Professional Documents

Culture Documents

Study Bipolar and Cni

Study Bipolar and Cni

Uploaded by

GaneshOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Study Bipolar and Cni

Study Bipolar and Cni

Uploaded by

GaneshCopyright:

Available Formats

International Journal of Science and Research (IJSR)

ISSN: 2319-7064

Index Copernicus Value (2016): 79.57 | Impact Factor (2017): 7.296

A Study on the Effect of Anodic and Bipolar

Corrosion Inhibiting Admixtures on Strength

Parameters of Concrete

V L Satish1, Dr V Ravindra2

1

Engineer-SF, SDSC ISRO & Research Scholar JNTUK, Kakinada, Andhra Pradesh, India

2

Professor of Civil Engineering JNTUK, Kakinada, Andhra Pradesh, India

Abstract: Corrosion inhibitors in concrete have become a viable solution for controlling the corrosion in concrete structures. However,

the effect of the corrosion inhibitors on the strength parameters of concrete is also important. This study examined workability and

compressive strength development in concretes mixed with Anodic Inhibitor (Calcium Nitrite based) and Bipolar Corrosion inhibitor.

Two types of Concretes made from Portland Pozzolana Cement (PPC) and Ordinary Portland Cement (OPC) and the effect of corrosion

inhibitors on the strength parameters are studied.Test results showed that there is no much improvement in workability of OPC concrete

mixes or PPC concrete mixes by addition of both types of corrosion inhibitors used in this study. Addition of Calcium Nitrite based

inhibitor has resulted in marginal increase of compressive strength of concrete at 28 days, whereas, the addition of Bipolar inhibitor has

resulted in marginal decrease of compressive strength of concrete at 28 days.

Keywords: Corrosion inhibitors, Anodic Inhibitor/ Calcium Nitrite based inhibitor, Bipolar Corrosion inhibitor, workability, compressive

strength

1. Introduction Potassium chromate, Sodium benzoate and stannous chloride

(Saraswathy et al. 2001).

The main cause for deterioration of reinforced concrete

structures is the corrosion of the embedded steel, in Hence, two commercially available corrosion inhibitors,

particular when exposed to marine environments or deicing Anodic inhibitor (Calcium Nitrite based) and Bipolar

salts, due to the action of chloride. Deterioration of Inhibitor mixed in concrete made from Portland pozzolana

reinforced concrete structures results from external factors or cement (PPC) and Ordinary Portland cement (OPC) are

internal causes within the concrete itself. External chemical studied in terms of modification of the workability and

attack occurs mainly through the action of aggressive ions, compressive strength of concrete.

such as chlorides, sulphates or carbon dioxide, as well as

many natural or industrial liquids and gases. Corrosion of 2. Experimental

steel bars is a main factor affecting both the concrete

durability and strength. Since the mid 1960’s, several 2.1 Materials

methods have been investigated to extend the time to

corrosion damage in structures. Methods like epoxy and M 35 grade concretes using PPC and OPC were used to

galvanized coatings of reinforcing steel, active and passive assess the effect of corrosion inhibitors in terms of

cathodic protection systems, and use of corrosion inhibiting modification of workability and compressive strength of

admixtures in concrete have been adopted in the recent concrete. The properties of each of these materials used in

times[1]. Cathodic protection systems have been proven to the concrete are tested and used for mix design of concrete.

be effective, but requires constant monitoring to ensure The materials are tested in conformation with the IS code.

effectiveness and, depending upon the application, may be

maintenance intensive and expensive to install.[2,3]. Epoxy The materials used for this experimental work are

coating of steel became the corrosion prevention method of 1) Cement: Ordinary Portland Cement

choice in the late 1970's [4]. In the recent past, the use of 2) Cement: Portland Pozollona cement

corrosion inhibitors has become more common in preventing 3) Sand : Zone II

or delaying corrosion related damage in reinforced concrete 4) Coarse aggregate: HBG 20 mm graded

structures [5]. 5) Water: potable water

Corrosion Inhibitor is defined as “a chemical substance that Admixtures

decreases the corrosion rate when present in the corrosion 1) Commercially available Anodic (Calcium nitrate based)

system at suitable concentration, without significantly corrosion inhibiting admixtures (CNIA)

changing the concentration of any other corrosion agent.” 2) Commercially available Bipolar corrosion inhibiting

(ISO 8044- 1989). Corrosion – inhibiting admixtures are admixtures (BIA)

mainly used in concrete exposed to seawater or to varying

degrees of exposure to aggressive chemical environment.

Earlier studies looked at numerous corrosion inhibition

admixtures with the most attention focused on sodium nitrite,

Volume 7 Issue 12, December 2018

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20183211 10.21275/ART20183211 1

International Journal of Science and Research (IJSR)

ISSN: 2319-7064

Index Copernicus Value (2016): 79.57 | Impact Factor (2017): 7.296

2.1.1 Ordinary Portland Cement (OPC) and Pozollona containing molecules in which electron density distribution

Portland Cement (PPC) causes the inhibitor to be attracted to both anodic and

53 grade Ordinary Portland Cement conforming to IS:8112 cathodic processes. Due to the good quality of its vapour

and Portland Pozzolana Cement conforming to IS:1489– pressure and distribution with the moisture within the

Part-I are used in this study and the test parameters are given concrete, these molecules migrate to the steel and form a

in Table 1. monomolecular layer along the reinforcement in concrete.

Thus corrosion vis-à-vis micro cell formation is inhibited.

Table1: Physical Properties of Cement The test parameters of the corrosion inhibitors are given in

S. Test Conducted PPC OPC table 2.

No

1. Consistency 30.0% 28.0% Table 2: Test parameters of the corrosion inhibitors

2. Initial setting time 135 Minutes 120 Minutes S Test Conducted Calcium Nitrite Bi Polar

3. Final setting time 290 Minutes 185 Minutes No Inhibitor Inhibitor

4. Compressive strength:(Average 46.0 MPa 62.0 Mpa 1 Dry Material content ( by % weight) 31.78 16.15

of three results) 28 days 2 pH 6.03 8.17

5. FINENESS (by Blaine’s air 314 m2 /kg 305 m2 /kg 3 Ash content ( by % weight) 15.55 17.59

permeability method) 4 Relative density 1.18 1.1

6. SOUNDNESS (by Le-Chatelier’s 1.0mm 1.0mm 5 Chloride (%) Nil Nil

method)

2.2 Mix proportions

2.1.2Anodic Corrosion inhibitors

A commercially available Anodic Inhibitor (Calcium Nitrite M35 grade concretes using PPC and OPC were used to

based inhibitor) was used in this study. This is a chloride assess the effect of corrosion inhibitors. Based on the

free, ready to use aqueous solution of calcium nitrite. properties of the ingredients, the mix was designed for M35

Calcium nitrite is an ingredient which reacts chemically to grade of concrete as per IS 10262:2009. The concrete

interrupt chloride induced corrosion. Nitrites (Calcium or specimens were cast to study the modification of the

sodium salt) are anodic inhibitors, they compete with workability and compressive strength of concrete. The

chloride ions for the ferrous ions at the anode to form a film various mix proportions used in this study are given in table

of ferric oxide, Fe2O3. 3. The Calcium Nitrite Inhibitor is designated as CN and Bi-

polar inhibitor is designated as BI.

2.1.3 Bipolar Inhibitor

A commercially available bipolar inhibitor was also used in

this study for comparison. The chemical based inhibitor

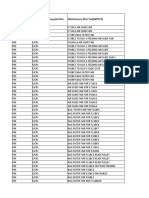

Table 3: Details of Concrete mix proportions

S NO Specimen Combination Cement Coarse Aggregate Fine Aggregate Water Inhibitor Remarks

KG 20mm KG 12mm KG KG Litre Litre

1 M35 GRADE CONCRETE WITH (OPC) 360 690 460 710 167 0.00 OPC Control Mix

2 M35 OPC + CN2% 360 690 460 710 159.80 7.20 2% Inhibitor

3 M35 OPC + CN5% 360 690 460 710 149.00 18.00 5% Inhibitor

4 M35 OPC + BI2% 360 690 460 710 159.80 7.20 2% Inhibitor

5 M35 OPC + BI5% 360 690 460 710 149.00 18.00 5% Inhibitor

6 M35 GRADE CONCRETE WITH (PPC) 390 676 482 740 172 0.00 PPC Control Mix

7 M35 PPC + CN2% 390 676 482 740 164.20 7.80 2% Inhibitor

8 M35 PPC + CN5% 390 676 482 740 152.50 19.50 5% Inhibitor

9 M35 PPC + BI2% 390 676 482 740 164.20 7.80 2% Inhibitor

10 M35 PPC + BI5% 390 676 482 740 152.50 19.50 5% Inhibitor

2.3 Tests Conducted 3. Results and Discussion

The slump cone test was conducted on all the mixes for both Workability: The workability tests were conducted for

OPC and PPC for determining the workability. Concrete various mixes are presented in table 4. There is no

cubes of size 150 x 150 x 150 mm were casted for M35 improvement in workability by addition of corrosion

grade concrete using both PPC and OPC cements. Both the inhibitors in concrete. For OPC mixes, by adding the calcium

inhibitors viz the anodic inhibitor (Calcium Nitrite based) Nitrite based inhibitor at dosage of 2% has shown a

and the Bipolar inhibitor in dosages of 2% and 5% by weight reduction of slump value by about 9% and addition at 5%

of cement are mixed in the concrete mixes and cubes were has shown a reduction of slump value by about 16%. For the

casted. These dosages are adopted based on the literature Bipolar inhibitor, the slump values are reduced by 23% and

review and manufacturer’s dosage range. The cubes are 18% for dosages of 2% and 5% respectively.For PPC mixes,

cured under water and are tested for determining the by adding the calcium Nitrite based inhibitor at dosage of 2%

compressive strength at 3 days, 7 days and 28 days. The has shown a reduction of slump value by about 13% and

Testing of specimens for compressive strength were carried addition at 5% has shown a reduction of slump value by

out according to IS: 516-1959in an automatic compression about 19%. For the Bipolar inhibitor, the slump values are

testing machine of capacity 5000 kN.

Volume 7 Issue 12, December 2018

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20183211 10.21275/ART20183211 2

International Journal of Science and Research (IJSR)

ISSN: 2319-7064

Index Copernicus Value (2016): 79.57 | Impact Factor (2017): 7.296

reduced by 24% and 26% for dosages of 2% and 5% 9% at 3 days and 7 days respectively compared to the control

respectively. mix. However by addition of 2% Calcium Nitrite inhibitor,

there is a marginal increase in compressive strength by 3.4%

Table 4: Slump values for various concrete mixes at 28 days. For the dosage of 5% calcium nitrite inhibitor,

OPC Mixes

Slump Value

PPC Mixes

Slump Value there is a reduction of compressive strength by 13%, 6% and

(mm) (mm) 4.5% at 3 days, 7 days and 28 days respectively compared to

OPC Concrete 55 PPC Concrete 68 the control mix. By addition of 2% Bipolar inhibitor, there is

OPC + 2% CN 50 PPC + 2% CN 59 a reduction of compressive strength by 14.6% and 11.2% at 3

OPC + 5% CN 46 PPC + 5% CN 55 days and 7 days respectively compared to the control mix.

OPC + 2% BI 42 PPC + 2% BI 52 However by addition of 2% Bipolar inhibitor, there is very

OPC + 5% BI 45 PPC + 5% BI 50

marginal increase in compressive strength by 4% at 28 days.

Addition of Bipolar inhibitor at dosage of 5% resulted in the

Compressive strength: The compressive strength tests were reduction of compressive strength by about 10.9%, 7.3% and

conducted for various mixes are presented in table 5 . 3.5% at 3 days, 7 days and 28 days respectively.

For OPC Mixes: By addition of 2% Calcium Nitrite Table 5: Compressive strength test results for OPC and PPC

inhibitor, there is an initial reduction of compressive strength mixes

by 10% at 3 days compared to the control mix. However by Compressive strength N/Sqmm

addition of 2% Calcium Nitrite inhibitor, there is an increase Mix Designation

3 DAYS 7 DAYS 28 DAYS

in compressive strength by 4% and 10% at 7 days and 28 OPC Control Mix 24.5 37.4 41.56

days respectively. For the dosage of 5% calcium nitrite OPC + 2% CN 22.1 38.81 45.85

inhibitor, the results are similar compared to that of 2% OPC + 5% CN 22.3 38.3 46.37

dosage.By addition of 2% Bipolar inhibitor, there is an initial OPC + 2% BI 18.5 32.59 42.59

reduction of compressive strength by 25% and 13% at 3 days OPC + 5% BI 16.4 23.63 43.56

and 7 days respectively compared to the control mix. PPC Control Mix 18.5 30.44 42.81

However by addition of 2% Bipolar inhibitor, there is very PPC + 2% CN 16.4 27.7 44.44

marginal increase in compressive strength by 2.5% at 28 PPC + 5% CN 16.1 28.52 40.89

days. Addition of Bipolar inhibitor at dosage of 5% resulted PPC + 2% BI 15.8 27.04 44.44

in the reduction of compressive strength by about 33% to PPC + 5% BI 16.5 28.22 41.33

36%.

For PPC Mixes: By addition of 2% Calcium Nitrite inhibitor,

there is a reduction of compressive strength by 11.4% and

Figure 1: Compressive strength results for OPC mixes

Figure 2: Compressive strength results for PPC mixes

Volume 7 Issue 12, December 2018

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20183211 10.21275/ART20183211 3

International Journal of Science and Research (IJSR)

ISSN: 2319-7064

Index Copernicus Value (2016): 79.57 | Impact Factor (2017): 7.296

4. Conclusions

There is no improvement in the workability of OPC concrete

mixes or PPC concrete mixes by addition of both the

Corrosion inhibitors compared to the control mix. The 3 days

and 7 days compressive strength result yielded less values

compared to the control mix for Calcium Nitrite inhibitor in

OPC mixes. However the 28 days result is marginally more

compared to the control Mix. The Calcium Nitrite inhibitor

has shown improvement in strength properties of OPC mix

may be due to the reduction of total porosity of the cement

paste by addition of inhibitors.

Addition of Bipolar inhibitor at dosage of 5% resulted in the

considerable reduction of compressive strength by about

33% to 36% in OPC mixes. Higher dosages i.e at 5% of

Calcium Nitrite inhibitor in PPC mixes has a reduction of

compressive strength by 13%, 6% and 4.5% at 3 days, 7 days

and 28 days respectively. Bipolar inhibitor at dosage of 5%

in PPC Mixes has resulted in the reduction of compressive

strength by about 10.9%, 7.3% and 3.5% at 3 days, 7 days

and 28 days respectively.

References

[1] Neville A. M., "Properties of Concrete", 3rd Edition,

Pitman Publishing Ltd., London, Chapter 10, (2010)

[2] Anon., ACI Committee 222, Corrosion of Metals in

Concrete. Detroit, MI, American Concrete Institute. ACI

Manual of Concrete Practice, Part I, 1996

[3] SHRP, Cathodic Protection of Reinforced Concrete

Bridge Elements: A State-of-the-Art Report..

Washington, D.C., Strategic Highway Research Program,

National Research Council, 1993

[4] Smith, Jeffrey L. and Virmani, Yash Paul, "Performance

of Epoxy-Coated Rebars in Bridge Decks", Public Roads

(Online), 1-11, 1996

[5] M C Brown, “Assessment of Commercial Corrosion

Inhibiting Admixtures for Reinforced Concrete”

Blacksburg, Virginia, 1999.

[6] BIS Standards, Specification for 43 grade Ordinary

Portland Cement, IS 8112, New Delhi, India, 2013.

[7] BIS Standards, Specification for Portland Pozzolana

cement, IS 1489-1:, New Delhi, India, 1999

[8] BIS Standards, Guidelines for concrete mix design

proportioning, IS 10262:, New Delhi, India, 2009

Volume 7 Issue 12, December 2018

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20183211 10.21275/ART20183211 4

You might also like

- Anchor Bolt MSDocument7 pagesAnchor Bolt MSGaneshNo ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Case Study ThesisDocument29 pagesCase Study ThesisSamanyu Bhatnagar100% (5)

- Differences Between Mortar and GroutDocument3 pagesDifferences Between Mortar and GroutAshrafNo ratings yet

- Answers To Common ABAQUS Questions PDFDocument4 pagesAnswers To Common ABAQUS Questions PDFEvgeny Shavelzon100% (1)

- Paper FinalDocument21 pagesPaper FinalBollywood RetroNo ratings yet

- Concrete 315Document9 pagesConcrete 315dinoNo ratings yet

- 1 s2.0 S0950061814014019 MainDocument10 pages1 s2.0 S0950061814014019 MainMaria CeNo ratings yet

- Study On The Influence of Compound Rust Inhibitor On Corrosion of Steel Bars in Chloride Concrete by Electrical ParametersDocument14 pagesStudy On The Influence of Compound Rust Inhibitor On Corrosion of Steel Bars in Chloride Concrete by Electrical ParametersRAGHUNo ratings yet

- Influence of Rust Inhibitor On The Corrosion ResisDocument10 pagesInfluence of Rust Inhibitor On The Corrosion Resisaldrinramirez20No ratings yet

- Artículo Cientifico 1 - TB01Document7 pagesArtículo Cientifico 1 - TB01Harold CuentasNo ratings yet

- Paper - CorrosiónDocument18 pagesPaper - CorrosióncarlosNo ratings yet

- Evaluation of Corrosion Protection Properties of Additives For Waterborne Epoxy Coatings On SteelDocument9 pagesEvaluation of Corrosion Protection Properties of Additives For Waterborne Epoxy Coatings On SteelJhon jairo100% (1)

- A Study On Effect of Carbonation On The Properties of ConcreteDocument4 pagesA Study On Effect of Carbonation On The Properties of ConcreteSunny DecorNo ratings yet

- Papaer Impact of Chloride Attack On Basalt FibreDocument4 pagesPapaer Impact of Chloride Attack On Basalt FibreNobel AsresuNo ratings yet

- A Study On Mechanical Properties of Porous ConcretDocument11 pagesA Study On Mechanical Properties of Porous Concretchaitanya mycherlaNo ratings yet

- Effects of Accelerated Carbonation On Physical Properties of MortarDocument6 pagesEffects of Accelerated Carbonation On Physical Properties of MortarБојана ВучићевићNo ratings yet

- Effect of Various Accelerators On Different Strength Parameters of M - 20 Grade of ConcreteDocument10 pagesEffect of Various Accelerators On Different Strength Parameters of M - 20 Grade of ConcreteTJPRC PublicationsNo ratings yet

- Mechanical Properties of Geopolymer Concrete With Mineral AdmixturesDocument6 pagesMechanical Properties of Geopolymer Concrete With Mineral AdmixturesJHON WILMAR CARDENAS PULIDONo ratings yet

- Concrete Silica ReactionDocument4 pagesConcrete Silica ReactionHusain Masood ChandharNo ratings yet

- Astm G109.1 PDFDocument5 pagesAstm G109.1 PDFsantoruno lupinottiNo ratings yet

- Inhibitive Effect of Organic Inhibitors in Concrete Containing Quarry Dust As Fine AggregateDocument7 pagesInhibitive Effect of Organic Inhibitors in Concrete Containing Quarry Dust As Fine AggregateReeja MathewNo ratings yet

- Analysis of Self Compacting Concrete by Partial Replacement of Cement With Industrial Waste Under Variable TemperatureDocument33 pagesAnalysis of Self Compacting Concrete by Partial Replacement of Cement With Industrial Waste Under Variable TemperatureThe CiVil Engineering ESENo ratings yet

- Effect of Silica Fumes On Corrosion of Rebar in ConcreteDocument6 pagesEffect of Silica Fumes On Corrosion of Rebar in ConcreteSrinivas AyyalasomayajulaNo ratings yet

- Content ServerDocument10 pagesContent ServerEdwinArturoLopezPenagosNo ratings yet

- Bernal 2011Document8 pagesBernal 2011Jamman Shahid ShiblyNo ratings yet

- Prevention of Corrosion of SteelDocument8 pagesPrevention of Corrosion of SteelZainal AbidhynNo ratings yet

- Journal of Building Engineering: S.C. Devi, R.A. KhanDocument12 pagesJournal of Building Engineering: S.C. Devi, R.A. Khanshri ramNo ratings yet

- Materials Today: Proceedings: Richa Palod, S.V. Deo, G.D. RamtekkarDocument6 pagesMaterials Today: Proceedings: Richa Palod, S.V. Deo, G.D. RamtekkarWalid YahiaouiNo ratings yet

- Effect of Fly Ash and Nano Titanium Dioxide On Compressive Strength of ConcreteDocument5 pagesEffect of Fly Ash and Nano Titanium Dioxide On Compressive Strength of Concretesruthi jayadeepNo ratings yet

- Construction and Building Materials: Ana Paula Kirchheim, Vanessa Rheinheimer, Denise C.C. Dal MolinDocument11 pagesConstruction and Building Materials: Ana Paula Kirchheim, Vanessa Rheinheimer, Denise C.C. Dal MolinFrancisco CabreraNo ratings yet

- Effect of Chloride Ions On The Corrosion of Galvanized Steel Embedded in Concrete Prepared With Cements of Different CompositionDocument13 pagesEffect of Chloride Ions On The Corrosion of Galvanized Steel Embedded in Concrete Prepared With Cements of Different CompositionAbubakar Yakubu YakubuNo ratings yet

- J Jclepro 2017 02 176Document18 pagesJ Jclepro 2017 02 176Kashyap PanchalNo ratings yet

- Artigo Corrosao Revista AlconpatDocument16 pagesArtigo Corrosao Revista AlconpatElizabete NakanishiNo ratings yet

- CIB - DC24731Concrete Deterioration Caused by Sulfuric Acid AttackDocument7 pagesCIB - DC24731Concrete Deterioration Caused by Sulfuric Acid Attackm_shahbaghiNo ratings yet

- Efectos de Los Metodos de Curado en Climas Calidos Sobre Las Propiedades de Los Hormigones de Alta ResistenciaDocument12 pagesEfectos de Los Metodos de Curado en Climas Calidos Sobre Las Propiedades de Los Hormigones de Alta ResistenciaCarito Salinas AgredaNo ratings yet

- Experimental Study of Foam Concrete by Using Different MixesDocument10 pagesExperimental Study of Foam Concrete by Using Different MixesIJRASETPublicationsNo ratings yet

- "Evaluating The Effect of Bentonite On Strength and Durability of High Performance ConcreteDocument5 pages"Evaluating The Effect of Bentonite On Strength and Durability of High Performance ConcreteAshfaq AhmadNo ratings yet

- Electrochemical Protection of Steel in Concrete To Enhance The Service Life of Concrete Structures 2014 Procedia EngineeringDocument8 pagesElectrochemical Protection of Steel in Concrete To Enhance The Service Life of Concrete Structures 2014 Procedia EngineeringalkhiatNo ratings yet

- Peng 2022Document7 pagesPeng 2022Lizie Froeder NevesNo ratings yet

- Experimental Investigation of Rice Husk Ash On Compressive Strength Carbonation and Corrosion Resistance of Reinforced ConcreteDocument10 pagesExperimental Investigation of Rice Husk Ash On Compressive Strength Carbonation and Corrosion Resistance of Reinforced ConcreteCIVIL ENGINEERINGNo ratings yet

- Experimental Study of Self Compacting Concrete Using Portland Cement and Mineral AdmixtureDocument6 pagesExperimental Study of Self Compacting Concrete Using Portland Cement and Mineral AdmixtureInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Tittarelli 2017 IOP Conf. Ser. Mater. Sci. Eng. 225 012107Document10 pagesTittarelli 2017 IOP Conf. Ser. Mater. Sci. Eng. 225 012107Noman AhmadNo ratings yet

- Characteristics of Silica Fume Concrete: April 2015Document5 pagesCharacteristics of Silica Fume Concrete: April 2015Abhishek KaranNo ratings yet

- 14.verificación de La Resistencia A La Compresión Entre Un Hormigón Convencional y Su Adición de 5, 10 y 15% en Volumen de Cenizas Volantes en Sustitución de Aridos FinosDocument6 pages14.verificación de La Resistencia A La Compresión Entre Un Hormigón Convencional y Su Adición de 5, 10 y 15% en Volumen de Cenizas Volantes en Sustitución de Aridos FinosJoel HernandezNo ratings yet

- Synergetic Effect of Two Inhibitors For Enhanced Corrosion Protection On The Reinforcing Steel in The Chloride-Contaminated Carbonated SolutionsDocument14 pagesSynergetic Effect of Two Inhibitors For Enhanced Corrosion Protection On The Reinforcing Steel in The Chloride-Contaminated Carbonated SolutionsHans Sebastian Contreras RodriguezNo ratings yet

- Experimental Study On Self Compacting Concrete SSC Using Ggbs and Fly Ash 1 11Document11 pagesExperimental Study On Self Compacting Concrete SSC Using Ggbs and Fly Ash 1 11Shilpa ShiNo ratings yet

- An Experimental Investigation On Fly Ash Blended Cement ConcreteDocument9 pagesAn Experimental Investigation On Fly Ash Blended Cement ConcreteJHON WILMAR CARDENAS PULIDONo ratings yet

- Conference+2018+Pore Structure Characterization in Concrete Prepared With Carbonated Fly AshDocument7 pagesConference+2018+Pore Structure Characterization in Concrete Prepared With Carbonated Fly AshHaoyan LyuNo ratings yet

- Binary and Quaternary Blends in High Strength ConcreteDocument5 pagesBinary and Quaternary Blends in High Strength ConcreteKalashNo ratings yet

- 1 Brooke N J 2005 Seismic Performance of Green Concrete Interior Beam-Column JointsDocument10 pages1 Brooke N J 2005 Seismic Performance of Green Concrete Interior Beam-Column Jointskam.muda111No ratings yet

- The Influence of Fiber On The Resistance To Chloride-Ion Penetration of Concrete Under The Environment of CarbonationDocument6 pagesThe Influence of Fiber On The Resistance To Chloride-Ion Penetration of Concrete Under The Environment of CarbonationArfazNo ratings yet

- Angst Etal 2011Document14 pagesAngst Etal 2011Manuel MirandaNo ratings yet

- Carbonated Concrete StrengthDocument7 pagesCarbonated Concrete StrengthDianna LambertNo ratings yet

- Study On The Light Weight Geopolymer Concrete Made of Recycled Aggregates From Lightweight BlocksDocument11 pagesStudy On The Light Weight Geopolymer Concrete Made of Recycled Aggregates From Lightweight BlocksIJRASETPublicationsNo ratings yet

- Resistance of Mineral Admixture Concrete To Acid AttackDocument11 pagesResistance of Mineral Admixture Concrete To Acid AttackFarkhand SetyawandNo ratings yet

- Study On The Durability of Surface Coating Materials For Concrete StructuresDocument12 pagesStudy On The Durability of Surface Coating Materials For Concrete StructuresagustinussetNo ratings yet

- Pitroda 2018 IOP Conf. Ser. Mater. Sci. Eng. 431 032008Document8 pagesPitroda 2018 IOP Conf. Ser. Mater. Sci. Eng. 431 032008SivarajSivaNo ratings yet

- Durability Study of Low Calcium Fly Ash Geopolymer ConcreteDocument7 pagesDurability Study of Low Calcium Fly Ash Geopolymer Concretethisisatest402003No ratings yet

- Avaliação Do Efeito de Inibidores Na Resistência A Corrosão de Aço de Construção CivilDocument14 pagesAvaliação Do Efeito de Inibidores Na Resistência A Corrosão de Aço de Construção CivilAna Flávia GherardiNo ratings yet

- Effectiveness of Surface Applied Corrosion Inhibitor On Steel Reinforcement Bars in ConcreteDocument41 pagesEffectiveness of Surface Applied Corrosion Inhibitor On Steel Reinforcement Bars in Concreteer.praveenraj30No ratings yet

- Study of Flexural Behavior of Hybrid Fibre Reinforced Geopolymer Concrete BeamDocument6 pagesStudy of Flexural Behavior of Hybrid Fibre Reinforced Geopolymer Concrete BeamjasimabdNo ratings yet

- Synergistic Inhibition Effects of Octadecylamine and Tetradecyl Trimethyl Ammonium Bromide On Carbon Steel Corrosion in The H2S and CO2 Brine SolutionDocument8 pagesSynergistic Inhibition Effects of Octadecylamine and Tetradecyl Trimethyl Ammonium Bromide On Carbon Steel Corrosion in The H2S and CO2 Brine SolutionMarcus BaltesNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- FRP SizeDocument2 pagesFRP SizeGaneshNo ratings yet

- Temporary Backfill LogDocument2 pagesTemporary Backfill LogGaneshNo ratings yet

- Mass Concrete Report AnalysisDocument2 pagesMass Concrete Report AnalysisGaneshNo ratings yet

- Method Statement and Jsa StatusDocument9 pagesMethod Statement and Jsa StatusGaneshNo ratings yet

- Twla-From 10-June-2023 To 13-June-23 (Pwisgcp1)Document7 pagesTwla-From 10-June-2023 To 13-June-23 (Pwisgcp1)GaneshNo ratings yet

- Method of Statement For Internal External Oil Water Tanks Repairing and Coating SystemDocument19 pagesMethod of Statement For Internal External Oil Water Tanks Repairing and Coating SystemGaneshNo ratings yet

- Hdpe Lining - TanksDocument15 pagesHdpe Lining - TanksGaneshNo ratings yet

- Hdpe Liner Installation and TestingDocument2 pagesHdpe Liner Installation and TestingGaneshNo ratings yet

- Duct Bank InformationDocument19 pagesDuct Bank InformationGaneshNo ratings yet

- JCC Card For HDPE Applicators - SpecimenDocument2 pagesJCC Card For HDPE Applicators - SpecimenGaneshNo ratings yet

- 2 Solid and Hollow Block MSDocument7 pages2 Solid and Hollow Block MSGaneshNo ratings yet

- Asphalt ITPDocument9 pagesAsphalt ITPGaneshNo ratings yet

- QM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01Document11 pagesQM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01GaneshNo ratings yet

- QM-099-DP-xxxx Procedure For Forms Rebars and Concrete Works Rev. 01Document20 pagesQM-099-DP-xxxx Procedure For Forms Rebars and Concrete Works Rev. 01GaneshNo ratings yet

- QM 769 PL 2319 - CRSDocument1 pageQM 769 PL 2319 - CRSGaneshNo ratings yet

- QM-R83-PL-4039 Procedure For Excavation Backfilling and Compaction Rev. 00Document16 pagesQM-R83-PL-4039 Procedure For Excavation Backfilling and Compaction Rev. 00GaneshNo ratings yet

- Procedure For Concrete RepairDocument2 pagesProcedure For Concrete RepairGaneshNo ratings yet

- QM-R83-PL-4024 Procedure For Notification of Inspection ActivitiesDocument15 pagesQM-R83-PL-4024 Procedure For Notification of Inspection ActivitiesGaneshNo ratings yet

- QM-099-DP - XXXX Procedure For Concrete Finishing Rev ADocument11 pagesQM-099-DP - XXXX Procedure For Concrete Finishing Rev AGaneshNo ratings yet

- 2 External Cavity Wall MSDocument8 pages2 External Cavity Wall MSGaneshNo ratings yet

- 2 Substructure Waterproofing MSDocument6 pages2 Substructure Waterproofing MSGaneshNo ratings yet

- GR5HRM-CIVIL-ITP-ENGLISH VersionDocument66 pagesGR5HRM-CIVIL-ITP-ENGLISH VersionGaneshNo ratings yet

- 2 Glass Block MSDocument6 pages2 Glass Block MSGaneshNo ratings yet

- GR5HRM-330-ST-TI-0002 Rev B - ITP - Steel Structures - EnglishDocument8 pagesGR5HRM-330-ST-TI-0002 Rev B - ITP - Steel Structures - EnglishGaneshNo ratings yet

- 2 Concrete Repair MSDocument6 pages2 Concrete Repair MSGaneshNo ratings yet

- Time and Cost Overruns in The Edinburgh Tram Network (ETN) Project: Causes and Scientific Modelling'Document47 pagesTime and Cost Overruns in The Edinburgh Tram Network (ETN) Project: Causes and Scientific Modelling'GaneshNo ratings yet

- 2 Concrete Works MSDocument7 pages2 Concrete Works MSGaneshNo ratings yet

- Technical Guide On Internal Audit of Tendering Process: ISBN: 978-81-8441-547-6Document125 pagesTechnical Guide On Internal Audit of Tendering Process: ISBN: 978-81-8441-547-6GaneshNo ratings yet

- 2 Plaster Work MSDocument7 pages2 Plaster Work MSGaneshNo ratings yet

- High QB PDFDocument22 pagesHigh QB PDFShikhin GargNo ratings yet

- Fosroc Nitomortar PEDocument5 pagesFosroc Nitomortar PEShahril ZainulNo ratings yet

- Durabond GPDocument2 pagesDurabond GPengramir07No ratings yet

- Construction and Building Materials: Yimmy Fernando Silva, Rafael Andres Robayo, Pedro Enrique Mattey, Silvio DelvastoDocument6 pagesConstruction and Building Materials: Yimmy Fernando Silva, Rafael Andres Robayo, Pedro Enrique Mattey, Silvio DelvastoSurender SinghNo ratings yet

- Certificate Program Details - Fundamentals of Concrete ConstructionDocument1 pageCertificate Program Details - Fundamentals of Concrete ConstructionOscar MataNo ratings yet

- Nitobond EP : Constructive SolutionsDocument4 pagesNitobond EP : Constructive SolutionsChidi OkoloNo ratings yet

- Hcs IntroDocument24 pagesHcs IntroPavan PatchigollaNo ratings yet

- RCD Library Work - QuizDocument1 pageRCD Library Work - QuizPatricia TubangNo ratings yet

- Project: Proposed Billboard Location: Subject: Project Cost EstimateDocument5 pagesProject: Proposed Billboard Location: Subject: Project Cost EstimateRexter UnabiaNo ratings yet

- 005-Sample Method Statement CivilDocument2 pages005-Sample Method Statement CivilS.C.Satish Chander100% (1)

- Complete Parking Lot Design: Pdhonline Course C620 (6 PDH)Document51 pagesComplete Parking Lot Design: Pdhonline Course C620 (6 PDH)Sahit NgjeçiNo ratings yet

- C FIX Report3Document10 pagesC FIX Report3MdShahbazAhmedNo ratings yet

- Sikarep® Sa: Product Data SheetDocument3 pagesSikarep® Sa: Product Data SheetMichael MazoNo ratings yet

- Department of Earth Sciences IIT Roorkee: Concrete and Masonry DamsDocument10 pagesDepartment of Earth Sciences IIT Roorkee: Concrete and Masonry DamsHarryKumar100% (1)

- AISC Trusses 03Document7 pagesAISC Trusses 03sugi zhuangNo ratings yet

- Tunnel Fire ProtectionDocument2 pagesTunnel Fire ProtectionLeon BruceNo ratings yet

- Esr 2713Document15 pagesEsr 2713MD MDDNo ratings yet

- Complete Bar Bending Schedule For Different Structure (Free E-Book)Document20 pagesComplete Bar Bending Schedule For Different Structure (Free E-Book)Prakhar PatidarNo ratings yet

- Post Pyro Ip01Document56 pagesPost Pyro Ip01Durga PrasadNo ratings yet

- Upgrade Storage Web BrochureDocument476 pagesUpgrade Storage Web Brochuredony ramdhaniNo ratings yet

- Structural Design Manual: ALDOT Bridge BureauDocument59 pagesStructural Design Manual: ALDOT Bridge BureaukoreshNo ratings yet

- Aci T11 - 01Document15 pagesAci T11 - 01Rifqi AnraNo ratings yet

- New Series 6000Document78 pagesNew Series 6000Kintu MunabangogoNo ratings yet

- DPWH Concrete SPECIFICATIONSDocument6 pagesDPWH Concrete SPECIFICATIONSShe Timbancaya100% (1)

- SILRES BS 16 en 2020.07.01Document3 pagesSILRES BS 16 en 2020.07.01Vaittianathan MahavapillaiNo ratings yet

- 128 FPDocument6 pages128 FPRajesh KumarNo ratings yet