Professional Documents

Culture Documents

Carcoseal / UN

Carcoseal / UN

Uploaded by

mattiaCopyright:

Available Formats

You might also like

- AGPT06-09 Guide To Pavement Technology Part 6 Unsealed Pavements PDFDocument87 pagesAGPT06-09 Guide To Pavement Technology Part 6 Unsealed Pavements PDFThomasJohnnoStevensonNo ratings yet

- Annex 4 - Work Prog - Reach 1A & 1BDocument3 pagesAnnex 4 - Work Prog - Reach 1A & 1BGANGARAJU N BNo ratings yet

- Concrete TechnologyDocument3 pagesConcrete TechnologyJiabin Li100% (1)

- CH 14 Science Note BookDocument4 pagesCH 14 Science Note BookSavannah Montelongo100% (2)

- CarcosealunsfDocument2 pagesCarcosealunsfmattiaNo ratings yet

- 0607 Carcoseal Un Data SheetDocument2 pages0607 Carcoseal Un Data SheetMarco FranceseNo ratings yet

- Carcoseal AP / WT. The Lip Is Designed So That TheDocument2 pagesCarcoseal AP / WT. The Lip Is Designed So That ThemattiaNo ratings yet

- Carcoseal AP/WT/RR. The Lip Is Designed So ThatDocument2 pagesCarcoseal AP/WT/RR. The Lip Is Designed So ThatmattiaNo ratings yet

- Soldering Joint Criteria: For CHIP-R and MLCCDocument21 pagesSoldering Joint Criteria: For CHIP-R and MLCCAdriano AraujoNo ratings yet

- NIC Components NACV SeriesDocument3 pagesNIC Components NACV SeriesNICCompNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- General Information: 2.1. ConcreteDocument3 pagesGeneral Information: 2.1. ConcreteGeloNo ratings yet

- 19/33kV Three Core: DescriptionDocument5 pages19/33kV Three Core: DescriptionVikas guptaNo ratings yet

- BS 7211 CableDocument22 pagesBS 7211 CablehanoiNo ratings yet

- Beam Splitter Output Coupler Coatings (Materiais para Laser)Document1 pageBeam Splitter Output Coupler Coatings (Materiais para Laser)AndréNo ratings yet

- NIC Components NRE-LS SeriesDocument5 pagesNIC Components NRE-LS SeriesNICCompNo ratings yet

- RESM Angle EncoderDocument8 pagesRESM Angle EncoderJaswinder SinghNo ratings yet

- Maintenance and Instruction Manual 1. Transport: Galperti TechDocument7 pagesMaintenance and Instruction Manual 1. Transport: Galperti TechDavid C HouserNo ratings yet

- VHM 106 161 PDFDocument56 pagesVHM 106 161 PDFGeronimo PrincipeNo ratings yet

- Productdatasheet en KF 50b494c18fDocument3 pagesProductdatasheet en KF 50b494c18fDarko MemarovicNo ratings yet

- Surface Mounting TechnlogyDocument161 pagesSurface Mounting Technlogyhariharasankar100% (2)

- En ChemiklerepdmDocument2 pagesEn Chemiklerepdmeloy marroquinNo ratings yet

- Datasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Document5 pagesDatasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Raja Sekaran SajjaNo ratings yet

- 42CrMo4QT-Pulley Shaft MaterialDocument1 page42CrMo4QT-Pulley Shaft MaterialanishgirmeNo ratings yet

- En Chemiklerd-EpdmDocument2 pagesEn Chemiklerd-Epdmeloy marroquinNo ratings yet

- Tabular Presentation of Basic Technical Data RMC ConductorsDocument2 pagesTabular Presentation of Basic Technical Data RMC ConductorsBuyme1 CNC BIZNo ratings yet

- H07RN-F - (LTC) - 4Document6 pagesH07RN-F - (LTC) - 4Faizal AzwaryNo ratings yet

- Rod Seal: DesignDocument7 pagesRod Seal: Designgamal abousamraNo ratings yet

- Beryllium Copper (C17200) DatasheetDocument2 pagesBeryllium Copper (C17200) Datasheetjr_satishNo ratings yet

- NIC Components NRM SeriesDocument1 pageNIC Components NRM SeriesNICCompNo ratings yet

- NIC Components NRE-HDocument6 pagesNIC Components NRE-HNICCompNo ratings yet

- L-9517-9154-08-B Data Sheet RESM enDocument12 pagesL-9517-9154-08-B Data Sheet RESM enAlex ZXNo ratings yet

- AUSREO Product Catalogue May2020 Final WebDocument36 pagesAUSREO Product Catalogue May2020 Final WebTemp UseNo ratings yet

- THHN - THWN 90°C 600V - Columbia Wire & Cable CorporationDocument1 pageTHHN - THWN 90°C 600V - Columbia Wire & Cable CorporationDanilo BabolNo ratings yet

- TDS SikaDocument4 pagesTDS SikaBara GailNo ratings yet

- Cromax 280X: Hard Chrome BarDocument4 pagesCromax 280X: Hard Chrome BarpeterNo ratings yet

- Vishay Dale: FeaturesDocument6 pagesVishay Dale: FeaturesnemoneoNo ratings yet

- Mu Dia of Bar Mu Ast Fy FCK Spacing 905.1580914 B D D Ast mm2Document2 pagesMu Dia of Bar Mu Ast Fy FCK Spacing 905.1580914 B D D Ast mm2PrakashNo ratings yet

- H05V-K / H07V-K: Low Voltage - Energy and CablingDocument2 pagesH05V-K / H07V-K: Low Voltage - Energy and CablingMuhamad YasrinNo ratings yet

- NIC Components NRSK SeriesDocument5 pagesNIC Components NRSK SeriesNICCompNo ratings yet

- DK35-P Piston Seal Datasheet - 16296 EN PDFDocument2 pagesDK35-P Piston Seal Datasheet - 16296 EN PDFSridhar TholasingamNo ratings yet

- Carcotex Un RosDocument8 pagesCarcotex Un RosheyyjnkdlxdvwkgqcwNo ratings yet

- NIC Components NRE-L SeriesDocument5 pagesNIC Components NRE-L SeriesNICCompNo ratings yet

- L-9517-9154-09-A Data Sheet RESM enDocument18 pagesL-9517-9154-09-A Data Sheet RESM enShafiqul IslamNo ratings yet

- Piston Seals: Technical DetailsDocument4 pagesPiston Seals: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Post TensionDocument8 pagesPost Tensionedc1312No ratings yet

- 17PS M001VvvDocument1 page17PS M001VvvBen sayari Mohamed AmineNo ratings yet

- Informative Annex 2 - Surface FinishDocument10 pagesInformative Annex 2 - Surface FinishzaheerNo ratings yet

- CL 425 MARINE Floating Hose - GasDocument1 pageCL 425 MARINE Floating Hose - GasTaufiqNo ratings yet

- Airvent - Dae - DC - DF - 1 - S11.1 - en - 10&4Document5 pagesAirvent - Dae - DC - DF - 1 - S11.1 - en - 10&4honghieutrNo ratings yet

- 10/100 PC Card LAN Magnetic Modules: MechanicalsDocument2 pages10/100 PC Card LAN Magnetic Modules: MechanicalsAbdelrhman ElsayedNo ratings yet

- Cabone Lorraine Sintering Brochure 2008Document6 pagesCabone Lorraine Sintering Brochure 2008Varun DodhiaNo ratings yet

- TDS BOPP Clear LSA47 TaghleefDocument2 pagesTDS BOPP Clear LSA47 TaghleefEmmanuel AlvarezNo ratings yet

- MG CatalogDocument21 pagesMG CatalogSanket IchakeNo ratings yet

- T 65 PG 91-94 PDFDocument4 pagesT 65 PG 91-94 PDFJossimar PerezNo ratings yet

- ABC428201544125PM1Document15 pagesABC428201544125PM1deborahNo ratings yet

- T 606 PG 157-160 PDFDocument4 pagesT 606 PG 157-160 PDFJossimar PerezNo ratings yet

- LKIF in Line Strainers Product LeafletDocument3 pagesLKIF in Line Strainers Product LeafletGisela ViskaNo ratings yet

- LUMBERG Brochure Press Fit Technology ENDocument8 pagesLUMBERG Brochure Press Fit Technology ENcurioushoainamNo ratings yet

- PI Fatigue HDA: TensionDocument11 pagesPI Fatigue HDA: TensionJaime Magno Gutierrez RamirezNo ratings yet

- Cosonic (Radial Thru-Hole) RHT SeriesDocument2 pagesCosonic (Radial Thru-Hole) RHT Seriesjghjkhgkh87No ratings yet

- 3D Printer Troubleshooting Handbook: The Ultimate Guide To Fix all Common and Uncommon FDM 3D Printing Issues!From Everand3D Printer Troubleshooting Handbook: The Ultimate Guide To Fix all Common and Uncommon FDM 3D Printing Issues!No ratings yet

- SealMaster InflatableDocument8 pagesSealMaster InflatablemattiaNo ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- Sandvik SAF 2507: Duplex Stainless SteelDocument8 pagesSandvik SAF 2507: Duplex Stainless SteelmattiaNo ratings yet

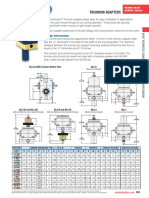

- Trunnion Adapters: Design InformationDocument1 pageTrunnion Adapters: Design InformationmattiaNo ratings yet

- Europe Germany France Italy Belgium Sweden U.K. Canada India Japan International USADocument1 pageEurope Germany France Italy Belgium Sweden U.K. Canada India Japan International USAmattiaNo ratings yet

- Sym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedDocument6 pagesSym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedmattiaNo ratings yet

- Carcoseal AP / WT. The Lip Is Designed So That TheDocument2 pagesCarcoseal AP / WT. The Lip Is Designed So That ThemattiaNo ratings yet

- Aisi 316 L: Operating Valves - Evax SerieDocument59 pagesAisi 316 L: Operating Valves - Evax SeriemattiaNo ratings yet

- Aisi 316 L and Aluminium: Gas Springs Molle A GasDocument32 pagesAisi 316 L and Aluminium: Gas Springs Molle A GasmattiaNo ratings yet

- Proven Water Lubricated Propeller Shaft Bearing Solutions: V IronDocument8 pagesProven Water Lubricated Propeller Shaft Bearing Solutions: V IronmattiaNo ratings yet

- CarcosealapDocument2 pagesCarcosealapmattiaNo ratings yet

- Process Pumps: Typical Fluids Pump UnitsDocument4 pagesProcess Pumps: Typical Fluids Pump UnitsmattiaNo ratings yet

- BallScrews and BallSplinesDocument160 pagesBallScrews and BallSplinesmattiaNo ratings yet

- CarcosealunsfDocument2 pagesCarcosealunsfmattiaNo ratings yet

- Thordon Rudder BrochureDocument8 pagesThordon Rudder BrochuremattiaNo ratings yet

- Self Blocking Rail ClampsDocument17 pagesSelf Blocking Rail ClampsmattiaNo ratings yet

- Thomson Precision Linear Actuators Sep06Document8 pagesThomson Precision Linear Actuators Sep06mattiaNo ratings yet

- Pluto Safety PLCDocument42 pagesPluto Safety PLCmattiaNo ratings yet

- Ramnäs Quality Chains and AccessoriesDocument13 pagesRamnäs Quality Chains and AccessoriesmattiaNo ratings yet

- Carcoseal AP/WT/RR. The Lip Is Designed So ThatDocument2 pagesCarcoseal AP/WT/RR. The Lip Is Designed So ThatmattiaNo ratings yet

- Catene Rigide SerapidDocument19 pagesCatene Rigide SerapidmattiaNo ratings yet

- Structural Analysis Using NX Nastran 9.0Document9 pagesStructural Analysis Using NX Nastran 9.0mattiaNo ratings yet

- The Iraqi Journal For Mechanical and Material Engineering, Vol.12, No.2, 2012Document18 pagesThe Iraqi Journal For Mechanical and Material Engineering, Vol.12, No.2, 2012mattiaNo ratings yet

- Materials: Bending and Buckling of Circular Sandwich Plates With A Hardened CoreDocument14 pagesMaterials: Bending and Buckling of Circular Sandwich Plates With A Hardened CoremattiaNo ratings yet

- 2014 Overview of Bureau of Reclamation Corrosion and Mitigation IssuesDocument16 pages2014 Overview of Bureau of Reclamation Corrosion and Mitigation IssuesLee SearsNo ratings yet

- Manufacturing of Liquids: Presented By-Supriya Suman Pharmd 4 Year Roll No.-15Document17 pagesManufacturing of Liquids: Presented By-Supriya Suman Pharmd 4 Year Roll No.-15balamuruganNo ratings yet

- New Microsoft Office Word DocumentDocument7 pagesNew Microsoft Office Word DocumentSab Ka Malik EkNo ratings yet

- US01CPHY01 Unit2 Elasticity PMPDocument20 pagesUS01CPHY01 Unit2 Elasticity PMPAjay Adithya0% (1)

- Karakterisasi Material (S3) ENMT802007Document19 pagesKarakterisasi Material (S3) ENMT802007fikri wahyu pratamaNo ratings yet

- Properties of FibersDocument116 pagesProperties of Fibersparthraj89100% (1)

- Compilation of Activity in General Chemistry 1Document12 pagesCompilation of Activity in General Chemistry 1Lalaine ConejosNo ratings yet

- 2nd Q - Summative Test 2021 - 1Document17 pages2nd Q - Summative Test 2021 - 1Lesley AntojadoNo ratings yet

- Investigation On 3-D-Printing Technologies For Millimeter-Wave and Terahertz ApplicationsDocument14 pagesInvestigation On 3-D-Printing Technologies For Millimeter-Wave and Terahertz ApplicationsAnuj SharmaNo ratings yet

- Reactive Metals in ExplosivesDocument13 pagesReactive Metals in ExplosivesAnonymous QFUEsUAnNo ratings yet

- Para FormaldehydeDocument5 pagesPara FormaldehydeVinh Do Thanh100% (1)

- Magnesium SulfateDocument2 pagesMagnesium SulfateArlette AndradeNo ratings yet

- 4-Teaser-Phonon-Technical InfoDocument1 page4-Teaser-Phonon-Technical InfoCristian MendozaNo ratings yet

- Small Arms and Ammunition Factory: C-09 ShopDocument7 pagesSmall Arms and Ammunition Factory: C-09 ShopAnis BadshahNo ratings yet

- Adobe Scan Aug 17, 2023Document3 pagesAdobe Scan Aug 17, 2023gulatisrishti15No ratings yet

- Microlenses - Microlens Arrays - Micralyne MEMS ManufacturerDocument1 pageMicrolenses - Microlens Arrays - Micralyne MEMS ManufacturerMicralyne100% (1)

- Numerical Study On 3D Effect and Practical Design in Shield TunnelingDocument9 pagesNumerical Study On 3D Effect and Practical Design in Shield TunnelingDidaBouchNo ratings yet

- 7 Kimia PDFDocument3 pages7 Kimia PDFFitria Istikomah Dewi100% (2)

- Solution To Problem 133 Pressure VesselDocument1 pageSolution To Problem 133 Pressure Vesseljimmy_d_nasutionNo ratings yet

- Cambridge Assessment International Education: Co-Ordinated Sciences 0654/41 May/June 2018Document11 pagesCambridge Assessment International Education: Co-Ordinated Sciences 0654/41 May/June 2018The MumtazNo ratings yet

- Material Safety Data Sheet: Performance Pipe (PE Pipe and Fittings: Various Colors)Document8 pagesMaterial Safety Data Sheet: Performance Pipe (PE Pipe and Fittings: Various Colors)mariannyNo ratings yet

- Investigate of Parameter Setting in Plastic Injection MoldingDocument28 pagesInvestigate of Parameter Setting in Plastic Injection MoldingKristine de ClaroNo ratings yet

- Pickering Emulsions - Preparation Processes, Key Parameters Governing Their Properties and Potential For Pharmaceutical ApplicationsDocument31 pagesPickering Emulsions - Preparation Processes, Key Parameters Governing Their Properties and Potential For Pharmaceutical ApplicationsEsteban MalamboNo ratings yet

- Selection of Materials Biomedical ApplicationDocument30 pagesSelection of Materials Biomedical ApplicationsciencystuffNo ratings yet

- Ecg354-Aggregate Impact TestDocument7 pagesEcg354-Aggregate Impact TestNurin AdlinaNo ratings yet

- 34POWRDocument103 pages34POWRbiskaalNo ratings yet

Carcoseal / UN

Carcoseal / UN

Uploaded by

mattiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carcoseal / UN

Carcoseal / UN

Uploaded by

mattiaCopyright:

Available Formats

CARCOSEAL UN

other and therefore a sealing problem is always

complex.

Carcoseal / UN. Is by far the most popular covering

the majority applications.

This seal require a retaining plate. When bolted in

position the plate exerts adequate axial compression Surface finish

on the shoulder of the Carcoseal, ensuring good

O.D. sealing. Surface roughness Min Max

HxA b E C H

d (mm)

(mm) (mm) (mm) (mm) (mm)

Ra 0,2 mm 0,8 mm

100 ÷ 250 16 x 20 2,0 9 4 16 ±0,1

250 ÷ 400 20 x 22 2,2 11 6 20 ±0,2

Rt 1 mm 4 mm

400 ÷ 600 22 x 25 2,5 11 7 22 ±0,2

> 600 25 x 32 3,2 14 8 25 ±0,2

Standard section related to shaft diameters.

Our sealing systems are mainly produced with

rubberized fabric & elastomers. Today we mainly

offer 3 standard materials.

MATERIAL Temperature Speed Pressure

(°C) (m/s) (MPa)

Code Type

S820 NBR -40 ÷ 120 15 0,05

HT720 HNBR -40 ÷ 170 25 0,05

Z420 VITON -30 ÷ 200 25 0,05

Our three standard materials are designed to cope

with these conditions .

All our products undergo our exclusive Carcoflon

treatment which gives considerable reduction of

the dry friction coefficient.

Many parameters like, as example, bad finish,

eccentricity, high temperature, bad lubrication, may

reduce maximum permissible speed sometimes

dramatically. All these parameters interact each

____________________________________________________________________________EDITION 01/07

To facilitate the installation the shaft should have Static eccentricity: the distance between the

centre of the internal edge of the lip and the shaft

rotation centre;

Dynamic eccentricity: the distance between the

geometric centre of the shaft section and the rotation

centre;

Ecc. Stat. Max

d (mm) HxA (mm)

(mm) Es

a chamfer with length “L” as function of its diameter 100 ÷ 250 16 x 20 0,50

“d” as indicated in graph below.

250 ÷ 400 20 x 22 0,55

400 ÷ 600 22 x 25 0,62

> 600 25 x 32 0,70

L [mm]

d [mm]

Each particular shaft size seal will have a

corresponding bore and width dimension. It’s

important that the bore be finished smooth and free Tab. shows static limits as function of shaft

from longitudinal scratches which could provide diameter “d” and of our standard cross section “H x

leakage path; also that a generous lead-in chamfer is A”, and dynamic limits as function of shaft speed.

incorporated on the leading edge of the housing to

facilitate fitting.

Please contact our technical dept for details.

CARCO S.r.l.

r 2= 0.5 with H≤ 10 Via U. Foscolo, 4

r2 = 0.75 with H> 10 20060 – Basiano (MI)

Tel +39.02.95760331

Fax +39.02.95760333

http://www.carco.it

CARCO GmbH

Verkaufsbüro Nord

Neehusenstrasse 22

21147 Hamburg

Tel: +49 40 79612464

Fax: +49 40 79612466

http://www.carco-germany.de

____________________________________________________________________________EDITION 01/07

You might also like

- AGPT06-09 Guide To Pavement Technology Part 6 Unsealed Pavements PDFDocument87 pagesAGPT06-09 Guide To Pavement Technology Part 6 Unsealed Pavements PDFThomasJohnnoStevensonNo ratings yet

- Annex 4 - Work Prog - Reach 1A & 1BDocument3 pagesAnnex 4 - Work Prog - Reach 1A & 1BGANGARAJU N BNo ratings yet

- Concrete TechnologyDocument3 pagesConcrete TechnologyJiabin Li100% (1)

- CH 14 Science Note BookDocument4 pagesCH 14 Science Note BookSavannah Montelongo100% (2)

- CarcosealunsfDocument2 pagesCarcosealunsfmattiaNo ratings yet

- 0607 Carcoseal Un Data SheetDocument2 pages0607 Carcoseal Un Data SheetMarco FranceseNo ratings yet

- Carcoseal AP / WT. The Lip Is Designed So That TheDocument2 pagesCarcoseal AP / WT. The Lip Is Designed So That ThemattiaNo ratings yet

- Carcoseal AP/WT/RR. The Lip Is Designed So ThatDocument2 pagesCarcoseal AP/WT/RR. The Lip Is Designed So ThatmattiaNo ratings yet

- Soldering Joint Criteria: For CHIP-R and MLCCDocument21 pagesSoldering Joint Criteria: For CHIP-R and MLCCAdriano AraujoNo ratings yet

- NIC Components NACV SeriesDocument3 pagesNIC Components NACV SeriesNICCompNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- General Information: 2.1. ConcreteDocument3 pagesGeneral Information: 2.1. ConcreteGeloNo ratings yet

- 19/33kV Three Core: DescriptionDocument5 pages19/33kV Three Core: DescriptionVikas guptaNo ratings yet

- BS 7211 CableDocument22 pagesBS 7211 CablehanoiNo ratings yet

- Beam Splitter Output Coupler Coatings (Materiais para Laser)Document1 pageBeam Splitter Output Coupler Coatings (Materiais para Laser)AndréNo ratings yet

- NIC Components NRE-LS SeriesDocument5 pagesNIC Components NRE-LS SeriesNICCompNo ratings yet

- RESM Angle EncoderDocument8 pagesRESM Angle EncoderJaswinder SinghNo ratings yet

- Maintenance and Instruction Manual 1. Transport: Galperti TechDocument7 pagesMaintenance and Instruction Manual 1. Transport: Galperti TechDavid C HouserNo ratings yet

- VHM 106 161 PDFDocument56 pagesVHM 106 161 PDFGeronimo PrincipeNo ratings yet

- Productdatasheet en KF 50b494c18fDocument3 pagesProductdatasheet en KF 50b494c18fDarko MemarovicNo ratings yet

- Surface Mounting TechnlogyDocument161 pagesSurface Mounting Technlogyhariharasankar100% (2)

- En ChemiklerepdmDocument2 pagesEn Chemiklerepdmeloy marroquinNo ratings yet

- Datasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Document5 pagesDatasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Raja Sekaran SajjaNo ratings yet

- 42CrMo4QT-Pulley Shaft MaterialDocument1 page42CrMo4QT-Pulley Shaft MaterialanishgirmeNo ratings yet

- En Chemiklerd-EpdmDocument2 pagesEn Chemiklerd-Epdmeloy marroquinNo ratings yet

- Tabular Presentation of Basic Technical Data RMC ConductorsDocument2 pagesTabular Presentation of Basic Technical Data RMC ConductorsBuyme1 CNC BIZNo ratings yet

- H07RN-F - (LTC) - 4Document6 pagesH07RN-F - (LTC) - 4Faizal AzwaryNo ratings yet

- Rod Seal: DesignDocument7 pagesRod Seal: Designgamal abousamraNo ratings yet

- Beryllium Copper (C17200) DatasheetDocument2 pagesBeryllium Copper (C17200) Datasheetjr_satishNo ratings yet

- NIC Components NRM SeriesDocument1 pageNIC Components NRM SeriesNICCompNo ratings yet

- NIC Components NRE-HDocument6 pagesNIC Components NRE-HNICCompNo ratings yet

- L-9517-9154-08-B Data Sheet RESM enDocument12 pagesL-9517-9154-08-B Data Sheet RESM enAlex ZXNo ratings yet

- AUSREO Product Catalogue May2020 Final WebDocument36 pagesAUSREO Product Catalogue May2020 Final WebTemp UseNo ratings yet

- THHN - THWN 90°C 600V - Columbia Wire & Cable CorporationDocument1 pageTHHN - THWN 90°C 600V - Columbia Wire & Cable CorporationDanilo BabolNo ratings yet

- TDS SikaDocument4 pagesTDS SikaBara GailNo ratings yet

- Cromax 280X: Hard Chrome BarDocument4 pagesCromax 280X: Hard Chrome BarpeterNo ratings yet

- Vishay Dale: FeaturesDocument6 pagesVishay Dale: FeaturesnemoneoNo ratings yet

- Mu Dia of Bar Mu Ast Fy FCK Spacing 905.1580914 B D D Ast mm2Document2 pagesMu Dia of Bar Mu Ast Fy FCK Spacing 905.1580914 B D D Ast mm2PrakashNo ratings yet

- H05V-K / H07V-K: Low Voltage - Energy and CablingDocument2 pagesH05V-K / H07V-K: Low Voltage - Energy and CablingMuhamad YasrinNo ratings yet

- NIC Components NRSK SeriesDocument5 pagesNIC Components NRSK SeriesNICCompNo ratings yet

- DK35-P Piston Seal Datasheet - 16296 EN PDFDocument2 pagesDK35-P Piston Seal Datasheet - 16296 EN PDFSridhar TholasingamNo ratings yet

- Carcotex Un RosDocument8 pagesCarcotex Un RosheyyjnkdlxdvwkgqcwNo ratings yet

- NIC Components NRE-L SeriesDocument5 pagesNIC Components NRE-L SeriesNICCompNo ratings yet

- L-9517-9154-09-A Data Sheet RESM enDocument18 pagesL-9517-9154-09-A Data Sheet RESM enShafiqul IslamNo ratings yet

- Piston Seals: Technical DetailsDocument4 pagesPiston Seals: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Post TensionDocument8 pagesPost Tensionedc1312No ratings yet

- 17PS M001VvvDocument1 page17PS M001VvvBen sayari Mohamed AmineNo ratings yet

- Informative Annex 2 - Surface FinishDocument10 pagesInformative Annex 2 - Surface FinishzaheerNo ratings yet

- CL 425 MARINE Floating Hose - GasDocument1 pageCL 425 MARINE Floating Hose - GasTaufiqNo ratings yet

- Airvent - Dae - DC - DF - 1 - S11.1 - en - 10&4Document5 pagesAirvent - Dae - DC - DF - 1 - S11.1 - en - 10&4honghieutrNo ratings yet

- 10/100 PC Card LAN Magnetic Modules: MechanicalsDocument2 pages10/100 PC Card LAN Magnetic Modules: MechanicalsAbdelrhman ElsayedNo ratings yet

- Cabone Lorraine Sintering Brochure 2008Document6 pagesCabone Lorraine Sintering Brochure 2008Varun DodhiaNo ratings yet

- TDS BOPP Clear LSA47 TaghleefDocument2 pagesTDS BOPP Clear LSA47 TaghleefEmmanuel AlvarezNo ratings yet

- MG CatalogDocument21 pagesMG CatalogSanket IchakeNo ratings yet

- T 65 PG 91-94 PDFDocument4 pagesT 65 PG 91-94 PDFJossimar PerezNo ratings yet

- ABC428201544125PM1Document15 pagesABC428201544125PM1deborahNo ratings yet

- T 606 PG 157-160 PDFDocument4 pagesT 606 PG 157-160 PDFJossimar PerezNo ratings yet

- LKIF in Line Strainers Product LeafletDocument3 pagesLKIF in Line Strainers Product LeafletGisela ViskaNo ratings yet

- LUMBERG Brochure Press Fit Technology ENDocument8 pagesLUMBERG Brochure Press Fit Technology ENcurioushoainamNo ratings yet

- PI Fatigue HDA: TensionDocument11 pagesPI Fatigue HDA: TensionJaime Magno Gutierrez RamirezNo ratings yet

- Cosonic (Radial Thru-Hole) RHT SeriesDocument2 pagesCosonic (Radial Thru-Hole) RHT Seriesjghjkhgkh87No ratings yet

- 3D Printer Troubleshooting Handbook: The Ultimate Guide To Fix all Common and Uncommon FDM 3D Printing Issues!From Everand3D Printer Troubleshooting Handbook: The Ultimate Guide To Fix all Common and Uncommon FDM 3D Printing Issues!No ratings yet

- SealMaster InflatableDocument8 pagesSealMaster InflatablemattiaNo ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- Sandvik SAF 2507: Duplex Stainless SteelDocument8 pagesSandvik SAF 2507: Duplex Stainless SteelmattiaNo ratings yet

- Trunnion Adapters: Design InformationDocument1 pageTrunnion Adapters: Design InformationmattiaNo ratings yet

- Europe Germany France Italy Belgium Sweden U.K. Canada India Japan International USADocument1 pageEurope Germany France Italy Belgium Sweden U.K. Canada India Japan International USAmattiaNo ratings yet

- Sym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedDocument6 pagesSym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedmattiaNo ratings yet

- Carcoseal AP / WT. The Lip Is Designed So That TheDocument2 pagesCarcoseal AP / WT. The Lip Is Designed So That ThemattiaNo ratings yet

- Aisi 316 L: Operating Valves - Evax SerieDocument59 pagesAisi 316 L: Operating Valves - Evax SeriemattiaNo ratings yet

- Aisi 316 L and Aluminium: Gas Springs Molle A GasDocument32 pagesAisi 316 L and Aluminium: Gas Springs Molle A GasmattiaNo ratings yet

- Proven Water Lubricated Propeller Shaft Bearing Solutions: V IronDocument8 pagesProven Water Lubricated Propeller Shaft Bearing Solutions: V IronmattiaNo ratings yet

- CarcosealapDocument2 pagesCarcosealapmattiaNo ratings yet

- Process Pumps: Typical Fluids Pump UnitsDocument4 pagesProcess Pumps: Typical Fluids Pump UnitsmattiaNo ratings yet

- BallScrews and BallSplinesDocument160 pagesBallScrews and BallSplinesmattiaNo ratings yet

- CarcosealunsfDocument2 pagesCarcosealunsfmattiaNo ratings yet

- Thordon Rudder BrochureDocument8 pagesThordon Rudder BrochuremattiaNo ratings yet

- Self Blocking Rail ClampsDocument17 pagesSelf Blocking Rail ClampsmattiaNo ratings yet

- Thomson Precision Linear Actuators Sep06Document8 pagesThomson Precision Linear Actuators Sep06mattiaNo ratings yet

- Pluto Safety PLCDocument42 pagesPluto Safety PLCmattiaNo ratings yet

- Ramnäs Quality Chains and AccessoriesDocument13 pagesRamnäs Quality Chains and AccessoriesmattiaNo ratings yet

- Carcoseal AP/WT/RR. The Lip Is Designed So ThatDocument2 pagesCarcoseal AP/WT/RR. The Lip Is Designed So ThatmattiaNo ratings yet

- Catene Rigide SerapidDocument19 pagesCatene Rigide SerapidmattiaNo ratings yet

- Structural Analysis Using NX Nastran 9.0Document9 pagesStructural Analysis Using NX Nastran 9.0mattiaNo ratings yet

- The Iraqi Journal For Mechanical and Material Engineering, Vol.12, No.2, 2012Document18 pagesThe Iraqi Journal For Mechanical and Material Engineering, Vol.12, No.2, 2012mattiaNo ratings yet

- Materials: Bending and Buckling of Circular Sandwich Plates With A Hardened CoreDocument14 pagesMaterials: Bending and Buckling of Circular Sandwich Plates With A Hardened CoremattiaNo ratings yet

- 2014 Overview of Bureau of Reclamation Corrosion and Mitigation IssuesDocument16 pages2014 Overview of Bureau of Reclamation Corrosion and Mitigation IssuesLee SearsNo ratings yet

- Manufacturing of Liquids: Presented By-Supriya Suman Pharmd 4 Year Roll No.-15Document17 pagesManufacturing of Liquids: Presented By-Supriya Suman Pharmd 4 Year Roll No.-15balamuruganNo ratings yet

- New Microsoft Office Word DocumentDocument7 pagesNew Microsoft Office Word DocumentSab Ka Malik EkNo ratings yet

- US01CPHY01 Unit2 Elasticity PMPDocument20 pagesUS01CPHY01 Unit2 Elasticity PMPAjay Adithya0% (1)

- Karakterisasi Material (S3) ENMT802007Document19 pagesKarakterisasi Material (S3) ENMT802007fikri wahyu pratamaNo ratings yet

- Properties of FibersDocument116 pagesProperties of Fibersparthraj89100% (1)

- Compilation of Activity in General Chemistry 1Document12 pagesCompilation of Activity in General Chemistry 1Lalaine ConejosNo ratings yet

- 2nd Q - Summative Test 2021 - 1Document17 pages2nd Q - Summative Test 2021 - 1Lesley AntojadoNo ratings yet

- Investigation On 3-D-Printing Technologies For Millimeter-Wave and Terahertz ApplicationsDocument14 pagesInvestigation On 3-D-Printing Technologies For Millimeter-Wave and Terahertz ApplicationsAnuj SharmaNo ratings yet

- Reactive Metals in ExplosivesDocument13 pagesReactive Metals in ExplosivesAnonymous QFUEsUAnNo ratings yet

- Para FormaldehydeDocument5 pagesPara FormaldehydeVinh Do Thanh100% (1)

- Magnesium SulfateDocument2 pagesMagnesium SulfateArlette AndradeNo ratings yet

- 4-Teaser-Phonon-Technical InfoDocument1 page4-Teaser-Phonon-Technical InfoCristian MendozaNo ratings yet

- Small Arms and Ammunition Factory: C-09 ShopDocument7 pagesSmall Arms and Ammunition Factory: C-09 ShopAnis BadshahNo ratings yet

- Adobe Scan Aug 17, 2023Document3 pagesAdobe Scan Aug 17, 2023gulatisrishti15No ratings yet

- Microlenses - Microlens Arrays - Micralyne MEMS ManufacturerDocument1 pageMicrolenses - Microlens Arrays - Micralyne MEMS ManufacturerMicralyne100% (1)

- Numerical Study On 3D Effect and Practical Design in Shield TunnelingDocument9 pagesNumerical Study On 3D Effect and Practical Design in Shield TunnelingDidaBouchNo ratings yet

- 7 Kimia PDFDocument3 pages7 Kimia PDFFitria Istikomah Dewi100% (2)

- Solution To Problem 133 Pressure VesselDocument1 pageSolution To Problem 133 Pressure Vesseljimmy_d_nasutionNo ratings yet

- Cambridge Assessment International Education: Co-Ordinated Sciences 0654/41 May/June 2018Document11 pagesCambridge Assessment International Education: Co-Ordinated Sciences 0654/41 May/June 2018The MumtazNo ratings yet

- Material Safety Data Sheet: Performance Pipe (PE Pipe and Fittings: Various Colors)Document8 pagesMaterial Safety Data Sheet: Performance Pipe (PE Pipe and Fittings: Various Colors)mariannyNo ratings yet

- Investigate of Parameter Setting in Plastic Injection MoldingDocument28 pagesInvestigate of Parameter Setting in Plastic Injection MoldingKristine de ClaroNo ratings yet

- Pickering Emulsions - Preparation Processes, Key Parameters Governing Their Properties and Potential For Pharmaceutical ApplicationsDocument31 pagesPickering Emulsions - Preparation Processes, Key Parameters Governing Their Properties and Potential For Pharmaceutical ApplicationsEsteban MalamboNo ratings yet

- Selection of Materials Biomedical ApplicationDocument30 pagesSelection of Materials Biomedical ApplicationsciencystuffNo ratings yet

- Ecg354-Aggregate Impact TestDocument7 pagesEcg354-Aggregate Impact TestNurin AdlinaNo ratings yet

- 34POWRDocument103 pages34POWRbiskaalNo ratings yet