Professional Documents

Culture Documents

Torque Tools Are Measurement Equipment 5. Selection of Tightening Tools

Torque Tools Are Measurement Equipment 5. Selection of Tightening Tools

Uploaded by

Xuan Tri NOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torque Tools Are Measurement Equipment 5. Selection of Tightening Tools

Torque Tools Are Measurement Equipment 5. Selection of Tightening Tools

Uploaded by

Xuan Tri NCopyright:

Available Formats

5. Selection of Tightening Tools 6.

Torque Tools are Measurement Equipment

5-4 Selection of Power Tools 6-1 Torque Tools are Measurement Equipment

Technical Data

Technical Data

(1) Selection process (1) All measurement equipment

① Power (air, electric, hydraulic) Torque tools are categorized into measurement equipment same as calipers and

② Shape (holding by hand, fixed, head shape, reaction force support) dial gauges.

③ Capacity (tightening torque value, tightening accuracy) Beam type torque wrench Dial type torque wrench

④ Tightening time (rotation)

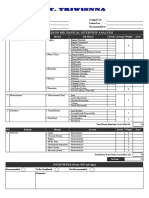

Table 5-6 Selection of power torque tools

Air Electric

Manual Power

Fixed Fixed

Hand type With reaction Hand type With reaction Caliper Dial gauge

Auto stop by toggle With reaction arm to Built-in automatic Auto stop by toggle With arm to get Built-in automatic

mechanism get reaction on equipment auto stop mechanism reaction on equipment auto stop

tightening auto stop by toggle Drive by electric tightening by or control by

Structure

by toggle mechanism motor multiple tightening

mechanism tightening completion driver

signal by LS

General tightening Tightening of middle, Auto tightening or General tightening for Tightening of middle, Auto tightening or units

Main purpose large screw each bolt multiple units each bolt small screw screw inside and for huge tightening in

in factories in factories outside factories

(2) ISO standard

Small screw ◎ × ○ ◎ × △

Middle screw △ ○ ◎ △ ○ ◎

I SO 9001: 2 0 0 0 E x tra c t

Model comparison

Large screw × ◎ ◎ × ◎ △

General multi purpose tightening ○ ○ × ○ ○ ×

Same screw huge quantity tightening △ △ ◎ △ △ ◎

Rotation(auto shift) ◎ ○ ◎(○) ○ △ ◎(○) 6.2.2 Competence, awareness and training

Weight ◎ ○ ○ ○ △ ○ a)determine the necessary competence for personnel performing work affecting

Noise ○ △ ○(△) ◎ ○ ○(△)

Accuracy ○ ○ ○(◎) ○ ○ ○(◎) product quality,

Operation ○ ○ ◎ ○ ○ ◎ b)provide training or take other actions to satisfy these needs,

Price ◎ ○ △ ○ ○ △

U,AUR,AS AP MG,MF,ME, HAT DAP DCME c)evalute the effectiveness of the actions taken,

Model MC,AME Control of monitoring and mesuring devices

7.6

(2) Tightening time of tool Where necessary to ensure valid results, measuring equipment shall

Table 5-7 Tightening time of tool [sec/piece] a)be calibrated or verified at specified intervals, or prior to use, against meaure-

Screw joint Manual Power Power+Manual ment standards traceable to international or national measurement standards;

Screw, Simultaneous Full automatic Impact wrench Semi automatic where no such standards exist, the basis used for calibration or verification

Turns

tightening of ridge tightening Direct reading Click direct control +click (Air motor +click in a body)

torque [Pieces] shall be recorded;

(DB50N) (QL50N)(ASH40N) (QL50N) (AC50N) (AC100N)

b)be adjusted or re-adjusted as necessary;

M8 10 1 9.6 8.0 3.2 5.4 4.0 3.5

( P1.25 ) c)be identified to enable the calibration status to be determined;

10 4 7.2 6.5 1.9 3.0 2.3 2.3

T=22 d)be safeguarded from adjustments that would invalidate the measurement

[N・m] 16 1 14.6 12.6 4.6 7.3 6.7 5.6

(e=10) result;

16 4 12.5 10.6 2.5 4.0 4.0 3.6

e)be protected from damage and deterioration during handling, maintenance and

Prepare the test conditions by inserting the screw in the tapped hole and placing the tool on table. Measure the time interval from the start of

tightening until the tool has been returned to the table and tightening completed. For manual tools, you may tighten the screw with your hand. storage.

52 Technical Data 5-4 6-1 Technical Data 53

6. Torque Tools are Measurement Equipment

6-2 Daily Inspection

Technical Data

Technical Data

(3) Accuracy of torque tools Every torque tool will make errors. To prevent this, a daily check and regular calibration are required

Daily check :To prevent occurrence of a large quantity of defects.

A type (Measurement value: Value to show tester) Regular calibration :To control the accuracy of torque tools (For traceability)

(1) Control method

Example : calibration of torque wrench or torque driver to use

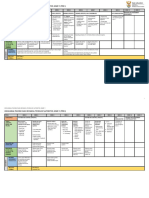

Table 6-1 Individual control and Centralized control

measurement point

Individual control Centralized control

Example of calibration of models:DB・FTD

Accuracy Daily inspection by the worker. Regular inspection in the tool room.

Indicated by tools −Measured value

Relative Error= ×100 Degradation of torque Earlier detection. Can be detected only during a regular inspection.

Measured value

Adaptable torque wrench Click-type torque wrench,

Power-type torque wrench. All types.

Tester Torque wrench checker Torque wrench tester

B type

Adaptable tester Checker (LC) Tester (DOT, DOTE, TTC, TF)

Worker Precision check, and replaces only Replacement of defective torque wrenches.

Example : calibrate accuracy of torque tools to use weight Control of defective torque wrenches.

torque wrench Checking tester at the field and readjusts or Checking all normal and defective torque wrenches,of repairs read-

Example of calibration of models:TG・TM Tool room arranging the repair of defective torque wrenches. justment of defective torque wrenches, and arrangement of repairs.

(2) Selection of testers

Indicated by tools −Base torque Checker(daily check)

Relative Error= ×100

Base torque ■ Dry weight correction is necessary because dry weight of torque wrench will be added on vertical

direction. (LC etc.)

■ It is not stable all the time because not loaded by loading equipment and loaded by the hand. (Speed,

position, direction etc.)

Tester (for calibration)

(4) Durable accuracy of torque tools ■ It is not affected by gravitational acceleration (g) because the torque wrench is loaded by horizontal

direction.

Manual torque tools … 100,000 cycles (at maximum torque value) or one year. ■ Speed, loaded position, direction can be constant because it is loaded by loading equipment.

Table 6-2 Selection of tester

If you will measure and adjust each 100,000 cycles, it is

Checker/ tester Checker Tester

possible to use up to around 1,000,000 cycles. model Torque range Torque range Torque range Torque range

For wrench For rotation 1:30 1:10 1:10 wide

(Digital) (Mechanical) (Digital) (Digital)

Power tool……………… 500,000∼1,000,000 cycles (at maximum torque) or one Spec. LC ST TDT DOT DOTE TF, TTC

year. Measurement Instrument Torque wrench Power tool torque wrench Torque driver Torque wrench Torque wrench Torque wrench

Accuracy ±1%+1digit F.S.±1% ±1%+1digit ±2% ±1%+1digit ±1%+1digit

Capacity small, middle small, middle, large small small, middle small, middle, large small, middle, large

Analog display × × × ○ × ×

Digital display ○ ○ ○ × ○ ○

Manual (handle) ○ ○ ○ ○ ○(DOTE) ×

Power (motor drive) × × × ○(DOT-MD) ○(DOTE-MD) ○

Measurement right right right/left right right/left right/left

Price ◎ ◎ ○ ◎ ○ △

54 Technical Data 6-1 6-2 Technical Data 55

6. Torque Tools are Measurement Equipment

Technical Data

Technical Data

(3) Tester of torque tools (4) Standards of Tohnichi、ISO、JIS

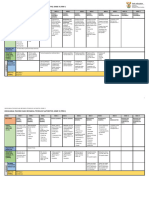

Table 6-3 Torque tools and tester and checker Table 6-5 Permissible deviation of torque value

Torque tools Tester 1, Tohnichi standard ±3%

A.Dial indication type 2, ISO standard ±4%∼±6% Dial indication type

Uni screw driver TCF+TP+CD42

3, JIS standard ±3%

Semi-automatic airtork DOT, DOTE, TTC, LC, TF Torque wrench tester 1, Tohnichi standard ±3%

Fully-automatic airtork TCF+TP+CD4,ST ±4%∼±6% Wrench type

B.Adjustable type 2, ISO standard

±6% Driver type

Multiple unit TCF+TP+CD4,ST

3, JIS standard ±3%

Torque driver TDT 1, Tohnichi standard ±3%

Manual type torque wrench DOT, DOTE, TTC, LC, TF Torque wrench tester ±4%∼±6% Wrench type

C.Preset type 2, ISO standard

±6% Driver type

Torque meter Calibration kits (Weight + calibration lever)

3, JIS standard ±3%

Table 6-6 Measurement procedure

1, Tohnichi standard Additional loading (min.→ max. scale) 1 time

A.Dial indication type 2, ISO standard 5 times successively at each measuring points

3, JIS standard Not described

1, Tohnichi standard Mean value of 3 times measurements at each measuring points

B.Adjustable type 2, ISO standard 5 times successively at each measuring points

3, JIS standard Mean value of 3 times or more measurements

1, Tohnichi standard Mean value of 3 times measurements

C.Preset type 2, ISO standard 5 times successively at measuring point

3, JIS standard Mean value of 3 times or more measurements

Table 6-7 Measurement point

1, Tohnichi standard Min., around center, max. of scale

A.Dial indication type 2, ISO standard 20, 60, 100%

3, JIS standard Min., close 2 points of equally divided 3, max. of scale

1, Tohnichi standard Min., center, max. of scale

B.Adjustable type 2, ISO standard 20, 60, 100%

3, JIS standard Min., close 2 points of equally divided 3, max. of scale

1, Tohnichi standard Setting torque

C.Preset type 2, ISO standard Any of torque

3, JIS standard Setting torque

(ISO 6789), (JIS B 4650)

56 Technical Data 6-2 6-2 Technical Data 57

6. Torque

6. ト tools are measurement equipment

ルク機器は測定器

6-3 Traceability

Technical Data

Technical Data

Torque is the result of multiplying the length by the force. As the units of length and force are (3) Management of torque tools

approved by the official organization respectively, the traceability is obtained through these units.

The process for controlling torque tools (Figure 6-3) involves ascertaining the accuracy by adequately

(1) Traceability system checking the measurement of the tools upon reception in the facility and or on a daily basis. Decide how

Use the Tohnichi tools for ISO 9000 torque control systems. to setup a process for control by referencing JIS standards, (JIS B 4650) and nominal accuracy as

Tohnichi is produces a wide variety of torque tools that are involved in traceability systems (Figure defined by the manufacturer and by assessing the following factors: importance, usage frequency, and

6-2). Services, such as calibration and repair, are very important and necessary factors in the usage torque capacity of the measuring instruments. The periodic check cycle depends on these

control process. All of these are necessary for internal company controls for torque tools, such as factors, but normally this falls between 3 months and a year and, if possible, readjusts the cycle as the

inspection sheets, calibration certificates, traceability systems are available upon request. Use tool ages.

TEL TOHNICHI

FAX

the application forms for such traceability requests. Selection of E-mail REFERENCES

Torque wrench

Figure 6-3 Control for Reference Website

torque tool RETURN

Figure 6-1Traceability of Tohnichi products Figure 6-2 Traceability chart Torque Handbook Technical

Order reference

Traceability

NATIONAL INSTITUTE OF ADVANCED INDUSTRIAL

OFFICIAL FACILITY

Sales assistance

SCIENCE AND TECHNOLOGY (AIST) Delivery Torque seminar

Parts list Parts supplies

MEASURING CALIBRATION

MEASURING CALIBRATION INSTITUTE INSTITUTE Laboratory

LENGTH MASS FORCE

NG

STANDARD TEST

Acceptance

EQUIPMENT

LENGTH

MASS STANDARD FORCE STANDARD

STANDARD OK Certificate of

Calibration

OUTER

INNER COMPANY

COMPANY

STANDARD EQUIPMENT

CALIBRATION Registration Work

WEIGHT

LEVER OUTER

BASIC FORCE COMPANY INNER

COMPANY

INSTRUMENT

Work Control

BASIC TORQUE INSTRUMENT

SPARE TOOLS

Work Storage

CALIBRATED MODEL

POWER TORQUE TOOL

BOLT TENSION METER

OK Daily Regular OK

TORQUE WRENCH

TORQUE DRIVER

TORQUE GAUGE

TORQUE METER

inspection inspection

Example:

NG Once a Year NG

OK

Repair Adjusting

inspection

NG

Disposal

(2) Examination and calibration

(4) Trends to provide the new traceability control and the national torque standards

Because torque is expressed as Torque = Force × Length, it is required that the standard instrumentation

should be calibrated using weights for the force and a scale or caliper for the length. Instruments being As industrial globalization has accelerated, so has the use of torque tools. Their importance in the field of

used as the standard for testing other torque tools should be 3 times more accurate than the item being quality control has led to increased requirements for traceablility through national torque standards and

tested. Therefore to calibrate a torque wrench with a 1% accuracy rating a more than ±0.3% rated tor- international agreements. Currently, preparations are being made for a system to provide torque

que standard must be used. The standard must then be periodically calibrated and examined to maintain standards and the calibration methods for torque tools. These preparations are proceeding and the

its accuracy and traceability. provisions for a national torque standard has already started.

58 Technical Data 6-3 6-3 Technical Data 59

6. Torque tools are measurement equipment

6-4 Accuracy and Uncertainty

Technical Data

Technical Data

(5) ISO related documents (1) Accuracy

Figure 6-6 Accuracy

Tohnichi provides the customers who are approved / being approved by ISO 9000 with the requires

documents. The documents available are as follows (Figure 6-4); The maximum

Accuracy=Deviation + Dispersion scale value ±

%

Measured torque

Acceptable range

Deviation : Graduated torque measuring devices: The difference

Figure 6-4 ISO related documents issued by Tohnichi between the scale and the measured values.

1.Inspection Certificate 3.General Traceability Chart

Torque measuring device without graduation (single-purpose

2.Calibration Certificate type): The difference between the set value and the

The minimum scale or main

measured value. minimum scale value

4.Respective Traceability Dispersion: The standard is 2σ or 3σ

Chart

Scale value

Table 6-8 Torque dispersion

Item Model name Accuracy

Tohnichi will provide the document service related to ISO 9000 accreditation. In general, the required

Digital torque wrench tester TF, TTC, DOTE

documents for accreditation are the inspection certificate and calibration certificate. Upon the

Digital torque meter TME

customer's request, we also issue a traceability chart. Tohnichi keeps the histories of issued documents

Digital torque driver tester TDT

for the required period for the customers who maintain ISO 9000. ±1%+1digit

Digital torque wrench checker LC

Digital torque driver STC

Figure 6-5 The certificate of calibration supplied with torque wrenches

Digital torque wrench CEM, CTA, CTA-P, CTB

Analog torque meter TG, TM

±2%

Analog torque wrench tester DOT

Manual torque driver FTD-S, FTD, MTD, RTD, LTD, NTD, RNTD, AMLD

±3%

Manual torque wrench F, DB, CDB, QL, CL, YCL, QSP, SP

※±5%(repaired)

Semi-automatic torque wrench A, AC

Power torque tool U, AUR, AS, AP, M, DAP, HAT ±5%

(2) Uncertainty

Without assuming the conventional conception of true value (in general unknown), it is obtained

from the data dispersion (already known) in the data range, using the measured results.

The methods to evaluate uncertainty are classified under the following two methods:

①Evaluation method by statistical analysis from a series of measured values. (Uncertainty type-A)

②Evaluation method by other means for statistical analysis from a series of measured values.

(Uncertainty type-B)

Further, for both type-A and B, evalute the standard uncertainties as the standard deviations (or

similar values) from normal distribution, rectangular distribution and trapezoid distribution. And

finally, compound them by the propagation rule of errors. (The combined standard uncertainty)

under the procedures like these, the comprehensive uncertainty is indicated as the Extended

Uncertainty.

60 Technical Data 6-3 6-4 Technical Data 61

6. Torque Tools are Measurement Equipment

Technical Data

Technical Data

Figure 6-7 Factors about uncertainty in general measurements

(3) Analysis procedure about uncertainty in measurements

Measurement method Measuring device Work piece Measuring environment

① Set a method of measurement and calibration. (Describe the procedure concisely.) Describe

Measurement the principles and measuring methods, measuring devices and instruments, concisely.

Principle

(Rule・Definition)

② Construction of mathematics model (Write formulas or put principal factors.)

Measuring facilities Measuring person Measurement time a) Describe the formula if it can lead to uncertainty.

b) If the uncertainty cannot be expressed by numerical formulas, point out the factors of

Figure 6-8 Scope of the measured values

uncertainties and compound them by adding.

測定した値が存在する範囲

c) Execute the test of significance through experiments based upon the design of experiments

Generally within 2σ(K=2)

and factorial experiments. Then estimate the uncertainties factor by factor.

96 97 98 99 100 101 102 103

③ Corrections of values (Describe the correction items and the methods, if any.) If corrections are

made, the estimations of uncertainties are executed after data corrections. Then get the

discretion estimation Y.

Measured value Uncertainty

99.3 0.96

④ Analysis and estimation about uncertainty elements (Including type-A and type-B classification)

98.34 100.26

the uncertainty elements are pointed out and classified. Estimate the standard deviation (or

Figure 6-9 How to estimate the uncertainty similar values) per element as follows;

At normal distribution, σ(standard a) Uncertainty which standard has. (Described in standard uncertainty.)

Normal distribution Rectangular distribution

a uncertainty) equals standard uncertainty b) Uncertainty, comparing to standard. Uncertainty resulted from calibration equipment, calibra-

σ Standard

uncertainty and generally, 2σ equals extended

tion environment, calibration period, work piece, etc. (Described in standard uncertainty).

uncertainty. At rectangular distribution,

σ=a/ 3 divide a (half width of distribution) by 3 ⑤ Calculation about combined standard uncertainty

2σ Triangle distribution

equals extended uncertainty(a/ 3) . At

Extended uncertainty a triangle distribution, divide a (half width n

1/2

of distribution) by 6 equals extended u c =(Σu i 2 ) = u 1 2+u 2 2+…+un 2

uncertainty (a/ 6). i=1

(Apparently there is no distinction between type-A and type-B)

σ=a/ 6

Figure 6-10 Estimate the uncertainty from rectangular distribution

Resolution of digital display To get the resolution of digital display for ⑥ Calculation about extended uncertainty

Uncertainty for 1digit (Udigit) 1[digit]

uncertainty of 1[digit], divide 0.5[digit]

Resolution Nmin at Tmin 1 (half width of 1[digit]) by 3 equals

Udigit=

1

×100% resolution

×100%

standard uncertainty (1[digit]/2 3). For

U=k・uc

Nmin×2 3

1 example, if the resolution (Nmin) of the k: Coefficient

×100%

resolution

minimum torque capacity (Tmin) is 100, (Generally k=2 is taken. If not, describe the reason)

Nmin Udigit

100 0.29% u u 1[digit] equals 1% and the uncertainty of

200 0.14%

400 0.07%

1[digit]/2 3 its resolution (Udigit) equals 0.29.

62 Technical Data 6-4 6-4 Technical Data 63

6. Torque Tools are Measurement Equipment

Technical Data

Technical Data

(4) Example for uncertainty ⑤ Uncertainty of torque calibration work

Factors Standard uncertainty

① Theoretical formula

Torque [N.m] ・Level of wire 0.06%

= Mass of dead weight [kg]×Gravitational acceleration [m/s2]×Effective length of calibration lever [mm] ・Inclination of lever (level) 0.06%

② Hypothetical models ・Length of lever (angle of drive) 0.03%

・Torque calibration kit DOTCL100N ・Newton conversion 0.03%

・Torque wrench tester DOTE100N ・Repeated uncertainty 0.1%

③ Uncertainty of calibration of torque tester Combined standard uncertainty of torque calibration work;

Extended uncertainty of torque calibration kit: UIA ub = 0.062+0.062+0.032+0.032+0.12 = 0.14%

Extended uncertainty of torque calibration work: UIB

2 2 2

Extended uncertainty of measured torque: UIT(UIT =UIA +UIB ) Extended uncertainty of torque calibration work;

Extended uncertainty of torque wrench tester: UC UIB = 2 × ub = 0.28%

Extended uncertainty of calibration of torque wrench tester; UT(UT2=UIT2+UC2) Extended uncertainty of measured torque;

④ Uncertainty of torque calibration kit UIT = UIA2 + UIB2 = 0.29%

Factors Standard uncertainty

・Mass (standard dead weight) 0.0004% ⑥ Uncertainty of calibration of torque wrench tester

・Mass for measurement 0.01% Factors Standard uncertainty

・Gravitational acceleration 0.005% *(Table 1-1) ・Resolution of torque wrench tester (zero point) 0.06%

・Corrections of specific gravity 0.015% ・Resolution of torque wrench tester (display) 0.06%

・Vertical/horizontal conversion 0.014% ・Friction of bearing area 0.005%

・Uncertainty of gauge 0.14%

Combined standard uncertainty for force;

・Uncertainty of display 0.14%

uf= 0.00042 + 0.012 + 0.0052 + 0.0152 + 0.0142 = 0.023%

Combined standard uncertainty of torque wrench tester;

・Scale (calibration) 0.006% uc = 0.062+0.062+0.0052+0.142+0.142 = 0.22%

・Length of lever (processing tolerance) 0.02%

・Diameter of wire 0.02% Extended uncertainty of torque wrench tester;

・Elongation of lever 0.014% UC =2 × uc = 0.44%

Extended uncertainty of calibration of torque wrench tester;

Combined standard uncertainty of torque length of lever;

UT = UIT2 + UC2 = 0.52%

ul = 0.0062 + 0.022 + 0.022 + 0.0142 = 0.032%

⑦ Traceability of torque tools

Combined standard uncertainty of torque calibration kit;

The expanded uncertainty of torque wrench tester requires below ±1% (k=2).

ua = uf2 + ul2 = 0.0232 + 0.0322 = 0.04%

The expanded uncertainty of torque calibration kit is expected below ±0.3% (k=2).

Extended standard uncertainty of torque calibration kit (k=2); Therefore, standard uncertainty of calibration kit is expected below 0.15%.

UIA = 2 × ua = 0.08% Each standard uncertainty of inferior characteristics, which is below 0.015%, can be ignored.

64 Technical Data 6-4 6-4 Technical Data 65

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Instruction Manual Sunstar SPS-E1201H PDFDocument49 pagesInstruction Manual Sunstar SPS-E1201H PDFMaskusyani88% (8)

- Teste Ingles TecnologiaDocument5 pagesTeste Ingles TecnologiaMeninaDuMarNo ratings yet

- Chap 1a - Instrumentation and PID DiagramDocument20 pagesChap 1a - Instrumentation and PID Diagramraj varman100% (2)

- Stoichiometry 1Document60 pagesStoichiometry 1Aryan Anchan0% (1)

- 10 Dungeon Maps With Seed IdeasDocument12 pages10 Dungeon Maps With Seed IdeasEzequiel Escanellas100% (2)

- The Elements of Dance: Part 1 Space Shape 1: Shapes With Straight Lines and AnglesDocument3 pagesThe Elements of Dance: Part 1 Space Shape 1: Shapes With Straight Lines and AnglesEarl johnNo ratings yet

- Torque Machine Data Sheert PDFDocument16 pagesTorque Machine Data Sheert PDFHakim HakimNo ratings yet

- Tue 100Document1 pageTue 100Anderson GoisNo ratings yet

- Flow Chart of Tool Selection Manual Torque ToolsDocument8 pagesFlow Chart of Tool Selection Manual Torque ToolsIsboNo ratings yet

- Selection of Tightening Tools 4. Tightening ReliabilityDocument4 pagesSelection of Tightening Tools 4. Tightening ReliabilityXuan Tri NNo ratings yet

- Spec BookDocument194 pagesSpec BookCataNo ratings yet

- Servo TG e 1 1Document19 pagesServo TG e 1 1juanvimgNo ratings yet

- Torque Monitoring: Prüftechnik Condition Monitoring GMBH Seite 1Document17 pagesTorque Monitoring: Prüftechnik Condition Monitoring GMBH Seite 1SunnyNo ratings yet

- 21-Industrial Vibration AnalysisDocument5 pages21-Industrial Vibration Analysissuna06m6403100% (1)

- Motor Grader Operator Training - GD705-5 WebinarDocument52 pagesMotor Grader Operator Training - GD705-5 WebinarMichael DavidNo ratings yet

- Technical Explanation of Rotary EncodersDocument6 pagesTechnical Explanation of Rotary Encoderssanthoshkumar.sNo ratings yet

- bk101 Chapter4.4metal Forming EquipmentDocument9 pagesbk101 Chapter4.4metal Forming EquipmentMỹ LanNo ratings yet

- Product Information: Universal Gripper EGIDocument18 pagesProduct Information: Universal Gripper EGImarcelo alonsoNo ratings yet

- FR D700Document34 pagesFR D700rondinelliaquinoNo ratings yet

- Turbo Machinery Analysis & DiagnosticsDocument24 pagesTurbo Machinery Analysis & DiagnosticsBryanMojalottMoroteNo ratings yet

- Omron - Technical Explanation For Rotary EncodersDocument10 pagesOmron - Technical Explanation For Rotary EncodersmicaNo ratings yet

- 470 Ba Ha175075eng 1Document99 pages470 Ba Ha175075eng 1RaviNo ratings yet

- 05 Selection of Tightening Tools PDFDocument8 pages05 Selection of Tightening Tools PDFJuanGómezNo ratings yet

- Downloaded From Manuals Search EngineDocument18 pagesDownloaded From Manuals Search EngineEdwin JiménezNo ratings yet

- Ep80 enDocument7 pagesEp80 eneki miftakhul firdausNo ratings yet

- Camara de Visión Lna06098eng ADocument28 pagesCamara de Visión Lna06098eng Aangel SanchezNo ratings yet

- Form Interview MekanikDocument4 pagesForm Interview MekanikFranchesNo ratings yet

- Datenblatt-INVEOR MPmodular-6seiter Screen ENDocument5 pagesDatenblatt-INVEOR MPmodular-6seiter Screen ENOrlando AriasNo ratings yet

- 1.060 ATP 2023-24 GR 11 Mech Tech Aut FinalDocument4 pages1.060 ATP 2023-24 GR 11 Mech Tech Aut FinalNigel EvertsonNo ratings yet

- 9000 Series and Cruisecommand Product Brochure: Marine Propulsion SystemsDocument6 pages9000 Series and Cruisecommand Product Brochure: Marine Propulsion SystemsBoris ZhilkinNo ratings yet

- Selección de Fajas PagDocument10 pagesSelección de Fajas PagMichael SernaqueNo ratings yet

- Introduction To Instrumentation System: by Prof - Bikash MohantyDocument25 pagesIntroduction To Instrumentation System: by Prof - Bikash MohantyKaran Deep SinghNo ratings yet

- CM1 Vibration HoqueDocument23 pagesCM1 Vibration Hoqueashraful anikNo ratings yet

- Lecture-03 - Architecture of Industrial Automaton SystemDocument17 pagesLecture-03 - Architecture of Industrial Automaton SystemAbdullah Al JubairNo ratings yet

- Tor QuestDocument5 pagesTor QuestBe HappyNo ratings yet

- HT800 30mm Pushbuttons Specifications: Typical WiringDocument6 pagesHT800 30mm Pushbuttons Specifications: Typical WiringKang IndraNo ratings yet

- 4cycle ChassisDocument2 pages4cycle ChassislutfilatifNo ratings yet

- Motorized Torque Stand MTS SeriesDocument6 pagesMotorized Torque Stand MTS Seriesadi cahya saputraNo ratings yet

- Torque-Angle Measurement System TAA SeriesDocument10 pagesTorque-Angle Measurement System TAA SeriesSharan DaraindharaneNo ratings yet

- Introduction To CNC MachineDocument4 pagesIntroduction To CNC MachineRamanujam O SNo ratings yet

- 3194 Motor/Harmonic HitesterDocument4 pages3194 Motor/Harmonic Hitesterapi-20293216No ratings yet

- Installation and Operating InstructionsDocument8 pagesInstallation and Operating Instructionsronalde90No ratings yet

- Curriculum of Competency Unit (Cocu)Document13 pagesCurriculum of Competency Unit (Cocu)Tran MarkNo ratings yet

- TeikokuDocument1 pageTeikokuAnuson SangkhananNo ratings yet

- Infineon Solutions For Industrial Drives ABR v10 00 enDocument16 pagesInfineon Solutions For Industrial Drives ABR v10 00 enkondurumahi50No ratings yet

- Cross Precision Measurement Dimensional and Mechanical MetrologyDocument3 pagesCross Precision Measurement Dimensional and Mechanical MetrologyRakesh ReddyNo ratings yet

- Industrial Robotics: Dr. M V A Raju BahubalendruniDocument39 pagesIndustrial Robotics: Dr. M V A Raju Bahubalendruniabdul rahmanNo ratings yet

- High Speed Assembly With Ergonomics & Quality Control.: ECL Brushless ScrewdriverDocument6 pagesHigh Speed Assembly With Ergonomics & Quality Control.: ECL Brushless ScrewdriverBe HappyNo ratings yet

- Torque Wrench Calibration and UncertaintDocument7 pagesTorque Wrench Calibration and UncertaintWin AsharNo ratings yet

- Pdf-F000-Support-Ctlg-3ef016-1704e-01 (1) - 1-153-150Document1 pagePdf-F000-Support-Ctlg-3ef016-1704e-01 (1) - 1-153-150kutty thambiNo ratings yet

- Genset Control For Single Unit Operation: FlexrangeDocument4 pagesGenset Control For Single Unit Operation: FlexrangeitamarpereiraNo ratings yet

- Easygen 1500 Prod Spec 37180 PDFDocument4 pagesEasygen 1500 Prod Spec 37180 PDFbambangNo ratings yet

- Mme BroshureDocument10 pagesMme BroshureElshan jalilzadehNo ratings yet

- SynchrocouplerDocument6 pagesSynchrocouplerMandark0009No ratings yet

- 1.340 ATP 2023-24 GR 10 Mech Tech Aut FinalDocument4 pages1.340 ATP 2023-24 GR 10 Mech Tech Aut FinalNigel EvertsonNo ratings yet

- Overview of Mechatronics Overview of MechatronicsDocument65 pagesOverview of Mechatronics Overview of Mechatronicsdoan luc100% (3)

- rg6 Gripper Datasheet PDFDocument6 pagesrg6 Gripper Datasheet PDFRaj RajNo ratings yet

- What Is A Limit Switch?: 1. Seals 2. Enclosure Case 3.built in Basic Switch 4. Connectors 5. ActuatorDocument7 pagesWhat Is A Limit Switch?: 1. Seals 2. Enclosure Case 3.built in Basic Switch 4. Connectors 5. ActuatorRohitNo ratings yet

- Vibration Shakers 2Document5 pagesVibration Shakers 2aal_shurafaNo ratings yet

- 2 - Vib AnalysisDocument67 pages2 - Vib AnalysismemoaljawiNo ratings yet

- VIB Booklet ENDocument36 pagesVIB Booklet ENPetra HeutsNo ratings yet

- Robot Mechanisms and Mechanical Devices IllustratedFrom EverandRobot Mechanisms and Mechanical Devices IllustratedRating: 4 out of 5 stars4/5 (1)

- Quick Review On All The Aphorisms of Organon of Medicine 6 EditionDocument11 pagesQuick Review On All The Aphorisms of Organon of Medicine 6 EditionVishalNo ratings yet

- An Overview On The Validation Approach For Steam Sterilization - Part II, Madalina Brindusa Boca Et. Al.Document9 pagesAn Overview On The Validation Approach For Steam Sterilization - Part II, Madalina Brindusa Boca Et. Al.bocam100% (1)

- 2005 تأثير المعالجة المسبقة للبذور عن طريق المجال المغناطيسي على حساسية شتلات الخيار للأشعة فوق البنفسجيةDocument9 pages2005 تأثير المعالجة المسبقة للبذور عن طريق المجال المغناطيسي على حساسية شتلات الخيار للأشعة فوق البنفسجيةMUHAMMED ALSUVAİDNo ratings yet

- Role of Citizen Journalism in Strengthening Societies: Margalla Papers 2011Document20 pagesRole of Citizen Journalism in Strengthening Societies: Margalla Papers 2011WANINo ratings yet

- Parameters For IPG-83H40PL-BDocument5 pagesParameters For IPG-83H40PL-BJack DanielsNo ratings yet

- Broucher (2023)Document2 pagesBroucher (2023)Atta Ul Mustafa ZainNo ratings yet

- BC 0071Document1 pageBC 0071Sebastian JesusNo ratings yet

- Advanced Cardiac Life Support AsystoleDocument14 pagesAdvanced Cardiac Life Support AsystoleKar TwentyfiveNo ratings yet

- Drone pg1Document1 pageDrone pg1kokiuaNo ratings yet

- ShockDocument30 pagesShockvinnu kalyanNo ratings yet

- Week 7 Chapter 7: Guest RegistrationDocument12 pagesWeek 7 Chapter 7: Guest RegistrationechxNo ratings yet

- Barcoo Independent 230410Document8 pagesBarcoo Independent 230410barcooindependentNo ratings yet

- Jurnal Ekonomi SyariahDocument5 pagesJurnal Ekonomi Syariahjubaidahnurhayati100% (1)

- 5 Famous Poems by Robert Frost A) From North of Boston (1914)Document10 pages5 Famous Poems by Robert Frost A) From North of Boston (1914)Francisco EmmanuelNo ratings yet

- Government Engineering College Dahod: Dadhichi HostelDocument5 pagesGovernment Engineering College Dahod: Dadhichi HostelSandip MouryaNo ratings yet

- Daily Lesson Plan: Understand and Use The Concept of Sine Rule To Solve ProblemsDocument4 pagesDaily Lesson Plan: Understand and Use The Concept of Sine Rule To Solve ProblemsRaj'z KingzterNo ratings yet

- Greaves Cotton Ar 2018 1 PDFDocument168 pagesGreaves Cotton Ar 2018 1 PDFanand_parchureNo ratings yet

- ISB - Co2014 Consulting Case Book - FrameworksDocument24 pagesISB - Co2014 Consulting Case Book - Frameworksanshul suryanNo ratings yet

- Sonic Marketing Plan - Nguyen Thi Hong Diep, Truong Minh Hoang, Vu Quynh NgaDocument44 pagesSonic Marketing Plan - Nguyen Thi Hong Diep, Truong Minh Hoang, Vu Quynh NgaTruong Minh Hoang100% (1)

- Creative Writing MelcsDocument3 pagesCreative Writing MelcsArnel Navales100% (7)

- DeepFX LDocument1 pageDeepFX LSasha DimiciNo ratings yet

- Module 1-Chapter 4 The Selection of The Civil EngineerDocument6 pagesModule 1-Chapter 4 The Selection of The Civil EngineerKrisangel AbletesNo ratings yet

- K8V-X Se: User GuideDocument82 pagesK8V-X Se: User GuidethegamersNo ratings yet

- ReproDocument14 pagesRepro41umeshcha41No ratings yet

- Sorcerer's GardenDocument63 pagesSorcerer's Gardenswierck100% (2)

- Group 1 LanguagesDocument4 pagesGroup 1 Languagesbhis PuneNo ratings yet