMedia Charge Dynamics Ball Millsedwin javier valdivia guillenNo ratings yet

- Multistage Flowsheets Sabc1Document189 pagesMultistage Flowsheets Sabc1joseluisNo ratings yet

- Media Charge - Dynamics - SAG MillsDocument31 pagesMedia Charge - Dynamics - SAG Millsedwin javier valdivia guillenNo ratings yet

- Media Charge Wear Rod MillsDocument3 pagesMedia Charge Wear Rod MillspolsiemprealdoNo ratings yet

- Media Charge - Wear - Non-LinearDocument85 pagesMedia Charge - Wear - Non-LinearPedro Rodriguez100% (1)

- Media Charge - Linear Wear - Ball MillsDocument5 pagesMedia Charge - Linear Wear - Ball MillsLuis Katsumoto Huere AnayaNo ratings yet

- Riza Marie L. Castorico BSEM-4th Yr. Activity No. 3 Comminution (Disc Pulverizer)Document5 pagesRiza Marie L. Castorico BSEM-4th Yr. Activity No. 3 Comminution (Disc Pulverizer)Riza CastoricoNo ratings yet

- Scope:: About The Cyclobal - Single Spreadsheet ..Document18 pagesScope:: About The Cyclobal - Single Spreadsheet ..Gaby Nancy Catura MaynaNo ratings yet

- Media Charge - Dynamics - SAG Mills - ModifiedDocument85 pagesMedia Charge - Dynamics - SAG Mills - Modifiededwin javier valdivia guillenNo ratings yet

- SAGSim OpenDocument124 pagesSAGSim OpenFelipe Gonzalez JimenezNo ratings yet

- A Comparison of The Bond Method For Sizing Wet Tumbling Mills With A Size Mass Balance Simulation ModelDocument14 pagesA Comparison of The Bond Method For Sizing Wet Tumbling Mills With A Size Mass Balance Simulation ModelJavier Enrique Toro YentzenNo ratings yet

- Copia de Copy of Ballbal - Direc - Mol I (03!06!15)Document30 pagesCopia de Copy of Ballbal - Direc - Mol I (03!06!15)Travis BradyNo ratings yet

- Scope:: Ballsim - Direct or Ballsim - Reverse)Document129 pagesScope:: Ballsim - Direct or Ballsim - Reverse)Irving Dirzo CarrilloNo ratings yet

- SAGParam OpenDocument128 pagesSAGParam OpenpercyNo ratings yet

- CycloSim SingleDocument124 pagesCycloSim SingleGaby Nancy Catura MaynaNo ratings yet

- Media Charge - LevelDocument7 pagesMedia Charge - LevelHarold Leòn CadenasNo ratings yet

- BallParam BatchDocument16 pagesBallParam BatchAnonymous TsKN7XZBNo ratings yet

- #21. Pearce, Gagnon, Klein, MacIver, Makni, Fisher, - Kumar - Investigation of A Novel HPGR and Size Classification Circuit PDFDocument11 pages#21. Pearce, Gagnon, Klein, MacIver, Makni, Fisher, - Kumar - Investigation of A Novel HPGR and Size Classification Circuit PDFManolo Sallo ValenzuelaNo ratings yet

- Scope:: About The Ballbal - Reverse Spreadsheet ..Document14 pagesScope:: About The Ballbal - Reverse Spreadsheet ..lewis poma rojasNo ratings yet

- SAGSim OpenDocument124 pagesSAGSim OpenpolsiemprealdoNo ratings yet

- Scope:: About The Ballbal - Reverse Spreadsheet ..Document15 pagesScope:: About The Ballbal - Reverse Spreadsheet ..julio carpio Franco100% (1)

- Paper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit DesignDocument13 pagesPaper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit Designcuberbill1980No ratings yet

- Mediacharge TrajectoriesDocument8 pagesMediacharge TrajectoriesRolando QuispeNo ratings yet

- BallParam Batch CursoDocument44 pagesBallParam Batch CursoH Marquez R GracielaNo ratings yet

- Ballsim ReverseDocument58 pagesBallsim Reversesnarf273No ratings yet

- ReporteDocument23 pagesReporteevizcardo4617No ratings yet

- Mine-to-Mill Optimization of Aggregate Production: Semi-Annual Report No. 4Document94 pagesMine-to-Mill Optimization of Aggregate Production: Semi-Annual Report No. 4Jeffrey KerrNo ratings yet

- Cyclosim SingleDocument8 pagesCyclosim SingleEmiliano GilNo ratings yet

- CrushSim OpenDocument124 pagesCrushSim Openedwin javier valdivia guillenNo ratings yet

- RowlandDocument5 pagesRowlandzicoNo ratings yet

- Multistage Flowsheets - SABC-2Document191 pagesMultistage Flowsheets - SABC-2lewis poma rojasNo ratings yet

- Mill Power - Ball MillsDocument3 pagesMill Power - Ball MillsvirginialeaoNo ratings yet

- Scope:: About The Ballparam - Dual Spreadsheet ..Document57 pagesScope:: About The Ballparam - Dual Spreadsheet ..lewis poma rojasNo ratings yet

- Scope:: About The Ballbal - Direct Spreadsheet ..Document18 pagesScope:: About The Ballbal - Direct Spreadsheet ..Erik Huarcaya SalcedoNo ratings yet

- A New Autogenous and Semi-Autogenous Mill Model For Scale-Up, Design and OptimisationDocument9 pagesA New Autogenous and Semi-Autogenous Mill Model For Scale-Up, Design and OptimisationJuanOlivaresNo ratings yet

- SAIL BSBK Visit Docx-15.06. R-1rtfDocument7 pagesSAIL BSBK Visit Docx-15.06. R-1rtfsssadangi100% (1)

- Cyclones: (Adapted From Air Pollution Control by C. D. Cooper & F.C - Alley, 1986)Document9 pagesCyclones: (Adapted From Air Pollution Control by C. D. Cooper & F.C - Alley, 1986)ePuL69No ratings yet

- SAGParam OpenDocument128 pagesSAGParam OpenFederico Hirsch EspinozaNo ratings yet

- Paper Virtual Pro Molienda AG-SAGDocument15 pagesPaper Virtual Pro Molienda AG-SAGDiego Alonso Almeyda BarzolaNo ratings yet

- Media Charge - Ball Size & DensityDocument3 pagesMedia Charge - Ball Size & DensityIrving Dirzo CarrilloNo ratings yet

- Scope:: About The Ballbal - Direct Spreadsheet ..Document14 pagesScope:: About The Ballbal - Direct Spreadsheet ..alonsogonzalesNo ratings yet

- SAGParam Open AresDocument127 pagesSAGParam Open AresVolney Quispe AyalaNo ratings yet

- Power-Based Comminution Calculations Using AusgrindDocument13 pagesPower-Based Comminution Calculations Using AusgrindMarcos Bueno100% (1)

- USIM PAC 32 Starting GuideDocument0 pagesUSIM PAC 32 Starting GuideEdinson Klever Ponce Ramirez100% (1)

- HydroFloat CPF - Cu ApplicationDocument34 pagesHydroFloat CPF - Cu ApplicationNicolas PerezNo ratings yet

- The Direct Electrowinning of Gold From Dilute Cyanide Leach LiquorsDocument15 pagesThe Direct Electrowinning of Gold From Dilute Cyanide Leach LiquorsLennonNo ratings yet

- Abrasion Test: Feed Sample RequirementsDocument1 pageAbrasion Test: Feed Sample RequirementsThiago JatobáNo ratings yet

- XRTDocument7 pagesXRTmushava nyokaNo ratings yet

- Comminution Example 5301 Crushing 11Document10 pagesComminution Example 5301 Crushing 11ModelamientoDeProcesosMinerosSimmodmetNo ratings yet

- Bonds Law ApplicationDocument1 pageBonds Law ApplicationDanny joaquinNo ratings yet

- Mill Power Ball MillsDocument5 pagesMill Power Ball MillsCarlos de la TorreNo ratings yet

- Media Charge - Wear - Ball MillsDocument4 pagesMedia Charge - Wear - Ball MillsPedro RodriguezNo ratings yet

- Media Charge - Linear Wear - Ball MillsDocument5 pagesMedia Charge - Linear Wear - Ball MillsLuis Katsumoto Huere AnayaNo ratings yet

- Mill Power - Ball MillsDocument6 pagesMill Power - Ball MillsPedro RodriguezNo ratings yet

- Media Charge - Wear - Non-LinearDocument85 pagesMedia Charge - Wear - Non-LinearPedro Rodriguez100% (1)

- Media Charge - Wear - PredictorDocument12 pagesMedia Charge - Wear - PredictorPedro RodriguezNo ratings yet

- Granulometrico Mod Hge FinalDocument50 pagesGranulometrico Mod Hge FinalPedro RodriguezNo ratings yet

- Media Charge - Wear - Ball MillsDocument4 pagesMedia Charge - Wear - Ball MillsPedro RodriguezNo ratings yet

- Ba - Masa Con DensidadesDocument9 pagesBa - Masa Con DensidadesPedro RodriguezNo ratings yet

- Balance ZarandaDocument4 pagesBalance ZarandaPedro RodriguezNo ratings yet

- Balance NodalDocument4 pagesBalance NodalPedro Rodriguez100% (1)

- Name: Luis Alberto Gonzalez Huaynacari: Hat Hat Hat HatDocument2 pagesName: Luis Alberto Gonzalez Huaynacari: Hat Hat Hat HatPedro RodriguezNo ratings yet

- Unit 4 Basic CiduntDocument108 pagesUnit 4 Basic CiduntPedro RodriguezNo ratings yet

- TMV Trading PricelistDocument8 pagesTMV Trading Pricelistronald s. rodrigoNo ratings yet

- Pilippine Short StoriesDocument75 pagesPilippine Short StoriesRaymond Bill Bela-o Patacsil50% (2)

- Triz 2Document170 pagesTriz 2ravikumarrampurNo ratings yet

- Hold Time Studies 1661741387Document8 pagesHold Time Studies 1661741387Cyclone Pharmaceuticals Pvt Ltd PuneNo ratings yet

- Sustamid PA6GOLDocument1 pageSustamid PA6GOLPatrick BaridonNo ratings yet

- Persuasive Essay Stem Cell ResearchDocument5 pagesPersuasive Essay Stem Cell Researchhqovwpaeg100% (2)

- Carton Manufacturing Defects Line 1 Line 2 Line 3 Total DefectsDocument31 pagesCarton Manufacturing Defects Line 1 Line 2 Line 3 Total Defectspeter25munchenNo ratings yet

- Quality of Work Life in Selected Public Universities in Dar Es Salaam, TanzaniaDocument6 pagesQuality of Work Life in Selected Public Universities in Dar Es Salaam, TanzaniaInternational Journal of Arts, Humanities and Social Studies (IJAHSS)No ratings yet

- 3e Ventilator PDFDocument6 pages3e Ventilator PDFNgoc Hau Pham ThiNo ratings yet

- Does Corporate Social Responsibility Disclosure Improve Firm Investment Efficiency? Evidence From ChinaDocument32 pagesDoes Corporate Social Responsibility Disclosure Improve Firm Investment Efficiency? Evidence From ChinaNi Luh Lemi Sushmita DeviNo ratings yet

- Introduction To Social Media Awareness 1Document5 pagesIntroduction To Social Media Awareness 1Dhruv SinghNo ratings yet

- Recreationalactivities 140317203039 Phpapp01 PDFDocument27 pagesRecreationalactivities 140317203039 Phpapp01 PDFRodjan MoscosoNo ratings yet

- Companion Log 2018 10 10T13 44 31ZDocument15 pagesCompanion Log 2018 10 10T13 44 31ZTerbaik2u HDNo ratings yet

- Option B - BiochemistryDocument24 pagesOption B - BiochemistryRosaNo ratings yet

- Preventionof HypothermiaDocument2 pagesPreventionof HypothermiarisnayektiNo ratings yet

- ACC2008 - Lec 3 - Flexible Budgeting and Analysis of Overhead CostsDocument29 pagesACC2008 - Lec 3 - Flexible Budgeting and Analysis of Overhead CostsSu-Kym TanNo ratings yet

- Essentials of Financial Management 3rd Edition Brigham Solutions Manual 1Document18 pagesEssentials of Financial Management 3rd Edition Brigham Solutions Manual 1whitneyreynoldsnzrtkbamfd100% (32)

- 1403 - Decoding The Education of Gifted Individual in The Ottoman Empire - Mimar Sinan's Education Case - İbrahim GÜLERDocument10 pages1403 - Decoding The Education of Gifted Individual in The Ottoman Empire - Mimar Sinan's Education Case - İbrahim GÜLERAHZeidanNo ratings yet

- WE503 IndicatorDocument1 pageWE503 IndicatorWANSNo ratings yet

- Veritek VIPS84 KWH MeterDocument2 pagesVeritek VIPS84 KWH MeterindustrialindiaNo ratings yet

- PL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CDocument1 pagePL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CJajang JajaNo ratings yet

- Narasimha StutiDocument21 pagesNarasimha StutiezioNo ratings yet

- Branches of Forensic ScienceDocument19 pagesBranches of Forensic ScienceSriram ShirkeNo ratings yet

- Jihyd-11846 YemkejDocument92 pagesJihyd-11846 YemkejhaNo ratings yet

- HEIGHTS and GROUND COVERAGEDocument5 pagesHEIGHTS and GROUND COVERAGEanon_871836529No ratings yet

- Can FD SpecDocument34 pagesCan FD SpecPreetham BaskaranNo ratings yet

- BJP8 v. 170Document91 pagesBJP8 v. 170LourdesNo ratings yet

- 2020 ECO Topic 1 International Economic Integration Notes HannahDocument23 pages2020 ECO Topic 1 International Economic Integration Notes HannahJimmyNo ratings yet