Professional Documents

Culture Documents

BarChartsInc 2014 ProcessManagement OperationsManagement

BarChartsInc 2014 ProcessManagement OperationsManagement

Uploaded by

John Michael SorianoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BarChartsInc 2014 ProcessManagement OperationsManagement

BarChartsInc 2014 ProcessManagement OperationsManagement

Uploaded by

John Michael SorianoCopyright:

Available Formats

PROCESS MANAGEMENT

process: A set or sequence of activities that adds value to an organization by taking inputs and transforming them into outputs.

process mapping: a.k.a. flowcharting, a graphical representation of a process that uses the following basic symbols:

Activity, task, or operation step:

All rights reserved. May not be reproduced in any form without permission from the publisher, except fair uses permitted under U.S. or applicable copyright law.

Decision point:

Storage or queue:

Flow of people, material, information, or money:

Process Measurement

cycle time: The average time between completion of successive products in a process.

flow time: The average time a product, task, or customer takes to move through the entire process (i.e., time-in-system).

Little’s law: WIP = Throughput Rate × Flow Time.

operation time: Setup Time + Run Time.

run time: The time required to actually make a product or do a task.

setup time: The time needed to prepare machines or other resources to make a product or do a task.

throughput rate: The output rate of a process.

work-in-process (WIP): Material or work that is in between the various steps in a process.

Process Types

batch: Moderate-volume, moderate-variety customized products or intermittent work processes, using moderately skilled workers and some flexible equipment (e.g., baking cookies and university education).

continuous flow: Very-high-volume, low-variety, highly standardized, nondiscrete-product, continuous (flow) processes; can be low to high skill; uses nonflexible (specialized) equipment (e.g., generating electricity

and refining petroleum).

job shop: Low-volume, high-variety highly customized products, using intermittent work processes, highly skilled workers, and flexible general-purpose equipment (e.g. auto servicing and hospital emergency room

service).

process selection: Strategic decision of selecting an appropriate process for making a product, depending on the product volume to be produced.

project: Very low volume (usually of one) and very high customization, using nonroutine, nonrepetitive activities (e.g., constructing buildings and building ships).

repetitive flow: High-volume, low-variety standardized discrete products or repetitive processes, with relatively low-skilled workers and less-flexible equipment (e.g., automobile and computer assembly lines).

Facility Layouts

cellular layout: Layout in which workstations are grouped into “cells” of workstations; cells process items or parts that require similar processing steps; has less work-in-process, reduced material handling or

movement through the production process, and faster setup times; referred to as a hybrid layout as it combines product and process layouts.

line balancing: Assigning tasks to workstations so that each workstation takes approximately the same time for work done, and the work is balanced across workstations, reducing workstation (resource) idle time and

cycle time.

process layout: For nonrepetitive processing or a discontinuous flow of products, equipment and tasks are arranged in groups of similar functions or departments where similar tasks are performed; work flows

between groups or departments as required for making the product (e.g., university campus of colleges and departments); a.k.a. functional layout.

product layout: For repetitive processing or a continuous flow of products, equipment and tasks arranged in a fixed sequence of workstations as needed for making the product; work flows progressively through the

sequence of work stations (e.g., production lines, assembly lines).

project layout: The product is in one position, and equipment and other resources are brought to the product; a.k.a. fixed-position layout.

service layout: Designed to maximize revenue, increase customer convenience and flow, or facilitate greater communication and teamwork in office layouts.

Copyright 2014. QuickStudy Reference Guides.

EBSCO Publishing : eBook Comprehensive Academic Collection (EBSCOhost) - printed on 3/14/2022 12:46 AM via CAGAYAN DE ORO COLLEGE- PHINMA EDUCATION NETWORK

(COC-PEN)

AN: 1534293 ; BarCharts, Inc.; Operations Management

Account: ns212602.CMAF.ehost 8

You might also like

- Quick Study Weights & Measures PDFDocument4 pagesQuick Study Weights & Measures PDFheysemberg100% (6)

- Chemistry Equations Answers QuickstudyDocument6 pagesChemistry Equations Answers QuickstudyRafael Ramos100% (6)

- English Composition and Style - QsDocument4 pagesEnglish Composition and Style - Qssadaq84100% (2)

- Spark Charts - NursingDocument4 pagesSpark Charts - Nursinggeminix92100% (1)

- (A. Thomas Fenik) Strategic Management (Quickstudy PDFDocument4 pages(A. Thomas Fenik) Strategic Management (Quickstudy PDFZewdu Tsegaye100% (4)

- BarCharts QuickStudy Business Facts PDFDocument4 pagesBarCharts QuickStudy Business Facts PDF220479100% (1)

- Nate APESDocument6 pagesNate APESlykkhai100% (4)

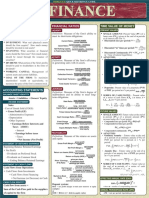

- Quick Study FinanceDocument4 pagesQuick Study FinanceFrancis Kwame OwireduNo ratings yet

- (Quickstudy - Academic) Inc. BarCharts - Geometric Formulas-QuickStudy (2005)Document6 pages(Quickstudy - Academic) Inc. BarCharts - Geometric Formulas-QuickStudy (2005)Dany el100% (2)

- QuickStudy Resumes & Interviews PDFDocument4 pagesQuickStudy Resumes & Interviews PDFJohn100% (3)

- Chapter 4Document11 pagesChapter 4Gabriel Garza100% (4)

- Weather Disasters & Epidemics - QuickStudyDocument4 pagesWeather Disasters & Epidemics - QuickStudyalejaqueNo ratings yet

- Printable Periodic TableDocument1 pagePrintable Periodic TableAbigail MendozaNo ratings yet

- Blood Vessels List HandoutDocument2 pagesBlood Vessels List HandoutSopheNo ratings yet

- Quick Study For Financial RatiosDocument2 pagesQuick Study For Financial RatiosMio Fitrananto PerdaniNo ratings yet

- Motors Selection Guide PDFDocument6 pagesMotors Selection Guide PDFogom30eNo ratings yet

- The World The World: Canada CanadaDocument4 pagesThe World The World: Canada CanadaStipe KodzomanNo ratings yet

- Animal GKDocument4 pagesAnimal GKSARVEJAYA KRISHNANo ratings yet

- BarChartsInc 2014 NewProductDevelopment OperationsManagementDocument1 pageBarChartsInc 2014 NewProductDevelopment OperationsManagementJohn Michael SorianoNo ratings yet

- Reading Fundamentals 4 - Expert EditionsDocument4 pagesReading Fundamentals 4 - Expert EditionsGigicaNo ratings yet

- Periodic TableCheap Charts Frank Schaffer Publications - BarCharts QuickStudyDocument2 pagesPeriodic TableCheap Charts Frank Schaffer Publications - BarCharts QuickStudyMatheus Eduardo100% (1)

- Computer ShortcutsDocument2 pagesComputer ShortcutsJeebanjyoti DehuryNo ratings yet

- Periodic Table Basic, 2nd EditionDocument2 pagesPeriodic Table Basic, 2nd EditionMaki MajomNo ratings yet

- QuickStudy FinanceDocument4 pagesQuickStudy FinanceAnge William Kouadio100% (1)

- Hundreds of Titles At: Word/Phrase Replace WithDocument1 pageHundreds of Titles At: Word/Phrase Replace WithenriNo ratings yet

- English Business LettersDocument6 pagesEnglish Business Lettersvaminos100% (1)

- Literary Terms 1spark Charts1Document6 pagesLiterary Terms 1spark Charts12ygbk7100% (2)

- Clause: - There Are Two Types of ClausesDocument10 pagesClause: - There Are Two Types of ClausesSarlita NugrahaNo ratings yet

- BarCharts QuickStudy Academics Parliamentary Procedures (BarCharts) (Z-Library)Document4 pagesBarCharts QuickStudy Academics Parliamentary Procedures (BarCharts) (Z-Library)Qareen Sarmaan100% (1)

- P5 Advanced Performance ManagementDocument12 pagesP5 Advanced Performance ManagementmigraneNo ratings yet

- Quick Study - Biology PDFDocument4 pagesQuick Study - Biology PDFPh SamerNo ratings yet

- Review ChartDocument6 pagesReview Chartapi-238667529100% (1)

- Microbiology - (Beneficial or Pathogenic) PDFDocument1 pageMicrobiology - (Beneficial or Pathogenic) PDFanaNo ratings yet

- BarCharts QuickStudy Memorial DayDocument2 pagesBarCharts QuickStudy Memorial DayBrandon WangNo ratings yet

- Computer Shortcuts PDFDocument2 pagesComputer Shortcuts PDFzqzifvkk100% (4)

- Lymphatic SystemDocument2 pagesLymphatic SystemDN NLL100% (1)

- Computer ShortcutsDocument2 pagesComputer ShortcutsAbhishek50% (2)

- Quick Study For Financial Ratios 2Document2 pagesQuick Study For Financial Ratios 2Mio Fitrananto PerdaniNo ratings yet

- BUS 101 - Business FundamentalsDocument4 pagesBUS 101 - Business FundamentalsJRod100% (1)

- Anatomy of The Senses QuickStudy Reference Guide - (HEARING)Document2 pagesAnatomy of The Senses QuickStudy Reference Guide - (HEARING)statsoNo ratings yet

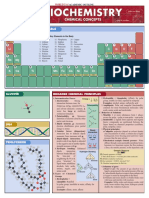

- Biochemical Periodic Table: Key Elements in The BodyDocument6 pagesBiochemical Periodic Table: Key Elements in The BodyEline Moyo100% (1)

- In The Classroom Study Strategies: Better GradesDocument4 pagesIn The Classroom Study Strategies: Better GradesAloah122346100% (1)

- (A. Thomas Fenik) Strategic Management (Quickstudy (BookFi)Document4 pages(A. Thomas Fenik) Strategic Management (Quickstudy (BookFi)Nurma LussyNo ratings yet

- Macro (Concise Study Guide)Document4 pagesMacro (Concise Study Guide)Spencer Thomas100% (1)

- Basic Math (PDFDrive)Document6 pagesBasic Math (PDFDrive)rahimdad mukhtariNo ratings yet

- Stats Statcrunch Card PDFDocument2 pagesStats Statcrunch Card PDFEliana LopezNo ratings yet

- Muscular System (Quick Study Academic) - Inc. BarChartsDocument4 pagesMuscular System (Quick Study Academic) - Inc. BarChartskogawobu0% (2)

- OMReviewer SomeTermsArentIncludedDocument7 pagesOMReviewer SomeTermsArentIncludedAlexis John LegaspiNo ratings yet

- 2.4 Plant LayoutDocument11 pages2.4 Plant Layoutashraf zhafryNo ratings yet

- Lecture 7 NotesDocument9 pagesLecture 7 NotesMaria SmithNo ratings yet

- NotebookDocument3 pagesNotebookCarlos GilNo ratings yet

- WP Difference-Between-A-Process-And-A-Procedures-Approach-In-Iso-Standards-July-2015Document6 pagesWP Difference-Between-A-Process-And-A-Procedures-Approach-In-Iso-Standards-July-2015sharnobyNo ratings yet

- Production TheoryDocument4 pagesProduction TheoryDC AranetaNo ratings yet

- CBMEC1 Final Materials AutosavedDocument30 pagesCBMEC1 Final Materials AutosavedPuti TaeNo ratings yet

- Slides 20 - 23Document4 pagesSlides 20 - 23nesey76043No ratings yet

- 04 ProcesosDocument10 pages04 ProcesosjdrppNo ratings yet

- Topic 2-Process Analysis & ChoiceDocument8 pagesTopic 2-Process Analysis & ChoicePule JackobNo ratings yet

- Lecture 2Document30 pagesLecture 2har309526No ratings yet

- Production and Operations Management OverviewDocument14 pagesProduction and Operations Management OverviewChari NaNo ratings yet

- SAS Journaling SY 20-21Document1 pageSAS Journaling SY 20-21John Michael SorianoNo ratings yet

- Acc 122 PracticeDocument2 pagesAcc 122 PracticeJohn Michael SorianoNo ratings yet

- SSP 007 - Module 6 - Ace Module Interview - SASDocument9 pagesSSP 007 - Module 6 - Ace Module Interview - SASJohn Michael SorianoNo ratings yet

- SSP 007 - Module 8 - Monitoring - Mentoring - SASDocument2 pagesSSP 007 - Module 8 - Monitoring - Mentoring - SASJohn Michael SorianoNo ratings yet

- BarChartsInc 2014 NewProductDevelopment OperationsManagementDocument1 pageBarChartsInc 2014 NewProductDevelopment OperationsManagementJohn Michael SorianoNo ratings yet

- Gonzales Quiz Chapter 8 Notes Part 2 PDFDocument7 pagesGonzales Quiz Chapter 8 Notes Part 2 PDFJohn Michael SorianoNo ratings yet

- The Filipino Cultures and Beliefs and Why Is It ImportantDocument5 pagesThe Filipino Cultures and Beliefs and Why Is It ImportantJohn Michael SorianoNo ratings yet

- Name: - Section: - Schedule: - Class Number: - DateDocument21 pagesName: - Section: - Schedule: - Class Number: - DateJohn Michael SorianoNo ratings yet

- Determinants of Human Acts and How It Differ To Acts of ManDocument3 pagesDeterminants of Human Acts and How It Differ To Acts of ManJohn Michael SorianoNo ratings yet

- Epilouge 1Document1 pageEpilouge 1John Michael SorianoNo ratings yet

- Name: - Section: - Schedule: - Class Number: - DateDocument5 pagesName: - Section: - Schedule: - Class Number: - DateJohn Michael SorianoNo ratings yet

- Blank Diagram Worksheet Direction: Label The Diagrams of The Following Biogeochemical CyclesDocument2 pagesBlank Diagram Worksheet Direction: Label The Diagrams of The Following Biogeochemical CyclesJohn Michael SorianoNo ratings yet

- Science and The EnvironmentDocument6 pagesScience and The EnvironmentJohn Michael SorianoNo ratings yet

- Philosophy Towards Vice and ValuesDocument4 pagesPhilosophy Towards Vice and ValuesJohn Michael SorianoNo ratings yet

- Religion and Culture ConnectionDocument2 pagesReligion and Culture ConnectionJohn Michael SorianoNo ratings yet

- The Moral Stages of Human LifeDocument4 pagesThe Moral Stages of Human LifeJohn Michael SorianoNo ratings yet

- Modifiers of Human Acts. Act of Man and Human ActsDocument5 pagesModifiers of Human Acts. Act of Man and Human ActsJohn Michael SorianoNo ratings yet

- Science and Its Importance To Protect Different SpeciesDocument5 pagesScience and Its Importance To Protect Different SpeciesJohn Michael SorianoNo ratings yet

- The Voluntary and Nonvoluntary Acts of ManDocument2 pagesThe Voluntary and Nonvoluntary Acts of ManJohn Michael SorianoNo ratings yet

- Introduction To Culture Relativism and How It Affects Human BehaviourDocument3 pagesIntroduction To Culture Relativism and How It Affects Human BehaviourJohn Michael SorianoNo ratings yet

- Chapter 1 - Accounting PRDocument21 pagesChapter 1 - Accounting PRJohn Michael SorianoNo ratings yet

- Science in Dealing With Natural DisastersDocument4 pagesScience in Dealing With Natural DisastersJohn Michael Soriano100% (1)

- Science and The Ecosystem and LifeDocument5 pagesScience and The Ecosystem and LifeJohn Michael SorianoNo ratings yet

- Cash and Cash EquivalentsDocument4 pagesCash and Cash EquivalentsJohn Michael SorianoNo ratings yet

- PartnershipDocument18 pagesPartnershipJohn Michael SorianoNo ratings yet

- PartnershipDocument6 pagesPartnershipJohn Michael SorianoNo ratings yet

- Revised Corporation CodeDocument2 pagesRevised Corporation CodeJohn Michael SorianoNo ratings yet

- AVEVA Customer FIRST Program User Guide v1.3 May 2020Document41 pagesAVEVA Customer FIRST Program User Guide v1.3 May 2020Eugene SolomatinNo ratings yet

- Application Note: Replacing A NXP/Philips P80C552 Processor With A P83C552/xxx ProcessorDocument2 pagesApplication Note: Replacing A NXP/Philips P80C552 Processor With A P83C552/xxx ProcessorPieter HoebenNo ratings yet

- Bus Root and Timing Display SystemDocument35 pagesBus Root and Timing Display SystemKeerthi Vasan LNo ratings yet

- Hua Hua Hua WDocument5 pagesHua Hua Hua WbiedhafiNo ratings yet

- Study Guide: Exam AI-900: Microsoft Azure AI FundamentalsDocument7 pagesStudy Guide: Exam AI-900: Microsoft Azure AI FundamentalsAman C. KapseNo ratings yet

- 12 Notes - Programming The Dynamical Systems EquationDocument23 pages12 Notes - Programming The Dynamical Systems EquationBebeNo ratings yet

- Bio - Mr. Harsha KDocument2 pagesBio - Mr. Harsha KDikshith DishuNo ratings yet

- Fabrik and Custom Joomla User Registration Forms2Document25 pagesFabrik and Custom Joomla User Registration Forms2Nasiru Abdullahi BabatsofoNo ratings yet

- Etical HackingDocument60 pagesEtical HackingraniNo ratings yet

- Guide To Map Design Part 1Document80 pagesGuide To Map Design Part 1vasile33100% (1)

- Deus Ex - Human Revolution Future Press Official Strategy GuideDocument340 pagesDeus Ex - Human Revolution Future Press Official Strategy Guidejmj9100% (4)

- ContextManager User GuideDocument48 pagesContextManager User GuideLloyd Rowell JusonNo ratings yet

- Retronyms Labs OverviewDocument15 pagesRetronyms Labs OverviewJohn-Paul WaltonNo ratings yet

- List AdtDocument6 pagesList Adt5052 - UTHRA .TNo ratings yet

- 12 It Practice AssignmentsDocument3 pages12 It Practice Assignmentsyashmota1256No ratings yet

- Configure Anyconnect Virtual Private Network (VPN) Connectivity On The Rv34X Series RouterDocument13 pagesConfigure Anyconnect Virtual Private Network (VPN) Connectivity On The Rv34X Series RouterThe Maison MaidsNo ratings yet

- Lightspeed Manual 2021Document118 pagesLightspeed Manual 2021finetradeNo ratings yet

- 03 Advanced Mobile Programming Using FlutterDocument64 pages03 Advanced Mobile Programming Using FlutterDANIEL ABERANo ratings yet

- Proposal Sample 2Document13 pagesProposal Sample 2E TailNo ratings yet

- Forticlient 7.0.1 Linux Release NotesDocument13 pagesForticlient 7.0.1 Linux Release Notesxenio qixNo ratings yet

- Bit Project Proposal TemplateDocument2 pagesBit Project Proposal TemplateRon Kandulu100% (2)

- David 3d Scanner Crack 351 PDFDocument4 pagesDavid 3d Scanner Crack 351 PDFMelissaNo ratings yet

- CG Unit 5Document76 pagesCG Unit 5Vamsi KrishnaNo ratings yet

- What Are The Best Places To Learn Python For Free Online Blog 10Document6 pagesWhat Are The Best Places To Learn Python For Free Online Blog 10Kumail NaqviNo ratings yet

- ADCADocument15 pagesADCAgyani broNo ratings yet

- OCI Introduction: Presented By: Rahul MiglaniDocument21 pagesOCI Introduction: Presented By: Rahul Miglanisss pppNo ratings yet

- Web SMS Key Feature: SMS Credit Price Per SMS Total PriceDocument2 pagesWeb SMS Key Feature: SMS Credit Price Per SMS Total Priceweb_sms1181No ratings yet

- Burpsuite Essential Content 2Document6 pagesBurpsuite Essential Content 2Aaron PreyNo ratings yet

- Service Recipes - FidesmoDocument1 pageService Recipes - FidesmoaafentNo ratings yet

- LogoDocument5 pagesLogoprdpNo ratings yet