Professional Documents

Culture Documents

STOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster Pumps

STOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster Pumps

Uploaded by

AHMED AMIRACopyright:

Available Formats

You might also like

- Rancangan Pengajaran Tahunan MatematikDocument8 pagesRancangan Pengajaran Tahunan MatematikWendy Bahari100% (5)

- Part A - Hvac Technical Specifications 1. Hot Water GeneratorDocument25 pagesPart A - Hvac Technical Specifications 1. Hot Water GeneratorAnand_HvacNo ratings yet

- Master Deliverable Register: C Electrical C1Document2 pagesMaster Deliverable Register: C Electrical C1LaelaeNo ratings yet

- PVT Report - 140319 - Zone - 8 - May'17 Separator SampleDocument28 pagesPVT Report - 140319 - Zone - 8 - May'17 Separator SampleIBIKUNLENo ratings yet

- Assignment MechanicalDocument5 pagesAssignment MechanicalSoufiane RamdaniNo ratings yet

- Checklist Bypass Line SizingDocument5 pagesChecklist Bypass Line Sizingsrinivas_gowthamNo ratings yet

- SM CH PDFDocument18 pagesSM CH PDFHector NaranjoNo ratings yet

- Fire PumpDocument1 pageFire PumpPaijo TejoNo ratings yet

- Booster Pump SizingDocument1 pageBooster Pump SizingjibinNo ratings yet

- 2 - Table 2 - Discharge Units (DU)Document1 page2 - Table 2 - Discharge Units (DU)Afsal JhNo ratings yet

- TENDER NO: 22-054-730 Request For Quotation: of 25 REV: 0 DATE: MAY 05, 2021Document25 pagesTENDER NO: 22-054-730 Request For Quotation: of 25 REV: 0 DATE: MAY 05, 2021Anonymous bHh1L1No ratings yet

- Hydrant Stand Post (Double) : Technical Data SheetDocument2 pagesHydrant Stand Post (Double) : Technical Data SheetshabahatNo ratings yet

- Zone Wise Fire Water Demand CalculationDocument13 pagesZone Wise Fire Water Demand Calculationabdulkidwai2009No ratings yet

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Document1 pagePMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Aditya PranotoNo ratings yet

- 2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetDocument10 pages2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetSamuel JohnsonNo ratings yet

- Design PHEDocument110 pagesDesign PHEAbhik BhattacharjeeNo ratings yet

- Evaporation Pond - LockheedDocument3 pagesEvaporation Pond - LockheedWickyNo ratings yet

- WTP Schematic DiagramDocument3 pagesWTP Schematic DiagramRhys PalmaNo ratings yet

- DBR of Luminous HosurDocument81 pagesDBR of Luminous HosurrajaNo ratings yet

- Air BlowDocument2 pagesAir BlowHussein Adnan FneishNo ratings yet

- Pipenet Vision Training Manual Standard: Chapter 4 Page 1 of 36 REVISION 2.1, SEP 2010Document36 pagesPipenet Vision Training Manual Standard: Chapter 4 Page 1 of 36 REVISION 2.1, SEP 2010ToyinNo ratings yet

- 756 Stairwell Pressurisation CalculationDocument8 pages756 Stairwell Pressurisation CalculationSelva Kumar Selva KumarNo ratings yet

- Zone Mechanical PresentationDocument58 pagesZone Mechanical Presentationspymaster1027No ratings yet

- Design of Calculation For LUP-08-Portable Water LineDocument8 pagesDesign of Calculation For LUP-08-Portable Water LineBhavanishankar shettyNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- (Novin) Hydraulic Calculation in Piping Networks (2006)Document34 pages(Novin) Hydraulic Calculation in Piping Networks (2006)Yoko GoldingNo ratings yet

- Deriverable List Fire FightingDocument1 pageDeriverable List Fire FightingAbidin RahmanNo ratings yet

- Design of Plumbing System-LUP-08 & LUP-09Document12 pagesDesign of Plumbing System-LUP-08 & LUP-09projects sureshNo ratings yet

- Calc-Plum Fire IrtankDocument6 pagesCalc-Plum Fire IrtankAmro Metwally El HendawyNo ratings yet

- 182268644-CW-Pump-CalculationDocument18 pages182268644-CW-Pump-CalculationPinak ProjectsNo ratings yet

- Water Demand & Spray Nozzle Calculation For 100 KL Horizontal TankDocument2 pagesWater Demand & Spray Nozzle Calculation For 100 KL Horizontal Tankbecpavan100% (1)

- Ps 50 Bypass Calculations 13.3.17Document10 pagesPs 50 Bypass Calculations 13.3.17Deepak JoyNo ratings yet

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPNo ratings yet

- Hose Stream Demands Part-1 PDFDocument4 pagesHose Stream Demands Part-1 PDFHugo Mario Ariza PalacioNo ratings yet

- Static Pressure Calculation Sheet For Ducts & Fittings - ASHRAE MethodDocument1 pageStatic Pressure Calculation Sheet For Ducts & Fittings - ASHRAE Methodsumair uddinNo ratings yet

- Dd2 (Detailed) Station - The White Palace Chilled Water Systems Schematic (East)Document1 pageDd2 (Detailed) Station - The White Palace Chilled Water Systems Schematic (East)Muhammad IshtiaqueNo ratings yet

- 00 BLANK Pipe Size Calc Sheet HWS - CWSDocument9 pages00 BLANK Pipe Size Calc Sheet HWS - CWSharoub_nasNo ratings yet

- Pumps Final TeDocument48 pagesPumps Final Tegharsallah mounaNo ratings yet

- Zeus Acds Series BrochureDocument40 pagesZeus Acds Series BrochureAntonio Osante LeyvaNo ratings yet

- CIS7:2014Document66 pagesCIS7:2014Ken ChuahNo ratings yet

- Carbon FilterDocument12 pagesCarbon FilterCalin SeraphimNo ratings yet

- PROJECT QC PLAN - AGAN (Revision Submission As Per RCRC Comments)Document172 pagesPROJECT QC PLAN - AGAN (Revision Submission As Per RCRC Comments)mohamed balasmehNo ratings yet

- Fan Power Pressure Loss CalculationDocument3 pagesFan Power Pressure Loss Calculationmashkhal luqmanNo ratings yet

- Ipmg B SF DSH 1005 03Document5 pagesIpmg B SF DSH 1005 03sgh1355No ratings yet

- Sand Filter Design GuideDocument2 pagesSand Filter Design Guideoanzar100% (1)

- Sample DrawingDocument1 pageSample DrawingFahad NaveedNo ratings yet

- C110-M410.01 - Rev. C - System Design Calculation - Accommodation - 08052015Document2 pagesC110-M410.01 - Rev. C - System Design Calculation - Accommodation - 08052015kokocdfNo ratings yet

- Project Reference List - ReferenceDocument7 pagesProject Reference List - ReferenceGohdsNo ratings yet

- Heat Load Calculation For Pumping Station - 13Document6 pagesHeat Load Calculation For Pumping Station - 13Deepak JoyNo ratings yet

- DCP & Co2Document13 pagesDCP & Co2SushilNo ratings yet

- Wsfu Storey BuildingDocument2 pagesWsfu Storey BuildingfebousNo ratings yet

- Compressed Air CommentsDocument4 pagesCompressed Air CommentsEslam ElsayedNo ratings yet

- TR CapexDocument1 pageTR Capexrahul281081No ratings yet

- 25oct BRK Down - C-51 FinalDocument307 pages25oct BRK Down - C-51 FinalRaziKhanNo ratings yet

- RA-2 BILL ClubDocument15 pagesRA-2 BILL ClubSaurabh DwivediNo ratings yet

- Project Name: Standpipe & Hose System of Norban Comtex LTD Area Reference: Most UnfavourableDocument4 pagesProject Name: Standpipe & Hose System of Norban Comtex LTD Area Reference: Most UnfavourablerashalNo ratings yet

- Hydraulic Calculation of Sprinkler System (Rev.c)Document10 pagesHydraulic Calculation of Sprinkler System (Rev.c)Tuong Nguyen Duc MinhNo ratings yet

- Method Statement For Air Handling UnitDocument7 pagesMethod Statement For Air Handling UnitBinod DavisNo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0006 - Functional Specification For Anaguid Water Bath HeaterDocument15 pagesSTOD-GEN-AED-0000-ME-SPE-0006 - Functional Specification For Anaguid Water Bath HeaterAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionDocument20 pagesSTOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionAHMED AMIRANo ratings yet

- Crude Oil Stroage Tanks SpecsDocument48 pagesCrude Oil Stroage Tanks Specsmanish318No ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Slickline WBEAC October 5 2011Document10 pagesSlickline WBEAC October 5 2011AHMED AMIRANo ratings yet

- Level 1, POM - Slickline - Dec - 2011, FinalDocument55 pagesLevel 1, POM - Slickline - Dec - 2011, FinalAHMED AMIRANo ratings yet

- Riduzioni Concentriche Ed Eccentriche Cod. RFW402 RFW409: Concentric and Eccentric ReducersDocument4 pagesRiduzioni Concentriche Ed Eccentriche Cod. RFW402 RFW409: Concentric and Eccentric ReducersAHMED AMIRANo ratings yet

- Maamoura and Baraka Development ProjectDocument12 pagesMaamoura and Baraka Development ProjectAHMED AMIRANo ratings yet

- Well Integrity Training ModuleDocument51 pagesWell Integrity Training ModuleAHMED AMIRA100% (1)

- RFW395Document1 pageRFW395AHMED AMIRANo ratings yet

- WI Level One Test FlyerDocument1 pageWI Level One Test FlyerAHMED AMIRANo ratings yet

- Raccordi A "T" Saldati in Acciaio Inox Cod. RFW1620 A Norme Ansi B 31Document1 pageRaccordi A "T" Saldati in Acciaio Inox Cod. RFW1620 A Norme Ansi B 31AHMED AMIRANo ratings yet

- Summary Well Integrity Standard22 Level1 TrainingDocument1 pageSummary Well Integrity Standard22 Level1 TrainingAHMED AMIRANo ratings yet

- Feuilles de Donnees Transmetteur de NiveauDocument5 pagesFeuilles de Donnees Transmetteur de NiveauAHMED AMIRA100% (1)

- DP 04 TocDocument1 pageDP 04 TocAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-PR-DAT-0009 - Anaguid Inlet Separator Data SheetDocument6 pagesSTOD-GEN-AED-0000-PR-DAT-0009 - Anaguid Inlet Separator Data SheetAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0007 - Functional Specification For WAHA Slug CatcherDocument30 pagesSTOD-GEN-AED-0000-ME-SPE-0007 - Functional Specification For WAHA Slug CatcherAHMED AMIRANo ratings yet

- DP 05 TocDocument1 pageDP 05 TocAHMED AMIRANo ratings yet

- Restricted Access Notice: Due To Third Party Proprietary InformationDocument38 pagesRestricted Access Notice: Due To Third Party Proprietary InformationAHMED AMIRANo ratings yet

- R1111-DSH-PL-00-006-DATA SHEET FOR INDUCTION BENDS - Rev 0ADocument3 pagesR1111-DSH-PL-00-006-DATA SHEET FOR INDUCTION BENDS - Rev 0AAHMED AMIRANo ratings yet

- Selection of Fired Process HeatersDocument24 pagesSelection of Fired Process HeatersAHMED AMIRANo ratings yet

- Community Investment: OMV-EP GuidelineDocument11 pagesCommunity Investment: OMV-EP GuidelineAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-PR-DAT-0008 - Anaguid Test Separator Data SheetDocument6 pagesSTOD-GEN-AED-0000-PR-DAT-0008 - Anaguid Test Separator Data SheetAHMED AMIRANo ratings yet

- R1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0ADocument4 pagesR1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0AAHMED AMIRANo ratings yet

- 4 Pressure Buildup and Falloff Tests: 4.1 BackgroundDocument38 pages4 Pressure Buildup and Falloff Tests: 4.1 BackgroundAHMED AMIRANo ratings yet

- HSEQ-HQ-11-03-00 HSE CommitteesDocument6 pagesHSEQ-HQ-11-03-00 HSE CommitteesAHMED AMIRANo ratings yet

- R1111-DSH-PP-00-001-INSPECTION DATA SHEET FOR MANUAL VALVES-rev 0ADocument4 pagesR1111-DSH-PP-00-001-INSPECTION DATA SHEET FOR MANUAL VALVES-rev 0AAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-PR-DAT-0011 - Chemical Injection Packages Data SheetDocument13 pagesSTOD-GEN-AED-0000-PR-DAT-0011 - Chemical Injection Packages Data SheetAHMED AMIRANo ratings yet

- Saipem - Serept - Piping ClassDocument67 pagesSaipem - Serept - Piping ClassAHMED AMIRANo ratings yet

- Effect of Chosen Producing Time On Buildup Analyses On Buildup AnalysesDocument16 pagesEffect of Chosen Producing Time On Buildup Analyses On Buildup AnalysesAHMED AMIRANo ratings yet

- WTC TransparenciesDocument105 pagesWTC TransparenciesAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionDocument20 pagesSTOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionAHMED AMIRANo ratings yet

- 5 Testing of Gas Wells: 5.1 Non-Darcy Flow EffectsDocument22 pages5 Testing of Gas Wells: 5.1 Non-Darcy Flow EffectsAHMED AMIRANo ratings yet

- R1111-SPC-PL-00-001 Line Pipe General Specification Rev 0Document34 pagesR1111-SPC-PL-00-001 Line Pipe General Specification Rev 0AHMED AMIRA100% (1)

- Three-Phase Induction MotorsDocument36 pagesThree-Phase Induction MotorsCARMEN DIMITRIUNo ratings yet

- Fluid and ElectrolytesDocument23 pagesFluid and ElectrolytesNanaNo ratings yet

- Chapter 7 - Cognitive DevelopmentDocument3 pagesChapter 7 - Cognitive DevelopmentmizbigspendaNo ratings yet

- Course Curriculum of PGP Renewable EnergyDocument6 pagesCourse Curriculum of PGP Renewable EnergyRonanki RaviNo ratings yet

- Juvenile Nasopharyngeal AngiofibromaDocument28 pagesJuvenile Nasopharyngeal AngiofibromamaNo ratings yet

- Teks Story TellingDocument2 pagesTeks Story TellingAve FauzisarNo ratings yet

- Quality Assurance of Developed Materials: Heidee F. Ferrer EddDocument60 pagesQuality Assurance of Developed Materials: Heidee F. Ferrer EddHeart SophieNo ratings yet

- DSM Mixing Tower SkyCiv ReportDocument484 pagesDSM Mixing Tower SkyCiv Reportmincho4104No ratings yet

- There's No Pill For This - IntroductionDocument4 pagesThere's No Pill For This - IntroductionChelsea Green PublishingNo ratings yet

- 1.2c atDocument3 pages1.2c atenyw160309No ratings yet

- Safety Instrumented Systems: GlobalDocument410 pagesSafety Instrumented Systems: Globalmohammed el erianNo ratings yet

- Macroeconomics Principles Applications and Tools 8th Edition Osullivan Solutions ManualDocument26 pagesMacroeconomics Principles Applications and Tools 8th Edition Osullivan Solutions ManualMrJosephCruzMDfojy100% (63)

- Final PPT Siemens & NAFTADocument23 pagesFinal PPT Siemens & NAFTAJohnnybravouNo ratings yet

- How To Give Feedback To Students The Advanced Guide Final1Document25 pagesHow To Give Feedback To Students The Advanced Guide Final1api-313584726No ratings yet

- How Deep Is Your LoveDocument1 pageHow Deep Is Your LoveJanina JaworskiNo ratings yet

- Memory Addressing and Instruction FormatsDocument9 pagesMemory Addressing and Instruction Formatsrobern ndoloNo ratings yet

- Total Marks: 25 Duration: One Hour: Xii-Msths Case Study Questions - Test Term-IDocument8 pagesTotal Marks: 25 Duration: One Hour: Xii-Msths Case Study Questions - Test Term-ISABARI SRINIVAS ANo ratings yet

- M. Wolves 11Document7 pagesM. Wolves 11rakiny05No ratings yet

- SerologyDocument3 pagesSerologyنوف الحربي.No ratings yet

- Ceramics II Project Ideas Spring 2019Document2 pagesCeramics II Project Ideas Spring 2019api-170572422No ratings yet

- Uv-Visibles Electronic TransitionDocument25 pagesUv-Visibles Electronic TransitionZareen Rashid Choudhury100% (1)

- Dressmaking 9 - Q2 - Module-2Document21 pagesDressmaking 9 - Q2 - Module-2Judith Bernadez-EspenidoNo ratings yet

- Oil Pressure Transmission PT2509Document3 pagesOil Pressure Transmission PT2509Trisna TeaNo ratings yet

- Coatings Knowledge, Basic Paint Technology - HMG Paints LimitedDocument3 pagesCoatings Knowledge, Basic Paint Technology - HMG Paints LimitedShyam Yadav0% (1)

- Essential Orthopaedics 2Nd Edition Mark D Miller Full ChapterDocument67 pagesEssential Orthopaedics 2Nd Edition Mark D Miller Full Chaptermargaret.jones429100% (8)

- Powerful Words To Use in PresentationsDocument9 pagesPowerful Words To Use in PresentationsGlobal CommNo ratings yet

- PHD Syllabus AMUDocument2 pagesPHD Syllabus AMUMohd ShahidNo ratings yet

- 5th-Sunday-of-Lent (2) .2Document1 page5th-Sunday-of-Lent (2) .2Emmanuel ToretaNo ratings yet

STOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster Pumps

STOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster Pumps

Uploaded by

AHMED AMIRAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster Pumps

STOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster Pumps

Uploaded by

AHMED AMIRACopyright:

Available Formats

Contents

ABBREVIATIONS ...................................................................................................... 3

TABLE OF HOLDS..................................................................................................... 5

1.0 INTRODUCTION................................................................................................ 6

2.0 SCOPE............................................................................................................... 7

2.1 Supply Description ..................................................................................... 7

3.0 APPLICABLE DOCUMENTS ............................................................................. 8

4.0 TECHNICAL REQUIREMENTS ......................................................................... 9

4.1 General Requirements ............................................................................... 9

4.2 Extent of Supply ......................................................................................... 9

4.3 Battery Limits ........................................................................................... 10

4.4 Design Requirements............................................................................... 10

5.0 TESTING.......................................................................................................... 12

5.1 Visual and dimensional check .................................................................. 12

5.2 Accessibility check ................................................................................... 12

5.3 Painting check.......................................................................................... 12

5.4 Performance Test..................................................................................... 12

5.5 Noise level measurement......................................................................... 13

6.0 GUARANTEES ................................................................................................ 14

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 2 of 14

ABBREVIATIONS

AED Anaguid East Development

AGP Anaguid Gathering Point

ASME American Society of Mechanical Engineers

API American Petroleum Institute

BEP Best Efficiency Point

CPF Central Processing Facility

CPU Central Processing Unit

EPC Engineering Procurement Construction

FEED Front End Engineering Design

I&TP Inspection and Test Plan

LV Low Voltage

NPSH Net Positive Suction Head

Nss Suction Specific Speed

P&ID Piping and Instrumentation Diagram

PLC Programmable Logic Controller

PSV Pressure Safety Valve

SI Système International D'unités

SPS Surface Pump system

USC United States Customary Units

TEFC Totally Enclosed, Fan Cooled

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 3 of 14

DEFINITIONS

COMPANY: OMV (Tunisien) Production GmbH

PROJECT: Anaguid East Development Project

CONTRACTOR: EPC Contractor or the Contractor(s) appointed by COMPANY for

the supply of equipment. Requirements of this specification shall be

enforced at all levels of the CONTRACTORs procurement process.

COMPANY shall have access to all CONTRACTORs SUPPLIERs

to the same extent as required of CONTRACTOR.

SUPPLIER/VENDOR: The party(s) which manufactures and/or supplies materials,

equipment, technical documents/drawings and services to perform

the duties specified by COMPANY.

Shall Is to be understood mandatory

Should Is to be understood as strongly recommended

May Is to be understood as an action to be undertaken at the

CONTRACTOR’s discretion.

The work All activities for the construction of the defined elements as detailed

in the scope of work.

Approved Agreed and approved by COMPANY in writing

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 4 of 14

TABLE OF HOLDS

Hold Section Comment

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 5 of 14

1.0 INTRODUCTION

OMV is undertaking the Anaguid East Development (AED) Project which comprises

of exploration and subsequent development of multiple hydrocarbon structures in the

South of Tunisia.

The hydrocarbon structures are located within the production concessions of

Cherouq and Dorra where OMV is currently the operator in addition to the

exploration permits of Anaguid (Anaguid East area) and Jenein Nord B & C. The

concessions are located relatively close to the existing Waha Central Processing

Facility (CPF) in the Cherouq concession some 750 km south of the capital city,

Tunis.

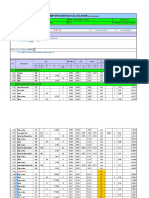

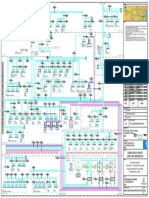

The general configuration of the AED Project is shown below:

The AED project surface facilities are the following:

• Initially 7 wellsites

• A gathering system (individual flow lines)

• Anaguid Gathering Point (AGP) facilities

• A multiphase trunk line from AGP to Waha CPF

• A receiving facility at Waha CPF

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 6 of 14

2.0 SCOPE

The scope of this specification is to define the general requirements for the design,

materials, fabrication, inspection, non-destructive examination, testing, preparation

for shipment and technical documentation for the supply of booster pump packages

to be installed at AGP.

2.1 Supply Description

Each package shall be supplied complete and furnished with all associated

auxiliaries as defined in the purchase order documentation and associated

specifications.

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 7 of 14

3.0 APPLICABLE DOCUMENTS

This specification shall be read in conjunction with the Anaguid Booster Pumps Data

Sheet STOD-GEN-AED-0000-PR-DAT-0005 and with the General Mechanical

Package Specification STOD-GEN-AED-0000-ME-SPE-0003.

As a minimum, the equipment shall comply with the requirements specified in the

General Mechanical Package Specification and applicable documents, Codes and

Standards referenced therein.

Any deviations or exceptions to the applicable documents, Codes and Standards

shall be explicitly highlighted by the SUPPLIER in their bid.

The General Mechanical Package Specification includes information on the

following:

• Order of precedence

• General design data

• Overall SUPPLIER responsibilities

• Overall design objectives

• Piping requirements for packaged mechanical equipment

• Structural requirements for packaged mechanical equipment

• Material requirements

• Detailed equipment nozzle loads

• Welding and non-destructive examination

• General health, safety and environmental requirements

• Quality assurance and quality control

• Inspection and certification

• General testing requirements

• Shipping, storage and preservation

• General requirements for SUPPLIER data

• Special tools and spare parts

• General requirements for SUPPLIER guarantees

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 8 of 14

4.0 TECHNICAL REQUIREMENTS

4.1 General Requirements

Booster pumps are required at AGP to increase the liquid pressure coming from the

wellsites and send the pumped liquid to the multiphase trunkline.

Centrifugal pumps or twin screw pumps driven by fixed speed electric motor are

recommended for the booster service.

4.2 Extent of Supply

Liquid booster pump packages shall be supplied as a completely assembled skid

mounted package in accordance with the Anaguid Booster Pumps Data Sheet and

the General Mechanical Package Specification and all the Specifications, Codes and

Standards referenced therein.

The scope of supply shall include but not be limited to the following components:

• Multistage centrifugal pump compliant with API 610 (latest edition) or twin

screw pumps compliant with API 676 (latest edition).

• LV electric motor driver.

• Coupling and non-sparking coupling guard.

• Mechanical seals and sealing system, as required.

• The equipment package shall be operationally complete and fit for purpose in

accordance with the data sheet.

• Structural steel skid complete with drip pan and flanged drain connection. A

shelter may be added to the skid-mounted package upon COMPANY

approval.

• All necessary instruments and electrical equipment.

• Local start/stop plus emergency stop pushbuttons (adjacent to each

package).

• On skid interconnecting piping, pipe supports, filters, valves and fittings for

utilities, drains, vents and relief systems terminating at skid edge with flanged

connections.

• On skid interconnecting instrument and electrical cabling, cable trays and

supports within the skid limits terminating at skid edge mounted junction

boxes.

• All necessary earthing and bonding.

• Single point lifting of the fully assembled skid.

• All necessary (certified) equipment/devices to lift the package and equipment

• Insulation and trace heating, where required.

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 9 of 14

• Spare parts for commissioning and start-up and two years operating.

• Special tools.

4.3 Battery Limits

The battery limits shall be considered to be at the booster pump package baseplate

edge and as further defined below.

• Liquid inlet and outlet connections at skid edge

• Outlet of drain connection(s) from skid baseplate

• Electric motor(s) terminal box(es)

• Instrumentation junction box(es) at skid edge.

4.4 Design Requirements

• Packages shall be designed in accordance with the General Mechanical

Package Specification and all the Specifications, Codes and Standards

referenced therein

• Packages shall be suitable for unprotected outdoor operation in a harsh

desert environment.

• Unless otherwise specified, package shall be installed in hazardous area. All

electrical and electronics equipment shall be ATEX certified and cables shall

be flame retardant.

• Packages shall be designed and constructed for continuous operation and

sized in accordance with the data sheet.

• Each pump shall be supplied complete with baseplate common to pump and

motor. Baseplate shall be of sufficient rigidity and stiffness so as to ensure the

alignment of the pump-motor against mechanical stresses transmitted by the

pipes. Thermal or hydraulic origin stresses due to transport and lifting

operation should be considered.

• The pump NPSH margin (NPSHa – NPSHr) shall be at least 1.0 m at all flows

in the allowable operating region of the pump.

• Centrifugal Pumps shall be designed to allow installation of upgraded impeller

bundle to increase head by at least 5%. Motor shall be sized for this whilst still

complying with API 610 power margin.

• The centrifugal pumps suction specific speed (Nss) at the best efficiency point

(BEP), with maximum diameter impeller shall be lower than 200, using SI unit

(11,000, using USC units). The Nss shall be calculated according to the

formula stated in API 610 (latest edition), annex A.

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 10 of 14

• Where the design criteria lead to an unjustified oversized motor, Supplier shall

quote as option a motor with lower power.

• The pump shall have flanged suction and discharge nozzles of equal ASME

pressure/temperature ratings.

• If required, SUPPLIER shall provide the suction and/or discharge expansion

joint(s).

• Valves shall not be welded to the pump.

• One casing accelerometer cabled to junction box shall be included in the

SUPPLIER scope of supply.

• Pumps shaft seals shall be mechanical type. Other type of seals shall be used

only if required on the data sheet. Type of seal, materials and relevant

auxiliary equipment of the mechanical seals shall be identified as per API

code and plan.

• Unless otherwise specified, the coupling shall be flexible type. The guards

shall be anti-spark material.

• Booster pumps shall be driven by fixed speed LV electric motor, squirrel cage

and induction type designed in accordance with IEC standards and with

enclosure IP55 (as minimum).

• Electric motor shall be Ex-d or Ex-N(A) type, TEFC and suitable for the

classified hazardous area.

• Electric motor shall be supplied with anti-condensing heater.

• All package’s components shall fall within the maximum perimeter of the skid.

• SUPPLIER shall indicate in the offer any start-up, shutdown or operating

restrictions required in order to protect the integrity of the equipment.

• Painting shall be in accordance with STOD-GEN-AED-0000-YL-SPE-0012

Coating and Painting Specification.

Sufficient paint shall be furnished for touch-up at site after installation.

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 11 of 14

5.0 TESTING

All equipment, piping, valves and components of the package shall be tested

according to I&TP approved by CONTRACTOR/COMPANY.

The fully assembled package shall be tested and inspected before delivery. This

shall include at least:

• Visual and dimensional check

• Accessibility check

• Painting check

• Performance Test

• Noise level measurement

• Check of electrical wiring and insulation (junction boxes, instruments) and

earth continuity.

5.1 Visual and dimensional check

The dimensional inspection shall be carried out to check if actual dimensions of the

package and the terminal points comply with approved drawings.

All actual dimensions within the allowable tolerances shall be recorded on a

dimensional test report.

5.2 Accessibility check

This test shall be carried out to verify the accessibility of all equipment for operating

and maintenance.

5.3 Painting check

The coating must be free of visual defects and the dry film thickness shall be spot

checked using an appropriate device (such as: magnetic gauge, ultrasonic gauge,

etc.).

5.4 Performance Test

Unless otherwise specified, the pumps will be run on water to verify the guarantee

figures, such as: capacity, efficiency, NPSH3 (for centrifugal pumps), power

consumption, and vibration levels.

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 12 of 14

5.6 Noise level measurement

During the package performance test, noise measurements shall be performed at

strategic locations (typically 1.0 m from the equipment) around the package at 100%

load.

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 13 of 14

6.0 GUARANTEES

Unless otherwise specified, the following parameters shall be guaranteed by the

SUPPLIER:

• Operating point(s) - the required duty and performance tolerances as

specified within the data sheet.

• NPSH3 (for centrifugal pumps)

• Power consumption.

• Vibration levels.

• Noise.

Client Name – OMV (Tunesien) Production GmbH

File name: STOD-GEN-AED-0000-ME-SPE-0012 Rev 000 Functional Specification for AGP Booster

Pumps

Genesis Date: November 2013

Page 14 of 14

You might also like

- Rancangan Pengajaran Tahunan MatematikDocument8 pagesRancangan Pengajaran Tahunan MatematikWendy Bahari100% (5)

- Part A - Hvac Technical Specifications 1. Hot Water GeneratorDocument25 pagesPart A - Hvac Technical Specifications 1. Hot Water GeneratorAnand_HvacNo ratings yet

- Master Deliverable Register: C Electrical C1Document2 pagesMaster Deliverable Register: C Electrical C1LaelaeNo ratings yet

- PVT Report - 140319 - Zone - 8 - May'17 Separator SampleDocument28 pagesPVT Report - 140319 - Zone - 8 - May'17 Separator SampleIBIKUNLENo ratings yet

- Assignment MechanicalDocument5 pagesAssignment MechanicalSoufiane RamdaniNo ratings yet

- Checklist Bypass Line SizingDocument5 pagesChecklist Bypass Line Sizingsrinivas_gowthamNo ratings yet

- SM CH PDFDocument18 pagesSM CH PDFHector NaranjoNo ratings yet

- Fire PumpDocument1 pageFire PumpPaijo TejoNo ratings yet

- Booster Pump SizingDocument1 pageBooster Pump SizingjibinNo ratings yet

- 2 - Table 2 - Discharge Units (DU)Document1 page2 - Table 2 - Discharge Units (DU)Afsal JhNo ratings yet

- TENDER NO: 22-054-730 Request For Quotation: of 25 REV: 0 DATE: MAY 05, 2021Document25 pagesTENDER NO: 22-054-730 Request For Quotation: of 25 REV: 0 DATE: MAY 05, 2021Anonymous bHh1L1No ratings yet

- Hydrant Stand Post (Double) : Technical Data SheetDocument2 pagesHydrant Stand Post (Double) : Technical Data SheetshabahatNo ratings yet

- Zone Wise Fire Water Demand CalculationDocument13 pagesZone Wise Fire Water Demand Calculationabdulkidwai2009No ratings yet

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Document1 pagePMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Aditya PranotoNo ratings yet

- 2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetDocument10 pages2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetSamuel JohnsonNo ratings yet

- Design PHEDocument110 pagesDesign PHEAbhik BhattacharjeeNo ratings yet

- Evaporation Pond - LockheedDocument3 pagesEvaporation Pond - LockheedWickyNo ratings yet

- WTP Schematic DiagramDocument3 pagesWTP Schematic DiagramRhys PalmaNo ratings yet

- DBR of Luminous HosurDocument81 pagesDBR of Luminous HosurrajaNo ratings yet

- Air BlowDocument2 pagesAir BlowHussein Adnan FneishNo ratings yet

- Pipenet Vision Training Manual Standard: Chapter 4 Page 1 of 36 REVISION 2.1, SEP 2010Document36 pagesPipenet Vision Training Manual Standard: Chapter 4 Page 1 of 36 REVISION 2.1, SEP 2010ToyinNo ratings yet

- 756 Stairwell Pressurisation CalculationDocument8 pages756 Stairwell Pressurisation CalculationSelva Kumar Selva KumarNo ratings yet

- Zone Mechanical PresentationDocument58 pagesZone Mechanical Presentationspymaster1027No ratings yet

- Design of Calculation For LUP-08-Portable Water LineDocument8 pagesDesign of Calculation For LUP-08-Portable Water LineBhavanishankar shettyNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- (Novin) Hydraulic Calculation in Piping Networks (2006)Document34 pages(Novin) Hydraulic Calculation in Piping Networks (2006)Yoko GoldingNo ratings yet

- Deriverable List Fire FightingDocument1 pageDeriverable List Fire FightingAbidin RahmanNo ratings yet

- Design of Plumbing System-LUP-08 & LUP-09Document12 pagesDesign of Plumbing System-LUP-08 & LUP-09projects sureshNo ratings yet

- Calc-Plum Fire IrtankDocument6 pagesCalc-Plum Fire IrtankAmro Metwally El HendawyNo ratings yet

- 182268644-CW-Pump-CalculationDocument18 pages182268644-CW-Pump-CalculationPinak ProjectsNo ratings yet

- Water Demand & Spray Nozzle Calculation For 100 KL Horizontal TankDocument2 pagesWater Demand & Spray Nozzle Calculation For 100 KL Horizontal Tankbecpavan100% (1)

- Ps 50 Bypass Calculations 13.3.17Document10 pagesPs 50 Bypass Calculations 13.3.17Deepak JoyNo ratings yet

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPNo ratings yet

- Hose Stream Demands Part-1 PDFDocument4 pagesHose Stream Demands Part-1 PDFHugo Mario Ariza PalacioNo ratings yet

- Static Pressure Calculation Sheet For Ducts & Fittings - ASHRAE MethodDocument1 pageStatic Pressure Calculation Sheet For Ducts & Fittings - ASHRAE Methodsumair uddinNo ratings yet

- Dd2 (Detailed) Station - The White Palace Chilled Water Systems Schematic (East)Document1 pageDd2 (Detailed) Station - The White Palace Chilled Water Systems Schematic (East)Muhammad IshtiaqueNo ratings yet

- 00 BLANK Pipe Size Calc Sheet HWS - CWSDocument9 pages00 BLANK Pipe Size Calc Sheet HWS - CWSharoub_nasNo ratings yet

- Pumps Final TeDocument48 pagesPumps Final Tegharsallah mounaNo ratings yet

- Zeus Acds Series BrochureDocument40 pagesZeus Acds Series BrochureAntonio Osante LeyvaNo ratings yet

- CIS7:2014Document66 pagesCIS7:2014Ken ChuahNo ratings yet

- Carbon FilterDocument12 pagesCarbon FilterCalin SeraphimNo ratings yet

- PROJECT QC PLAN - AGAN (Revision Submission As Per RCRC Comments)Document172 pagesPROJECT QC PLAN - AGAN (Revision Submission As Per RCRC Comments)mohamed balasmehNo ratings yet

- Fan Power Pressure Loss CalculationDocument3 pagesFan Power Pressure Loss Calculationmashkhal luqmanNo ratings yet

- Ipmg B SF DSH 1005 03Document5 pagesIpmg B SF DSH 1005 03sgh1355No ratings yet

- Sand Filter Design GuideDocument2 pagesSand Filter Design Guideoanzar100% (1)

- Sample DrawingDocument1 pageSample DrawingFahad NaveedNo ratings yet

- C110-M410.01 - Rev. C - System Design Calculation - Accommodation - 08052015Document2 pagesC110-M410.01 - Rev. C - System Design Calculation - Accommodation - 08052015kokocdfNo ratings yet

- Project Reference List - ReferenceDocument7 pagesProject Reference List - ReferenceGohdsNo ratings yet

- Heat Load Calculation For Pumping Station - 13Document6 pagesHeat Load Calculation For Pumping Station - 13Deepak JoyNo ratings yet

- DCP & Co2Document13 pagesDCP & Co2SushilNo ratings yet

- Wsfu Storey BuildingDocument2 pagesWsfu Storey BuildingfebousNo ratings yet

- Compressed Air CommentsDocument4 pagesCompressed Air CommentsEslam ElsayedNo ratings yet

- TR CapexDocument1 pageTR Capexrahul281081No ratings yet

- 25oct BRK Down - C-51 FinalDocument307 pages25oct BRK Down - C-51 FinalRaziKhanNo ratings yet

- RA-2 BILL ClubDocument15 pagesRA-2 BILL ClubSaurabh DwivediNo ratings yet

- Project Name: Standpipe & Hose System of Norban Comtex LTD Area Reference: Most UnfavourableDocument4 pagesProject Name: Standpipe & Hose System of Norban Comtex LTD Area Reference: Most UnfavourablerashalNo ratings yet

- Hydraulic Calculation of Sprinkler System (Rev.c)Document10 pagesHydraulic Calculation of Sprinkler System (Rev.c)Tuong Nguyen Duc MinhNo ratings yet

- Method Statement For Air Handling UnitDocument7 pagesMethod Statement For Air Handling UnitBinod DavisNo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0006 - Functional Specification For Anaguid Water Bath HeaterDocument15 pagesSTOD-GEN-AED-0000-ME-SPE-0006 - Functional Specification For Anaguid Water Bath HeaterAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionDocument20 pagesSTOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionAHMED AMIRANo ratings yet

- Crude Oil Stroage Tanks SpecsDocument48 pagesCrude Oil Stroage Tanks Specsmanish318No ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Slickline WBEAC October 5 2011Document10 pagesSlickline WBEAC October 5 2011AHMED AMIRANo ratings yet

- Level 1, POM - Slickline - Dec - 2011, FinalDocument55 pagesLevel 1, POM - Slickline - Dec - 2011, FinalAHMED AMIRANo ratings yet

- Riduzioni Concentriche Ed Eccentriche Cod. RFW402 RFW409: Concentric and Eccentric ReducersDocument4 pagesRiduzioni Concentriche Ed Eccentriche Cod. RFW402 RFW409: Concentric and Eccentric ReducersAHMED AMIRANo ratings yet

- Maamoura and Baraka Development ProjectDocument12 pagesMaamoura and Baraka Development ProjectAHMED AMIRANo ratings yet

- Well Integrity Training ModuleDocument51 pagesWell Integrity Training ModuleAHMED AMIRA100% (1)

- RFW395Document1 pageRFW395AHMED AMIRANo ratings yet

- WI Level One Test FlyerDocument1 pageWI Level One Test FlyerAHMED AMIRANo ratings yet

- Raccordi A "T" Saldati in Acciaio Inox Cod. RFW1620 A Norme Ansi B 31Document1 pageRaccordi A "T" Saldati in Acciaio Inox Cod. RFW1620 A Norme Ansi B 31AHMED AMIRANo ratings yet

- Summary Well Integrity Standard22 Level1 TrainingDocument1 pageSummary Well Integrity Standard22 Level1 TrainingAHMED AMIRANo ratings yet

- Feuilles de Donnees Transmetteur de NiveauDocument5 pagesFeuilles de Donnees Transmetteur de NiveauAHMED AMIRA100% (1)

- DP 04 TocDocument1 pageDP 04 TocAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-PR-DAT-0009 - Anaguid Inlet Separator Data SheetDocument6 pagesSTOD-GEN-AED-0000-PR-DAT-0009 - Anaguid Inlet Separator Data SheetAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0007 - Functional Specification For WAHA Slug CatcherDocument30 pagesSTOD-GEN-AED-0000-ME-SPE-0007 - Functional Specification For WAHA Slug CatcherAHMED AMIRANo ratings yet

- DP 05 TocDocument1 pageDP 05 TocAHMED AMIRANo ratings yet

- Restricted Access Notice: Due To Third Party Proprietary InformationDocument38 pagesRestricted Access Notice: Due To Third Party Proprietary InformationAHMED AMIRANo ratings yet

- R1111-DSH-PL-00-006-DATA SHEET FOR INDUCTION BENDS - Rev 0ADocument3 pagesR1111-DSH-PL-00-006-DATA SHEET FOR INDUCTION BENDS - Rev 0AAHMED AMIRANo ratings yet

- Selection of Fired Process HeatersDocument24 pagesSelection of Fired Process HeatersAHMED AMIRANo ratings yet

- Community Investment: OMV-EP GuidelineDocument11 pagesCommunity Investment: OMV-EP GuidelineAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-PR-DAT-0008 - Anaguid Test Separator Data SheetDocument6 pagesSTOD-GEN-AED-0000-PR-DAT-0008 - Anaguid Test Separator Data SheetAHMED AMIRANo ratings yet

- R1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0ADocument4 pagesR1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0AAHMED AMIRANo ratings yet

- 4 Pressure Buildup and Falloff Tests: 4.1 BackgroundDocument38 pages4 Pressure Buildup and Falloff Tests: 4.1 BackgroundAHMED AMIRANo ratings yet

- HSEQ-HQ-11-03-00 HSE CommitteesDocument6 pagesHSEQ-HQ-11-03-00 HSE CommitteesAHMED AMIRANo ratings yet

- R1111-DSH-PP-00-001-INSPECTION DATA SHEET FOR MANUAL VALVES-rev 0ADocument4 pagesR1111-DSH-PP-00-001-INSPECTION DATA SHEET FOR MANUAL VALVES-rev 0AAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-PR-DAT-0011 - Chemical Injection Packages Data SheetDocument13 pagesSTOD-GEN-AED-0000-PR-DAT-0011 - Chemical Injection Packages Data SheetAHMED AMIRANo ratings yet

- Saipem - Serept - Piping ClassDocument67 pagesSaipem - Serept - Piping ClassAHMED AMIRANo ratings yet

- Effect of Chosen Producing Time On Buildup Analyses On Buildup AnalysesDocument16 pagesEffect of Chosen Producing Time On Buildup Analyses On Buildup AnalysesAHMED AMIRANo ratings yet

- WTC TransparenciesDocument105 pagesWTC TransparenciesAHMED AMIRANo ratings yet

- STOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionDocument20 pagesSTOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionAHMED AMIRANo ratings yet

- 5 Testing of Gas Wells: 5.1 Non-Darcy Flow EffectsDocument22 pages5 Testing of Gas Wells: 5.1 Non-Darcy Flow EffectsAHMED AMIRANo ratings yet

- R1111-SPC-PL-00-001 Line Pipe General Specification Rev 0Document34 pagesR1111-SPC-PL-00-001 Line Pipe General Specification Rev 0AHMED AMIRA100% (1)

- Three-Phase Induction MotorsDocument36 pagesThree-Phase Induction MotorsCARMEN DIMITRIUNo ratings yet

- Fluid and ElectrolytesDocument23 pagesFluid and ElectrolytesNanaNo ratings yet

- Chapter 7 - Cognitive DevelopmentDocument3 pagesChapter 7 - Cognitive DevelopmentmizbigspendaNo ratings yet

- Course Curriculum of PGP Renewable EnergyDocument6 pagesCourse Curriculum of PGP Renewable EnergyRonanki RaviNo ratings yet

- Juvenile Nasopharyngeal AngiofibromaDocument28 pagesJuvenile Nasopharyngeal AngiofibromamaNo ratings yet

- Teks Story TellingDocument2 pagesTeks Story TellingAve FauzisarNo ratings yet

- Quality Assurance of Developed Materials: Heidee F. Ferrer EddDocument60 pagesQuality Assurance of Developed Materials: Heidee F. Ferrer EddHeart SophieNo ratings yet

- DSM Mixing Tower SkyCiv ReportDocument484 pagesDSM Mixing Tower SkyCiv Reportmincho4104No ratings yet

- There's No Pill For This - IntroductionDocument4 pagesThere's No Pill For This - IntroductionChelsea Green PublishingNo ratings yet

- 1.2c atDocument3 pages1.2c atenyw160309No ratings yet

- Safety Instrumented Systems: GlobalDocument410 pagesSafety Instrumented Systems: Globalmohammed el erianNo ratings yet

- Macroeconomics Principles Applications and Tools 8th Edition Osullivan Solutions ManualDocument26 pagesMacroeconomics Principles Applications and Tools 8th Edition Osullivan Solutions ManualMrJosephCruzMDfojy100% (63)

- Final PPT Siemens & NAFTADocument23 pagesFinal PPT Siemens & NAFTAJohnnybravouNo ratings yet

- How To Give Feedback To Students The Advanced Guide Final1Document25 pagesHow To Give Feedback To Students The Advanced Guide Final1api-313584726No ratings yet

- How Deep Is Your LoveDocument1 pageHow Deep Is Your LoveJanina JaworskiNo ratings yet

- Memory Addressing and Instruction FormatsDocument9 pagesMemory Addressing and Instruction Formatsrobern ndoloNo ratings yet

- Total Marks: 25 Duration: One Hour: Xii-Msths Case Study Questions - Test Term-IDocument8 pagesTotal Marks: 25 Duration: One Hour: Xii-Msths Case Study Questions - Test Term-ISABARI SRINIVAS ANo ratings yet

- M. Wolves 11Document7 pagesM. Wolves 11rakiny05No ratings yet

- SerologyDocument3 pagesSerologyنوف الحربي.No ratings yet

- Ceramics II Project Ideas Spring 2019Document2 pagesCeramics II Project Ideas Spring 2019api-170572422No ratings yet

- Uv-Visibles Electronic TransitionDocument25 pagesUv-Visibles Electronic TransitionZareen Rashid Choudhury100% (1)

- Dressmaking 9 - Q2 - Module-2Document21 pagesDressmaking 9 - Q2 - Module-2Judith Bernadez-EspenidoNo ratings yet

- Oil Pressure Transmission PT2509Document3 pagesOil Pressure Transmission PT2509Trisna TeaNo ratings yet

- Coatings Knowledge, Basic Paint Technology - HMG Paints LimitedDocument3 pagesCoatings Knowledge, Basic Paint Technology - HMG Paints LimitedShyam Yadav0% (1)

- Essential Orthopaedics 2Nd Edition Mark D Miller Full ChapterDocument67 pagesEssential Orthopaedics 2Nd Edition Mark D Miller Full Chaptermargaret.jones429100% (8)

- Powerful Words To Use in PresentationsDocument9 pagesPowerful Words To Use in PresentationsGlobal CommNo ratings yet

- PHD Syllabus AMUDocument2 pagesPHD Syllabus AMUMohd ShahidNo ratings yet

- 5th-Sunday-of-Lent (2) .2Document1 page5th-Sunday-of-Lent (2) .2Emmanuel ToretaNo ratings yet