Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

8 viewsTHERMAL ENGINEERING - II Oct-Nov 2020

THERMAL ENGINEERING - II Oct-Nov 2020

Uploaded by

Syed RoshanThe document is a question paper for a Thermal Engineering exam that consists of two parts - Part A with short answer questions and Part B with longer answer questions. Part A covers topics like comparing gaseous and liquid fuels, boiler mountings and accessories, nozzle velocity coefficient, velocity triangles in steam turbines, and gas turbine systems. Part B questions require explaining concepts like adiabatic flame temperature and performing calculations related to combustion, steam condensers, turbine blades and power, gas turbine cycles, and jet propulsion systems like turbojets and liquid propellant rockets.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- R16 March 2021Document4 pagesR16 March 2021Md. SunmunNo ratings yet

- R16 Aug 2021Document2 pagesR16 Aug 2021Md. SunmunNo ratings yet

- Thermal EngineeringDocument8 pagesThermal Engineeringboppana sujwalNo ratings yet

- III B. Tech I Semester Supplementary Examinations, May - 2016 Thermal Engineering - IiDocument2 pagesIII B. Tech I Semester Supplementary Examinations, May - 2016 Thermal Engineering - IiFAISAL KHANNo ratings yet

- WWW - Manaresults.Co - In: II B. Tech I Semester Supplementary Examinations, June - 2015 Thermal and Hydro Prime MoversDocument8 pagesWWW - Manaresults.Co - In: II B. Tech I Semester Supplementary Examinations, June - 2015 Thermal and Hydro Prime MoversParviz GhadimiNo ratings yet

- Question PapersDocument11 pagesQuestion Papersbharath devasothNo ratings yet

- II B.Tech Year II Sem Question BankDocument100 pagesII B.Tech Year II Sem Question Banksaiharish634No ratings yet

- WWW - Manaresults.Co - In: (Common To Ame, Me)Document3 pagesWWW - Manaresults.Co - In: (Common To Ame, Me)Anonymous 5HYsyrddpNo ratings yet

- Chapter 7 - Work Study (Time and Motion Study)Document8 pagesChapter 7 - Work Study (Time and Motion Study)Pankaj KanatheNo ratings yet

- r05220304 Thermal Engineering IDocument8 pagesr05220304 Thermal Engineering ISrinivasa Rao G100% (2)

- Thermal Engineering-I May 2017Document8 pagesThermal Engineering-I May 2017ChennaNo ratings yet

- WWW - Manaresults.Co - In: II B. Tech II Semester Supplementary Examinations, November - 2018 Thermal Engineering-IDocument2 pagesWWW - Manaresults.Co - In: II B. Tech II Semester Supplementary Examinations, November - 2018 Thermal Engineering-Iashoku24007No ratings yet

- Code - No: 35089: Jawaharlal Nehru Technological University HyderabadDocument6 pagesCode - No: 35089: Jawaharlal Nehru Technological University HyderabadSRINIVASA RAO GANTANo ratings yet

- Thermal Engineering IDocument8 pagesThermal Engineering IPujith PjNo ratings yet

- RT32037A112016Document2 pagesRT32037A112016maheshwaran0% (1)

- WWW - Manaresults.co - In: Refrigeration and Air ConditioningDocument2 pagesWWW - Manaresults.co - In: Refrigeration and Air ConditioningAnt SandNo ratings yet

- WWW - Manaresults.Co - In: II B. Tech I Semester Supplementary Examinations, May - 2018 Thermal and Hydro Prime MoversDocument2 pagesWWW - Manaresults.Co - In: II B. Tech I Semester Supplementary Examinations, May - 2018 Thermal and Hydro Prime MoversUnknownNo ratings yet

- Jntuk 2 1 T&HPM Nov 2017 Q.PDocument8 pagesJntuk 2 1 T&HPM Nov 2017 Q.Panon_920598081No ratings yet

- WWW - Manaresults.co - In: II B. Tech II Semester Regular/Supplementary Examinations, April/May - 2019 Thermal Engineering-IDocument6 pagesWWW - Manaresults.co - In: II B. Tech II Semester Regular/Supplementary Examinations, April/May - 2019 Thermal Engineering-Iashoku24007No ratings yet

- 115 Er 032016Document2 pages115 Er 032016Anonymous 5HYsyrddpNo ratings yet

- 07a4ec05-Thermal Engineering - IDocument7 pages07a4ec05-Thermal Engineering - ISRINIVASA RAO GANTANo ratings yet

- RT32037A042016Document8 pagesRT32037A042016tamilvananirttNo ratings yet

- Rr312405 Thermal Engineering IIDocument8 pagesRr312405 Thermal Engineering IISrinivasa Rao GNo ratings yet

- Jntu Kakinada - B.tech - Thermal Engineering II r13 Rt31035112017 FR 744Document8 pagesJntu Kakinada - B.tech - Thermal Engineering II r13 Rt31035112017 FR 744NAGA PAVAN KUMAR ANo ratings yet

- WWW - Manaresults.Co - In: II B. Tech I Semester Regular/Supplementary Examinations, October/November - 2018 ThermodynamicsDocument8 pagesWWW - Manaresults.Co - In: II B. Tech I Semester Regular/Supplementary Examinations, October/November - 2018 Thermodynamicsashoku24007No ratings yet

- Mechanical Engineering Question PaperDocument58 pagesMechanical Engineering Question PaperAniket Sankpal100% (1)

- Eme 21062010Document2 pagesEme 21062010Bhavesh PipaliyaNo ratings yet

- May-June 2015 Proplusion-1Document3 pagesMay-June 2015 Proplusion-1srinithims78No ratings yet

- Jan 2023Document10 pagesJan 2023Md. SunmunNo ratings yet

- ETD - III 2nd AssignmentDocument7 pagesETD - III 2nd Assignmentmallesh mendaNo ratings yet

- 136EB052019Document3 pages136EB052019Naveen niratkarNo ratings yet

- Refrigeration & Air Conditioning: III B. Tech II Semester Regular Examinations, April/May-2019Document8 pagesRefrigeration & Air Conditioning: III B. Tech II Semester Regular Examinations, April/May-2019srinivasNo ratings yet

- REFRIGERATION & AIR CONDITIONING Nov 2018 PDFDocument1 pageREFRIGERATION & AIR CONDITIONING Nov 2018 PDFPawan YNo ratings yet

- Thermodynamics Question Solve 2011Document3 pagesThermodynamics Question Solve 2011MD SR ShantoNo ratings yet

- 2018 Dec. ME204-D - Ktu QbankDocument3 pages2018 Dec. ME204-D - Ktu QbankamaljyothyrajNo ratings yet

- Fapej LD: (A08051: Roll No. Total No. of Questions: Ti91 (Total No. of Pages: 02 ('U'Lt'Lua ' Allsctlloct+Yt' 'Eltm IDocument2 pagesFapej LD: (A08051: Roll No. Total No. of Questions: Ti91 (Total No. of Pages: 02 ('U'Lt'Lua ' Allsctlloct+Yt' 'Eltm ItransendenceNo ratings yet

- B) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyDocument2 pagesB) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyMilan MottaNo ratings yet

- r05220304 Thermal Engineering IDocument8 pagesr05220304 Thermal Engineering ISRINIVASA RAO GANTANo ratings yet

- Question Paper Code: 77006Document3 pagesQuestion Paper Code: 77006Vishnu Kumar G CNo ratings yet

- IES 1988 - CONV - EditedDocument7 pagesIES 1988 - CONV - EditedAyush NarayanNo ratings yet

- Elements of Mechanical Engineering May 2017Document6 pagesElements of Mechanical Engineering May 2017vamsi krishna balagaNo ratings yet

- Nr-310303 Thermal Engineering IIDocument8 pagesNr-310303 Thermal Engineering IISrinivasa Rao G100% (1)

- ECT - Exam (Practice 2 - SV) 2014-2015Document10 pagesECT - Exam (Practice 2 - SV) 2014-2015SamNo ratings yet

- NR-420301-Jet Propulsion & Rocket EngineeringDocument8 pagesNR-420301-Jet Propulsion & Rocket EngineeringSrinivasa Rao GNo ratings yet

- Rr312003 Turbo MachineryDocument8 pagesRr312003 Turbo MachinerySrinivasa Rao GNo ratings yet

- REFRIGERATION & AIR CONDITIONING April 2017 PDFDocument8 pagesREFRIGERATION & AIR CONDITIONING April 2017 PDFPawan YNo ratings yet

- Coaching - I TEDocument2 pagesCoaching - I TEtagoreboopathyNo ratings yet

- R07 Set No. 2Document8 pagesR07 Set No. 2JanneNo ratings yet

- 15-151906-Conventional Power Engineering (Institute Elective - II)Document2 pages15-151906-Conventional Power Engineering (Institute Elective - II)BHARAT parmarNo ratings yet

- Be Mech 4 Sem Applied Thermodynamics 484 Jun 2018Document1 pageBe Mech 4 Sem Applied Thermodynamics 484 Jun 2018mohdamaan.070015No ratings yet

- GT & JP QuestionsDocument7 pagesGT & JP QuestionsNaveen gupiNo ratings yet

- r059211401 Thermal ScienceDocument8 pagesr059211401 Thermal ScienceSrinivasa Rao GNo ratings yet

- Nr420301 Jet Propulsion and Rocket EngineeringDocument2 pagesNr420301 Jet Propulsion and Rocket Engineeringgeddam06108825No ratings yet

- Ic Engines (2) Question PaperDocument2 pagesIc Engines (2) Question Paperstalinrajesh143No ratings yet

- (4959) - 1049 B.E. (Mechanical) Design of Pumps, Blowers & Compressors (2012 Course) (Elective-IV) (End Sem.) (Semester-II) (402050 C)Document2 pages(4959) - 1049 B.E. (Mechanical) Design of Pumps, Blowers & Compressors (2012 Course) (Elective-IV) (End Sem.) (Semester-II) (402050 C)shubhamNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityFrom EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityNo ratings yet

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignFrom EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignNo ratings yet

- Rotary Screw Gas: CompressorsDocument2 pagesRotary Screw Gas: CompressorsLucas SilvestreNo ratings yet

- RF ProductsDocument64 pagesRF ProductspuljkeNo ratings yet

- Mekton Zeta Mecha Lab v0.5Document52 pagesMekton Zeta Mecha Lab v0.5CalNo ratings yet

- Economic Dispatch - OPFDocument1 pageEconomic Dispatch - OPFAlok AgrawalNo ratings yet

- 02 2022 Critical and Emerging Technologies List UpdateDocument11 pages02 2022 Critical and Emerging Technologies List UpdateJota JacquesNo ratings yet

- Poster g4 Druck Englisch 0718Document1 pagePoster g4 Druck Englisch 0718Dardo GoyaNo ratings yet

- S&OP - Glide PathDocument4 pagesS&OP - Glide PathVidit GuptaNo ratings yet

- 6 SIGMA Vs ACE Case Study-1Document13 pages6 SIGMA Vs ACE Case Study-1gopala krishnaNo ratings yet

- Annual Report 2014 15.compressedDocument157 pagesAnnual Report 2014 15.compressednmkdsarmaNo ratings yet

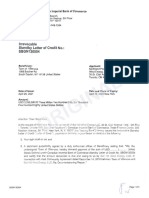

- Lrrrevocabos Standby Letter of Credh: Sbgn130554: Canadian Gmperiai Bank of CommerceDocument3 pagesLrrrevocabos Standby Letter of Credh: Sbgn130554: Canadian Gmperiai Bank of CommerceAhmed LaajiliNo ratings yet

- English 18th-Century Keyboard Concertos: Paul Nicholson The Parley of InstrumentsDocument13 pagesEnglish 18th-Century Keyboard Concertos: Paul Nicholson The Parley of InstrumentsDammy2011No ratings yet

- Motor Performance CurveDocument1 pageMotor Performance CurveVikrantNo ratings yet

- Irf13n50 Data SheetDocument7 pagesIrf13n50 Data SheetMuhammad IchsanNo ratings yet

- Articole Din Presa Online Interna Si InternationalaDocument129 pagesArticole Din Presa Online Interna Si InternationalaCarmen MoraruNo ratings yet

- Ten3 PDFDocument3 pagesTen3 PDFDan TranNo ratings yet

- Sky IslandsDocument4 pagesSky IslandsConnor Brassfield100% (2)

- ES 442 Homework #2: NAMEDocument8 pagesES 442 Homework #2: NAMEAsadRasheedNo ratings yet

- Dubai - The First City On The Blockchain: Case StudyDocument20 pagesDubai - The First City On The Blockchain: Case Studyk2mahenNo ratings yet

- Boiler Heating SurfacesDocument12 pagesBoiler Heating SurfacesHai NguyenNo ratings yet

- Bpes EntrepreneurshipDocument4 pagesBpes EntrepreneurshipVatsal ShahNo ratings yet

- S002980-Unit Pwer Installation PDFDocument9 pagesS002980-Unit Pwer Installation PDFIvan CabanaNo ratings yet

- Series LFII Residential, NFPA 13 Optimized Horizontal Sidewall Sprinklers 5.6 K-FactorDocument6 pagesSeries LFII Residential, NFPA 13 Optimized Horizontal Sidewall Sprinklers 5.6 K-FactorAchraf BoudayaNo ratings yet

- Social Media Addiction Research IIDocument35 pagesSocial Media Addiction Research IIJennaSimard100% (1)

- Global Classic: Cost-Effective, All-Purpose Bridge CMMDocument12 pagesGlobal Classic: Cost-Effective, All-Purpose Bridge CMMMauricio SilvaNo ratings yet

- Service: Touareg 2010 Touareg 2015Document54 pagesService: Touareg 2010 Touareg 2015Aluma MotorNo ratings yet

- ForTest - Air Leak Test and Flow Test Equipments M6990Document3 pagesForTest - Air Leak Test and Flow Test Equipments M6990bicciusNo ratings yet

- Gas Turbine Performance Acceptance Test Specification (Version 5) (TSMKO-00TG-T-30-TG0-321-A)Document91 pagesGas Turbine Performance Acceptance Test Specification (Version 5) (TSMKO-00TG-T-30-TG0-321-A)Anonymous kVwp7D67% (3)

- MidTerm Exam 2015 - Example To 2018Document7 pagesMidTerm Exam 2015 - Example To 2018kdhgxobjNo ratings yet

- F-35 Executive SummaryDocument84 pagesF-35 Executive SummaryPhilip TortoraNo ratings yet

- R.E.A.G.E.N.T. Final PDFDocument5 pagesR.E.A.G.E.N.T. Final PDFEsteban TamayoNo ratings yet

THERMAL ENGINEERING - II Oct-Nov 2020

THERMAL ENGINEERING - II Oct-Nov 2020

Uploaded by

Syed Roshan0 ratings0% found this document useful (0 votes)

8 views1 pageThe document is a question paper for a Thermal Engineering exam that consists of two parts - Part A with short answer questions and Part B with longer answer questions. Part A covers topics like comparing gaseous and liquid fuels, boiler mountings and accessories, nozzle velocity coefficient, velocity triangles in steam turbines, and gas turbine systems. Part B questions require explaining concepts like adiabatic flame temperature and performing calculations related to combustion, steam condensers, turbine blades and power, gas turbine cycles, and jet propulsion systems like turbojets and liquid propellant rockets.

Original Description:

Original Title

THERMAL ENGINEERING – II Oct-Nov 2020

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a question paper for a Thermal Engineering exam that consists of two parts - Part A with short answer questions and Part B with longer answer questions. Part A covers topics like comparing gaseous and liquid fuels, boiler mountings and accessories, nozzle velocity coefficient, velocity triangles in steam turbines, and gas turbine systems. Part B questions require explaining concepts like adiabatic flame temperature and performing calculations related to combustion, steam condensers, turbine blades and power, gas turbine cycles, and jet propulsion systems like turbojets and liquid propellant rockets.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

8 views1 pageTHERMAL ENGINEERING - II Oct-Nov 2020

THERMAL ENGINEERING - II Oct-Nov 2020

Uploaded by

Syed RoshanThe document is a question paper for a Thermal Engineering exam that consists of two parts - Part A with short answer questions and Part B with longer answer questions. Part A covers topics like comparing gaseous and liquid fuels, boiler mountings and accessories, nozzle velocity coefficient, velocity triangles in steam turbines, and gas turbine systems. Part B questions require explaining concepts like adiabatic flame temperature and performing calculations related to combustion, steam condensers, turbine blades and power, gas turbine cycles, and jet propulsion systems like turbojets and liquid propellant rockets.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

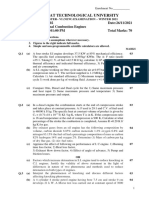

Code No: R1631035 R16 SET - 1

III B. Tech I Semester Supplementary Examinations, October/November - 2020

THERMAL ENGINEERING – II

(Mechanical Engineering)

Time: 3 hours Max. Marks: 70

Note: 1. Question Paper consists of two parts (Part-A and Part-B)

2. Answer ALL the question in Part-A

3. Answer any FOUR Questions from Part-B

4. Use of Steam Tables and Mollier Chart is allowed.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

PART –A (14 Marks)

1. a) Compare and contrast the gaseous and liquid fuels. [2M]

b) Explain significance of boiler mountings and accessories. [2M]

c) Define nozzle velocity coefficient and how it is related to nozzle efficiency? [2M]

d) Draw velocity triangle for 50% reaction steam turbine. [3M]

e) Draw the line diagram of gas turbine plant with regeneration, inter cooling and [3M]

reheating system.

f) Explain thrust power and propulsion efficiency of jet propulsion. [2M]

PART –B (56 Marks)

2. a) Explain the significance of adiabatic flame temperature. [6M]

b) Percentage composition of sample of liquid fuel by weight is, C=88.8% and [8M]

H2=15.2%, Calculate: i) the weight of air needed for combustion of 1kg of fuel, ii) the

volumetric composition of product of combustion if 15% excess air supplied.

3. a) Draw the line diagram and explain the working principle of economizer and discuss [7M]

the precautions to be made in usage.

b) Calculate the height of a chimney required to produce a draught equivalent to 1.6 cm [7M]

of water if the flue gas temperature is 2500 C and ambient temperature is 270 C and

minimum amount of air per kg of fuel is 20 kg.

4. a) Derive the equation for critical pressure ratio in nozzles. [6M]

b) A simple impulse turbine has one ring of moving blades running at 120 m/s, absolute [8M]

velocity of steam at exit is 75 m/s at an angle 800 with the tangent of wheel, friction

coefficient is 0.85, rate of steam flowing 2.5 Kg/s. Assuming the moving blades to be

a symmetrical, find the i) Blade angles, ii) Nozzle angle, iii) absolute velocity of

steam at entrance, and iv) power developed.

5. a) Sketch and describe the operation of central flow surface condenser. [7M]

b) Explain the working of single stage reaction turbine. Sketch the pressure and velocity [7M]

variations along the axis of the turbine.

6. a) In a gas turbine power plant, operating on Joule’s cycle, air is compressed from [7M]

1.5 bar and 250 C through a pressure ratio of 7. It is then heated to 6970 C in the

combustion chamber and expanded back to 1 bar. Calculate the net work done, cycle

efficiency and work ratio. Isentropic efficiency of turbine is 90% and of compressor is

85%.

b) Draw the line diagram and explain the working of Reheat gas turbine cycle. [7M]

7. a) Showing the basic components, explain the working of turbojet engine. [7M]

b) Explain the principle and working of liquid propellant rocket engine with neat sketch. [7M]

*****

||''|''||''||''''''|

You might also like

- R16 March 2021Document4 pagesR16 March 2021Md. SunmunNo ratings yet

- R16 Aug 2021Document2 pagesR16 Aug 2021Md. SunmunNo ratings yet

- Thermal EngineeringDocument8 pagesThermal Engineeringboppana sujwalNo ratings yet

- III B. Tech I Semester Supplementary Examinations, May - 2016 Thermal Engineering - IiDocument2 pagesIII B. Tech I Semester Supplementary Examinations, May - 2016 Thermal Engineering - IiFAISAL KHANNo ratings yet

- WWW - Manaresults.Co - In: II B. Tech I Semester Supplementary Examinations, June - 2015 Thermal and Hydro Prime MoversDocument8 pagesWWW - Manaresults.Co - In: II B. Tech I Semester Supplementary Examinations, June - 2015 Thermal and Hydro Prime MoversParviz GhadimiNo ratings yet

- Question PapersDocument11 pagesQuestion Papersbharath devasothNo ratings yet

- II B.Tech Year II Sem Question BankDocument100 pagesII B.Tech Year II Sem Question Banksaiharish634No ratings yet

- WWW - Manaresults.Co - In: (Common To Ame, Me)Document3 pagesWWW - Manaresults.Co - In: (Common To Ame, Me)Anonymous 5HYsyrddpNo ratings yet

- Chapter 7 - Work Study (Time and Motion Study)Document8 pagesChapter 7 - Work Study (Time and Motion Study)Pankaj KanatheNo ratings yet

- r05220304 Thermal Engineering IDocument8 pagesr05220304 Thermal Engineering ISrinivasa Rao G100% (2)

- Thermal Engineering-I May 2017Document8 pagesThermal Engineering-I May 2017ChennaNo ratings yet

- WWW - Manaresults.Co - In: II B. Tech II Semester Supplementary Examinations, November - 2018 Thermal Engineering-IDocument2 pagesWWW - Manaresults.Co - In: II B. Tech II Semester Supplementary Examinations, November - 2018 Thermal Engineering-Iashoku24007No ratings yet

- Code - No: 35089: Jawaharlal Nehru Technological University HyderabadDocument6 pagesCode - No: 35089: Jawaharlal Nehru Technological University HyderabadSRINIVASA RAO GANTANo ratings yet

- Thermal Engineering IDocument8 pagesThermal Engineering IPujith PjNo ratings yet

- RT32037A112016Document2 pagesRT32037A112016maheshwaran0% (1)

- WWW - Manaresults.co - In: Refrigeration and Air ConditioningDocument2 pagesWWW - Manaresults.co - In: Refrigeration and Air ConditioningAnt SandNo ratings yet

- WWW - Manaresults.Co - In: II B. Tech I Semester Supplementary Examinations, May - 2018 Thermal and Hydro Prime MoversDocument2 pagesWWW - Manaresults.Co - In: II B. Tech I Semester Supplementary Examinations, May - 2018 Thermal and Hydro Prime MoversUnknownNo ratings yet

- Jntuk 2 1 T&HPM Nov 2017 Q.PDocument8 pagesJntuk 2 1 T&HPM Nov 2017 Q.Panon_920598081No ratings yet

- WWW - Manaresults.co - In: II B. Tech II Semester Regular/Supplementary Examinations, April/May - 2019 Thermal Engineering-IDocument6 pagesWWW - Manaresults.co - In: II B. Tech II Semester Regular/Supplementary Examinations, April/May - 2019 Thermal Engineering-Iashoku24007No ratings yet

- 115 Er 032016Document2 pages115 Er 032016Anonymous 5HYsyrddpNo ratings yet

- 07a4ec05-Thermal Engineering - IDocument7 pages07a4ec05-Thermal Engineering - ISRINIVASA RAO GANTANo ratings yet

- RT32037A042016Document8 pagesRT32037A042016tamilvananirttNo ratings yet

- Rr312405 Thermal Engineering IIDocument8 pagesRr312405 Thermal Engineering IISrinivasa Rao GNo ratings yet

- Jntu Kakinada - B.tech - Thermal Engineering II r13 Rt31035112017 FR 744Document8 pagesJntu Kakinada - B.tech - Thermal Engineering II r13 Rt31035112017 FR 744NAGA PAVAN KUMAR ANo ratings yet

- WWW - Manaresults.Co - In: II B. Tech I Semester Regular/Supplementary Examinations, October/November - 2018 ThermodynamicsDocument8 pagesWWW - Manaresults.Co - In: II B. Tech I Semester Regular/Supplementary Examinations, October/November - 2018 Thermodynamicsashoku24007No ratings yet

- Mechanical Engineering Question PaperDocument58 pagesMechanical Engineering Question PaperAniket Sankpal100% (1)

- Eme 21062010Document2 pagesEme 21062010Bhavesh PipaliyaNo ratings yet

- May-June 2015 Proplusion-1Document3 pagesMay-June 2015 Proplusion-1srinithims78No ratings yet

- Jan 2023Document10 pagesJan 2023Md. SunmunNo ratings yet

- ETD - III 2nd AssignmentDocument7 pagesETD - III 2nd Assignmentmallesh mendaNo ratings yet

- 136EB052019Document3 pages136EB052019Naveen niratkarNo ratings yet

- Refrigeration & Air Conditioning: III B. Tech II Semester Regular Examinations, April/May-2019Document8 pagesRefrigeration & Air Conditioning: III B. Tech II Semester Regular Examinations, April/May-2019srinivasNo ratings yet

- REFRIGERATION & AIR CONDITIONING Nov 2018 PDFDocument1 pageREFRIGERATION & AIR CONDITIONING Nov 2018 PDFPawan YNo ratings yet

- Thermodynamics Question Solve 2011Document3 pagesThermodynamics Question Solve 2011MD SR ShantoNo ratings yet

- 2018 Dec. ME204-D - Ktu QbankDocument3 pages2018 Dec. ME204-D - Ktu QbankamaljyothyrajNo ratings yet

- Fapej LD: (A08051: Roll No. Total No. of Questions: Ti91 (Total No. of Pages: 02 ('U'Lt'Lua ' Allsctlloct+Yt' 'Eltm IDocument2 pagesFapej LD: (A08051: Roll No. Total No. of Questions: Ti91 (Total No. of Pages: 02 ('U'Lt'Lua ' Allsctlloct+Yt' 'Eltm ItransendenceNo ratings yet

- B) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyDocument2 pagesB) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyMilan MottaNo ratings yet

- r05220304 Thermal Engineering IDocument8 pagesr05220304 Thermal Engineering ISRINIVASA RAO GANTANo ratings yet

- Question Paper Code: 77006Document3 pagesQuestion Paper Code: 77006Vishnu Kumar G CNo ratings yet

- IES 1988 - CONV - EditedDocument7 pagesIES 1988 - CONV - EditedAyush NarayanNo ratings yet

- Elements of Mechanical Engineering May 2017Document6 pagesElements of Mechanical Engineering May 2017vamsi krishna balagaNo ratings yet

- Nr-310303 Thermal Engineering IIDocument8 pagesNr-310303 Thermal Engineering IISrinivasa Rao G100% (1)

- ECT - Exam (Practice 2 - SV) 2014-2015Document10 pagesECT - Exam (Practice 2 - SV) 2014-2015SamNo ratings yet

- NR-420301-Jet Propulsion & Rocket EngineeringDocument8 pagesNR-420301-Jet Propulsion & Rocket EngineeringSrinivasa Rao GNo ratings yet

- Rr312003 Turbo MachineryDocument8 pagesRr312003 Turbo MachinerySrinivasa Rao GNo ratings yet

- REFRIGERATION & AIR CONDITIONING April 2017 PDFDocument8 pagesREFRIGERATION & AIR CONDITIONING April 2017 PDFPawan YNo ratings yet

- Coaching - I TEDocument2 pagesCoaching - I TEtagoreboopathyNo ratings yet

- R07 Set No. 2Document8 pagesR07 Set No. 2JanneNo ratings yet

- 15-151906-Conventional Power Engineering (Institute Elective - II)Document2 pages15-151906-Conventional Power Engineering (Institute Elective - II)BHARAT parmarNo ratings yet

- Be Mech 4 Sem Applied Thermodynamics 484 Jun 2018Document1 pageBe Mech 4 Sem Applied Thermodynamics 484 Jun 2018mohdamaan.070015No ratings yet

- GT & JP QuestionsDocument7 pagesGT & JP QuestionsNaveen gupiNo ratings yet

- r059211401 Thermal ScienceDocument8 pagesr059211401 Thermal ScienceSrinivasa Rao GNo ratings yet

- Nr420301 Jet Propulsion and Rocket EngineeringDocument2 pagesNr420301 Jet Propulsion and Rocket Engineeringgeddam06108825No ratings yet

- Ic Engines (2) Question PaperDocument2 pagesIc Engines (2) Question Paperstalinrajesh143No ratings yet

- (4959) - 1049 B.E. (Mechanical) Design of Pumps, Blowers & Compressors (2012 Course) (Elective-IV) (End Sem.) (Semester-II) (402050 C)Document2 pages(4959) - 1049 B.E. (Mechanical) Design of Pumps, Blowers & Compressors (2012 Course) (Elective-IV) (End Sem.) (Semester-II) (402050 C)shubhamNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityFrom EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityNo ratings yet

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignFrom EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignNo ratings yet

- Rotary Screw Gas: CompressorsDocument2 pagesRotary Screw Gas: CompressorsLucas SilvestreNo ratings yet

- RF ProductsDocument64 pagesRF ProductspuljkeNo ratings yet

- Mekton Zeta Mecha Lab v0.5Document52 pagesMekton Zeta Mecha Lab v0.5CalNo ratings yet

- Economic Dispatch - OPFDocument1 pageEconomic Dispatch - OPFAlok AgrawalNo ratings yet

- 02 2022 Critical and Emerging Technologies List UpdateDocument11 pages02 2022 Critical and Emerging Technologies List UpdateJota JacquesNo ratings yet

- Poster g4 Druck Englisch 0718Document1 pagePoster g4 Druck Englisch 0718Dardo GoyaNo ratings yet

- S&OP - Glide PathDocument4 pagesS&OP - Glide PathVidit GuptaNo ratings yet

- 6 SIGMA Vs ACE Case Study-1Document13 pages6 SIGMA Vs ACE Case Study-1gopala krishnaNo ratings yet

- Annual Report 2014 15.compressedDocument157 pagesAnnual Report 2014 15.compressednmkdsarmaNo ratings yet

- Lrrrevocabos Standby Letter of Credh: Sbgn130554: Canadian Gmperiai Bank of CommerceDocument3 pagesLrrrevocabos Standby Letter of Credh: Sbgn130554: Canadian Gmperiai Bank of CommerceAhmed LaajiliNo ratings yet

- English 18th-Century Keyboard Concertos: Paul Nicholson The Parley of InstrumentsDocument13 pagesEnglish 18th-Century Keyboard Concertos: Paul Nicholson The Parley of InstrumentsDammy2011No ratings yet

- Motor Performance CurveDocument1 pageMotor Performance CurveVikrantNo ratings yet

- Irf13n50 Data SheetDocument7 pagesIrf13n50 Data SheetMuhammad IchsanNo ratings yet

- Articole Din Presa Online Interna Si InternationalaDocument129 pagesArticole Din Presa Online Interna Si InternationalaCarmen MoraruNo ratings yet

- Ten3 PDFDocument3 pagesTen3 PDFDan TranNo ratings yet

- Sky IslandsDocument4 pagesSky IslandsConnor Brassfield100% (2)

- ES 442 Homework #2: NAMEDocument8 pagesES 442 Homework #2: NAMEAsadRasheedNo ratings yet

- Dubai - The First City On The Blockchain: Case StudyDocument20 pagesDubai - The First City On The Blockchain: Case Studyk2mahenNo ratings yet

- Boiler Heating SurfacesDocument12 pagesBoiler Heating SurfacesHai NguyenNo ratings yet

- Bpes EntrepreneurshipDocument4 pagesBpes EntrepreneurshipVatsal ShahNo ratings yet

- S002980-Unit Pwer Installation PDFDocument9 pagesS002980-Unit Pwer Installation PDFIvan CabanaNo ratings yet

- Series LFII Residential, NFPA 13 Optimized Horizontal Sidewall Sprinklers 5.6 K-FactorDocument6 pagesSeries LFII Residential, NFPA 13 Optimized Horizontal Sidewall Sprinklers 5.6 K-FactorAchraf BoudayaNo ratings yet

- Social Media Addiction Research IIDocument35 pagesSocial Media Addiction Research IIJennaSimard100% (1)

- Global Classic: Cost-Effective, All-Purpose Bridge CMMDocument12 pagesGlobal Classic: Cost-Effective, All-Purpose Bridge CMMMauricio SilvaNo ratings yet

- Service: Touareg 2010 Touareg 2015Document54 pagesService: Touareg 2010 Touareg 2015Aluma MotorNo ratings yet

- ForTest - Air Leak Test and Flow Test Equipments M6990Document3 pagesForTest - Air Leak Test and Flow Test Equipments M6990bicciusNo ratings yet

- Gas Turbine Performance Acceptance Test Specification (Version 5) (TSMKO-00TG-T-30-TG0-321-A)Document91 pagesGas Turbine Performance Acceptance Test Specification (Version 5) (TSMKO-00TG-T-30-TG0-321-A)Anonymous kVwp7D67% (3)

- MidTerm Exam 2015 - Example To 2018Document7 pagesMidTerm Exam 2015 - Example To 2018kdhgxobjNo ratings yet

- F-35 Executive SummaryDocument84 pagesF-35 Executive SummaryPhilip TortoraNo ratings yet

- R.E.A.G.E.N.T. Final PDFDocument5 pagesR.E.A.G.E.N.T. Final PDFEsteban TamayoNo ratings yet