Professional Documents

Culture Documents

Curriculum Vitae: Duties & Responsibilities

Curriculum Vitae: Duties & Responsibilities

Uploaded by

Nazim HaiderOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Curriculum Vitae: Duties & Responsibilities

Curriculum Vitae: Duties & Responsibilities

Uploaded by

Nazim HaiderCopyright:

Available Formats

CURRICULUM VITAE

MD NAZIM

Contact No: +91-7358739593

Email Id: nazimhaider@aol.com

PROFILE SUMMARY

I’m a Graduate Mechanical Engineer with additional qualification in ASNT Level ii having

consolidated more than 6+ years of experience in Welding, with a wealth of experience in all

aspects of mechanical constructions in Oil & Gas industries . Knowledge and Familiar with codes of

ASTM, ASME, Welding Symbols.

ORGANIZATIONAL EXPERIENCE

Worked in SULZER INDIA Ltd. as Welding Supervisor (20/07/2021 to Till Now)

Duties & Responsibilities

Assisting QC Engineer in Welding Inspection, visual inspection of joint fit-ups, in process and

completed welding inspection on various materials, maintaining records.

Assuring that the welding is performed as required by the WPS and meets the required

qualities.

Checking and controlling welding consumables like Electrodes, Filler wires and Flux before

welding and during welding.

Verifying calibration records of welding instruments prior to start the welding, Updating &

maintaining the calibrations status for all instruments.

Monitoring PWHT and other site activities.

Maintaining daily record of completed and in process welding.

Worked in BALAJI TANK & VESSELS Ltd. as Welding Supervisor (02/04/2021 to

15/05/2021)

Duties & Responsibilities

Monitoring the welding activities, perform routine fit up inspection and welding inspections as

per approved WPS, Applicable codes & Approved drawings.

Planning / organizing and checking of Quality of work & schedules to meet the

deadlines/target dates & implementing production plans.

Coordinating & witnessing MPI, PT, RT tests & maintain the NDT documents/test reports.

Coordinate with Projects In-charge to close out the observations,

Responsible for the documentation of inspection activities and maintenance of quality control

records

Worked in RBP Engineers & Contracts Pvt. Ltd. as Welding Supervisor (03/07/2017 to

27/09/2020)

Duties & Responsibilities

Assist the site engineer to performing all welding activities in accordance with Quality

Plan, procedures, applicable codes, standards and specifications.

Monitoring the construction site to check whether all works, materials, equipment, are in

accordance with fabrication drawing & specification.

Assist site Engineer in conducting regular quality inspections and welder qualification test.

Monitoring incoming filler material inspection and filler material condition.

Welding Inspection, visual inspection of joint fit-ups, in process and completed welding

inspection on various materials, maintaining records.

Checking and controlling welding consumables like Electrodes, Filler wires and Flux before

welding and during welding.

Verifying calibration records of testing instruments prior to start the welding, Updating &

maintaining the calibrations status for all instruments.

Quality issues and representing matters with the higher authorities

Worked in T & C Engineers Pvt. Ltd. as Welding Supervisor (01/02/2015 to 25/06/2017)

Duties & Responsibilities

Review approved WPS, fabrication drawing with respect to job

Analysis risk and hazard safety point of view before starting the job

Receive the work permit as per requirement.

Conducting tools Box meeting daily

job distribution among the welder, fitter and other manpower

Ensuring the treatment of Low Hydrogen electrode

Before welding, during welding and after welding Inspection

Ensuring welder maintaining all welding parameters according to WPS

Ensuring Pre heating, inter-run heating so that minimizing the distortion, hydrogen and

solidification cracking

Ensuring inter-run cleaning to avoid slag inclusion

After welding informing NDT team

Identification of scope of PWHT

Tracing and repair in accordance with the nature of defects occurred

Conducting weekly review meetings with team and giving the feedback to my upper higher

authority

Ensuring completion of work within the budget time, customer satisfaction, project

progress reviews throughout the project execution within my scope.

WELDING JOB ACCOMPLISHED

Pipe

Storage Tank

Pressure Vessel

FAMILIAR WITH PROCESS & CONSUMABLE

WELDING PROCESS

SMAW, GTAW, GMAW

CONSUMABLES

Covered Electrode

Bare Filler Wire

Shielding Gases

CODES KNOWLEDGE

ASME Sec – ii Part A – Ferrous Materials

Part C – Filler Metal Specification

ASME Sec – v - NDT Procedure

ASME Sec – Viii Div. – 1 – Rules for Construction of pressure

Vessel & NDT acceptance criteria

API 650 – Storage Tank

ASME – Sec – ix – WPS

AMSE – B31.3

EDUCATION

2017: B.Tech (Mechanical Engineering) from Bharath Institute of Science and Technology,

Chennai, Bharath Institute of Higher Education and Research with 74%

2013: Higher Secondary from Islamia College, Bihar (Bihar Board) with 58%

2010: Matriculation from B.K.D Govt Boys High School, Bihar (Bihar Board) with 71%

NDT Level II from Advantech NDT Academy, Ghansoli, Mumbai

PERSONAL DETAILS

Languages: Hindi, Urdu, English

Date of Birth: 1st January 1996

Permanent Address: Vill - Dath, Post - Rupouli Ghat, Dist.-Darbhanga, Bihar-846003

Current Address: Ghansoli, Mumbai-400701

I hereby declare that the information furnished above is true to best of my knowledge and belief.

Place:

Date: MD NAZIM

You might also like

- Amended Petition For The Issuance of New TitleDocument6 pagesAmended Petition For The Issuance of New TitleStewart Paul Tolosa Torre100% (3)

- Piping QC CVDocument3 pagesPiping QC CVMd Sharique100% (1)

- Manual Liberty SelectDocument2 pagesManual Liberty SelectMarcos AcioliNo ratings yet

- Income Inequality in Singapore: Causes, Consequences and Policy Options - Ishita DhamaniDocument31 pagesIncome Inequality in Singapore: Causes, Consequences and Policy Options - Ishita DhamaniJunyuan100% (1)

- Finance 261 - Cheat SheetDocument2 pagesFinance 261 - Cheat SheetstevenNo ratings yet

- Curriculum Vitae: Duties & ResponsibilitiesDocument3 pagesCurriculum Vitae: Duties & ResponsibilitiesNazim HaiderNo ratings yet

- Welding Engineer: M.E. in Welding TechnologyDocument4 pagesWelding Engineer: M.E. in Welding TechnologySenthil KumaranNo ratings yet

- Resume - QC EngineerDocument4 pagesResume - QC EngineerSenthil Kumaran100% (1)

- Curriculum Vitae: Profile SummaryDocument3 pagesCurriculum Vitae: Profile SummaryNazim HaiderNo ratings yet

- Api, Qa, QC, Welding, Painting, NDT InspectorDocument7 pagesApi, Qa, QC, Welding, Painting, NDT InspectorBalaji ViswanathanNo ratings yet

- Ajin BabuDocument4 pagesAjin BabuJithuJohnNo ratings yet

- Saif Ullah Updated AramcoDocument4 pagesSaif Ullah Updated AramcoHaleem Ur Rashid BangashNo ratings yet

- QC Welding Inspector ImtiazDocument3 pagesQC Welding Inspector ImtiazImtiyaz MirzaNo ratings yet

- Curriculum VitDocument4 pagesCurriculum Vit1dzrbtcom ProfessionalprogramminglanguageNo ratings yet

- Curriculum Vitae: Name: Upendra KumarDocument6 pagesCurriculum Vitae: Name: Upendra KumarNitin KarboNo ratings yet

- QC/ Welding InspectorDocument6 pagesQC/ Welding Inspectorapi-78450733No ratings yet

- Mobile No: +91-8526351664: Post Applied For QC Welding Inspector Career GoalDocument3 pagesMobile No: +91-8526351664: Post Applied For QC Welding Inspector Career GoalMohammedBujairNo ratings yet

- Curriculum Vitae: S.Vinoth KumarDocument5 pagesCurriculum Vitae: S.Vinoth KumarVinoth Kumar SubramaniNo ratings yet

- Curriculum Vitae (Rahul Ramdas Yelve)Document5 pagesCurriculum Vitae (Rahul Ramdas Yelve)prashantghodkeNo ratings yet

- QC Welding Inspector - Khaja RafiuddinDocument5 pagesQC Welding Inspector - Khaja Rafiuddinkazim MirzaNo ratings yet

- Dhanasekaran CV QCI Welding PaintingDocument6 pagesDhanasekaran CV QCI Welding PaintingulocksystemNo ratings yet

- Mubeen Ahmed CVDocument7 pagesMubeen Ahmed CVMonis Hyder100% (1)

- Mudassir Naseer Khan: Qa/Qc Mechanical Engineer (Cswip 3.1 Welding Inspector) Cert:456316Document3 pagesMudassir Naseer Khan: Qa/Qc Mechanical Engineer (Cswip 3.1 Welding Inspector) Cert:456316Mudassir KhanNo ratings yet

- Curriculum Vitae: Training QualificationsDocument5 pagesCurriculum Vitae: Training QualificationsPipitNo ratings yet

- Mon Finlqaqce. 3Document4 pagesMon Finlqaqce. 3ulocksystemNo ratings yet

- Mohammad Rijwan: Aramco, Sabic, Sadara, SatorpDocument5 pagesMohammad Rijwan: Aramco, Sabic, Sadara, SatorpMohammad RizwanNo ratings yet

- Dhinesh Suman Prasath Cswip3.1, ASNT Level II Certified Inspection EngineerDocument4 pagesDhinesh Suman Prasath Cswip3.1, ASNT Level II Certified Inspection Engineersahaya freedonNo ratings yet

- Naukri VISHALRAJARAMINGALE (6y 9m)Document4 pagesNaukri VISHALRAJARAMINGALE (6y 9m)3asNo ratings yet

- Naukri SatishJibhauPagare (5y 0m)Document4 pagesNaukri SatishJibhauPagare (5y 0m)3asNo ratings yet

- Trimurtulu. Pedasingu: Assurance & Control With An Organisation of High Repute in Oil & Gas IndustryDocument4 pagesTrimurtulu. Pedasingu: Assurance & Control With An Organisation of High Repute in Oil & Gas IndustrySài TejaNo ratings yet

- Qa/Qc Welding Inspector: Curriculum VitaeDocument5 pagesQa/Qc Welding Inspector: Curriculum Vitaenaveed7861No ratings yet

- Subrat Kumar Barik: Curriculum VitaeDocument3 pagesSubrat Kumar Barik: Curriculum VitaeDeepak YadavNo ratings yet

- INSpECTION ENGINEER PDFDocument4 pagesINSpECTION ENGINEER PDFKaranDinaNo ratings yet

- Naukri NavanathKashid (6y 6m)Document4 pagesNaukri NavanathKashid (6y 6m)3asNo ratings yet

- CV 2Document5 pagesCV 2Kshama RaiNo ratings yet

- Sreekumar.S.I: Mechanical Engineer (B.E)Document3 pagesSreekumar.S.I: Mechanical Engineer (B.E)JunaidAsrarNo ratings yet

- QC Welding Inspector (CSWIP 3.2)Document5 pagesQC Welding Inspector (CSWIP 3.2)Tanveer Ahmed QuadriNo ratings yet

- New Resume AUG (1) - 1Document5 pagesNew Resume AUG (1) - 1manikantaNo ratings yet

- Mechanical Supervisor ResumeDocument4 pagesMechanical Supervisor ResumeAnwar Rahman100% (4)

- Sarath Sreekumar: Mechanical Engineer With 3+ Years of Work Experience As Quality InspectorDocument3 pagesSarath Sreekumar: Mechanical Engineer With 3+ Years of Work Experience As Quality InspectorabdulNo ratings yet

- Wasi Ullah Zeeshan-EngrDocument8 pagesWasi Ullah Zeeshan-EngrShani MalikNo ratings yet

- CV UpdatedDocument6 pagesCV UpdatedDavidNo ratings yet

- MD Nazim: Professional SummeryDocument2 pagesMD Nazim: Professional SummeryM NazimNo ratings yet

- Bio-Data: Name: Zain Yousaf Aramco Approved QCI WELDING Iqama # 2460058569 Driving License - Saudi ArabiaDocument6 pagesBio-Data: Name: Zain Yousaf Aramco Approved QCI WELDING Iqama # 2460058569 Driving License - Saudi ArabiaMd SogibNo ratings yet

- Yasar Arafath Habibullah: Personal ProfileDocument7 pagesYasar Arafath Habibullah: Personal ProfileMohamed AdelNo ratings yet

- Mymoonson CVDocument5 pagesMymoonson CVMahmoud shawkyNo ratings yet

- Knowledge in Autocad Plant3DDocument5 pagesKnowledge in Autocad Plant3DrajNo ratings yet

- Faizur Rahman CVDocument6 pagesFaizur Rahman CVmuneeshwaraperumalNo ratings yet

- Application For The Post of Suitable Position For Mechanical QA/QC INSPECTORDocument4 pagesApplication For The Post of Suitable Position For Mechanical QA/QC INSPECTORAhmed Imtiaz RaoNo ratings yet

- Shaikh ZaheerDocument4 pagesShaikh ZaheerMonika ShindeNo ratings yet

- CV 2023Document5 pagesCV 2023AmitNo ratings yet

- ASNT Level III, AWS-CWI, CSWIP, PCNDocument5 pagesASNT Level III, AWS-CWI, CSWIP, PCNShrikant UtekarNo ratings yet

- Curriculum Vitae: Career ObjectiveDocument4 pagesCurriculum Vitae: Career ObjectivePrashant KumarNo ratings yet

- Abdullah Alshaghab - CV - March 2016Document3 pagesAbdullah Alshaghab - CV - March 2016Ahmad fayyazNo ratings yet

- Piping SupervisorDocument4 pagesPiping SupervisorEr AkhlaqueNo ratings yet

- Mechanical Engineer ..Document4 pagesMechanical Engineer ..Saswat Kumar RoutNo ratings yet

- Sanu Krishnankutty Nair Subject: Application For The Post of Qa/ QC Inspector / Welding InspectorDocument5 pagesSanu Krishnankutty Nair Subject: Application For The Post of Qa/ QC Inspector / Welding InspectorSANUNo ratings yet

- Curriculum Vitae: Khermache MokhtarDocument4 pagesCurriculum Vitae: Khermache MokhtarMokhtar KhermacheNo ratings yet

- Piping SupervisorDocument4 pagesPiping Supervisorviswamanoj100% (1)

- Muhammed Thanzeel QC Mechanical Inspector: ObjectivesDocument5 pagesMuhammed Thanzeel QC Mechanical Inspector: ObjectivesMuhammed ThanzeelNo ratings yet

- Joel e Jose - CV - 2023 05Document3 pagesJoel e Jose - CV - 2023 05joelNo ratings yet

- Rakesh Rahulan1Document6 pagesRakesh Rahulan1rakeshNo ratings yet

- Sudarshan GujarDocument5 pagesSudarshan GujarNitin GhotekarNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Curriculum Vitae: Profile SummaryDocument3 pagesCurriculum Vitae: Profile SummaryNazim HaiderNo ratings yet

- Fabricator CVDocument2 pagesFabricator CVNazim Haider100% (1)

- MD Nazim: Profile SummaryDocument3 pagesMD Nazim: Profile SummaryNazim HaiderNo ratings yet

- Curriculum Vitae: Duties & ResponsibilitiesDocument3 pagesCurriculum Vitae: Duties & ResponsibilitiesNazim HaiderNo ratings yet

- MD Nazim: Profile SummaryDocument3 pagesMD Nazim: Profile SummaryNazim HaiderNo ratings yet

- Piping EngineeringDocument11 pagesPiping EngineeringNazim HaiderNo ratings yet

- Popular WoodworkingDocument100 pagesPopular WoodworkingSimsoneNo ratings yet

- 1 s2.0 S1044580316303412 MainDocument15 pages1 s2.0 S1044580316303412 MainShariful IslamNo ratings yet

- 4 Managing Sales ForceDocument72 pages4 Managing Sales Forcekishor khadkaNo ratings yet

- Bar Matter No. 1153Document1 pageBar Matter No. 1153Neldy VeeNo ratings yet

- Bentley Motors CompanyDocument18 pagesBentley Motors CompanyMiroq 254No ratings yet

- Social Media and ElectionsDocument89 pagesSocial Media and ElectionsShara LynNo ratings yet

- Culinarian CookwareDocument2 pagesCulinarian Cookwarespaw1108100% (1)

- Movipro Diagnóstico PPT Movipro-Sdc Diagnose Prozessdaten enDocument23 pagesMovipro Diagnóstico PPT Movipro-Sdc Diagnose Prozessdaten enAlfredo Jose Centeno CortesNo ratings yet

- Intellipaats Cloud and DevOps Architect Masters CourseDocument13 pagesIntellipaats Cloud and DevOps Architect Masters Coursek2shNo ratings yet

- Accounting For Labor Part 2Document11 pagesAccounting For Labor Part 2Ghillian Mae GuiangNo ratings yet

- Harman/Kardon AVR 254 Service Manual)Document189 pagesHarman/Kardon AVR 254 Service Manual)jrubins100% (1)

- Deep Vein ThrombosisDocument11 pagesDeep Vein ThrombosisTushar GhuleNo ratings yet

- Design and Simulation of Digital Phase Locked Loop Using MOSFET SPICE Models of 300nmDocument4 pagesDesign and Simulation of Digital Phase Locked Loop Using MOSFET SPICE Models of 300nmIJRT OnlineNo ratings yet

- A320 Generator Control SystemDocument5 pagesA320 Generator Control Systemdo hai tran leNo ratings yet

- Acceleration PrincipleDocument2 pagesAcceleration PrincipleRashidAliNo ratings yet

- Leadership and Governance Dalam SKNDocument13 pagesLeadership and Governance Dalam SKNWenna YolandaNo ratings yet

- Lesson 4: Qualitative Research in Different Areas of KnowledgeDocument9 pagesLesson 4: Qualitative Research in Different Areas of KnowledgeCarmela Del MarNo ratings yet

- Freeman V ReyesDocument7 pagesFreeman V ReyesEzekiel T. MostieroNo ratings yet

- Construction Planning 2019 MemoDocument6 pagesConstruction Planning 2019 MemoNtokozo JiyanaNo ratings yet

- Mock Test MSDocument4 pagesMock Test MSrita sehgalNo ratings yet

- Basic AccountingDocument25 pagesBasic AccountingMahmoodul Haque100% (3)

- EUROPART Inter Catalog MB Truck 2014 ENDocument400 pagesEUROPART Inter Catalog MB Truck 2014 ENBoumediene CHIKHAOUINo ratings yet

- Competency Based Training (CBT) Curriculum FrameworkDocument19 pagesCompetency Based Training (CBT) Curriculum FrameworkCuk Junkies100% (1)

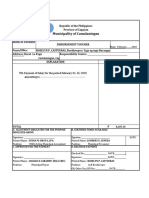

- Municipality of Camalaniugan: Amounting ToDocument3 pagesMunicipality of Camalaniugan: Amounting ToMelody Frac ZapateroNo ratings yet

- Steam BoilerDocument3 pagesSteam BoilerMohammad AzlanNo ratings yet

- Professional English II (Job Interview) 24032021Document8 pagesProfessional English II (Job Interview) 24032021Chaterine FebbyNo ratings yet