Professional Documents

Culture Documents

Per Uoroalkoxy Resin: Parameter Unit Value References

Per Uoroalkoxy Resin: Parameter Unit Value References

Uploaded by

diǝgOz F.Copyright:

Available Formats

You might also like

- SWANCOR 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSWANCOR 901-3: Epoxy Vinyl Ester ResinsSofya Andarina100% (1)

- Der 331 PDFDocument5 pagesDer 331 PDFTamer BidakNo ratings yet

- Astm C 1116Document7 pagesAstm C 1116Joel Josué Vargas BarturénNo ratings yet

- Fiberglass Grating and Structural Products Design ManualDocument75 pagesFiberglass Grating and Structural Products Design Manuali_tiberius_m8153100% (1)

- Uorinated Ethylene-Propylene Copolymer: Parameter Unit Value ReferencesDocument4 pagesUorinated Ethylene-Propylene Copolymer: Parameter Unit Value ReferencesdiǝgOz F.No ratings yet

- Poly (Ethylene-Co-Acrylic Acid) : Parameter Unit Value ReferencesDocument3 pagesPoly (Ethylene-Co-Acrylic Acid) : Parameter Unit Value ReferencesMatt HillocksNo ratings yet

- Cellulose Acetate Butyrate: Parameter Unit Value ReferencesDocument4 pagesCellulose Acetate Butyrate: Parameter Unit Value ReferencesMatt HillocksNo ratings yet

- BIIR - Bromobutyl RubberDocument2 pagesBIIR - Bromobutyl Rubbersandrine guerinNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- Poly AcrylonitrileDocument16 pagesPoly AcrylonitrileParul Kumar SharmaNo ratings yet

- FUVPP FRPM21 Poster FinalDocument1 pageFUVPP FRPM21 Poster FinalDimitrios KorresNo ratings yet

- Styrene StyreneDocument22 pagesStyrene StyrenedeboNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Timetal: Ti - 1 0 V-2 F e - 3 A LDocument2 pagesTimetal: Ti - 1 0 V-2 F e - 3 A LBüyüleyici GözlerNo ratings yet

- Poly (Vinyl Fluoride)Document10 pagesPoly (Vinyl Fluoride)Rifki Amirul HakimNo ratings yet

- TDS - Vinyl 901-3 (En)Document2 pagesTDS - Vinyl 901-3 (En)OXY Composite TechNo ratings yet

- Atlac 590 002126 - 1520269898Document2 pagesAtlac 590 002126 - 1520269898Jainam ShahNo ratings yet

- Tecnical R 802Document16 pagesTecnical R 802Dyah Ayu100% (1)

- Plastisol Foaming Process. Decomposition of The Foaming Agent, Polymer Behavior in The Corresponding Temperature Range and Resulting Foam PropertiesDocument7 pagesPlastisol Foaming Process. Decomposition of The Foaming Agent, Polymer Behavior in The Corresponding Temperature Range and Resulting Foam Propertieshost1000youtubNo ratings yet

- Epoxy Curing With INVISTA DiaminesDocument5 pagesEpoxy Curing With INVISTA DiaminesUnknownNo ratings yet

- Araldite Epoxy Resin Cy 230 and Hy 951 HardenerDocument6 pagesAraldite Epoxy Resin Cy 230 and Hy 951 HardenerVaibhav AnuseNo ratings yet

- Araldite Epoxy Resin Cy 230 and Hy 951 HardenerDocument6 pagesAraldite Epoxy Resin Cy 230 and Hy 951 Hardenersonu50% (2)

- Thermal Oxidation of Anhydride Cured Epoxies. 1 - Mechanistic AspectsDocument10 pagesThermal Oxidation of Anhydride Cured Epoxies. 1 - Mechanistic AspectsIgor SilvaNo ratings yet

- WWW - Glueonline.co - Uk: Loctite EA 9492Document4 pagesWWW - Glueonline.co - Uk: Loctite EA 9492SanjyNo ratings yet

- CelluloseDocument5 pagesCelluloseMatt HillocksNo ratings yet

- Catalysts 06 00154Document16 pagesCatalysts 06 00154vibage2942No ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- Thermal Al2o3Document7 pagesThermal Al2o3ashishNo ratings yet

- Styrene-Butadiene Rubber: Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons, Inc. All Rights ReservedDocument17 pagesStyrene-Butadiene Rubber: Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons, Inc. All Rights ReservedTHỊ HÀ NGUYỄNNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDocument1 pageIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovNo ratings yet

- Astman NPG Glycol: Powder Coating Resin PC-17-4N Based OnDocument4 pagesAstman NPG Glycol: Powder Coating Resin PC-17-4N Based OnRAZA MEHDINo ratings yet

- Cote LDocument1 pageCote Lalvarado.hdez05No ratings yet

- PFR 06HCDocument16 pagesPFR 06HCprasanna kumarNo ratings yet

- Iso Dis 23936-2appendix+a08Document33 pagesIso Dis 23936-2appendix+a08Abel Lopez JoachinNo ratings yet

- Cohn1987 PDFDocument5 pagesCohn1987 PDFJuan Pablo BulaciosNo ratings yet

- Araldite FT CW 2250-1 Aradur HY 2251 ENDocument5 pagesAraldite FT CW 2250-1 Aradur HY 2251 ENMannepalli SrihariNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Fundamental PropertiesDocument8 pagesFundamental PropertiesLogusarojNo ratings yet

- Dyes and PigmentsDocument8 pagesDyes and PigmentsBehramand KhanNo ratings yet

- Acetone: Shell ChemicalsDocument3 pagesAcetone: Shell ChemicalsUzair BukhariNo ratings yet

- Ria PDFDocument23 pagesRia PDFria andrianiNo ratings yet

- Effect of - Irradiation On The Properties of Rubber-Based Conductive Blend CompositesDocument10 pagesEffect of - Irradiation On The Properties of Rubber-Based Conductive Blend CompositesDr. Ahmed Abdel-HakimNo ratings yet

- 907 1TDSDocument2 pages907 1TDSJainam Shah100% (1)

- Aspects of Solid State SynthesisDocument14 pagesAspects of Solid State Synthesisleen aliNo ratings yet

- Presentation STLE 2015 v4Document25 pagesPresentation STLE 2015 v4Carlos ZapataNo ratings yet

- Recommended Methods For Purification Solvent PDFDocument10 pagesRecommended Methods For Purification Solvent PDFNestor Armando Marin SolanoNo ratings yet

- Structure and Properties of 2,3,3,3-Tetrafluoropropene (HFO-1234yf)Document9 pagesStructure and Properties of 2,3,3,3-Tetrafluoropropene (HFO-1234yf)carzevedoNo ratings yet

- Ines SilesDocument2 pagesInes SilesEdgar Erwin Roman ChoqueNo ratings yet

- Enr PDFDocument19 pagesEnr PDFArjun Satheesh KumarNo ratings yet

- Ceramic Brush On: Technical Reference InformationDocument2 pagesCeramic Brush On: Technical Reference InformationAbdul RafiiNo ratings yet

- Pipepline Flow Assurance: A Case Study of Oil With High Paraffin Concentration in VietnamDocument6 pagesPipepline Flow Assurance: A Case Study of Oil With High Paraffin Concentration in VietnamOmar WardehNo ratings yet

- Applied Catalysis, 31 (1987) 113-118 Elsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands 113Document6 pagesApplied Catalysis, 31 (1987) 113-118 Elsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands 113snurain_3No ratings yet

- Novel Zinc Oxide Nanoparticles Deposited Acrylamide Comp - 2016 - Journal of PetDocument16 pagesNovel Zinc Oxide Nanoparticles Deposited Acrylamide Comp - 2016 - Journal of Petlabiba nusratNo ratings yet

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Document3 pagesLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNo ratings yet

- Ceramic Brush On - 95010K-1Document2 pagesCeramic Brush On - 95010K-1NazmiNo ratings yet

- Rubber Epoxidation For Adhesive ApplicationsDocument8 pagesRubber Epoxidation For Adhesive ApplicationsKithminiNo ratings yet

- E Book HydrogenDocument133 pagesE Book Hydrogenbao_ngoc_trinhNo ratings yet

- LGHB 2Document2 pagesLGHB 2sergio.sanchezcmiNo ratings yet

- (2001) The Thermal Degradation of Poly (Vinyl Alcohol)Document9 pages(2001) The Thermal Degradation of Poly (Vinyl Alcohol)Nam Huu TranNo ratings yet

- Wabo Mbrace Design GuideDocument124 pagesWabo Mbrace Design Guidejerlson83No ratings yet

- Aijaz Report Advanced Buiding MaterialsDocument14 pagesAijaz Report Advanced Buiding Materialsaijaz hussainNo ratings yet

- Durability Issues of FRP Rebars in Reinforced Concrete MembersDocument12 pagesDurability Issues of FRP Rebars in Reinforced Concrete MembersJamalNo ratings yet

- Camelyaf KCR2Document1 pageCamelyaf KCR2Waldomiro MoreiraNo ratings yet

- CrossPure Cartridge FilterDocument2 pagesCrossPure Cartridge FilterLU DustinNo ratings yet

- CompositesDocument58 pagesCompositeskasvikrajNo ratings yet

- Fiber1 ECM2 E-Glass CSM-PB Ver 1.4Document2 pagesFiber1 ECM2 E-Glass CSM-PB Ver 1.4Ibrahim sulaiman alalwaniNo ratings yet

- Clock Spring Pipe Repair System PDFDocument2 pagesClock Spring Pipe Repair System PDFNeo_1982No ratings yet

- Material Properties Filament Wound Composite Structures: A Versatile Solution To Today's Design ProblemsDocument4 pagesMaterial Properties Filament Wound Composite Structures: A Versatile Solution To Today's Design ProblemsOliver RisteskiNo ratings yet

- Pes PDFDocument3 pagesPes PDFSaidur Rahman SajibNo ratings yet

- Anti Crak Brochure ScreenDocument7 pagesAnti Crak Brochure ScreenPablo Quinteros PizarroNo ratings yet

- 4 RadomeDocument39 pages4 RadomeAbdul RazzakNo ratings yet

- PPSDocument19 pagesPPSsujoyludNo ratings yet

- Iso 5256 1985Document15 pagesIso 5256 1985lela84kNo ratings yet

- A Thesis Proposal On Producing Concrete Masonry UnitDocument46 pagesA Thesis Proposal On Producing Concrete Masonry UnitAna Camille De GuzmanNo ratings yet

- Natural Fibers As Viable Sources For The Development of Structural, Semi-Structural, and Technological Materials - A ReviewDocument14 pagesNatural Fibers As Viable Sources For The Development of Structural, Semi-Structural, and Technological Materials - A ReviewDiptoNo ratings yet

- Strengthening Competition Using Fiber-Reinforced Polymer (FRP) CompositesDocument6 pagesStrengthening Competition Using Fiber-Reinforced Polymer (FRP) Composites侯柏毅No ratings yet

- Fiber-Reinforced Plastic Grid For Reinforced Concrete ConstructionDocument18 pagesFiber-Reinforced Plastic Grid For Reinforced Concrete ConstructionPari PatelNo ratings yet

- Design, Codes and Guidelines: 10.1 OverviewDocument3 pagesDesign, Codes and Guidelines: 10.1 OverviewMiljan TrivicNo ratings yet

- AC454Document23 pagesAC454Tigon Vo NgocNo ratings yet

- techNOTE 11 - AR GlassfibresDocument3 pagestechNOTE 11 - AR GlassfibresJoseph JayakanthanNo ratings yet

- E Glass WovenDocument2 pagesE Glass WovenAdnan AhmedNo ratings yet

- 1338 GlasGrid Technical ManualDocument32 pages1338 GlasGrid Technical ManualMax Cedeño De LeónNo ratings yet

- 4.0 Product Design & Engineering Analysis 4.1 Design Solution Vehicle DimensionsDocument34 pages4.0 Product Design & Engineering Analysis 4.1 Design Solution Vehicle DimensionsKhairul SyahmiNo ratings yet

- EP2620419A1 - Polyamide Based Sizing Composition For Glass Fibres - Google PatentsDocument9 pagesEP2620419A1 - Polyamide Based Sizing Composition For Glass Fibres - Google Patentsمهدی عارفخانیNo ratings yet

- AutomotiveDocument155 pagesAutomotivevn_fanelli9364No ratings yet

- Aircraft Composite Materials - Lecture 03Document80 pagesAircraft Composite Materials - Lecture 03Kaushika Rajapaksha PereraNo ratings yet

- PP Compounds For Automotives PDFDocument16 pagesPP Compounds For Automotives PDFziradagreat539No ratings yet

Per Uoroalkoxy Resin: Parameter Unit Value References

Per Uoroalkoxy Resin: Parameter Unit Value References

Uploaded by

diǝgOz F.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Per Uoroalkoxy Resin: Parameter Unit Value References

Per Uoroalkoxy Resin: Parameter Unit Value References

Uploaded by

diǝgOz F.Copyright:

Available Formats

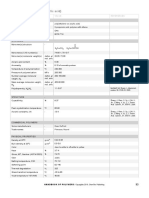

PFA perfluoroalkoxy resin

PARAMETER UNIT VALUE REFERENCES

GENERAL

Common name - perfluoroalkoxy resin; poly[tetrafluoroethylene-co-

perfluoro(alkyl vinyl ether)]

CAS name - propane, 1,1,1,2,2,3,3-heptafluoro-3-[(1,2,2-trifluoroethenyl)

oxy]-, polymer with 1,1,2,2-tetrafluoroethene

Acronym - PFA

CAS number - 26655-00-5

Formula CF2CF2CFCF2

OCF2CF2CF3

n

HISTORY

Person to discover - Carlson, D P

Date - 1970; 1973 (commercialization)

Details - copolymerization in halogenated solvents Ebnesajjad, S, Fluoroplastics. Vol.

2. Melt Processible Fluoroplastics,

William Andrew, 2003.

SYNTHESIS

Monomer(s) structure -

F3CCF2CF2OCF CF2 F2C CF2

Monomer(s) CAS number(s) - 1623-05-8; 116-14-3

Monomer(s) molecular weight(s) dalton, g/ 266.04; 100.02

mol, amu

Monomer(s) expected purity(ies) % 98

Formulation example - monomers, water, water-soluble initiator, surfactant

Method of synthesis - aqueous polymerization

Temperature of polymerization o

C 70-95

Time of polymerization h 3-6

Pressure of polymerization MPa 1.7-2.4

Drying temperature o

C 125-150

STRUCTURE

Crystallinity % 45-70

Chain conformation - 13/6 helix

COMMERCIAL POLYMERS

Some manufacturers - 3M; Daikin; Solvay

Trade names - Dyneon; Neoflon; Hyflon

PHYSICAL PROPERTIES

Density at 20oC g cm-3 2.12-2.18

Bulk density at 20oC g cm-3 0.25-0.6

Color - translucent to white

Refractive index, 20oC - 1.34-1.35

Transmittance % 71-91 (UV); 91-96 (vis); 96-98 (IR) Ebnesajjad, S, Fluoroplastics. Vol.

2. Melt Processible Fluoroplastics,

William Andrew, 2003.

Haze % 4

410 HANDBOOK OF POLYMERS / Copyrights 2016; ChemTec Publishing

PFA perfluoroalkoxy resin

PARAMETER UNIT VALUE REFERENCES

Odor - odorless

Melting temperature, DSC o

C 285-315

Decomposition temperature o

C 270; 400

Thermal expansion coefficient, o

C-1 1.2-2.1E-4

23-80oC

Thermal conductivity, melt W m-1 0.19-0.195

K-1

Glass transition temperature o

C 2-15

Specific heat capacity J K-1 kg-1 1,172

Heat of fusion Jg -1 17.1 Zhong, X; Yu, L; Zhao, W; Zhang,

Y; Sun, J, Polym. Deg. Stab., 40,

115-16, 1993.

Maximum service temperature o

C -240 to 260

Long term service temperature o

C 250-260

Heat deflection temperature at o

C 72

0.45 MPa

Heat deflection temperature at o

C 49; 85 (20% glass fiber)

1.8 MPa

Surface tension mN m-1 22.0 Becker, K, Int. Biodet. Biodeg., 41,

93-100, 1998.

Dielectric constant at 100 Hz/1 - 2.04/2.04

MHz

Dissipation factor at 100 Hz E-4 2

Dissipation factor at 1 MHz E-4 7

Volume resistivity ohm-m 1E15 to 1E16

Surface resistivity ohm 1E15

Electric strength K20/P50, kV mm -1 260

d=0.60.8 mm

Coefficient of friction - 0.1-0.3 (kinetic, PFA/steel); 0.13-0.16 (20% glass fiber)

Permeability to nitrogen, 25 C o

cm m 3 -2 2,000

24 h-1

atm-1

Permeability to oxygen, 25oC cm3 m-2 6,700

24 h-1

atm-1

Permeability to water vapor, 25oC g m-2 2

day-1

Diffusion coefficient of water cm2 s-1 4.05 (20oC); 8.5 (90oC) Hansen, C M, Prog. Org. Coat., 42,

vapor 167-78, 2001.

x107

Contact angle of water, 20oC degree 122

MECHANICAL & RHEOLOGICAL PROPERTIES

Tensile strength MPa 20-31.7; 34 (20% glass fiber)

Tensile modulus MPa 276

Tensile stress at yield MPa 12-15

Elongation % 150-360; 6 (20% glass fiber)

Flexural modulus MPa 550-740; 1,145 (20% glass fiber)

Elastic modulus MPa 480

Shore D hardness - 55-65

Shrinkage % 1 (150oC)

HANDBOOK OF POLYMERS / Copyrights 2016; ChemTec Publishing 411

PFA perfluoroalkoxy resin

PARAMETER UNIT VALUE REFERENCES

Water absorption, equilibrium in % <0.02 to <0.03

water at 23oC

CHEMICAL RESISTANCE

Acid dilute/concentrated - resistant

Alcohols - resistant

Alkalis - resistant

Aliphatic hydrocarbons - resistant

Aromatic hydrocarbons - resistant

Esters - resistant

Greases & oils - resistant

Halogenated hydrocarbons - resistant

Ketones - resistant

Other - reacts with fluorine and molten alkalis

FLAMMABILITY

Ignition temperature o

C 530-550

Autoignition temperature o

C 530-560

Limiting oxygen index % O2 >95

Heat of combustion Jg -1 6,110

Volatile products of combustion - CO, CO2, HF, smoke

UL rating - V-0

TOXICITY

HMIS: Health, Flammability, Re- - 2/1/0

activity rating

Carcinogenic effect - not listed by ACGIH, NIOSH, NTP

OSHA mg m -3 5 (respirable), 15 (total)

Oral rat, LD50 mg kg -1 >11,000

ENVIRONMENTAL IMPACT

Aquatic toxicity, Daphnia magna, mg l-1 >10,000

LC50, 48 h

Aquatic toxicity, Fathead mg l-1 >10,000

minnow, LC50, 48 h

PROCESSING

Typical processing methods - coating, extrusion, injection molding

Additives used in final products - Fillers: calcium hydroxide, carbon black, graphite, magnesium

oxide, metal particles, molybdenum disulfide, PTFE

Applications - automotive weather seals for doors and windows, coating for

hostile environments, column packing, filtration, fittings, marine

coatings, pipes, pump, silicon wafer carriers, tubing, wear

resistant products

Outstanding properties - weather resistance, thermal resistance, chemical resistance

ANALYSIS

FTIR (wavenumber-assignment) cm-1/- COF 1884; C=O 1813, 1775; CONH2 1768, 1587 Pianca, M; Barchiesi, E; Esposto,

G; Radice, S, J. Fluorine Chem.,

95, 71-84, 1999.

412 HANDBOOK OF POLYMERS / Copyrights 2016; ChemTec Publishing

You might also like

- SWANCOR 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSWANCOR 901-3: Epoxy Vinyl Ester ResinsSofya Andarina100% (1)

- Der 331 PDFDocument5 pagesDer 331 PDFTamer BidakNo ratings yet

- Astm C 1116Document7 pagesAstm C 1116Joel Josué Vargas BarturénNo ratings yet

- Fiberglass Grating and Structural Products Design ManualDocument75 pagesFiberglass Grating and Structural Products Design Manuali_tiberius_m8153100% (1)

- Uorinated Ethylene-Propylene Copolymer: Parameter Unit Value ReferencesDocument4 pagesUorinated Ethylene-Propylene Copolymer: Parameter Unit Value ReferencesdiǝgOz F.No ratings yet

- Poly (Ethylene-Co-Acrylic Acid) : Parameter Unit Value ReferencesDocument3 pagesPoly (Ethylene-Co-Acrylic Acid) : Parameter Unit Value ReferencesMatt HillocksNo ratings yet

- Cellulose Acetate Butyrate: Parameter Unit Value ReferencesDocument4 pagesCellulose Acetate Butyrate: Parameter Unit Value ReferencesMatt HillocksNo ratings yet

- BIIR - Bromobutyl RubberDocument2 pagesBIIR - Bromobutyl Rubbersandrine guerinNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- Poly AcrylonitrileDocument16 pagesPoly AcrylonitrileParul Kumar SharmaNo ratings yet

- FUVPP FRPM21 Poster FinalDocument1 pageFUVPP FRPM21 Poster FinalDimitrios KorresNo ratings yet

- Styrene StyreneDocument22 pagesStyrene StyrenedeboNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Timetal: Ti - 1 0 V-2 F e - 3 A LDocument2 pagesTimetal: Ti - 1 0 V-2 F e - 3 A LBüyüleyici GözlerNo ratings yet

- Poly (Vinyl Fluoride)Document10 pagesPoly (Vinyl Fluoride)Rifki Amirul HakimNo ratings yet

- TDS - Vinyl 901-3 (En)Document2 pagesTDS - Vinyl 901-3 (En)OXY Composite TechNo ratings yet

- Atlac 590 002126 - 1520269898Document2 pagesAtlac 590 002126 - 1520269898Jainam ShahNo ratings yet

- Tecnical R 802Document16 pagesTecnical R 802Dyah Ayu100% (1)

- Plastisol Foaming Process. Decomposition of The Foaming Agent, Polymer Behavior in The Corresponding Temperature Range and Resulting Foam PropertiesDocument7 pagesPlastisol Foaming Process. Decomposition of The Foaming Agent, Polymer Behavior in The Corresponding Temperature Range and Resulting Foam Propertieshost1000youtubNo ratings yet

- Epoxy Curing With INVISTA DiaminesDocument5 pagesEpoxy Curing With INVISTA DiaminesUnknownNo ratings yet

- Araldite Epoxy Resin Cy 230 and Hy 951 HardenerDocument6 pagesAraldite Epoxy Resin Cy 230 and Hy 951 HardenerVaibhav AnuseNo ratings yet

- Araldite Epoxy Resin Cy 230 and Hy 951 HardenerDocument6 pagesAraldite Epoxy Resin Cy 230 and Hy 951 Hardenersonu50% (2)

- Thermal Oxidation of Anhydride Cured Epoxies. 1 - Mechanistic AspectsDocument10 pagesThermal Oxidation of Anhydride Cured Epoxies. 1 - Mechanistic AspectsIgor SilvaNo ratings yet

- WWW - Glueonline.co - Uk: Loctite EA 9492Document4 pagesWWW - Glueonline.co - Uk: Loctite EA 9492SanjyNo ratings yet

- CelluloseDocument5 pagesCelluloseMatt HillocksNo ratings yet

- Catalysts 06 00154Document16 pagesCatalysts 06 00154vibage2942No ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- Thermal Al2o3Document7 pagesThermal Al2o3ashishNo ratings yet

- Styrene-Butadiene Rubber: Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons, Inc. All Rights ReservedDocument17 pagesStyrene-Butadiene Rubber: Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons, Inc. All Rights ReservedTHỊ HÀ NGUYỄNNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDocument1 pageIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovNo ratings yet

- Astman NPG Glycol: Powder Coating Resin PC-17-4N Based OnDocument4 pagesAstman NPG Glycol: Powder Coating Resin PC-17-4N Based OnRAZA MEHDINo ratings yet

- Cote LDocument1 pageCote Lalvarado.hdez05No ratings yet

- PFR 06HCDocument16 pagesPFR 06HCprasanna kumarNo ratings yet

- Iso Dis 23936-2appendix+a08Document33 pagesIso Dis 23936-2appendix+a08Abel Lopez JoachinNo ratings yet

- Cohn1987 PDFDocument5 pagesCohn1987 PDFJuan Pablo BulaciosNo ratings yet

- Araldite FT CW 2250-1 Aradur HY 2251 ENDocument5 pagesAraldite FT CW 2250-1 Aradur HY 2251 ENMannepalli SrihariNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Fundamental PropertiesDocument8 pagesFundamental PropertiesLogusarojNo ratings yet

- Dyes and PigmentsDocument8 pagesDyes and PigmentsBehramand KhanNo ratings yet

- Acetone: Shell ChemicalsDocument3 pagesAcetone: Shell ChemicalsUzair BukhariNo ratings yet

- Ria PDFDocument23 pagesRia PDFria andrianiNo ratings yet

- Effect of - Irradiation On The Properties of Rubber-Based Conductive Blend CompositesDocument10 pagesEffect of - Irradiation On The Properties of Rubber-Based Conductive Blend CompositesDr. Ahmed Abdel-HakimNo ratings yet

- 907 1TDSDocument2 pages907 1TDSJainam Shah100% (1)

- Aspects of Solid State SynthesisDocument14 pagesAspects of Solid State Synthesisleen aliNo ratings yet

- Presentation STLE 2015 v4Document25 pagesPresentation STLE 2015 v4Carlos ZapataNo ratings yet

- Recommended Methods For Purification Solvent PDFDocument10 pagesRecommended Methods For Purification Solvent PDFNestor Armando Marin SolanoNo ratings yet

- Structure and Properties of 2,3,3,3-Tetrafluoropropene (HFO-1234yf)Document9 pagesStructure and Properties of 2,3,3,3-Tetrafluoropropene (HFO-1234yf)carzevedoNo ratings yet

- Ines SilesDocument2 pagesInes SilesEdgar Erwin Roman ChoqueNo ratings yet

- Enr PDFDocument19 pagesEnr PDFArjun Satheesh KumarNo ratings yet

- Ceramic Brush On: Technical Reference InformationDocument2 pagesCeramic Brush On: Technical Reference InformationAbdul RafiiNo ratings yet

- Pipepline Flow Assurance: A Case Study of Oil With High Paraffin Concentration in VietnamDocument6 pagesPipepline Flow Assurance: A Case Study of Oil With High Paraffin Concentration in VietnamOmar WardehNo ratings yet

- Applied Catalysis, 31 (1987) 113-118 Elsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands 113Document6 pagesApplied Catalysis, 31 (1987) 113-118 Elsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands 113snurain_3No ratings yet

- Novel Zinc Oxide Nanoparticles Deposited Acrylamide Comp - 2016 - Journal of PetDocument16 pagesNovel Zinc Oxide Nanoparticles Deposited Acrylamide Comp - 2016 - Journal of Petlabiba nusratNo ratings yet

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Document3 pagesLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNo ratings yet

- Ceramic Brush On - 95010K-1Document2 pagesCeramic Brush On - 95010K-1NazmiNo ratings yet

- Rubber Epoxidation For Adhesive ApplicationsDocument8 pagesRubber Epoxidation For Adhesive ApplicationsKithminiNo ratings yet

- E Book HydrogenDocument133 pagesE Book Hydrogenbao_ngoc_trinhNo ratings yet

- LGHB 2Document2 pagesLGHB 2sergio.sanchezcmiNo ratings yet

- (2001) The Thermal Degradation of Poly (Vinyl Alcohol)Document9 pages(2001) The Thermal Degradation of Poly (Vinyl Alcohol)Nam Huu TranNo ratings yet

- Wabo Mbrace Design GuideDocument124 pagesWabo Mbrace Design Guidejerlson83No ratings yet

- Aijaz Report Advanced Buiding MaterialsDocument14 pagesAijaz Report Advanced Buiding Materialsaijaz hussainNo ratings yet

- Durability Issues of FRP Rebars in Reinforced Concrete MembersDocument12 pagesDurability Issues of FRP Rebars in Reinforced Concrete MembersJamalNo ratings yet

- Camelyaf KCR2Document1 pageCamelyaf KCR2Waldomiro MoreiraNo ratings yet

- CrossPure Cartridge FilterDocument2 pagesCrossPure Cartridge FilterLU DustinNo ratings yet

- CompositesDocument58 pagesCompositeskasvikrajNo ratings yet

- Fiber1 ECM2 E-Glass CSM-PB Ver 1.4Document2 pagesFiber1 ECM2 E-Glass CSM-PB Ver 1.4Ibrahim sulaiman alalwaniNo ratings yet

- Clock Spring Pipe Repair System PDFDocument2 pagesClock Spring Pipe Repair System PDFNeo_1982No ratings yet

- Material Properties Filament Wound Composite Structures: A Versatile Solution To Today's Design ProblemsDocument4 pagesMaterial Properties Filament Wound Composite Structures: A Versatile Solution To Today's Design ProblemsOliver RisteskiNo ratings yet

- Pes PDFDocument3 pagesPes PDFSaidur Rahman SajibNo ratings yet

- Anti Crak Brochure ScreenDocument7 pagesAnti Crak Brochure ScreenPablo Quinteros PizarroNo ratings yet

- 4 RadomeDocument39 pages4 RadomeAbdul RazzakNo ratings yet

- PPSDocument19 pagesPPSsujoyludNo ratings yet

- Iso 5256 1985Document15 pagesIso 5256 1985lela84kNo ratings yet

- A Thesis Proposal On Producing Concrete Masonry UnitDocument46 pagesA Thesis Proposal On Producing Concrete Masonry UnitAna Camille De GuzmanNo ratings yet

- Natural Fibers As Viable Sources For The Development of Structural, Semi-Structural, and Technological Materials - A ReviewDocument14 pagesNatural Fibers As Viable Sources For The Development of Structural, Semi-Structural, and Technological Materials - A ReviewDiptoNo ratings yet

- Strengthening Competition Using Fiber-Reinforced Polymer (FRP) CompositesDocument6 pagesStrengthening Competition Using Fiber-Reinforced Polymer (FRP) Composites侯柏毅No ratings yet

- Fiber-Reinforced Plastic Grid For Reinforced Concrete ConstructionDocument18 pagesFiber-Reinforced Plastic Grid For Reinforced Concrete ConstructionPari PatelNo ratings yet

- Design, Codes and Guidelines: 10.1 OverviewDocument3 pagesDesign, Codes and Guidelines: 10.1 OverviewMiljan TrivicNo ratings yet

- AC454Document23 pagesAC454Tigon Vo NgocNo ratings yet

- techNOTE 11 - AR GlassfibresDocument3 pagestechNOTE 11 - AR GlassfibresJoseph JayakanthanNo ratings yet

- E Glass WovenDocument2 pagesE Glass WovenAdnan AhmedNo ratings yet

- 1338 GlasGrid Technical ManualDocument32 pages1338 GlasGrid Technical ManualMax Cedeño De LeónNo ratings yet

- 4.0 Product Design & Engineering Analysis 4.1 Design Solution Vehicle DimensionsDocument34 pages4.0 Product Design & Engineering Analysis 4.1 Design Solution Vehicle DimensionsKhairul SyahmiNo ratings yet

- EP2620419A1 - Polyamide Based Sizing Composition For Glass Fibres - Google PatentsDocument9 pagesEP2620419A1 - Polyamide Based Sizing Composition For Glass Fibres - Google Patentsمهدی عارفخانیNo ratings yet

- AutomotiveDocument155 pagesAutomotivevn_fanelli9364No ratings yet

- Aircraft Composite Materials - Lecture 03Document80 pagesAircraft Composite Materials - Lecture 03Kaushika Rajapaksha PereraNo ratings yet

- PP Compounds For Automotives PDFDocument16 pagesPP Compounds For Automotives PDFziradagreat539No ratings yet