Professional Documents

Culture Documents

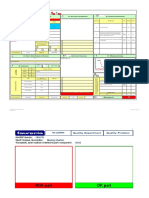

Potential Failure Mode and Effective Analysis (Process FMEA)

Potential Failure Mode and Effective Analysis (Process FMEA)

Uploaded by

nainarmuthuramalingamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Potential Failure Mode and Effective Analysis (Process FMEA)

Potential Failure Mode and Effective Analysis (Process FMEA)

Uploaded by

nainarmuthuramalingamCopyright:

Available Formats

Home

Potential Failure Mode and Effective Analysis (Process FMEA)

Home

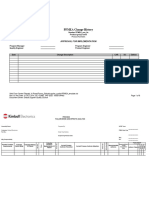

Part Name : Prepared By : Approved By :

Customer Part No.

Rev Level. / : FMEA Date(orig) : Rev Date :

XYZ Part No.

PFMEA No : Issue Level :

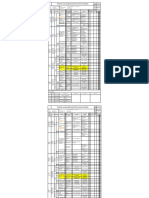

Action Results

OCCUR

Requirement Potential Potential S Potential Cause / Current Process Current Process D R Responsibility

CLASS

Process Recommended

(Balooned Failure Effect(s) of E Mechanism(s) of Controls Controls E P and Target with S O D

Function Actions Actions

Dimension) Mode Failure V Failure (Prevention) (Detection) T N Date E C E

Taken

V C T

1 Raw Material

Adherence to Chemistry Wrong material

Variation in Chemistry Heat Treatment Defects 9 1 Material Specification Sheet. 1 Inspection Report 1 ### None

(51) specification given to mill

Supplier Mill Certificate

01 RAW MATERIAL

RECEIPT

Free from surface Variation in Hardness,Mechanical Leads to Problem in Sawing. XYZ Raw Material

defects,Adherence to Properties,Cracks & Surface ( Reduce 9 -- --- Material Specification Sheet. 1 Inspection Report 6 ### None

mechanical properties Defects Tool life , Saw life) Supplier Mill Certificate

1 2 Customer Identified Special Characteristics 1

You might also like

- Management Information Systems 13th Edition Laudon Test BankDocument23 pagesManagement Information Systems 13th Edition Laudon Test Bankroryhungzad6100% (25)

- PFMEA - StampingDocument8 pagesPFMEA - StampingNimesh Mehta67% (6)

- 1.2 Weak Components AnalysisDocument15 pages1.2 Weak Components Analysissherif mahmoud100% (1)

- Eddy Current Testing ProcedureDocument10 pagesEddy Current Testing ProcedureLalit MohanNo ratings yet

- CAP PT Survey Master Activity List - 2019Document144 pagesCAP PT Survey Master Activity List - 2019Shahid HussainNo ratings yet

- QAMDocument10 pagesQAMRavi Krishna IIM, CalcuttaNo ratings yet

- Design Fmea 1 ST Pipe Teflon HoseDocument11 pagesDesign Fmea 1 ST Pipe Teflon HoseSandeep PandeyNo ratings yet

- DFMEA Examples 29JUN2020 7.2.19Document24 pagesDFMEA Examples 29JUN2020 7.2.19Mani Rathinam RajamaniNo ratings yet

- Dfmea ExampleDocument3 pagesDfmea ExampleParag Kulkarni100% (1)

- DSD ProcessDocument48 pagesDSD Processtananth86% (7)

- Potential Failure Mode and Effects Analysis (Process FEMA)Document1 pagePotential Failure Mode and Effects Analysis (Process FEMA)Asif Iqbal100% (2)

- Root Cause Analysis To Reduce Error and Improve Quality in Forensic Science Labs - Hollway.labmgmtDocument16 pagesRoot Cause Analysis To Reduce Error and Improve Quality in Forensic Science Labs - Hollway.labmgmtSaravnan RajendranNo ratings yet

- Quality ManagementDocument8 pagesQuality ManagementHaris PrayogoNo ratings yet

- Lab Med Quality IndicatorsDocument15 pagesLab Med Quality IndicatorsMelani Sinasri RenagupitaNo ratings yet

- Work Permit ProcedureDocument2 pagesWork Permit Procedureवात्सल्य कृतार्थNo ratings yet

- Confined Space - RA-R9-01-002-01Document1 pageConfined Space - RA-R9-01-002-01cmrig74No ratings yet

- Wasserlab Brochure Autwomatic Plus 1+2Document10 pagesWasserlab Brochure Autwomatic Plus 1+2Lloid LauretaNo ratings yet

- Six Sigma Methods and Tools For Process Improvement 1664037686Document86 pagesSix Sigma Methods and Tools For Process Improvement 1664037686Haris PrayogoNo ratings yet

- 7.CCLM 2018 WG BV HarmonisationDocument8 pages7.CCLM 2018 WG BV HarmonisationJulián Mesa SierraNo ratings yet

- RISK ASSESSMENT FORM - رــــطاخملــا ـمييقــت جذوــمــنDocument8 pagesRISK ASSESSMENT FORM - رــــطاخملــا ـمييقــت جذوــمــنAlper SaltaşNo ratings yet

- Performance Efficiency Pillar: AWS Well-Architected FrameworkDocument43 pagesPerformance Efficiency Pillar: AWS Well-Architected FrameworkSupratik GoswamiNo ratings yet

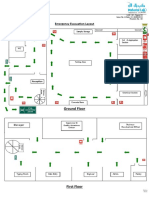

- Emergency Evacuation Layout-Abu DhabiDocument1 pageEmergency Evacuation Layout-Abu DhabiSherryNo ratings yet

- Qa SpreadsheetDocument21 pagesQa Spreadsheetapi-329968843No ratings yet

- SBI SO Computer QuestionsDocument2 pagesSBI SO Computer QuestionsAsmaNo ratings yet

- Mining Valuation PDFDocument5 pagesMining Valuation PDFSayaPintarSekaliNo ratings yet

- Storage Calculator ValerusDocument14 pagesStorage Calculator Valeruspeugeniu_1No ratings yet

- FF00101 01 Free Abelas Charts 16x91Document10 pagesFF00101 01 Free Abelas Charts 16x91Jagoan NeonNo ratings yet

- GM 1927 87 Special Nonconforming Material AuditDocument6 pagesGM 1927 87 Special Nonconforming Material AuditNeumar Neumann100% (1)

- 8D - Faurecia Valcea - Logistics ClaimDocument30 pages8D - Faurecia Valcea - Logistics ClaimRx DentviewNo ratings yet

- Item Name: FMEA Team: Prepared By: FMEA Date (Orig) : Revision #Document4 pagesItem Name: FMEA Team: Prepared By: FMEA Date (Orig) : Revision #Alper GmNo ratings yet

- 8D ReportDocument1 page8D ReportqualityNo ratings yet

- Pfmea TemplateDocument6 pagesPfmea TemplatekatalinaNo ratings yet

- Anpqp - Design Potential FmeaDocument2 pagesAnpqp - Design Potential FmeaJoaquinNo ratings yet

- Anpqp - Process Potential Fmea: Nissan Important Part Renault - CSRDocument2 pagesAnpqp - Process Potential Fmea: Nissan Important Part Renault - CSRjefry sitorusNo ratings yet

- Potential Failure Mode and Effects AnalysisDocument1 pagePotential Failure Mode and Effects AnalysisNatarajan GopalaswamyNo ratings yet

- Oposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseDocument1 pageOposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseSethasan SrikochNo ratings yet

- Meenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09Document4 pagesMeenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09ilaya rajaNo ratings yet

- Welcome To The FMEA Worksheet: This Spreadsheet Can Be Used ToDocument25 pagesWelcome To The FMEA Worksheet: This Spreadsheet Can Be Used ToMadhaviNarulaNo ratings yet

- Pfmea 02F11150027Document8 pagesPfmea 02F11150027shivan.cNo ratings yet

- Failure Mode and Effects Analysis (Process Fmea) : PotentialDocument2 pagesFailure Mode and Effects Analysis (Process Fmea) : Potentialjavier ortizNo ratings yet

- Defect History: Sr. No Typeof Defect Action StatusDocument22 pagesDefect History: Sr. No Typeof Defect Action StatusSameer SaxenaNo ratings yet

- Potential Failure Mode and Effects Analysis (Design FMEA)Document12 pagesPotential Failure Mode and Effects Analysis (Design FMEA)sachNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Design FMEA Template Rev 1.0Document8 pagesDesign FMEA Template Rev 1.0Lê Hoàn VũNo ratings yet

- FMEADocument1 pageFMEADiego MartínNo ratings yet

- Potential Failure Mode and Effect Analysis: (Pfmea)Document2 pagesPotential Failure Mode and Effect Analysis: (Pfmea)Mohit KaushikNo ratings yet

- Design and Process FMEA TemplateDocument4 pagesDesign and Process FMEA TemplateKrunal PandyaNo ratings yet

- Design and Process FMEA TemplateDocument4 pagesDesign and Process FMEA TemplateMadhuseptember2022100% (1)

- TQM 2021HB79113Document1 pageTQM 2021HB79113chirag sharmaNo ratings yet

- Potential Failure Mode and Effects Analysis (DESIGN FMEA) : Disk Brake Sub-AssemblyDocument6 pagesPotential Failure Mode and Effects Analysis (DESIGN FMEA) : Disk Brake Sub-AssemblyLuis Carlos SuarezNo ratings yet

- Process Map Template 09Document6 pagesProcess Map Template 09Luis Isaac Rodriguez sanchezNo ratings yet

- Potential Failure Mode and Effects Analysis (Design)Document12 pagesPotential Failure Mode and Effects Analysis (Design)PiyushNo ratings yet

- DFMEA-Oven RacksDocument8 pagesDFMEA-Oven RacksEdgar MonteroNo ratings yet

- Design and Process FMEA TemplateDocument7 pagesDesign and Process FMEA TemplateRajkumar VijNo ratings yet

- FMEA - Design - TutorialDocument14 pagesFMEA - Design - TutorialTutis05No ratings yet

- Emmforce Inc.: Failure Mode and Effects Analysis (Process Fmea)Document1 pageEmmforce Inc.: Failure Mode and Effects Analysis (Process Fmea)Satya PalNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document1 pagePotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- FMEA TemplateDocument23 pagesFMEA TemplateGurumoorthiNo ratings yet

- AIAG & VDA PFMEA FormatDocument1 pageAIAG & VDA PFMEA Formatmahesh KhatalNo ratings yet

- FMEA TemplateDocument28 pagesFMEA TemplatehiryanizamNo ratings yet

- QA003011 PFMEA TemplateDocument5 pagesQA003011 PFMEA TemplateChris GloverNo ratings yet

- Welcome To The FMEA Worksheet: This Spreadsheet Can Be Used ToDocument22 pagesWelcome To The FMEA Worksheet: This Spreadsheet Can Be Used ToshekharNo ratings yet

- 6000 Series PFMEA (English For Reference)Document8 pages6000 Series PFMEA (English For Reference)RonNo ratings yet

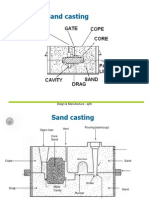

- Design Sand Casting Class IDocument23 pagesDesign Sand Casting Class Iiamajith123No ratings yet

- Chapter 4 - Marginal CostingDocument14 pagesChapter 4 - Marginal Costingphithuhang2909No ratings yet

- A Study On Implementing Digital Marketing Strategies For wallyAX To Grow The BrandDocument53 pagesA Study On Implementing Digital Marketing Strategies For wallyAX To Grow The Brand42 SUBASH KNo ratings yet

- Time Table Semester - I From 08.02.2021 To 13.02.2021Document11 pagesTime Table Semester - I From 08.02.2021 To 13.02.2021Nivedita AgarwalNo ratings yet

- Kotler Pom 15e Inppt 01 GEDocument56 pagesKotler Pom 15e Inppt 01 GEMohammed ElmisinyNo ratings yet

- Supply Chain Analytics QuizzDocument18 pagesSupply Chain Analytics Quizzvishvjeetpowar0202No ratings yet

- Advanced Systems Analysis & DesignDocument136 pagesAdvanced Systems Analysis & DesignMakaha Rutendo33% (3)

- KEID Company Profile January 2023Document26 pagesKEID Company Profile January 2023Ilham RamadhanNo ratings yet

- Digital Marketing Agency Near MeDocument13 pagesDigital Marketing Agency Near Me32 Muhammad Asad Ullah IbrahimNo ratings yet

- Chapter 16 30 Valix Practical Accounting 2011Document492 pagesChapter 16 30 Valix Practical Accounting 2011Joselito S. MalaluanNo ratings yet

- Supply Chain Intelligence Integration (Responses)Document46 pagesSupply Chain Intelligence Integration (Responses)Samanway Roy BhowmikNo ratings yet

- B2B Promotion PowerpointDocument25 pagesB2B Promotion PowerpointKSHITIZ CHOUDHARYNo ratings yet

- Business Model: Things Are Cheaper When Bought TogetherDocument22 pagesBusiness Model: Things Are Cheaper When Bought TogetherRavi ShankarNo ratings yet

- TOYOTA PRODUCTIOMN AyushDocument9 pagesTOYOTA PRODUCTIOMN AyushAnurag GoswamiNo ratings yet

- Marketing Cheat SheetDocument3 pagesMarketing Cheat SheetCharlotte GillandersNo ratings yet

- Chapter One Introduction To Operation Management 1.1 What Is Operation Management?Document13 pagesChapter One Introduction To Operation Management 1.1 What Is Operation Management?wubeNo ratings yet

- Cpei SopDocument5 pagesCpei SopCorrosion FactoryNo ratings yet

- Chapter Two-Accounting For InventoryDocument25 pagesChapter Two-Accounting For Inventoryzewdie100% (1)

- 1 s2.0 S2212827120307162 MainDocument6 pages1 s2.0 S2212827120307162 MainVaisakh DileepkumarNo ratings yet

- Service Management (5e) Operations, Strategy, Information Technology by Fitzsimmons and FitzsimmonsDocument40 pagesService Management (5e) Operations, Strategy, Information Technology by Fitzsimmons and FitzsimmonsAhsan MubeenNo ratings yet

- Chapter 18-Process Cost Systems: True/FalseDocument22 pagesChapter 18-Process Cost Systems: True/FalseROLANDO II EVANGELISTANo ratings yet

- Solutions-01 - PRODUCT DESIGN AND DEVELOPMENTDocument3 pagesSolutions-01 - PRODUCT DESIGN AND DEVELOPMENTHamid Masood 109-FET/MSME/F22No ratings yet

- 07 Leveraging Secondary Brand Associations To Build Brand EquityDocument27 pages07 Leveraging Secondary Brand Associations To Build Brand EquityDevillz AdvocateNo ratings yet

- Manajemen Pemasaran: Irsanti Hasyim - Program Studi Manajemen - Fakultas Ekonomi - Universitas Katolik ParahyanganDocument32 pagesManajemen Pemasaran: Irsanti Hasyim - Program Studi Manajemen - Fakultas Ekonomi - Universitas Katolik Parahyanganirsanti_102289604No ratings yet

- Leroy Kubvoruno ProposallDocument19 pagesLeroy Kubvoruno ProposallTafadzwa BhaselaNo ratings yet

- AbdulSamad - 12 - 16594 - 3 - CH 06 Merchandise InventoryDocument13 pagesAbdulSamad - 12 - 16594 - 3 - CH 06 Merchandise InventoryHassaan QaziNo ratings yet

- Practical Guide Measuring ShrinkageDocument4 pagesPractical Guide Measuring ShrinkageaguilarjmNo ratings yet