Professional Documents

Culture Documents

Easa Ad 2011-0236 1

Easa Ad 2011-0236 1

Uploaded by

Yuri SilvaCopyright:

Available Formats

You might also like

- Flight Manual CDL A319 132Document714 pagesFlight Manual CDL A319 132DithelNo ratings yet

- Unit 4 Test - Inside OutDocument5 pagesUnit 4 Test - Inside OutJesus VillanuevaNo ratings yet

- Angela Davis Are Prisons ObsoleteDocument65 pagesAngela Davis Are Prisons Obsoletefuglicia90% (30)

- 52R 06Document14 pages52R 06Showki Wani100% (1)

- Easa Airworthiness Directive: AD No.: 2015-0203Document3 pagesEasa Airworthiness Directive: AD No.: 2015-0203PhilNo ratings yet

- Easa Ad 2023-0105 1Document3 pagesEasa Ad 2023-0105 1edsel jose diaz sarmientoNo ratings yet

- Easa Emergency Airworthiness Directive: AD No.: 2007 - 0306-EDocument2 pagesEasa Emergency Airworthiness Directive: AD No.: 2007 - 0306-EItamar Ponciano SouzaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2015-0042Document2 pagesEasa Airworthiness Directive: AD No.: 2015-0042mazaherramazaniNo ratings yet

- Easa Ad 2013-0009 1Document3 pagesEasa Ad 2013-0009 1Yuri SilvaNo ratings yet

- Easa Ad 2013-0174 1Document3 pagesEasa Ad 2013-0174 1amerNo ratings yet

- Superseded: Airworthiness DirectiveDocument3 pagesSuperseded: Airworthiness DirectiveBahadorNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)BahadorNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)FaisNo ratings yet

- Easa Ad 2013-0090 1Document2 pagesEasa Ad 2013-0090 1amerNo ratings yet

- Easa Airworthiness Directive: AD No.: 2011-0072Document3 pagesEasa Airworthiness Directive: AD No.: 2011-0072Raymond ZamoraNo ratings yet

- Easa Ad 2013-0150R1 1Document3 pagesEasa Ad 2013-0150R1 1slam12125No ratings yet

- Easa Airworthiness Directive: AD No.: 2015-0213Document2 pagesEasa Airworthiness Directive: AD No.: 2015-0213philip00165No ratings yet

- Easa Ad 2007-0041 1Document2 pagesEasa Ad 2007-0041 1Yuri SilvaNo ratings yet

- Easa Ad 2018-0056 2Document4 pagesEasa Ad 2018-0056 2slam12125No ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)BahadorNo ratings yet

- Easa Pad 23-048 1Document3 pagesEasa Pad 23-048 1BahadorNo ratings yet

- Easa Ad 2013-0019 1Document2 pagesEasa Ad 2013-0019 1Stiven CastellanosNo ratings yet

- Easa Ad 2017-0138 1 PDFDocument7 pagesEasa Ad 2017-0138 1 PDFrenjithaeroNo ratings yet

- Easa Ad 2018-0188R1 1Document5 pagesEasa Ad 2018-0188R1 1Evangelos KopanakisNo ratings yet

- Emergency Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesEmergency Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)wellman zalukhuNo ratings yet

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument4 pagesNotification of A Proposal To Issue An Airworthiness DirectiveBahadorNo ratings yet

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument4 pagesNotification of A Proposal To Issue An Airworthiness Directivecf34No ratings yet

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument4 pagesNotification of A Proposal To Issue An Airworthiness DirectiveSuper FrankNo ratings yet

- Easa Emergency Airworthiness Directive: AD No.: 2011-0128-EDocument3 pagesEasa Emergency Airworthiness Directive: AD No.: 2011-0128-EBruno Alonso PachecoNo ratings yet

- Mandatory: AlertDocument15 pagesMandatory: AlertamerNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document6 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Victor Limber Yujra JimenezNo ratings yet

- Easa Ad 2021-0282 1Document3 pagesEasa Ad 2021-0282 1Luis Antonio HermozaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2013-0083Document3 pagesEasa Airworthiness Directive: AD No.: 2013-0083riversgardenNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)BahadorNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document6 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Raymond ZamoraNo ratings yet

- Easa Ad 2021-0011 1Document4 pagesEasa Ad 2021-0011 1vitalijusNo ratings yet

- Easa Ead 2018-0053-EDocument3 pagesEasa Ead 2018-0053-EhafiyNo ratings yet

- Easa Ad 2016-0261R1Document3 pagesEasa Ad 2016-0261R1hafiyNo ratings yet

- Ad2012 0177Document4 pagesAd2012 0177Milica MilicicNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Yuri SilvaNo ratings yet

- Easa Ad 2021-0281 1Document5 pagesEasa Ad 2021-0281 1Guillermo GonzálezNo ratings yet

- Easa Ad 2009-0269R1 1Document3 pagesEasa Ad 2009-0269R1 1emad24No ratings yet

- AD 2010 ListDocument63 pagesAD 2010 ListEstevam Gomes de AzevedoNo ratings yet

- Easa Ad 2014-0172 1Document4 pagesEasa Ad 2014-0172 1amerNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)BahadorNo ratings yet

- Superseded: Airworthiness DirectiveDocument3 pagesSuperseded: Airworthiness DirectiveErculesNo ratings yet

- Easa Pad 23-084R1 1Document3 pagesEasa Pad 23-084R1 1Pedro LucasNo ratings yet

- Easa Ad 2008-0215 1Document2 pagesEasa Ad 2008-0215 1ohm3011No ratings yet

- Easa Ad 2009-0072R1 1Document2 pagesEasa Ad 2009-0072R1 1BeyondXtreamNo ratings yet

- Emergency Airworthiness Directive: AD No.: 2017-0050-E Issued: 17 March 2017Document5 pagesEmergency Airworthiness Directive: AD No.: 2017-0050-E Issued: 17 March 2017philip00165No ratings yet

- Mandatory: Bollettino TecnicoDocument7 pagesMandatory: Bollettino TecnicomycopteraviationNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)cf34No ratings yet

- Easa Airworthiness Directive: AD No.: 2011-0090R1Document3 pagesEasa Airworthiness Directive: AD No.: 2011-0090R1ktsaknakis_1No ratings yet

- Euad 2015 0001R1Document5 pagesEuad 2015 0001R1sujitNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Carlyson SilvaNo ratings yet

- SB139338 TRSR Bumper InstDocument11 pagesSB139338 TRSR Bumper InstaeroNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Itamar Ponciano SouzaNo ratings yet

- Easa Ad 2010-0273R1 2Document3 pagesEasa Ad 2010-0273R1 2Yuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2013-0120Document3 pagesEasa Airworthiness Directive: AD No.: 2013-0120Yuri SilvaNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)ErculesNo ratings yet

- SI42NG 139 EASA AD 2024 0037 E Engine Main Bearing Studs ReplacementDocument4 pagesSI42NG 139 EASA AD 2024 0037 E Engine Main Bearing Studs ReplacementZane RiniNo ratings yet

- Easa Ad 2022-0191 1Document5 pagesEasa Ad 2022-0191 1PeteNo ratings yet

- Easa Ad 2013-0009 1Document3 pagesEasa Ad 2013-0009 1Yuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2012-0143Document6 pagesEasa Airworthiness Directive: AD No.: 2012-0143Yuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2013-0120Document3 pagesEasa Airworthiness Directive: AD No.: 2013-0120Yuri SilvaNo ratings yet

- Easa Ad F-1992-078R2 1Document2 pagesEasa Ad F-1992-078R2 1Yuri SilvaNo ratings yet

- Easa Ad 2007-0041 1Document2 pagesEasa Ad 2007-0041 1Yuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2012-0071Document4 pagesEasa Airworthiness Directive: AD No.: 2012-0071Yuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2012-0187R2Document4 pagesEasa Airworthiness Directive: AD No.: 2012-0187R2Yuri SilvaNo ratings yet

- Easa Ad 2010-0273R1 2Document3 pagesEasa Ad 2010-0273R1 2Yuri SilvaNo ratings yet

- Easa Emergency Airworthiness Directive: AD No.: 2009-0245-EDocument3 pagesEasa Emergency Airworthiness Directive: AD No.: 2009-0245-EYuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No: 2006-0068Document2 pagesEasa Airworthiness Directive: AD No: 2006-0068Yuri SilvaNo ratings yet

- Easa Ad 2021-0255 1Document3 pagesEasa Ad 2021-0255 1Yuri SilvaNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Yuri SilvaNo ratings yet

- Airworthiness DirectiveDocument2 pagesAirworthiness DirectiveYuri SilvaNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document5 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Yuri SilvaNo ratings yet

- Easa Ad 2009-0002 1Document2 pagesEasa Ad 2009-0002 1Yuri SilvaNo ratings yet

- Airworthiness Directive: Transport Transports Canada Canada CF-2009-32 24 July 2009Document2 pagesAirworthiness Directive: Transport Transports Canada Canada CF-2009-32 24 July 2009Yuri SilvaNo ratings yet

- 117 Class 12th EnglishDocument2 pages117 Class 12th EnglishPushpendra PatelNo ratings yet

- Suhartin MDocument69 pagesSuhartin MSilfitri handayaniNo ratings yet

- CPDFDocument3 pagesCPDFJustice AgbekoNo ratings yet

- Holy Eucharist - PotDocument19 pagesHoly Eucharist - PotMargie CalumpitNo ratings yet

- CV - Ana MeskovskaDocument6 pagesCV - Ana MeskovskaShenka Mustafai0% (1)

- Times-Trib 02 MG 2018 DummyDocument16 pagesTimes-Trib 02 MG 2018 DummynewspubincNo ratings yet

- Bill Evans Trio PaperDocument5 pagesBill Evans Trio PaperTimothy JohnNo ratings yet

- Villa Rey Transit Vs FerrerDocument2 pagesVilla Rey Transit Vs FerrerRia Kriselle Francia Pabale100% (2)

- YB1905Document202 pagesYB1905Brendan Paul ValiantNo ratings yet

- Shagun Dissertation Report 2023Document76 pagesShagun Dissertation Report 2023tarun ranaNo ratings yet

- Assignment 2 Kelompok 3 1. Fitriyanto 2. Garin Ario Tetuko 3. Retno Ajeng Zulia OctaviaDocument4 pagesAssignment 2 Kelompok 3 1. Fitriyanto 2. Garin Ario Tetuko 3. Retno Ajeng Zulia OctaviaiyanNo ratings yet

- Case Study of Capital BudgetingDocument38 pagesCase Study of Capital BudgetingZara Urooj100% (1)

- University Institute of Legal StudiesDocument62 pagesUniversity Institute of Legal StudiesnosheenNo ratings yet

- 2017 Sea Base Staff ManualDocument36 pages2017 Sea Base Staff Manualapi-246710508No ratings yet

- Republic Act No. 7942Document42 pagesRepublic Act No. 7942Paul John Page PachecoNo ratings yet

- Adoption: The Hindu Adoption and Maintenance Act, 1956Document5 pagesAdoption: The Hindu Adoption and Maintenance Act, 1956Harnoor KaurNo ratings yet

- File-4 (Chapter-3) PDFDocument136 pagesFile-4 (Chapter-3) PDFabc654No ratings yet

- Trends in Nursing InformaticsDocument2 pagesTrends in Nursing InformaticsHannah Jane PadernalNo ratings yet

- Sexy Asian Girls Feet - Beautiful and Sexy Asian Girl Xixis Sexy Big Feet5 HDDocument1 pageSexy Asian Girls Feet - Beautiful and Sexy Asian Girl Xixis Sexy Big Feet5 HDJason ZhaoNo ratings yet

- Findings and DiscussionsDocument25 pagesFindings and DiscussionsRAVEN O. LARONNo ratings yet

- Critique DraftDocument4 pagesCritique DraftJuan HenesisNo ratings yet

- Art Journal - 2nd Version - MidtermDocument70 pagesArt Journal - 2nd Version - MidtermDizon Rhean MaeNo ratings yet

- Pearson Mathematics Year 10-10a Homework Program AnswersDocument7 pagesPearson Mathematics Year 10-10a Homework Program Answersafeuaqppi100% (1)

- (Stephen Burt, Hannah Brooks-Motl) Randall JarrellDocument197 pages(Stephen Burt, Hannah Brooks-Motl) Randall JarrellAlene Saury100% (2)

- Cre Form 1 2020 Schemes of WorkDocument12 pagesCre Form 1 2020 Schemes of Worklydia mutuaNo ratings yet

- Executive SummaryDocument4 pagesExecutive Summaryskobarev50% (2)

- 12 - Epstein Barr Virus (EBV)Document20 pages12 - Epstein Barr Virus (EBV)Lusiana T. Sipil UnsulbarNo ratings yet

Easa Ad 2011-0236 1

Easa Ad 2011-0236 1

Uploaded by

Yuri SilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Easa Ad 2011-0236 1

Easa Ad 2011-0236 1

Uploaded by

Yuri SilvaCopyright:

Available Formats

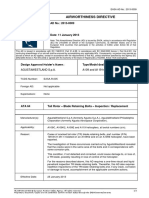

EASA AD No: 2011-0236

EASA AIRWORTHINESS DIRECTIVE

AD No.: 2011-0236

[Correction: 23 January 2012]

Date: 14 December 2011

Note: This Airworthiness Directive (AD) is issued by EASA, acting in accordance with

Regulation (EC) No 216/2008 on behalf of the European Community, its Member States and

of the European third countries that participate in the activities of EASA under Article 66 of

that Regulation.

This AD is issued in accordance with EC 1702/2003, Part 21A.3B. In accordance with EC 2042/2003 Annex I, Part M.A.301, the

continuing airworthiness of an aircraft shall be ensured by accomplishing any applicable ADs. Consequently, no person may operate

an aircraft to which an AD applies, except in accordance with the requirements of that AD, unless otherwise specified by the Agency

[EC 2042/2003 Annex I, Part M.A.303] or agreed with the Authority of the State of Registry [EC 216/2008, Article 14(4) exemption].

Type Approval Holder’s Name : Type/Model designation(s) :

Agusta S.p.A A109 helicopters

TCDS Number: EASA.R.005

Foreign AD: Not applicable

Supersedure: None

Landing Gear – Main Landing Gear (MLG) Actuator Bracket

ATA 32

Attachment Bolts – Replacement / Inspection

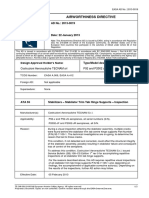

Manufacturer(s): AgustaWestland S.p.A.

Applicability: A109A, A109AII and A109C helicopters, all serial numbers.

Reason: A case of collapsed right-hand (RH) MLG has recently occurred on an

A109AII helicopter. The results of the technical investigation revealed that the

MLG collapsed due to fatigue fracture of the MLG actuator bracket

attachment bolts, caused by incorrect tightening of the bolts. The same Part

Number (P/N) NAS624H8 and P/N NAS624H10 bolts are also installed on

the MLG of A109A and A109C helicopters.

This condition, if not detected and corrected, could lead to further events of

MLG collapse, which could result in damage to the helicopter and injury to its

occupants.

To address this condition, AgustaWestland issued Bolletino Tecnico (BT)

109-133, which requires replacement of MLG actuator bracket attachment

bolts (with the same bolt P/N), reduces the tolerance of the torque value to be

applied when tightening the bolts and nuts of the MLG actuator bracket,

introduces repetitive inspections of the bolts at reduced intervals (from 600

flight hours) and, depending on findings, replacement of the bolts (with the

same bolt P/N).

For the reasons described above, this AD requires installation of new bolts,

using the correct torque value, repetitive inspections at the new intervals and,

depending on findings, replacement of bolts (with the same bolt P/N).

This AD has been republished to correct a typographical error in paragraph

EASA Form 110 Page 1/2

EASA AD No: 2011-0236

(3) of the RACT section of the AD, where an incorrect “part” number of

AgustaWestland BT 109-133 was quoted for the replacement of the bolts.

Effective Date: 28 December 2011

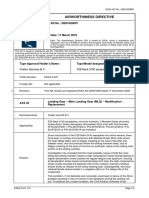

Required Action(s) Required as indicated, unless accomplished previously:

and Compliance

(1) Within 100 flight hours (FH) or 5 months, whichever occurs first after the

Time(s):

effective date of this AD, replace the RH and left-hand (LH) MLG

actuator bracket attachment bolts P/N NAS624H8 and P/N NAS624H10

applying the correct torque value, in accordance with the instructions of

part I of the AgustaWestland BT 109-133.

(2) Within 100 FH or 150 FH, as applicable, depending on the inspection

program adopted by the operator, or 12 months, whichever occurs first

after replacement of the MLG actuator bracket attachment bolts as

required by paragraph (1) of this AD, and, thereafter, at intervals not to

exceed 100 FH or 150 FH, as applicable, depending on the inspection

program adopted by the operator, or 12 months, whichever occurs first,

inspect the RH and LH MLG actuator bracket attachment bolts P/N

NAS624H8 and P/N NAS624H10, in accordance with the instructions of

part II of the AgustaWestland BT 109-133.

(3) If, during any inspection as required by paragraph (2) of this AD, a

discrepancy is identified on at least one of the bolts, RH or LH, before

next flight, replace all bolts, RH or LH, as applicable, with serviceable

parts and apply the correct torque value, in accordance with the

instructions of part I of AgustaWestland BT 109-133.

(4) Replacement of bolts, as required by paragraph (3) of this AD, does not

constitute terminating action for the repetitive inspections required by

paragraph (2) of this AD.

Ref. Publications: AgustaWestland Bollettino Tecnico 109-133 dated 04 November 2011.

The use of later approved revisions of this document is acceptable for

compliance with the requirements of this AD.

Remarks : 1. If requested and appropriately substantiated, EASA can approve

Alternative Methods of Compliance for this AD.

2. This AD was posted on 11 November 2011 as PAD 11-120 for

consultation until 09 November 2011. No comments were received

during the consultation period.

3. Enquiries regarding this AD should be referred to the Safety Information

Section, Executive Directorate, EASA. E-mail: ADs@easa.europa.eu .

4. For any question concerning the technical content of the requirements in

this AD, please contact:

AgustaWestland S.p.A. Customer Support

Via del Gregge, 100 - 21015 Lonate Pozzolo (VA) – Italy

Telephone + 39 0331-664396 ; Fax: + 39 0331-664680

E-mail: custserv@agustawestland.com.

EASA Form 110 Page 2/2

You might also like

- Flight Manual CDL A319 132Document714 pagesFlight Manual CDL A319 132DithelNo ratings yet

- Unit 4 Test - Inside OutDocument5 pagesUnit 4 Test - Inside OutJesus VillanuevaNo ratings yet

- Angela Davis Are Prisons ObsoleteDocument65 pagesAngela Davis Are Prisons Obsoletefuglicia90% (30)

- 52R 06Document14 pages52R 06Showki Wani100% (1)

- Easa Airworthiness Directive: AD No.: 2015-0203Document3 pagesEasa Airworthiness Directive: AD No.: 2015-0203PhilNo ratings yet

- Easa Ad 2023-0105 1Document3 pagesEasa Ad 2023-0105 1edsel jose diaz sarmientoNo ratings yet

- Easa Emergency Airworthiness Directive: AD No.: 2007 - 0306-EDocument2 pagesEasa Emergency Airworthiness Directive: AD No.: 2007 - 0306-EItamar Ponciano SouzaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2015-0042Document2 pagesEasa Airworthiness Directive: AD No.: 2015-0042mazaherramazaniNo ratings yet

- Easa Ad 2013-0009 1Document3 pagesEasa Ad 2013-0009 1Yuri SilvaNo ratings yet

- Easa Ad 2013-0174 1Document3 pagesEasa Ad 2013-0174 1amerNo ratings yet

- Superseded: Airworthiness DirectiveDocument3 pagesSuperseded: Airworthiness DirectiveBahadorNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)BahadorNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)FaisNo ratings yet

- Easa Ad 2013-0090 1Document2 pagesEasa Ad 2013-0090 1amerNo ratings yet

- Easa Airworthiness Directive: AD No.: 2011-0072Document3 pagesEasa Airworthiness Directive: AD No.: 2011-0072Raymond ZamoraNo ratings yet

- Easa Ad 2013-0150R1 1Document3 pagesEasa Ad 2013-0150R1 1slam12125No ratings yet

- Easa Airworthiness Directive: AD No.: 2015-0213Document2 pagesEasa Airworthiness Directive: AD No.: 2015-0213philip00165No ratings yet

- Easa Ad 2007-0041 1Document2 pagesEasa Ad 2007-0041 1Yuri SilvaNo ratings yet

- Easa Ad 2018-0056 2Document4 pagesEasa Ad 2018-0056 2slam12125No ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)BahadorNo ratings yet

- Easa Pad 23-048 1Document3 pagesEasa Pad 23-048 1BahadorNo ratings yet

- Easa Ad 2013-0019 1Document2 pagesEasa Ad 2013-0019 1Stiven CastellanosNo ratings yet

- Easa Ad 2017-0138 1 PDFDocument7 pagesEasa Ad 2017-0138 1 PDFrenjithaeroNo ratings yet

- Easa Ad 2018-0188R1 1Document5 pagesEasa Ad 2018-0188R1 1Evangelos KopanakisNo ratings yet

- Emergency Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesEmergency Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)wellman zalukhuNo ratings yet

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument4 pagesNotification of A Proposal To Issue An Airworthiness DirectiveBahadorNo ratings yet

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument4 pagesNotification of A Proposal To Issue An Airworthiness Directivecf34No ratings yet

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument4 pagesNotification of A Proposal To Issue An Airworthiness DirectiveSuper FrankNo ratings yet

- Easa Emergency Airworthiness Directive: AD No.: 2011-0128-EDocument3 pagesEasa Emergency Airworthiness Directive: AD No.: 2011-0128-EBruno Alonso PachecoNo ratings yet

- Mandatory: AlertDocument15 pagesMandatory: AlertamerNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document6 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Victor Limber Yujra JimenezNo ratings yet

- Easa Ad 2021-0282 1Document3 pagesEasa Ad 2021-0282 1Luis Antonio HermozaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2013-0083Document3 pagesEasa Airworthiness Directive: AD No.: 2013-0083riversgardenNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)BahadorNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document6 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Raymond ZamoraNo ratings yet

- Easa Ad 2021-0011 1Document4 pagesEasa Ad 2021-0011 1vitalijusNo ratings yet

- Easa Ead 2018-0053-EDocument3 pagesEasa Ead 2018-0053-EhafiyNo ratings yet

- Easa Ad 2016-0261R1Document3 pagesEasa Ad 2016-0261R1hafiyNo ratings yet

- Ad2012 0177Document4 pagesAd2012 0177Milica MilicicNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Yuri SilvaNo ratings yet

- Easa Ad 2021-0281 1Document5 pagesEasa Ad 2021-0281 1Guillermo GonzálezNo ratings yet

- Easa Ad 2009-0269R1 1Document3 pagesEasa Ad 2009-0269R1 1emad24No ratings yet

- AD 2010 ListDocument63 pagesAD 2010 ListEstevam Gomes de AzevedoNo ratings yet

- Easa Ad 2014-0172 1Document4 pagesEasa Ad 2014-0172 1amerNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)BahadorNo ratings yet

- Superseded: Airworthiness DirectiveDocument3 pagesSuperseded: Airworthiness DirectiveErculesNo ratings yet

- Easa Pad 23-084R1 1Document3 pagesEasa Pad 23-084R1 1Pedro LucasNo ratings yet

- Easa Ad 2008-0215 1Document2 pagesEasa Ad 2008-0215 1ohm3011No ratings yet

- Easa Ad 2009-0072R1 1Document2 pagesEasa Ad 2009-0072R1 1BeyondXtreamNo ratings yet

- Emergency Airworthiness Directive: AD No.: 2017-0050-E Issued: 17 March 2017Document5 pagesEmergency Airworthiness Directive: AD No.: 2017-0050-E Issued: 17 March 2017philip00165No ratings yet

- Mandatory: Bollettino TecnicoDocument7 pagesMandatory: Bollettino TecnicomycopteraviationNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)cf34No ratings yet

- Easa Airworthiness Directive: AD No.: 2011-0090R1Document3 pagesEasa Airworthiness Directive: AD No.: 2011-0090R1ktsaknakis_1No ratings yet

- Euad 2015 0001R1Document5 pagesEuad 2015 0001R1sujitNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Carlyson SilvaNo ratings yet

- SB139338 TRSR Bumper InstDocument11 pagesSB139338 TRSR Bumper InstaeroNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Itamar Ponciano SouzaNo ratings yet

- Easa Ad 2010-0273R1 2Document3 pagesEasa Ad 2010-0273R1 2Yuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2013-0120Document3 pagesEasa Airworthiness Directive: AD No.: 2013-0120Yuri SilvaNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)ErculesNo ratings yet

- SI42NG 139 EASA AD 2024 0037 E Engine Main Bearing Studs ReplacementDocument4 pagesSI42NG 139 EASA AD 2024 0037 E Engine Main Bearing Studs ReplacementZane RiniNo ratings yet

- Easa Ad 2022-0191 1Document5 pagesEasa Ad 2022-0191 1PeteNo ratings yet

- Easa Ad 2013-0009 1Document3 pagesEasa Ad 2013-0009 1Yuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2012-0143Document6 pagesEasa Airworthiness Directive: AD No.: 2012-0143Yuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2013-0120Document3 pagesEasa Airworthiness Directive: AD No.: 2013-0120Yuri SilvaNo ratings yet

- Easa Ad F-1992-078R2 1Document2 pagesEasa Ad F-1992-078R2 1Yuri SilvaNo ratings yet

- Easa Ad 2007-0041 1Document2 pagesEasa Ad 2007-0041 1Yuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2012-0071Document4 pagesEasa Airworthiness Directive: AD No.: 2012-0071Yuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No.: 2012-0187R2Document4 pagesEasa Airworthiness Directive: AD No.: 2012-0187R2Yuri SilvaNo ratings yet

- Easa Ad 2010-0273R1 2Document3 pagesEasa Ad 2010-0273R1 2Yuri SilvaNo ratings yet

- Easa Emergency Airworthiness Directive: AD No.: 2009-0245-EDocument3 pagesEasa Emergency Airworthiness Directive: AD No.: 2009-0245-EYuri SilvaNo ratings yet

- Easa Airworthiness Directive: AD No: 2006-0068Document2 pagesEasa Airworthiness Directive: AD No: 2006-0068Yuri SilvaNo ratings yet

- Easa Ad 2021-0255 1Document3 pagesEasa Ad 2021-0255 1Yuri SilvaNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Yuri SilvaNo ratings yet

- Airworthiness DirectiveDocument2 pagesAirworthiness DirectiveYuri SilvaNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document5 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Yuri SilvaNo ratings yet

- Easa Ad 2009-0002 1Document2 pagesEasa Ad 2009-0002 1Yuri SilvaNo ratings yet

- Airworthiness Directive: Transport Transports Canada Canada CF-2009-32 24 July 2009Document2 pagesAirworthiness Directive: Transport Transports Canada Canada CF-2009-32 24 July 2009Yuri SilvaNo ratings yet

- 117 Class 12th EnglishDocument2 pages117 Class 12th EnglishPushpendra PatelNo ratings yet

- Suhartin MDocument69 pagesSuhartin MSilfitri handayaniNo ratings yet

- CPDFDocument3 pagesCPDFJustice AgbekoNo ratings yet

- Holy Eucharist - PotDocument19 pagesHoly Eucharist - PotMargie CalumpitNo ratings yet

- CV - Ana MeskovskaDocument6 pagesCV - Ana MeskovskaShenka Mustafai0% (1)

- Times-Trib 02 MG 2018 DummyDocument16 pagesTimes-Trib 02 MG 2018 DummynewspubincNo ratings yet

- Bill Evans Trio PaperDocument5 pagesBill Evans Trio PaperTimothy JohnNo ratings yet

- Villa Rey Transit Vs FerrerDocument2 pagesVilla Rey Transit Vs FerrerRia Kriselle Francia Pabale100% (2)

- YB1905Document202 pagesYB1905Brendan Paul ValiantNo ratings yet

- Shagun Dissertation Report 2023Document76 pagesShagun Dissertation Report 2023tarun ranaNo ratings yet

- Assignment 2 Kelompok 3 1. Fitriyanto 2. Garin Ario Tetuko 3. Retno Ajeng Zulia OctaviaDocument4 pagesAssignment 2 Kelompok 3 1. Fitriyanto 2. Garin Ario Tetuko 3. Retno Ajeng Zulia OctaviaiyanNo ratings yet

- Case Study of Capital BudgetingDocument38 pagesCase Study of Capital BudgetingZara Urooj100% (1)

- University Institute of Legal StudiesDocument62 pagesUniversity Institute of Legal StudiesnosheenNo ratings yet

- 2017 Sea Base Staff ManualDocument36 pages2017 Sea Base Staff Manualapi-246710508No ratings yet

- Republic Act No. 7942Document42 pagesRepublic Act No. 7942Paul John Page PachecoNo ratings yet

- Adoption: The Hindu Adoption and Maintenance Act, 1956Document5 pagesAdoption: The Hindu Adoption and Maintenance Act, 1956Harnoor KaurNo ratings yet

- File-4 (Chapter-3) PDFDocument136 pagesFile-4 (Chapter-3) PDFabc654No ratings yet

- Trends in Nursing InformaticsDocument2 pagesTrends in Nursing InformaticsHannah Jane PadernalNo ratings yet

- Sexy Asian Girls Feet - Beautiful and Sexy Asian Girl Xixis Sexy Big Feet5 HDDocument1 pageSexy Asian Girls Feet - Beautiful and Sexy Asian Girl Xixis Sexy Big Feet5 HDJason ZhaoNo ratings yet

- Findings and DiscussionsDocument25 pagesFindings and DiscussionsRAVEN O. LARONNo ratings yet

- Critique DraftDocument4 pagesCritique DraftJuan HenesisNo ratings yet

- Art Journal - 2nd Version - MidtermDocument70 pagesArt Journal - 2nd Version - MidtermDizon Rhean MaeNo ratings yet

- Pearson Mathematics Year 10-10a Homework Program AnswersDocument7 pagesPearson Mathematics Year 10-10a Homework Program Answersafeuaqppi100% (1)

- (Stephen Burt, Hannah Brooks-Motl) Randall JarrellDocument197 pages(Stephen Burt, Hannah Brooks-Motl) Randall JarrellAlene Saury100% (2)

- Cre Form 1 2020 Schemes of WorkDocument12 pagesCre Form 1 2020 Schemes of Worklydia mutuaNo ratings yet

- Executive SummaryDocument4 pagesExecutive Summaryskobarev50% (2)

- 12 - Epstein Barr Virus (EBV)Document20 pages12 - Epstein Barr Virus (EBV)Lusiana T. Sipil UnsulbarNo ratings yet